Lead-free soldering paste

A lead-free solder paste and solder paste technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as poor carrier rheology, mismatch between activation point and welding temperature, and large residual after welding. , to improve the flux performance, reduce post-weld residues, and reduce post-weld corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The examples are described to further explain the invention. These examples are generally illustrative rather than restrictive. In the examples, the percentages represent weight percentages unless otherwise specified.

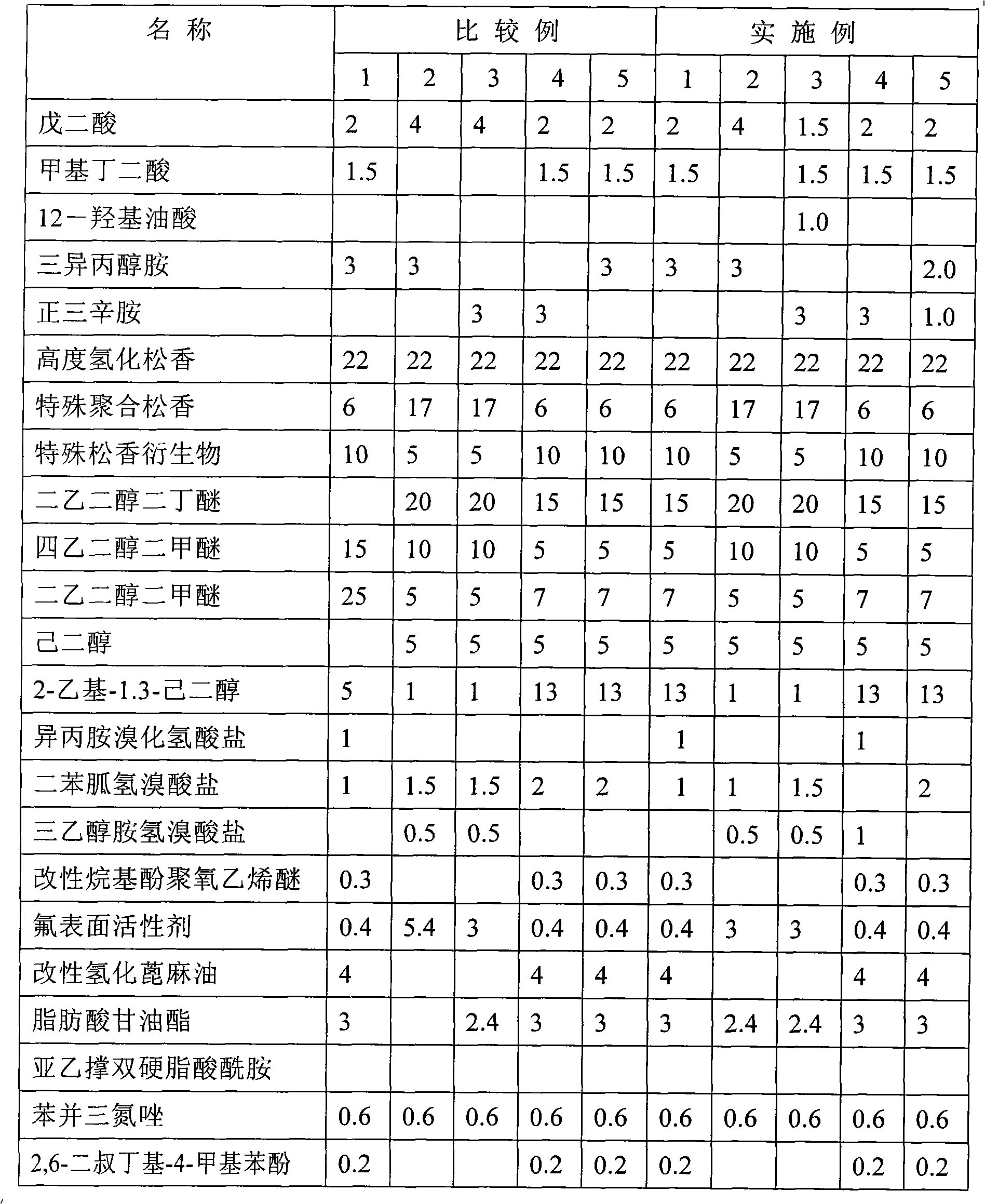

[0022] The following are Examples 1-5 and Comparative Examples 1-5 of the solder paste formulation of the present invention, see Table 1:

