Addition solidifying type organosilicone composition and photosemiconductor apparatus using the same

An addition curing silicone technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of curing resistance and unusability of addition curing silicone sealing materials, and achieve excellent ejection and light Excellent reflectivity and excellent shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1~4

[0088] The components shown below were uniformly mixed with the universal mixing mixer (Shinagawa mixer) manufactured by Dalton Co., Ltd. in accordance with the compounding amount shown in Table 1 to prepare a silicone composition.

[0089] [A] Organopolysiloxane with two vinyl groups directly bonded to silicon atoms in one molecule and a viscosity of 10,000 mPa·s (25°C with vinyl groups directly bonded to silicon atoms at both ends of the molecule 80 parts by mass of organopolysiloxane with a viscosity of 5,000 mPa·s and Me 3 SiO 1 / 2 , ViMe 2 SiO 1 / 2 (Me represents a methyl group, Vi represents a vinyl group. The same applies below.) and SiO 4 / 2 Unit composition, relative to SiO 4 / 2 , Me 3 SiO 1 / 2 And ViMe 2 SiO 1 / 2 The molar ratio of is 0.8, and the amount of vinyl relative to the solid content is 0.085 mol / 100g of a mixture of 20 parts by mass of silicone resin)

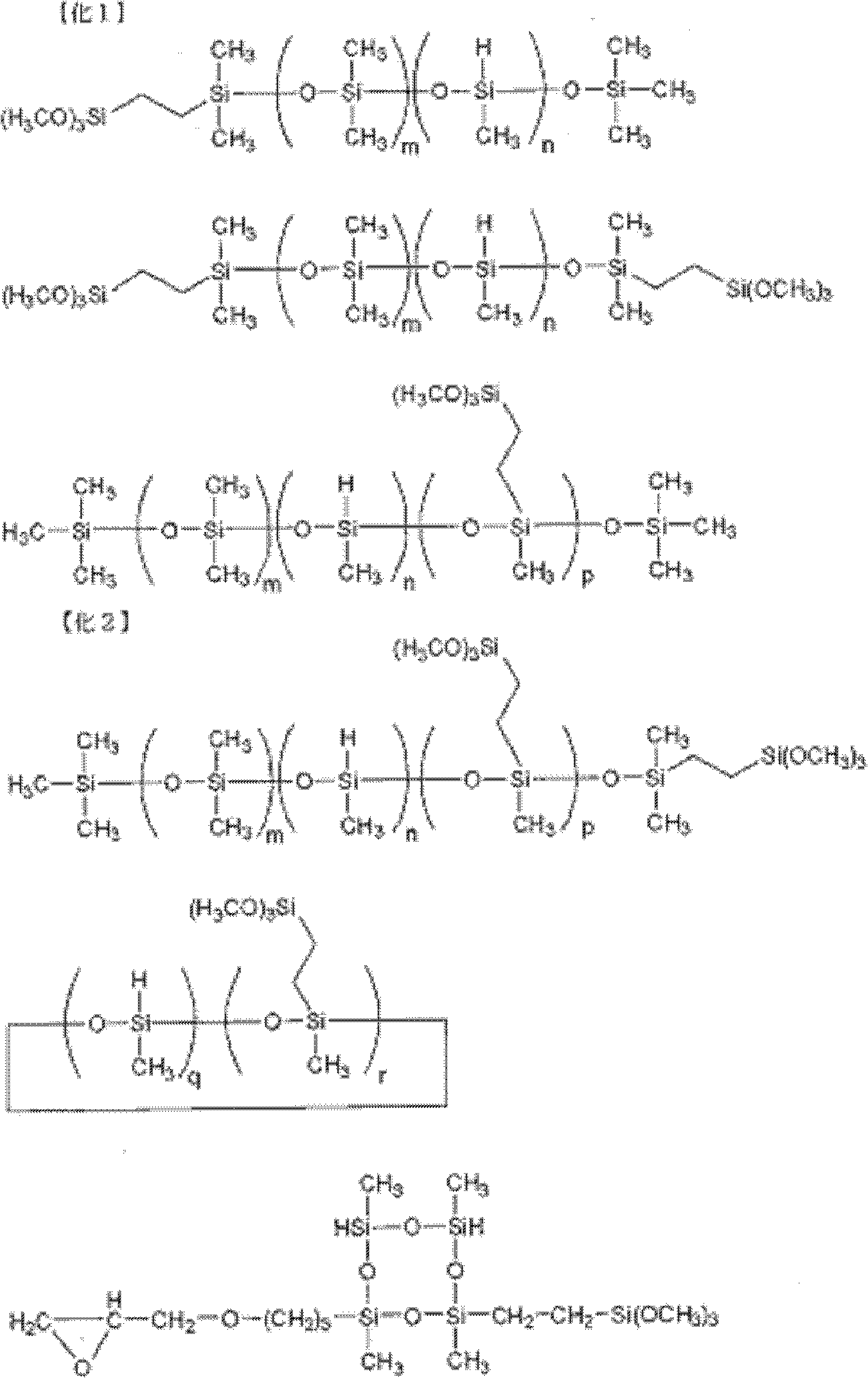

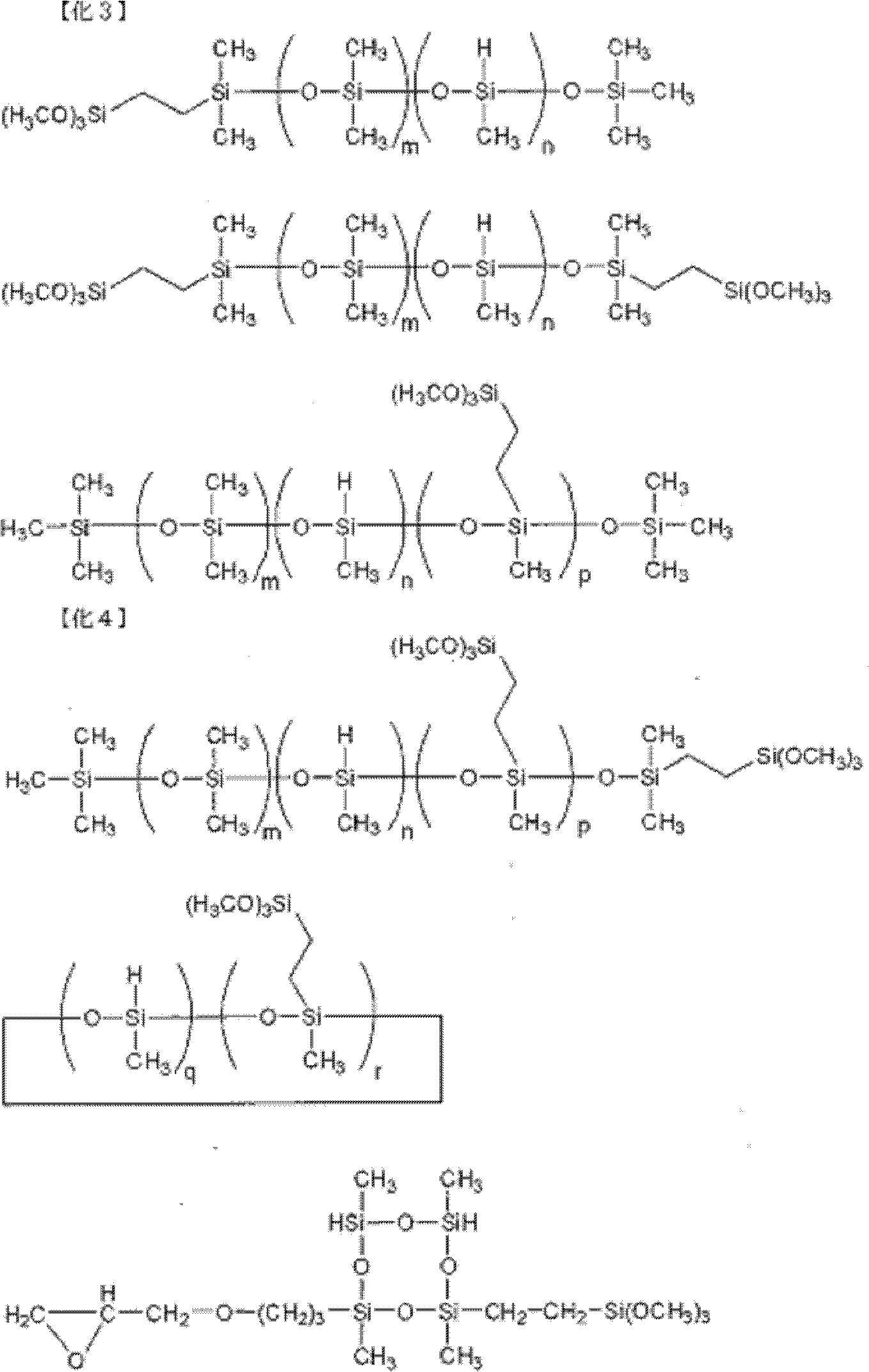

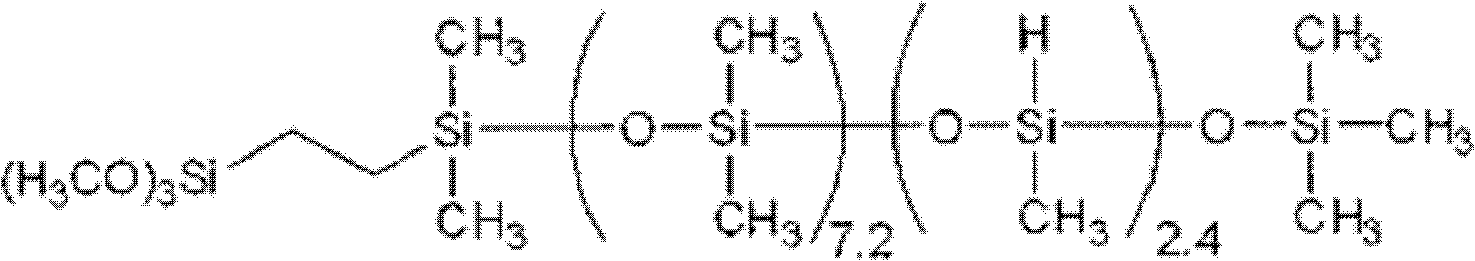

[0090] [B-1] The following formula has a trimethoxysilyl ethyl group directly bonded to a silicon atom at one end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com