Melt-blowing filter medium with nano/micron fiber interlocked structure and preparation method for melt-blowing filter medium

A filter medium and micron fiber technology, applied in fiber processing, filament/thread forming, conjugated synthetic polymer artificial filament, etc., can solve the problem of reduced filter service life, limited dirt holding capacity, easy to clog filter materials, etc. problems, to achieve the effect of increasing porosity, good filtering effect, and improving filtering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

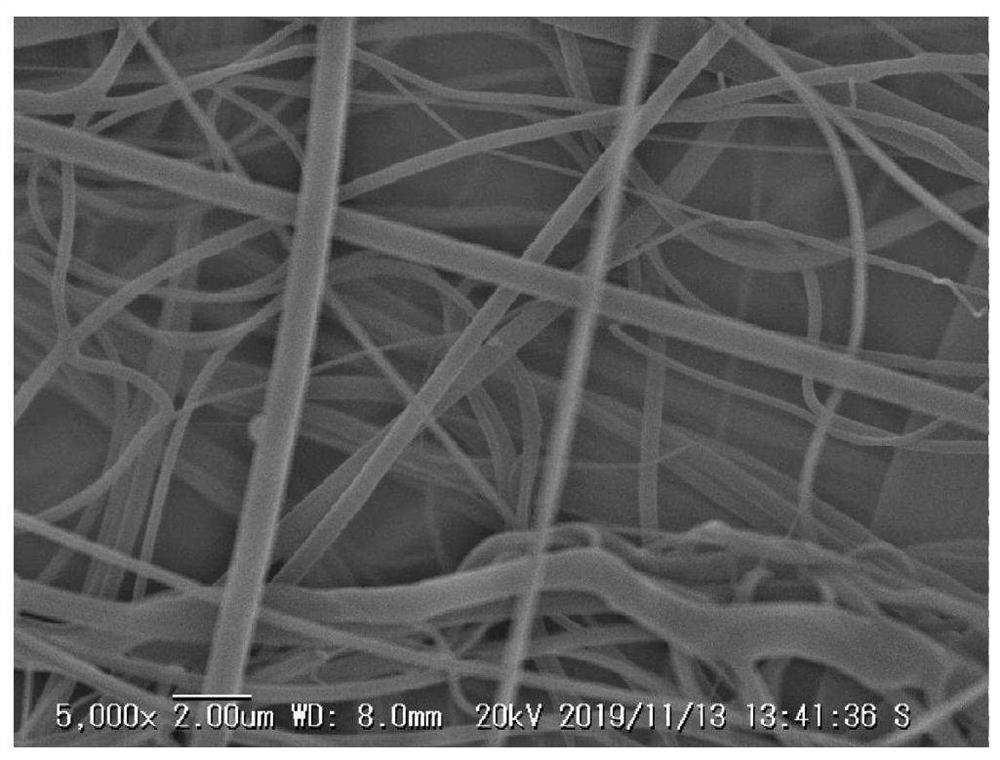

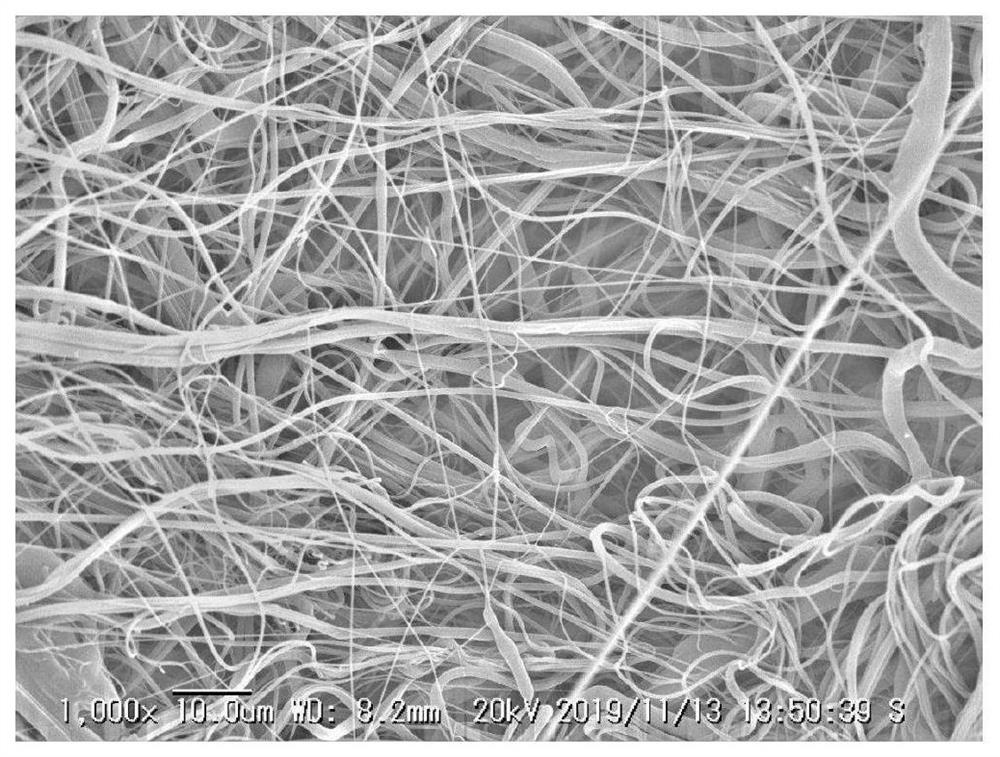

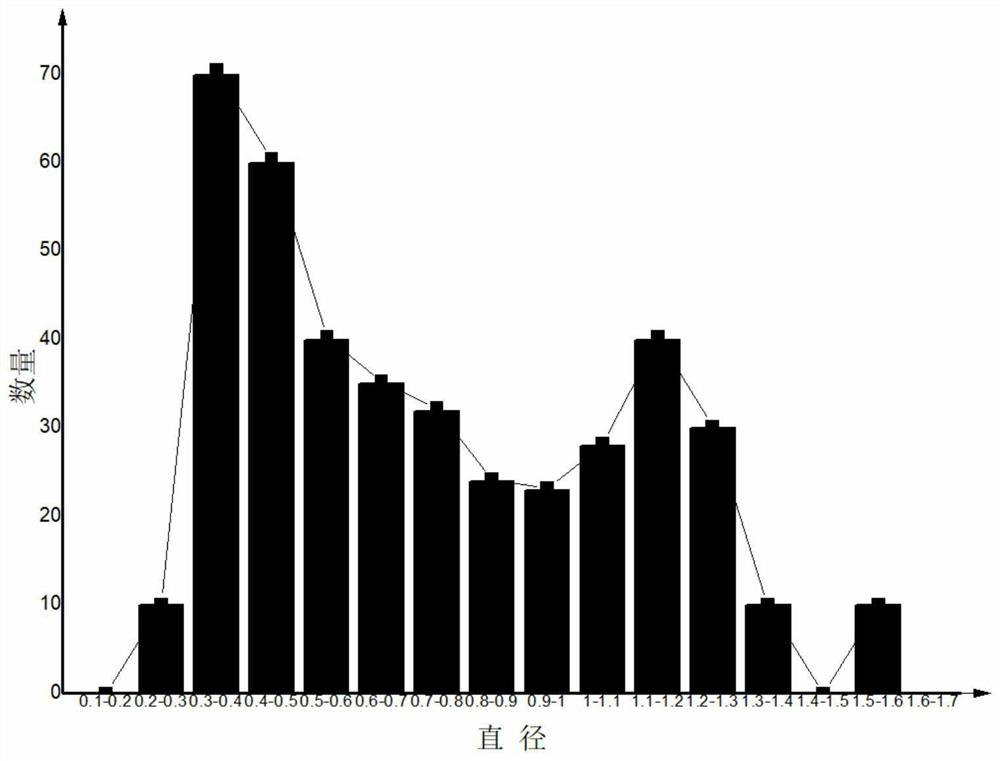

[0078] like Picture 1-1 , Figure 1-2 and figure 2 As shown, a melt-blown non-woven fabric with a nano / micro-scale fiber interlocking structure, including a nanofiber set and a micron fiber set, the nanofiber set and the micron fiber set are formed by meltblowing a mixture, and the mixture is formed by at least two melted Index of the same or different polymer composition.

[0079] The sets of nanofibers and microfibers are meltblown from a mixture of polymers comprising at least two of said polymers having a melt index, in this example the thermoplastic polymer polypropylene, which Contains polypropylene with high melt index and polypropylene with low melt index, wherein the melt index of high melt index polypropylene is 1800g / 10min, the content is 90wt%; the melt index of low melt index polypropylene is 28g / 10min, the content It is 5wt%; the mass ratio of high melt index polypropylene and low melt index polypropylene is 18:1.

[0080] The polymer is doped with a degradi...

Embodiment 2

