Patents

Literature

36results about How to "Good filtration and separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

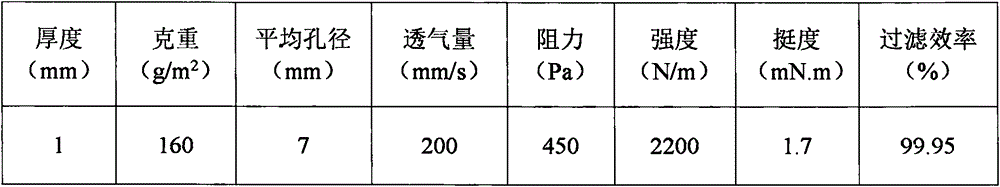

Filter material of gradient distribution and its preparation process

InactiveCN1623627AExtended service lifeSufficient filtration accuracyFiltration separationPlant fibreDistributed filtering

A gradiently distributed filter material with gradually decreased pore diameter from top to bottom for high selectivity and low filter resistance is prepared through beating plant fibres to obtain pulp, dispersing the synthetic fibres and inorganic fibres in the aqueous solution of disperser, mixing, adding wet reinforcing agent, shaping by net, dewatering, reinforcing by resin, and drying again.

Owner:SOUTH CHINA UNIV OF TECH

Three-layer composite filter paper and preparation method thereof

InactiveCN105970715AReasonable adjustment of filtration efficiencyReasonable adjustment of filter resistanceNon-fibrous pulp additionPaper/cardboardGlass fiberSlurry

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Preparation method of MOF (metal oxide framework)-loaded silver antibacterial scale-blocking ultrafiltration film and application thereof

InactiveCN109806770AImprove the bactericidal effectGood filtration and separation effectUltrafiltrationUltrafiltrationEngineering

The invention relates to a preparation method of a MOF (metal oxide framework)-loaded silver antibacterial scale-blocking ultrafiltration film, and belongs to the technical field of inorganic / organichybrid separation. The preparation method comprises the following steps of using metal salt and ligand as raw materials, preparing MOF under the hydrothermal reaction condition, mixing the MOF and silver salt, and reducing, so as to obtain the MOF-loaded silver; mixing the MOF-loaded silver and a film material, so as to prepare a film casting liquid; preparing the film casting liquid into the MOF-loaded silver antibacterial scale-blocking ultrafiltration film by TIPS (thermally induced phase separation), NIPS (nonsolvent-induced phase separation) and VIPS (vapor-induced phase separation) methods. The preparation method has the advantages that by adopting one-pot method, the MOF-loaded silver can be obtained, the production process is simple, and the operation is easy. The MOF-loaded silverantibacterial scale-blocking ultrafiltration film has the advantages that the sterilizing property is higher, and the sterilizing rate for staphylococcus aureus is 90 to 99.8%; the filtering and separating property is good, and the rejection rate for bovine serum albumin is 99% or above; the MOF-loaded silver antibacterial scale-blocking ultrafiltration film can stably exist in air and water, andcan be recycled and regenerated; the environment-friendly effect is realized, and the corrosion property is avoided.

Owner:QUANZHOU NORMAL UNIV

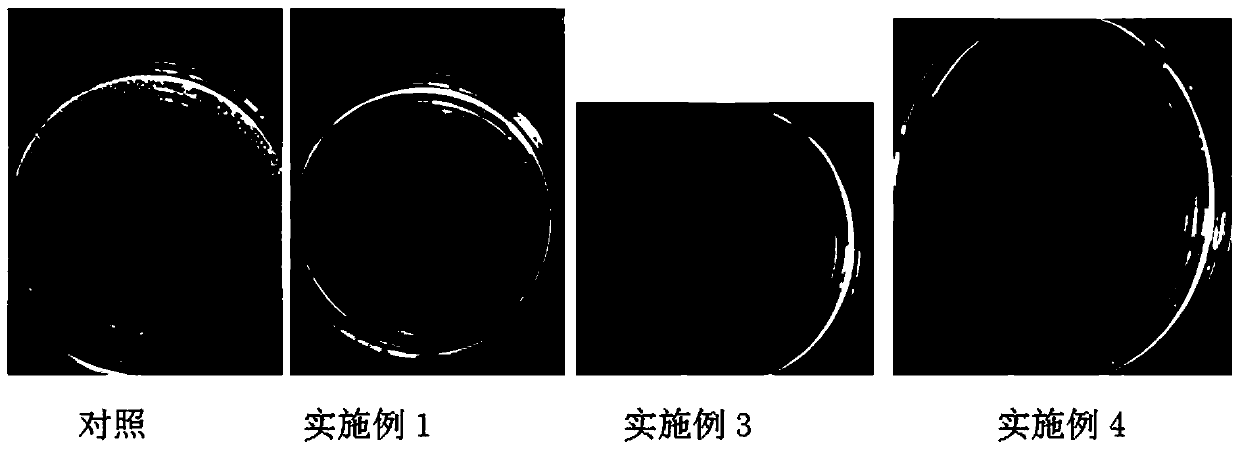

Antibacterial ultrafiltration membrane, preparation method thereof and membrane regeneration method

