Titanium tungsten alloys produced by additions of tungsten nanopowder

a technology of tungsten nanopowder and alloys, which is applied in the field of titanium tungsten alloys and composites, can solve the problems of poor mechanical properties in the final product, inability to commercialize, and difficult preparation of alloys by typical techniques,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

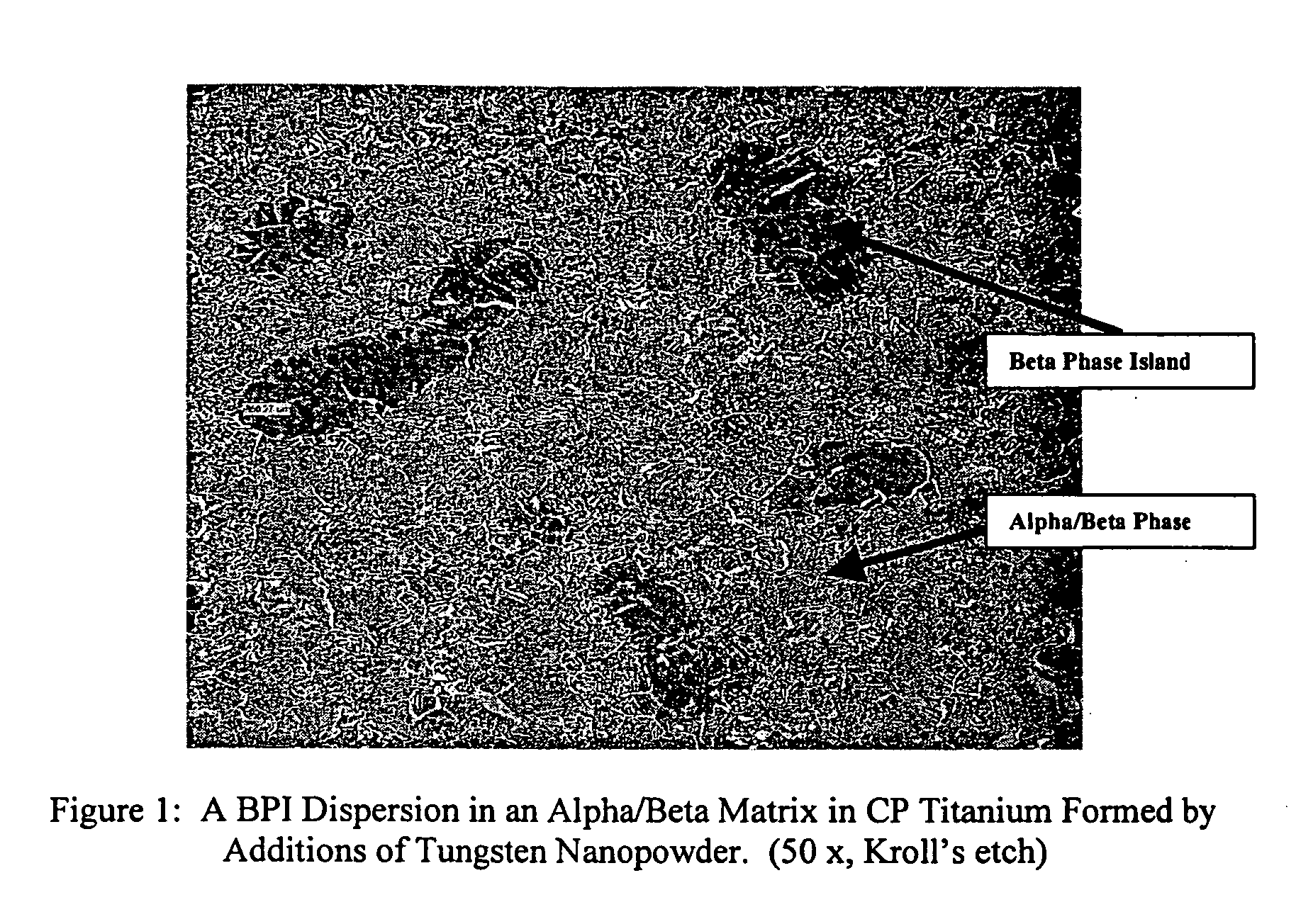

[0038] A powder metallurgy technique was used to produce a tungsten containing titanium alloy. Using this method, beta phase island dispersions were created in CP Ti and in Ti-6Al-4V with 10% by weight W. In this example, nanopowder 30 to 45 nanometers (0.003 to 0.004 μm) in size with a specific surface area of between 7 to 10 m2 / g was blended with CP Ti powder and processed as described above. These W nanopowders were also blended with CP Ti and master alloy powders to form the Ti-6Al-4V composition shown in Table 1.

[0039] The W nanopowder was taken into solution in the Ti matrix on sintering the compacted blend, forming an alpha / beta structure with a uniform beta phase island dispersion.

[0040]FIG. 1 shows that the W nanopowder completely diffused to form a beta phase island dispersion in the alpha / beta matrix. The diffusion of the W nanopowder transformed the all alpha microstructure typical of CP Ti to alpha / beta containing a dispersion of beta phase islands. In this case there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com