[0123] like Figure 3-1 , Figure 3-2 and Figure 4 As shown, a melt-blown non-woven fabric with a nano / micro-scale fiber interlocking structure, including a nanofiber set and a micron fiber set, the nanofiber set and the micron fiber set are formed by melt blown from a mixture of at least two melted Index of the same or different polymer compositions.

[0124] The sets of nanofibers and microfibers are meltblown from a mixture of polymers comprising at least two of said polymers having a melt index, in this example the thermoplastic polymer polypropylene, which Contains polypropylene with high melt index and polypropylene with low melt index, wherein the melt index of high melt index polypropylene is 1800g / 10min, the content is 90wt%; the melt index of low melt index polypropylene is 28g / 10min, the content It is 10wt%; the mass ratio of high melt index polypropylene and low melt index polypropylene is 9:1.

[0125] The mass proportion of the nanofiber set is 55%, and the ma...

Embodiment 3

[0158] like Figure 5-1 , Figure 5-2 and Image 6 As shown, a melt-blown non-woven fabric with a nano / micro-scale fiber interlocking structure, including a nanofiber set and a micron fiber set, the nanofiber set and the micron fiber set are formed by melt blown from a mixture of at least two melted Index of the same or different polymer composition.

[0159] The sets of nanofibers and microfibers are meltblown from a mixture of polymers comprising at least two of said polymers having a melt index, in this example the thermoplastic polymer polypropylene, which Contains polypropylene with high melt index and polypropylene with low melt index, wherein the melt index of high melt index polypropylene is 1500g / 10min, the content is 85wt%; the melt index of low melt index polypropylene is 28g / 10min, the content It is 15wt%; the mass ratio of high melt index polypropylene and low melt index polypropylene is 13:3.

[0160] The mass proportion of the nanofiber set is 45%, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com