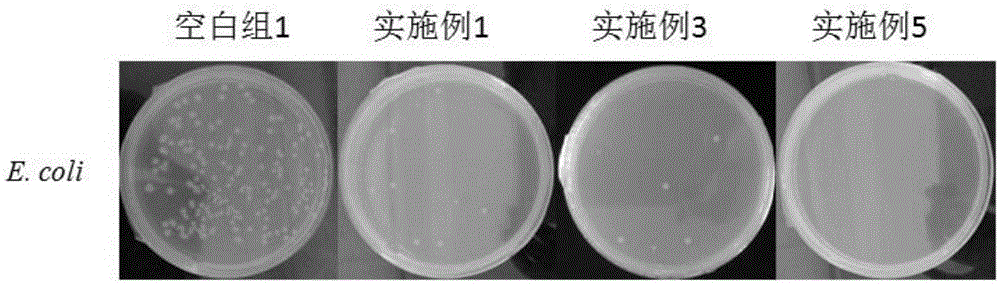

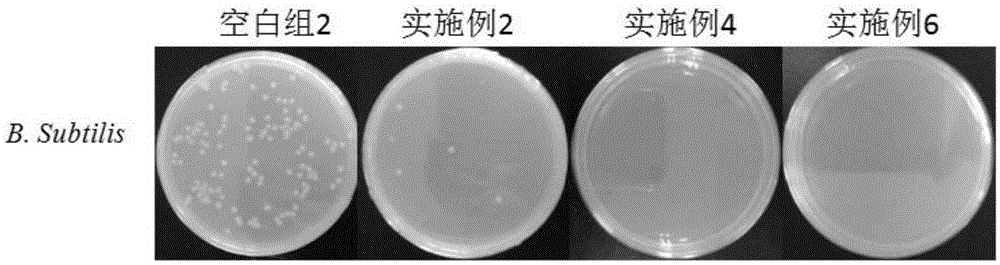

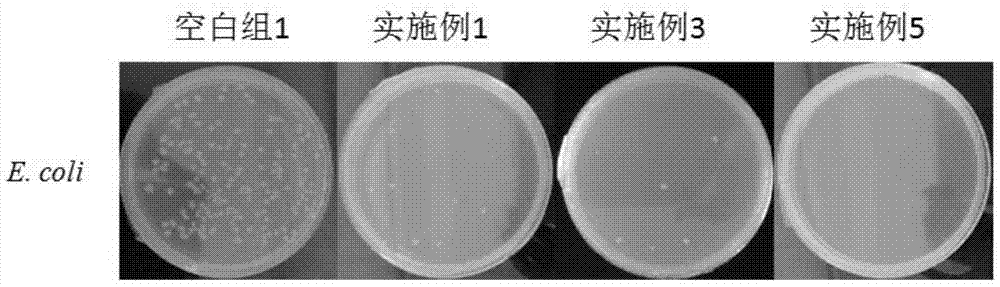

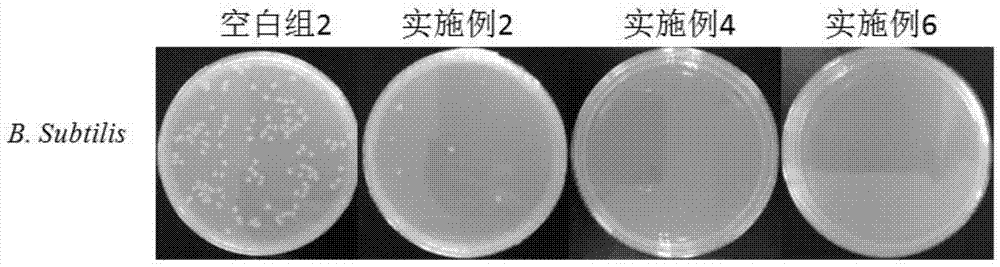

ActiveCN105289339AImprove the bactericidal effectGood filtration and separation effectSemi-permeable membranesEscherichia coliFiltration

The invention provides an antibacterial ultrafiltration membrane, a preparation method thereof and a membrane regeneration method. The antibacterial ultrafiltration membrane is prepared from an ultrafiltration membrane material possessing a repetitive unit shown as a formula I or a formula II, the repetitive unit shown as the formula I or the formula II contains N-Cl bond, so that the antibacterial ultrafiltration membrane prepared from an ultrafiltration membrane material possessing the repetitive unit shown as the formula I or the formula II possesses relatively high bactericidal activity. Additionally, the antibacterial ultrafiltration membrane possesses good filtration separation performance, can stably exist in air and water, can be recycled and regenerated, and is friendly to environment and free of corrosiveness. Experiment results show that the provided antibacterial ultrafiltration membrane possesses the bactericidal rate on escherichia coli or bacillus subtilis of 90-100%, possesses the bactericidal rate on escherichia coli or bacillus subtilis of 90-100% after being put in air for 6 months, and possesses the retention rate on bovine serum albumin of 99.2% or more.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of MOF (metal organic framework)-loaded ZnO scale inhibition ultrafiltration membrane

InactiveCN108854569AExcellent antibacterial adhesion and separation performanceHigh Antibacterial AdhesionSemi-permeable membranesUltrafiltrationChemistry

The invention relates to a preparation method of MOF (metal organic framework)-loaded ZnO scale inhibition ultrafiltration membrane and belongs to the technical field of inorganic / organic hybridization and separation. The method comprises the following steps: metal salt and ligand are taken as raw materials to prepare MOF under a hydrothermal reaction condition; the MOF and zinc salt are mixed andcalcined to produce an MOF-loaded ZnO; the MOF-loaded ZnO and membrane materials are mixed to prepare a membrane casting solution; and the membrane casting solution is used to prepare the MOF-loadedZnO scale inhibition ultrafiltration membrane in a plurality of methods. In particular, the MOF-loaded ZnO can be prepared using a one-pot method characterized by a simple production process and easyoperation. The MOF-loaded ZnO scale inhibition ultrafiltration membrane has a high anti-bacterial performance and an anti-adhesion of 80-90% to bacteria separated from wastewater; besides, the MOF-loaded ZnO scale inhibition ultrafiltration membrane has a sound filtering separation performance and can retain over 95% of bovine serum albumin; the MOF-loaded ZnO scale inhibition ultrafiltration membrane can stably exist in air and water; the MOF-loaded ZnO scale inhibition ultrafiltration membrane is recyclable; the MOF-loaded ZnO scale inhibition ultrafiltration membrane is environment-friendlyand non-corrosive.