[0023] Table 1 Flux Formula Table

[0024]

[0025] In the present invention, an activator made of an organic acid containing two carboxyl groups, a halogen-containing compound salt and an alkanolamine salt is added to the flux of the solder paste, the activator can continuously react with the tin powder, and the reaction temperature ranges It is very broad and also shows a strong effect of removing oxide film.

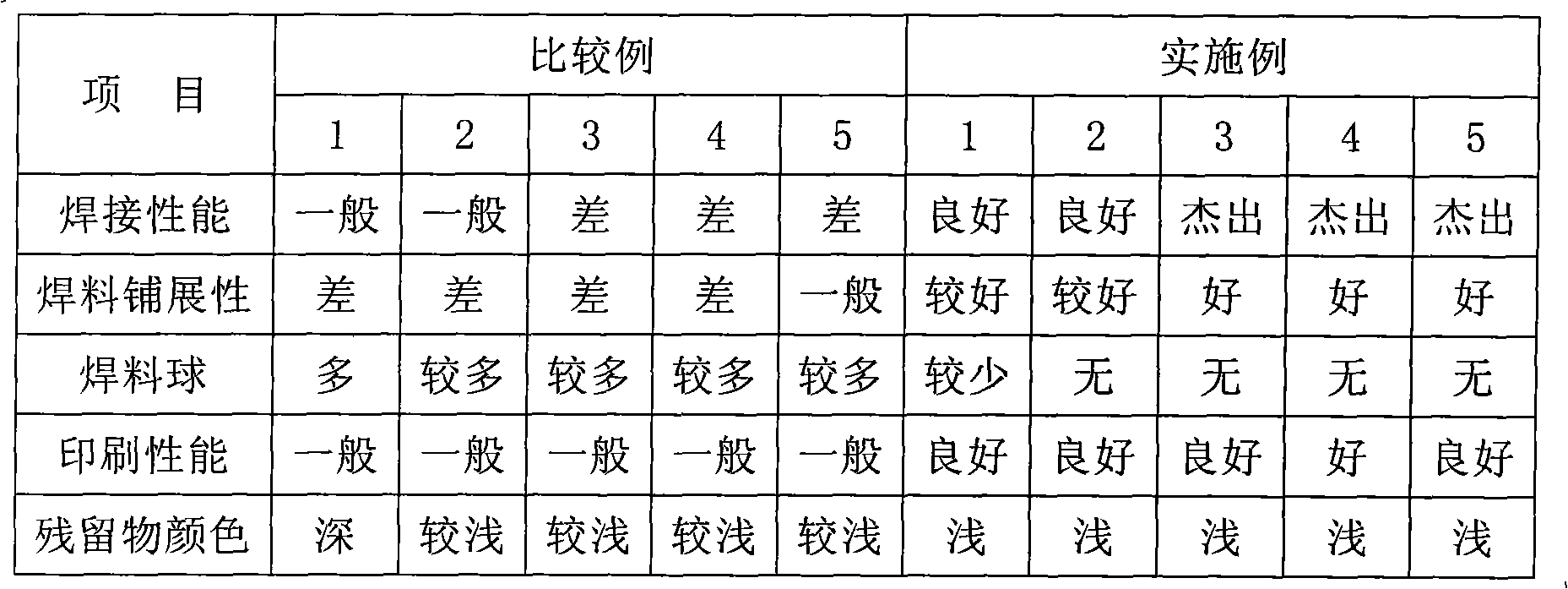

[0026] After the products obtained from the above-mentioned comparative examples and examples, referring to the detection method of SJ / T11186-199 "General Specification for Tin-Lead Paste Solder", the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com