Three-layer composite filter paper and preparation method thereof

A layer composite, filter paper technology, applied in filter paper, filtration separation, separation methods, etc., can solve the problems of affecting the filtration effect, complex production, filter blockage, etc., and achieve long service life, good temperature resistance, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

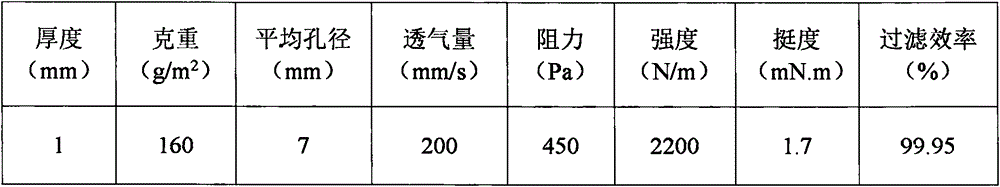

Embodiment 1

[0029] A three-layer composite filter paper, composed of ultrafine glass fiber, polytetrafluoroethylene fiber, polypropylene fiber and adhesive, is characterized in that the three-layer composite filter paper forms a gradient structure material, the continuous change of the internal pore size, the filtration efficiency The relationship with the filter resistance is balanced, and the ideal filter separation effect can be achieved; the diameter of the ultrafine glass fiber is between 3 μm and the fiber length is 7 mm; the diameter of the polytetrafluoroethylene fiber is between 4 μm and the fiber length is 12mm; the diameter of the polypropylene fiber is between 4 μm and the fiber length is 12mm; the adhesive is phenolic resin.

[0030] A kind of preparation method of three-layer composite filter paper is characterized in that comprising the following steps:

[0031] ①Prepare the first layer according to the single-layer filter paper preparation process, put it in a desiccator t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com