Owner:QUANZHOU NORMAL UNIV

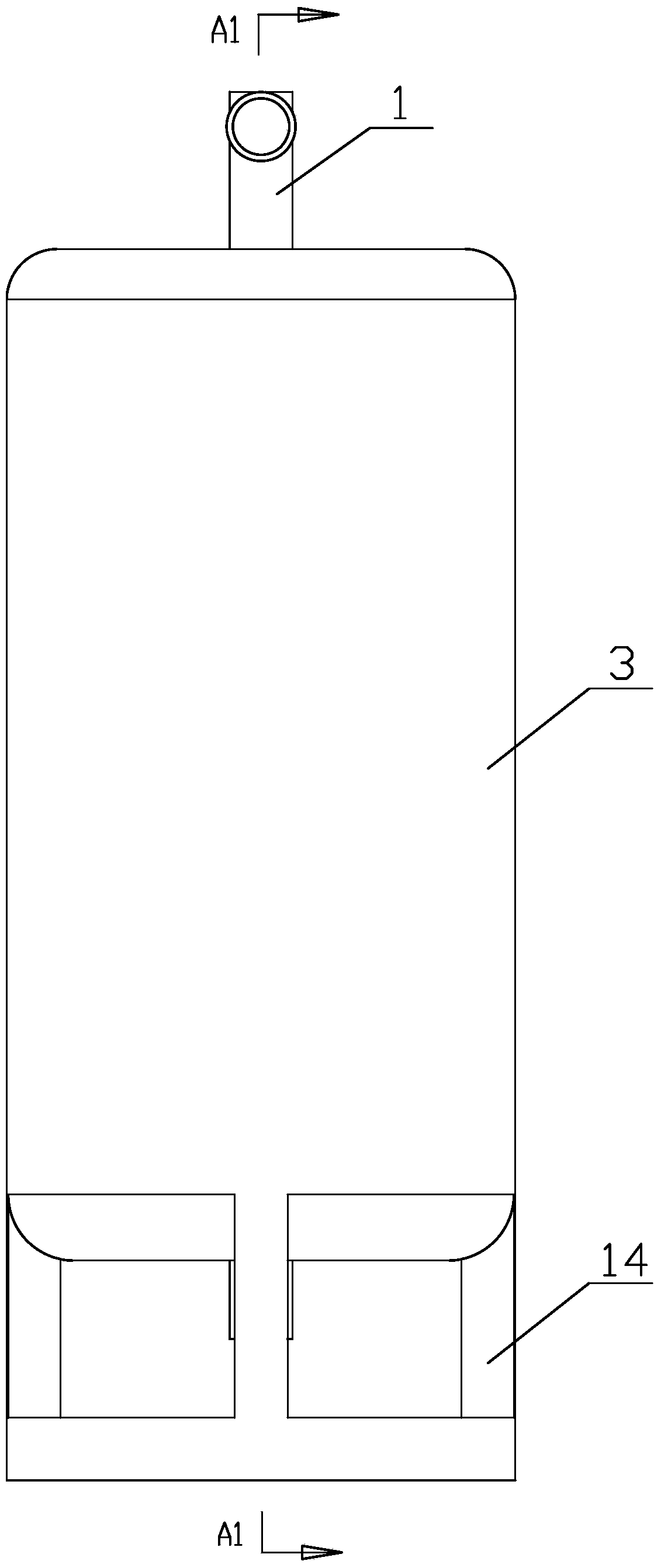

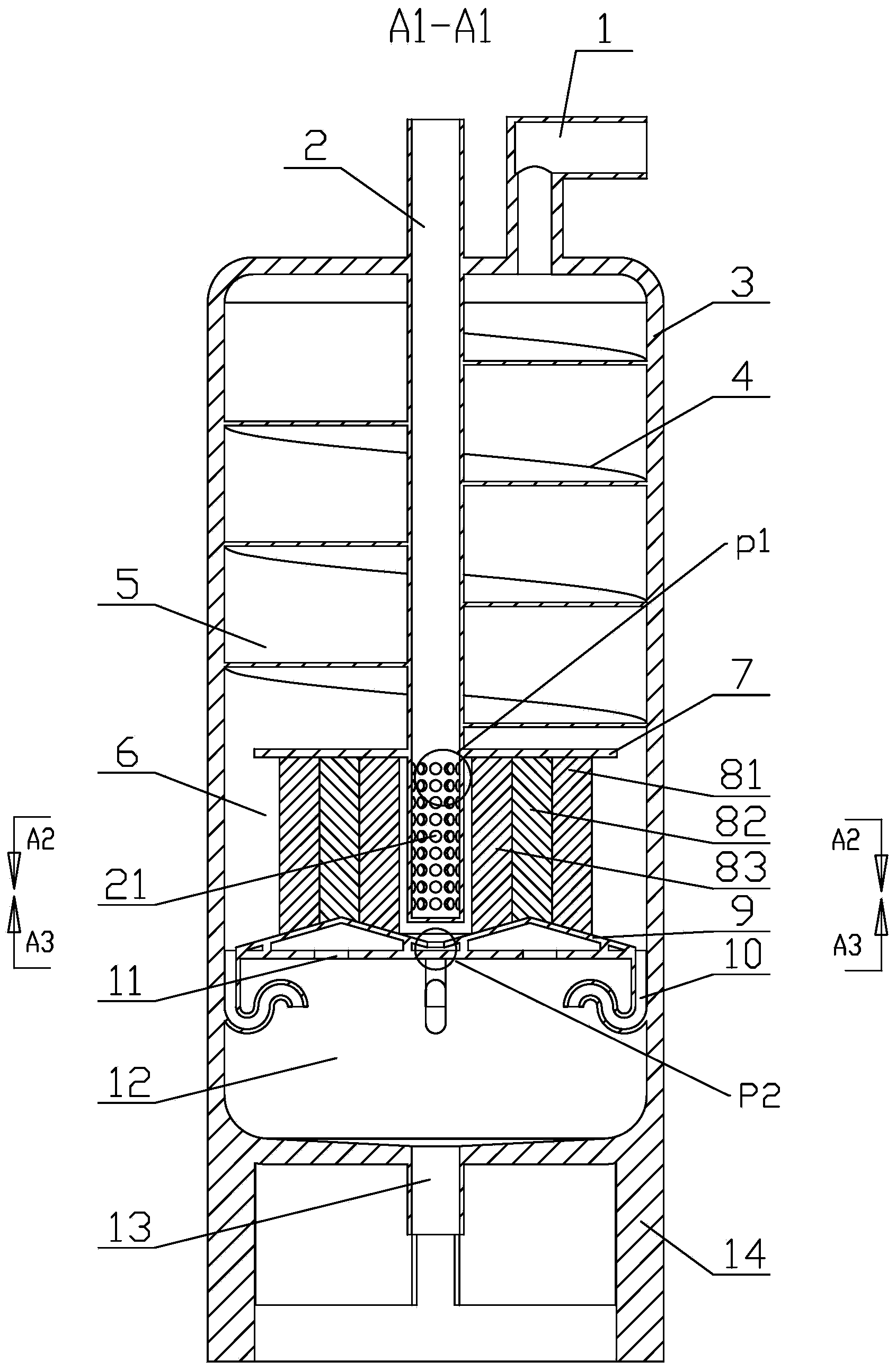

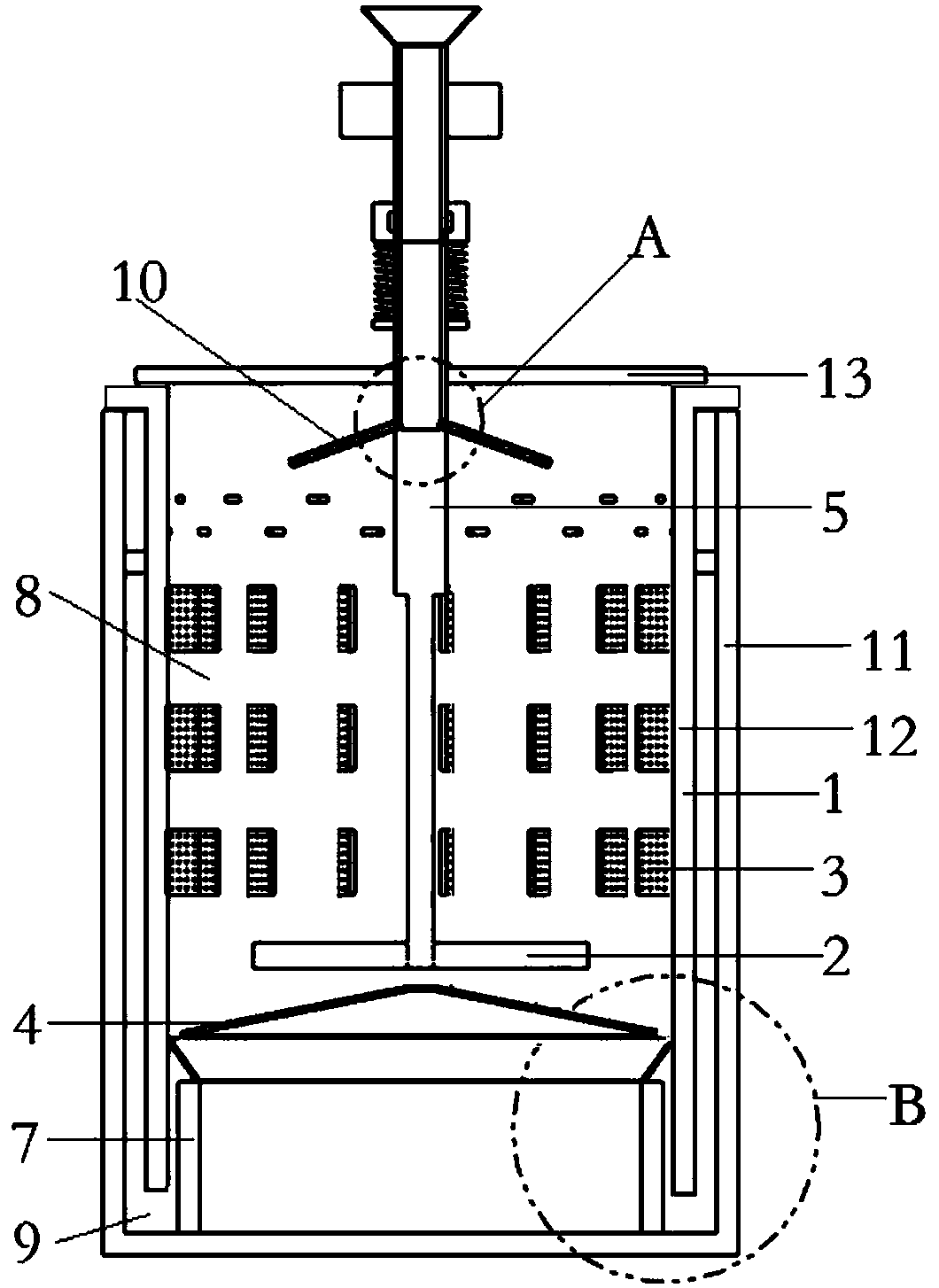

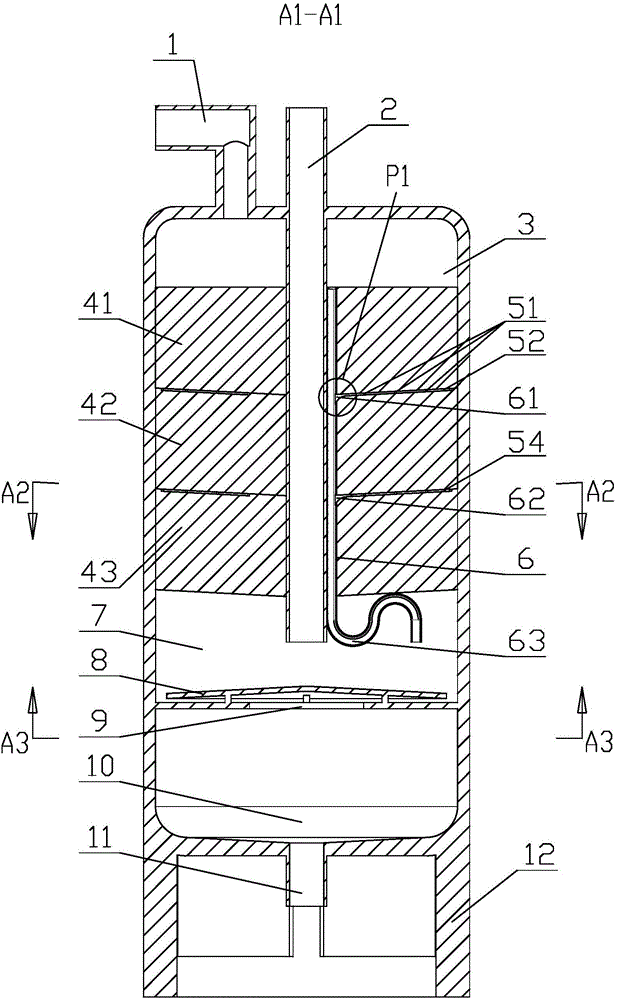

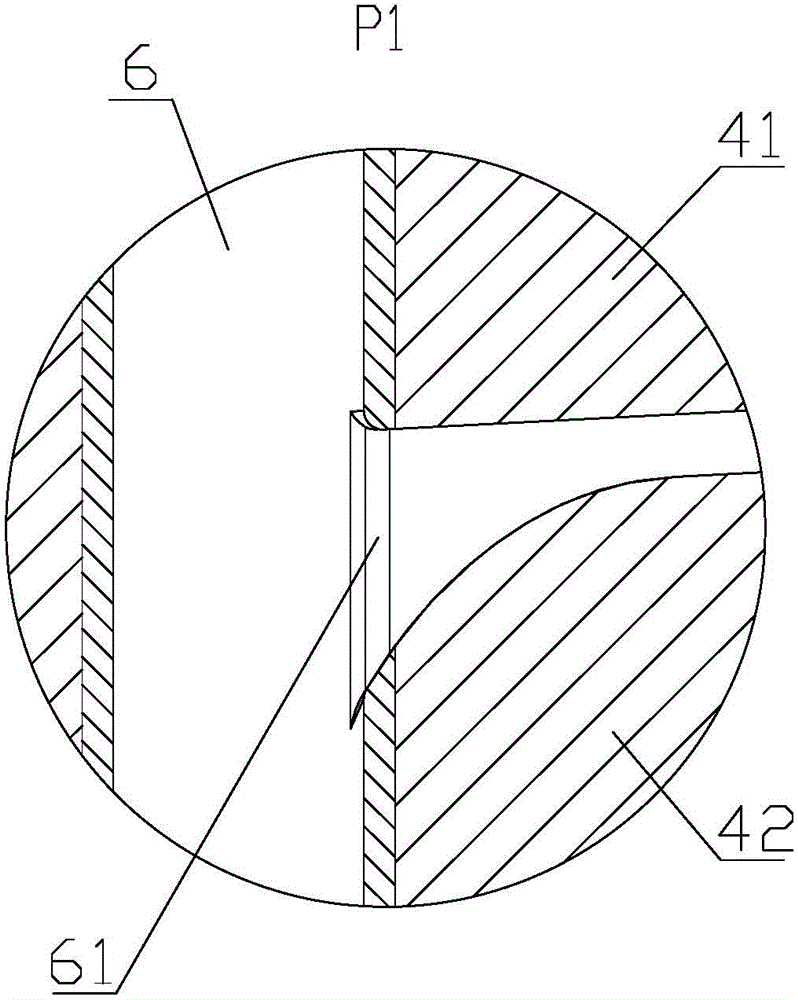

Foam metal filtering spiral type oil separator

InactiveCN103727713AReduce large oil droplet contentReduce contentRefrigeration componentsMetalPetroleum engineering

The invention discloses a foam metal filtering spiral type oil separator. The foam metal filtering spiral type oil separator comprises an outer barrel with the top provided with a gas inlet connector and a gas outlet guide tube, wherein the interior of the outer barrel is divided into a spiral gas inlet cavity, a filtering cavity and an oil collecting cavity from top to bottom; the bottom end of the gas outlet guide tube stretches to the bottom of the filtering cavity, and the bottom end face of the gas outlet guide tube is sealed; a spiral guide blade is arranged in the spiral gas inlet cavity; an annular three-layer foam metal filtering layer is arranged in the filtering cavity, and a circulating hole is formed in the gas outlet guide tube in the foam metal filtering layer; a partition plate is arranged on the top face of the three-layer foam metal filtering layer, and the bottom face of the three-layer foam metal filtering layer is arranged on an annular oil falling umbrella; the three-layer foam metal filtering layer and the oil collecting cavity are separated by the annular oil falling umbrella; a center hole is formed in the center of the annular oil falling umbrella, an oil guide tube is arranged on the edge of the annular oil falling umbrella, and an oil falling hole is formed below the annular oil falling umbrella; an oil outlet is formed in the center of the bottom face of the oil collecting cavity. According to the foam metal filtering spiral type oil separator, the content of large oil drops in air flow is reduced through the spiral guide blade, then the oil drops are effectively intercepted with the three-layer foam metal filtering layer, and therefore the gas-oil separating effect is improved.

