Automatic calibration parameter optimization method of engine based on genetic algorithm

A genetic algorithm and automatic calibration technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as lack of objectivity, and achieve high objectivity and correctness, high automation, and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

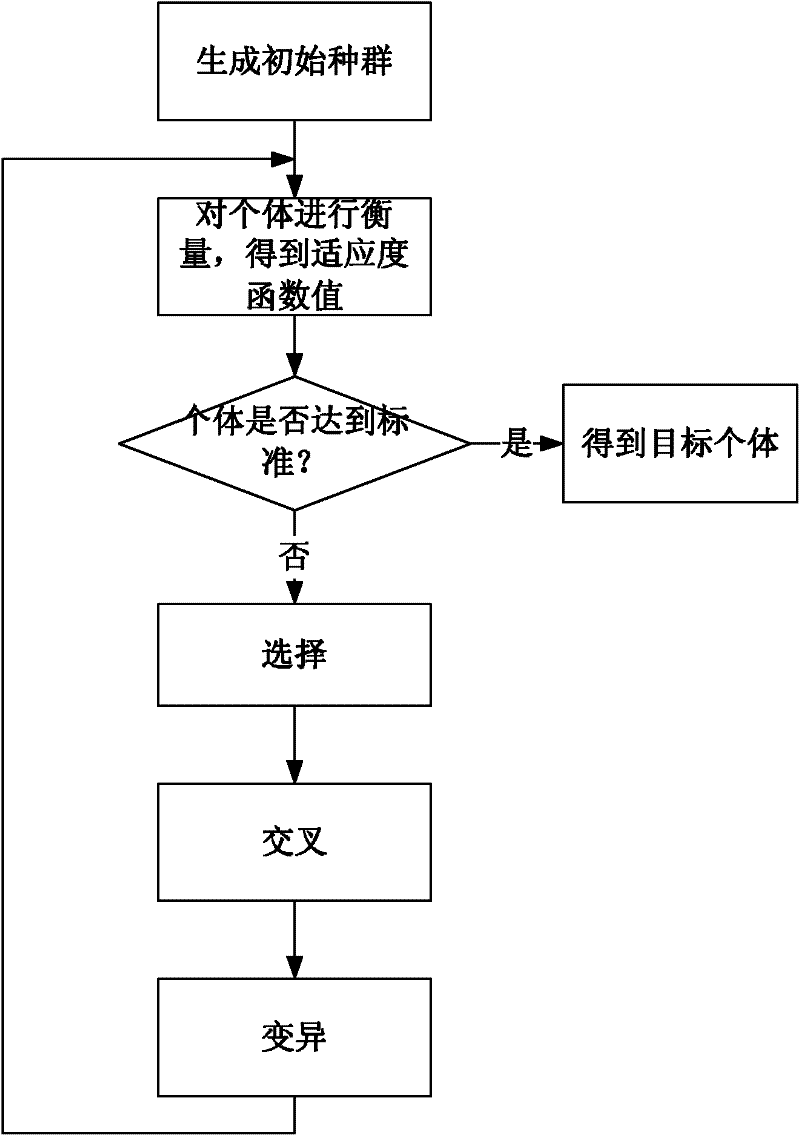

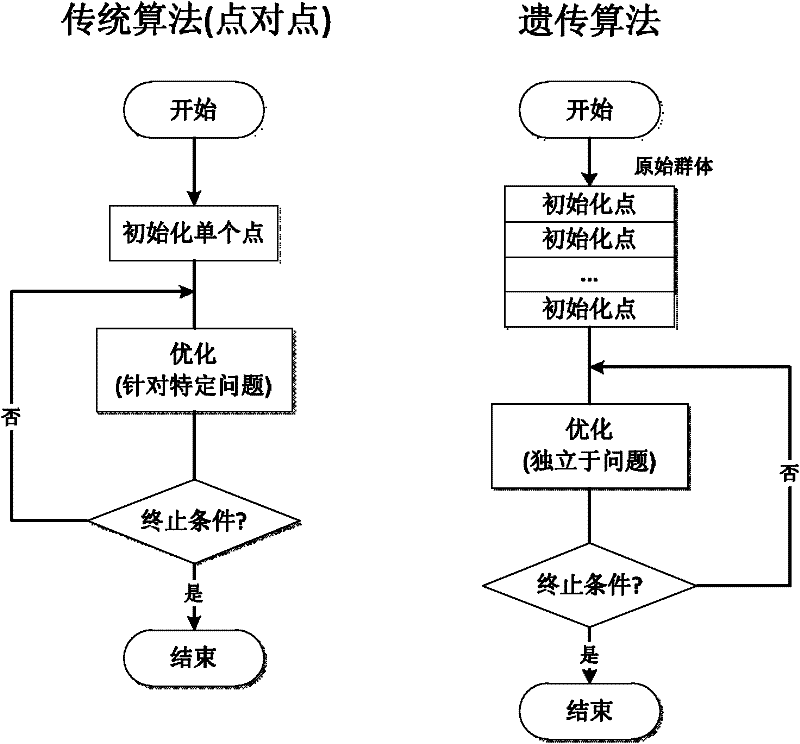

Method used

Image

Examples

Embodiment

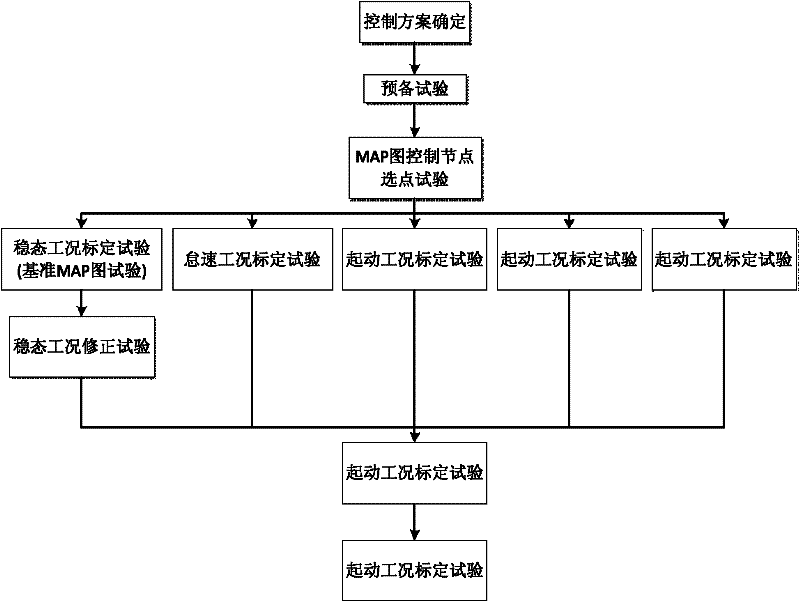

[0043] 1. Taking the calibration of the engine ignition advance angle as an example, the specific implementation method is explained: According to the design of the calibration scheme, this example uses the simplest four-cylinder engine Tesis model for the final simulation. In this model, the reference parameters of the ignition advance angle are engine speed and load torque, so the engine speed and load torque are taken as influencing factors to formulate the MAP diagram of the ignition advance angle. According to the calibration requirements, a 10*8 MAP map is selected for description in this example, and its granularity is 80. Its MAP diagram is shown in Table 1.

[0044]

[0045] Table 1. Calibration parameters MAP diagram operating point division under genetic algorithm (MAP diagram granularity depends on optimization objective)

[0046] 2. Perform genetic algorithm optimization on each Cell Task in the MAP graph. Taking Cell Task11 as an example, first specify the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com