Owner:TIANJIN UNIV

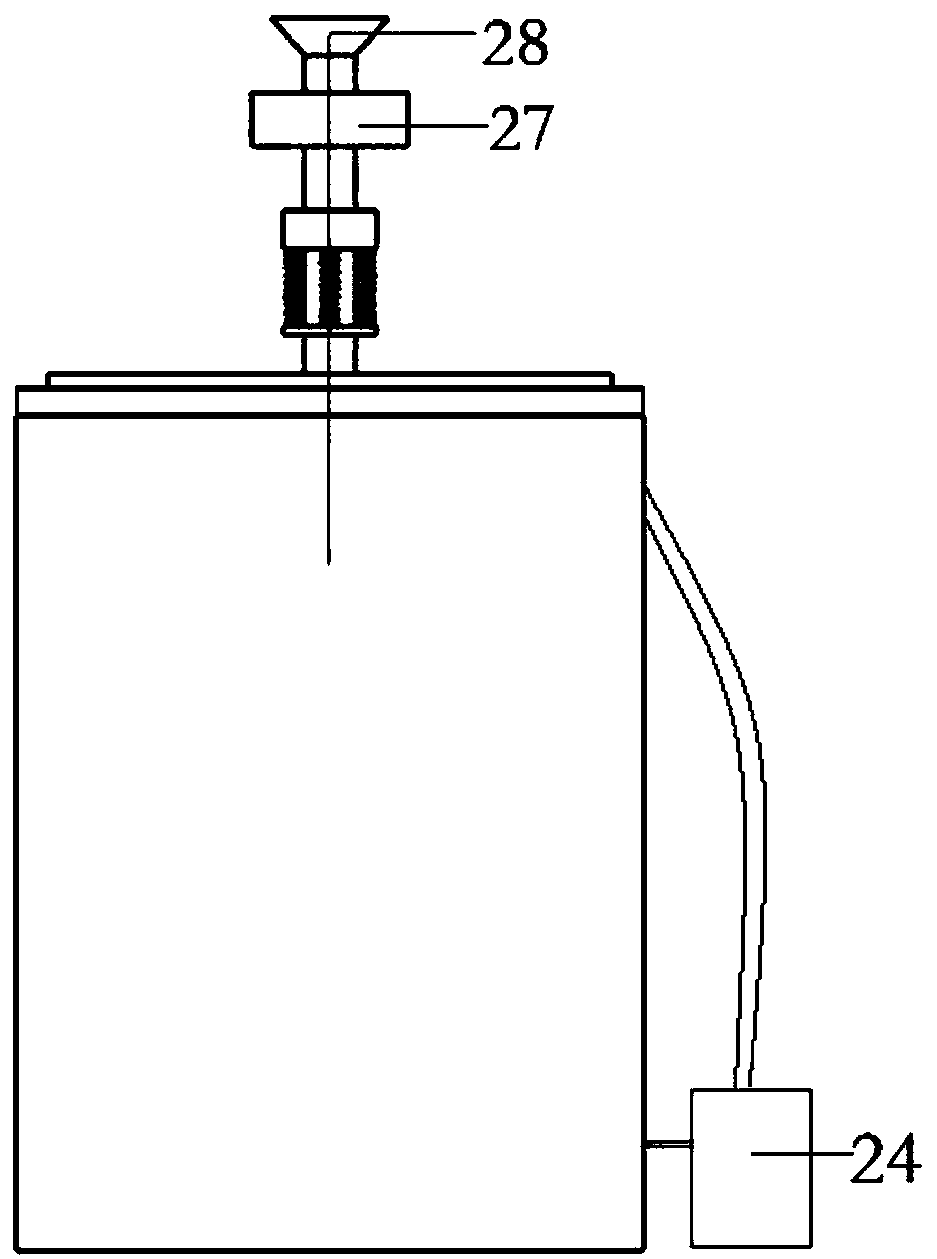

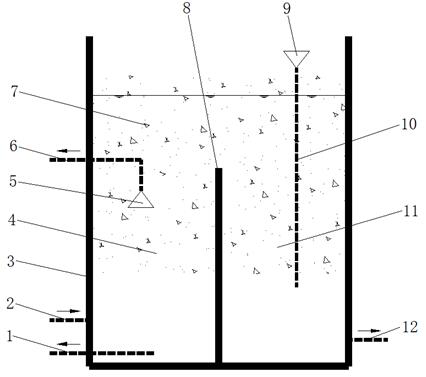

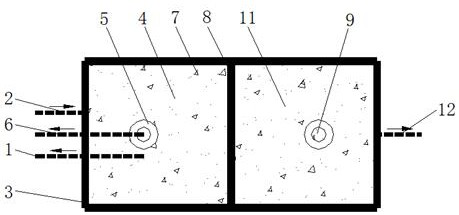

Sewage efficient filtering and separation device and method

InactiveCN108264161AThe overall structure is simpleEasy to operateWater/sewage treatment by centrifugal separationTreatment involving filtrationEngineeringSewage

The invention discloses a sewage efficient filtering and separation device and method. The sewage efficient filtering and separation device comprises a tube body container, a layering plate, an adsorbent adding assembly and a vortex generation assembly, wherein the layering plate is erected in the tube body container; the outer contour edge of the layering plate and the inner wall of the tube bodycontainer are in gap arrangement; the tube body container is separated into a separation cavity and a settling cavity in vertical mutual communication by the layering plate; the vortex generation assembly is arranged in the separation cavity; the vortex generation assembly is arranged above the layering plate; through the vortex generation assembly, sewage solution in the separation cavity rotates at high speed to form vortex; the adsorbent adding assembly is arranged in an opening part of the top end of the tube body container; the adsorbent adding assembly is filled with adsorbents. The sewage efficient filtering and separation device and method provided by the invention have the advantage that the sewage solution is effectively filtered.

Owner:绍兴三杰纺织印染有限公司

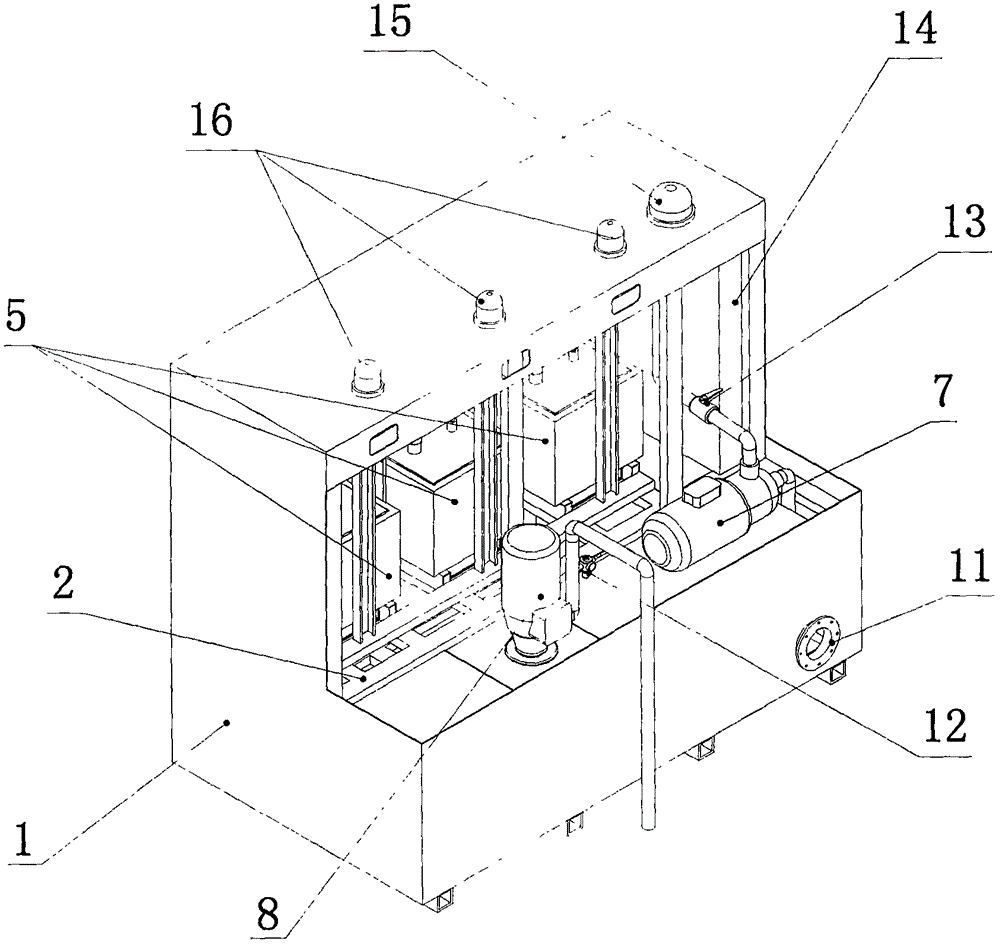

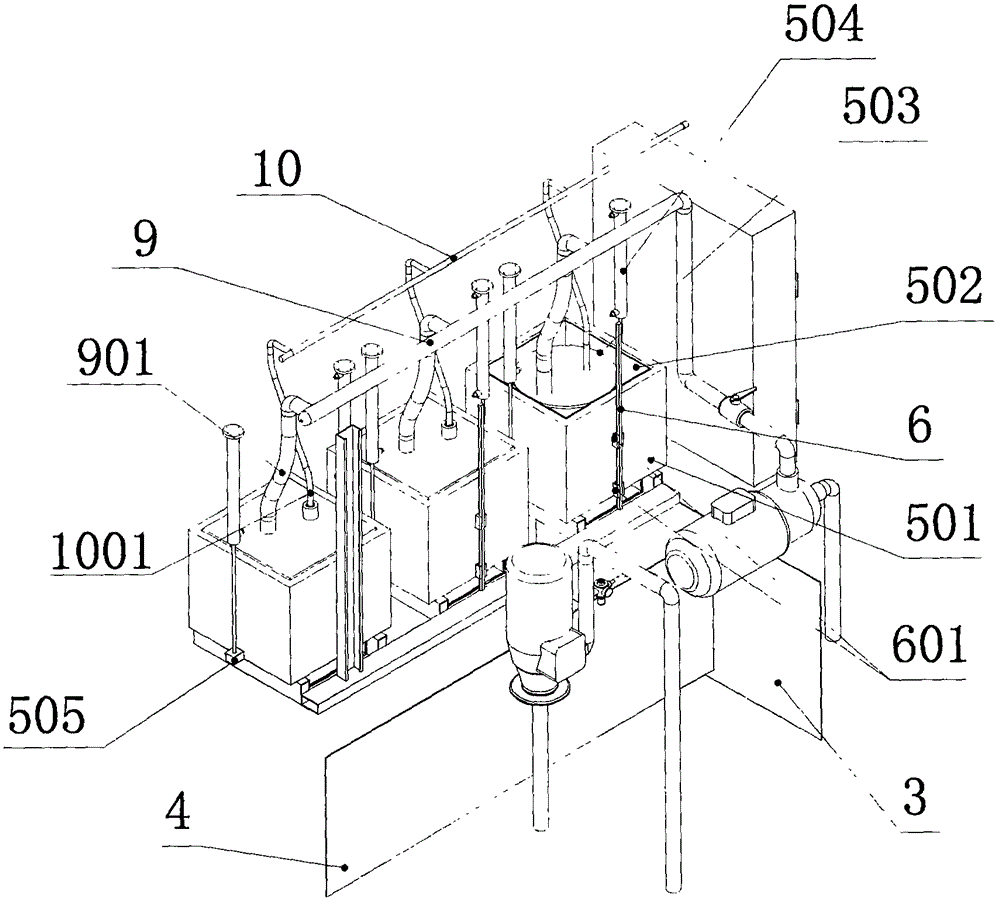

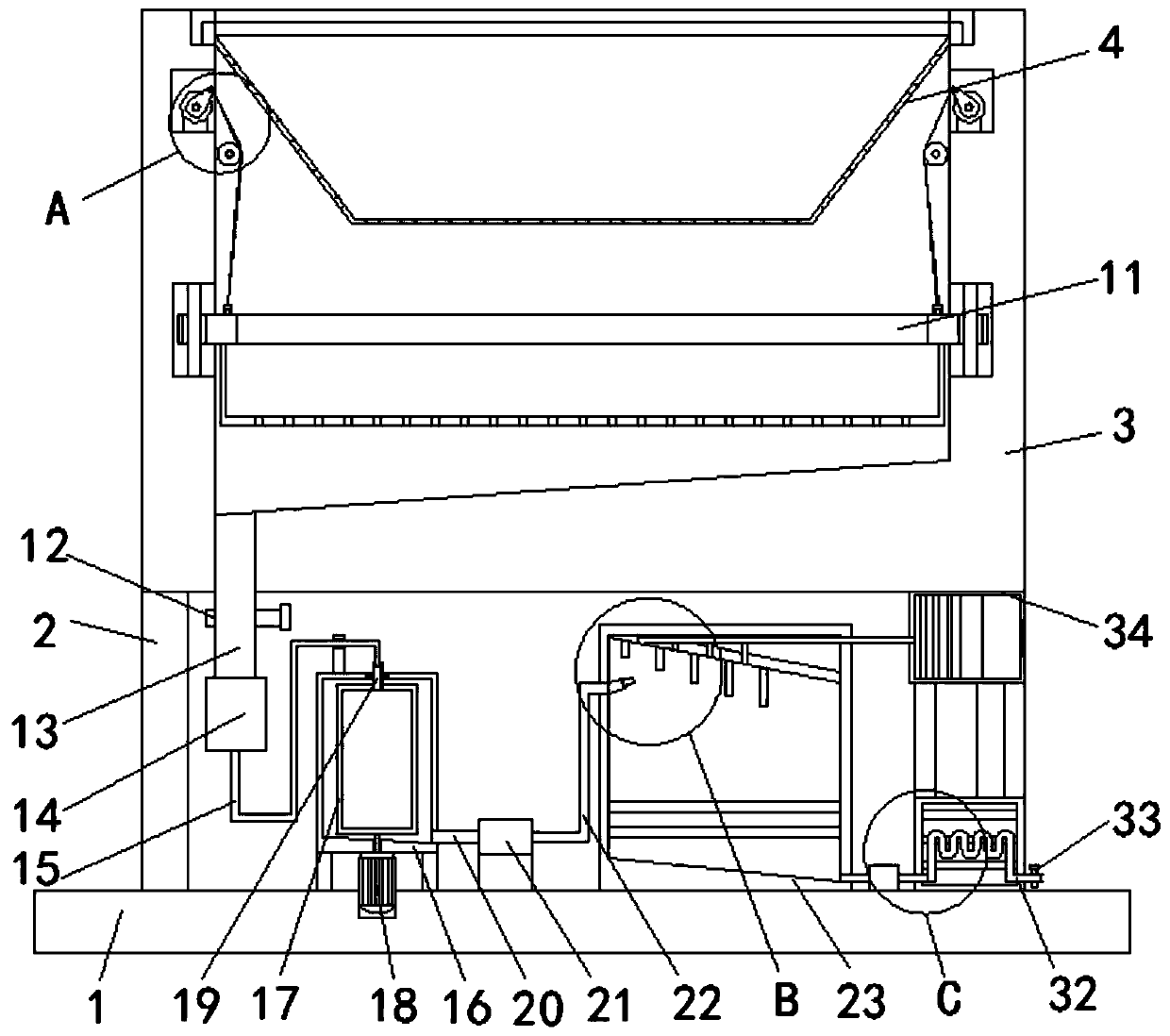

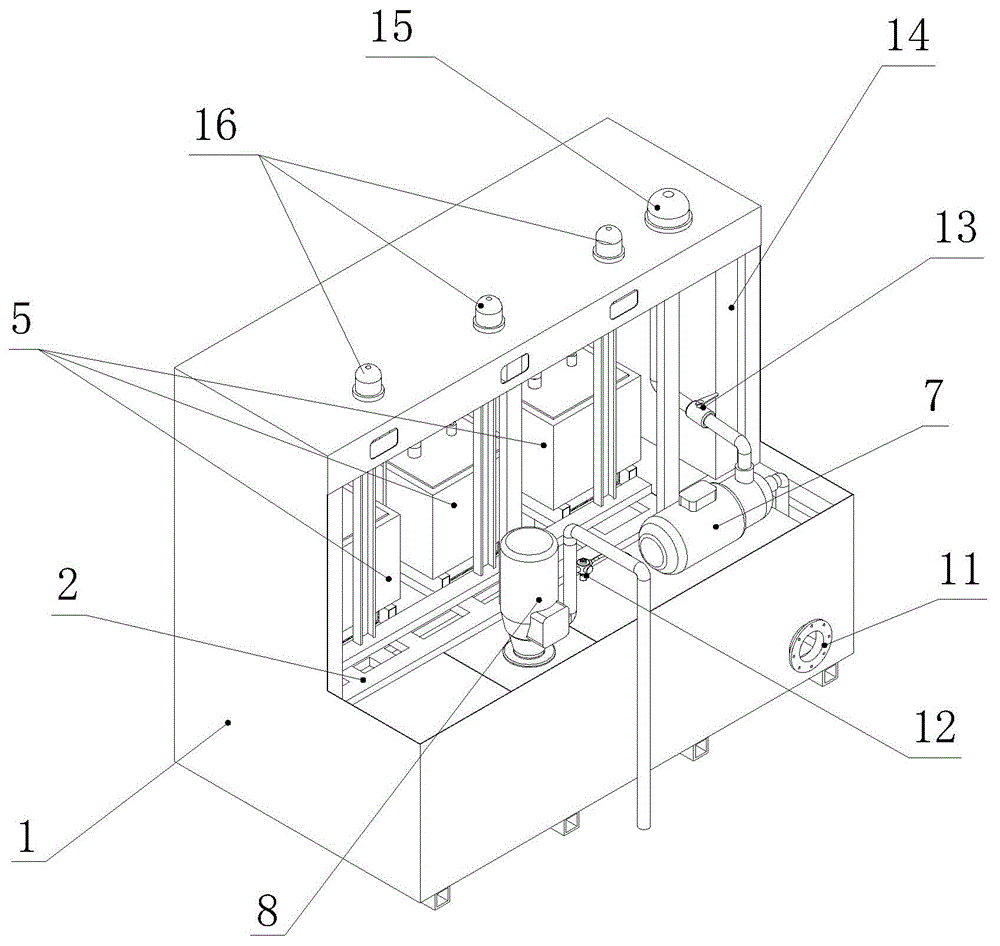

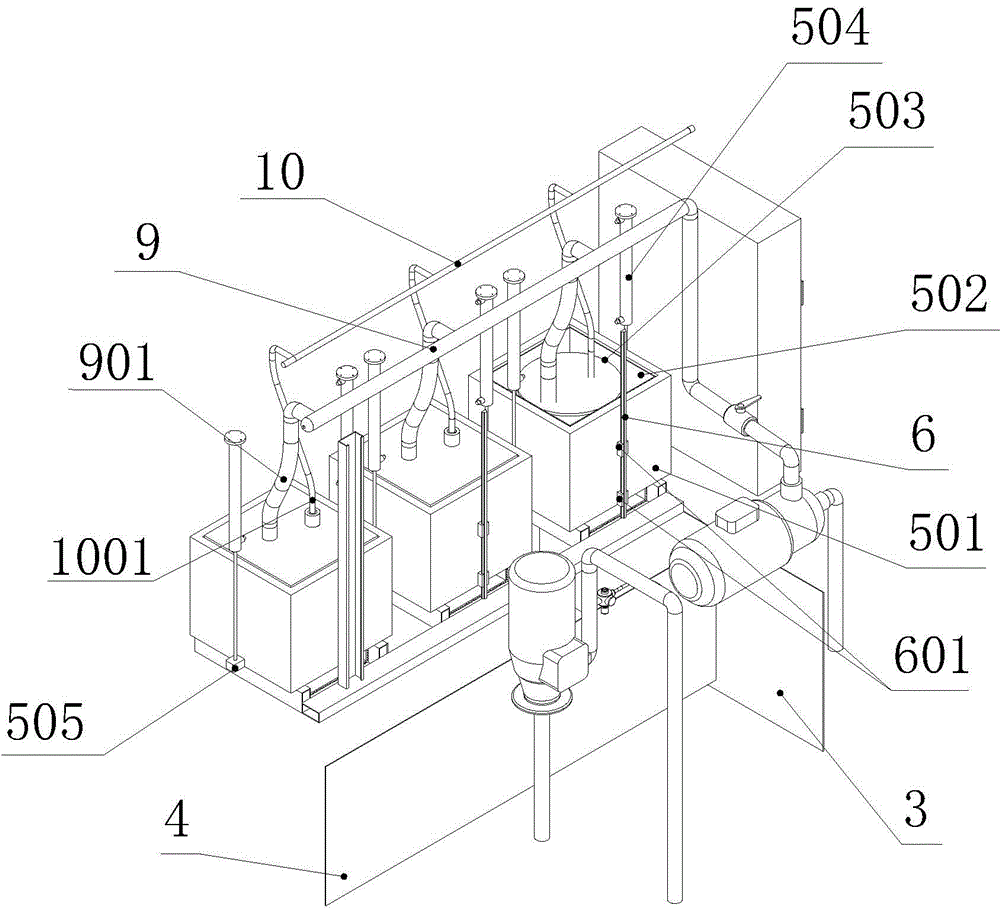

Cutting fluid purification equipment capable of treating residues online

InactiveCN106002473AProcessing capacity can be adjustedEasy to handleMaintainance and safety accessoriesAfter treatmentEngineering

The invention relates to the field of cutting fluid treatment, in particular to cutting fluid purification equipment capable of treating residues online. The cutting fluid purification equipment comprises a shell and a waste fluid filtering separation system arranged in the shell. The waste fluid filtering separation system comprises a waste fluid separation unit, a fluid storage pond, a fluid supply pipeline, an air supply pipeline, a water inlet pump and a water outlet pump. According to the cutting fluid purification equipment capable of treating the residues online, treatment capacity can be adjusted and can be enhanced along with increase of the treatment amount; the filtering separation effect is good, and work efficiency is high; and the cutting fluid residues generated after treatment can be cleaned away online, work cost is greatly reduced, and energy saving and environment friendliness are achieved.

Owner:宁波市镇海诚尚电气设备有限公司

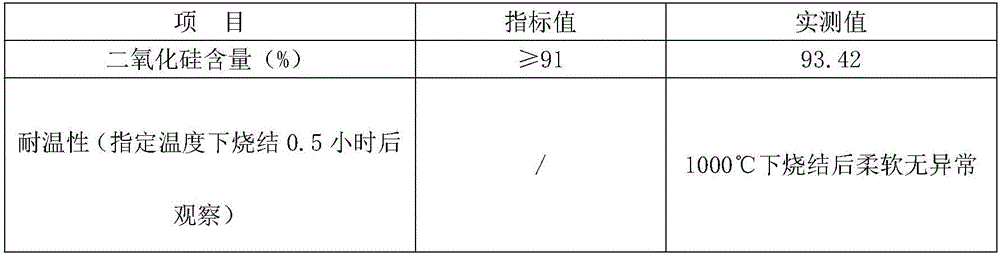

Method for preparing high-temperature resistant anti-corrosion ablation microfiber

InactiveCN106669284AGood separation and filtration effectQuality improvementMembrane filtersFiltration separationPolymer scienceAlkali free

The invention discloses a method for preparing high-temperature resistant anti-corrosion ablation microfiber, and belongs to the technical field of high-temperature filtration and ablation material preparation. The method comprises the following steps: 1, performing thermal acid leaching, namely, artificially crushing alkali-free glass fiber cotton of which the single fiber diameter is less than 1 [mu] m, soaking into a 2.5 mol / L acid solution, and stirring in two directions at a speed of 30-300 rpm; 2, performing water washing percolation, namely, firstly, washing a great amount of an acid liquid, adsorbed in the fiber cotton, with cold water, further washing with hot water and cold water respectively, testing acid residues on the surface of the fiber cotton by using extensive pH indicator paper of which the pH value is 1-14, and till the pH value is greater than 5, stopping washing; and 3, performing thermal treatment, drying the fiber cotton washed with water, and determining whether sintering is implemented or not according to application situations. The high-temperature resistant anti-corrosion ablation microfiber is high in high temperature resistance, high in corrosion resistance, rich in porous texture, excellent in separation and filtration effect, high in technical level, high in ablation property, low in cost and relatively good in prospect in market application.

Owner:宿迁市广昊纺织材料有限公司

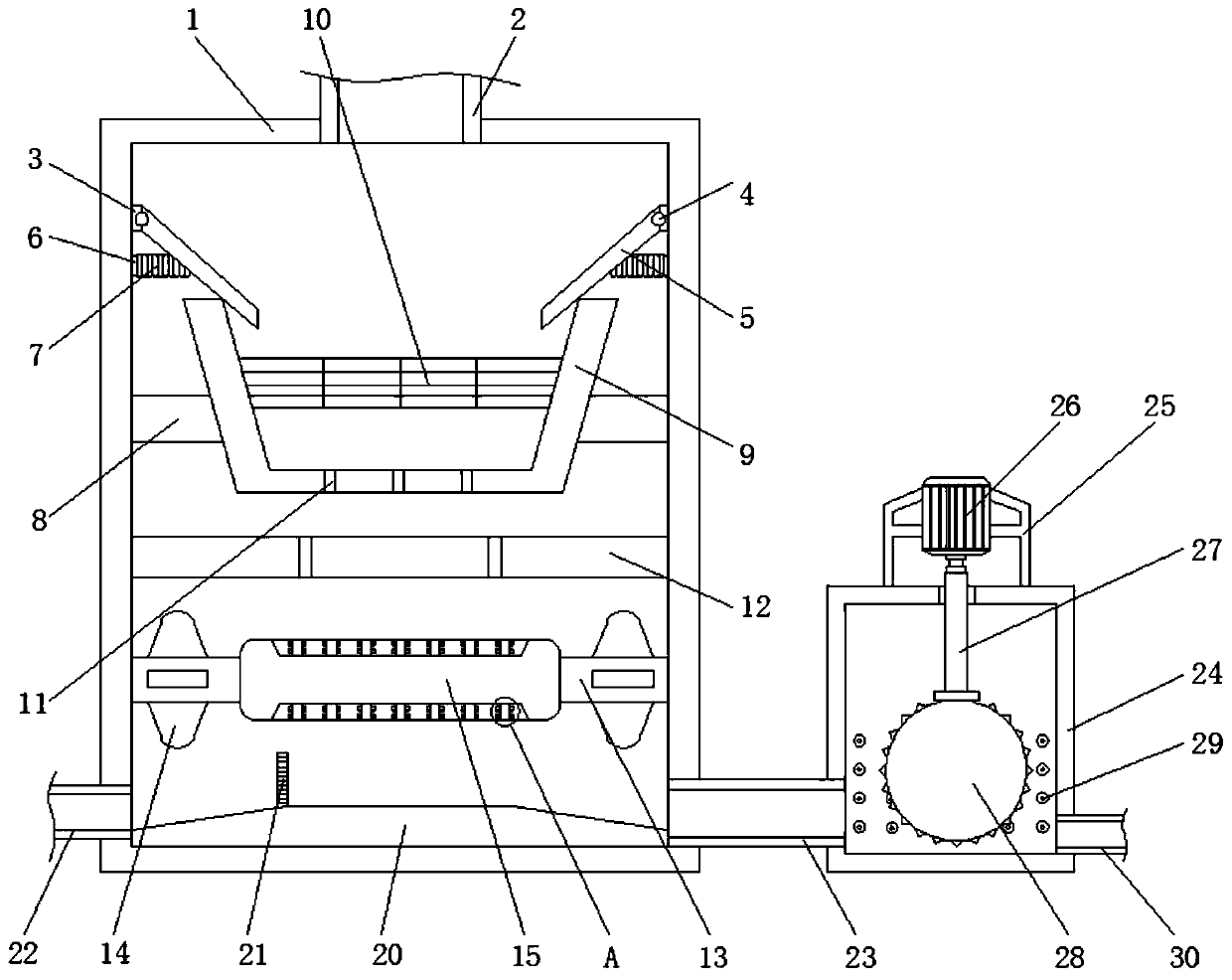

Extraction and separation device for vegetable oil production

InactiveCN110484360AInflow security and stabilityStable use positionFatty-oils/fats refiningEngineeringImpurity

The invention discloses an extraction and separation device for vegetable oil production. The extraction and separation device includes a shell, the top of the shell is fixedly connected with a feeding pipe, and mounting blocks are fixedly connected to the left side and the right side of the inner wall of the shell correspondingly; rotating shafts are rotatably connected at the opposite sides of the two mounting blocks correspondingly, the downstream plates are rotatably connected to the surfaces of the two rotating shafts correspondingly, the mounting shafts are fixedly connected to the positions, below the downstream plates, of the left side and the right side of the inner wall of the shell correspondingly, and a filtering frame is fixedly connected between the two mounting shafts. According to the extraction and separation device for the vegetable oil production, with the cooperation of the downstream plates and the rotating shafts, a vegetable oil mixture can be subjected to certain flow slowing and guiding effects when entering the shell, so that the vegetable oil can flow in more safely and stably; with the arrangement of the reset springs, the downstream plates can be kept at the stable using positions, the vegetable oil mixture can be filtered through the arrangement of the filtering frame and the filtering net plate, and the large-particle impurities are intercepted.

Owner:佛山市欧若拉生物科技有限公司

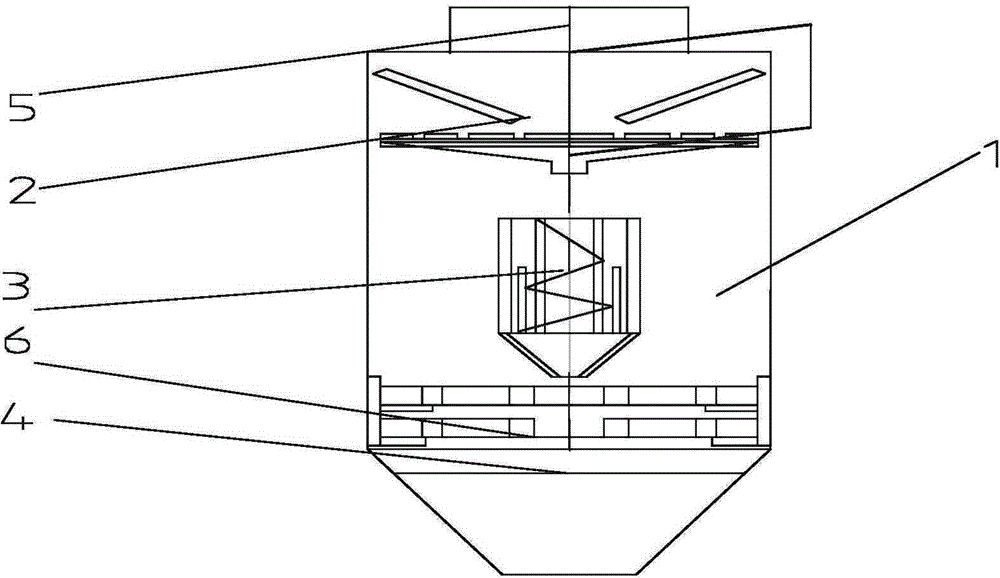

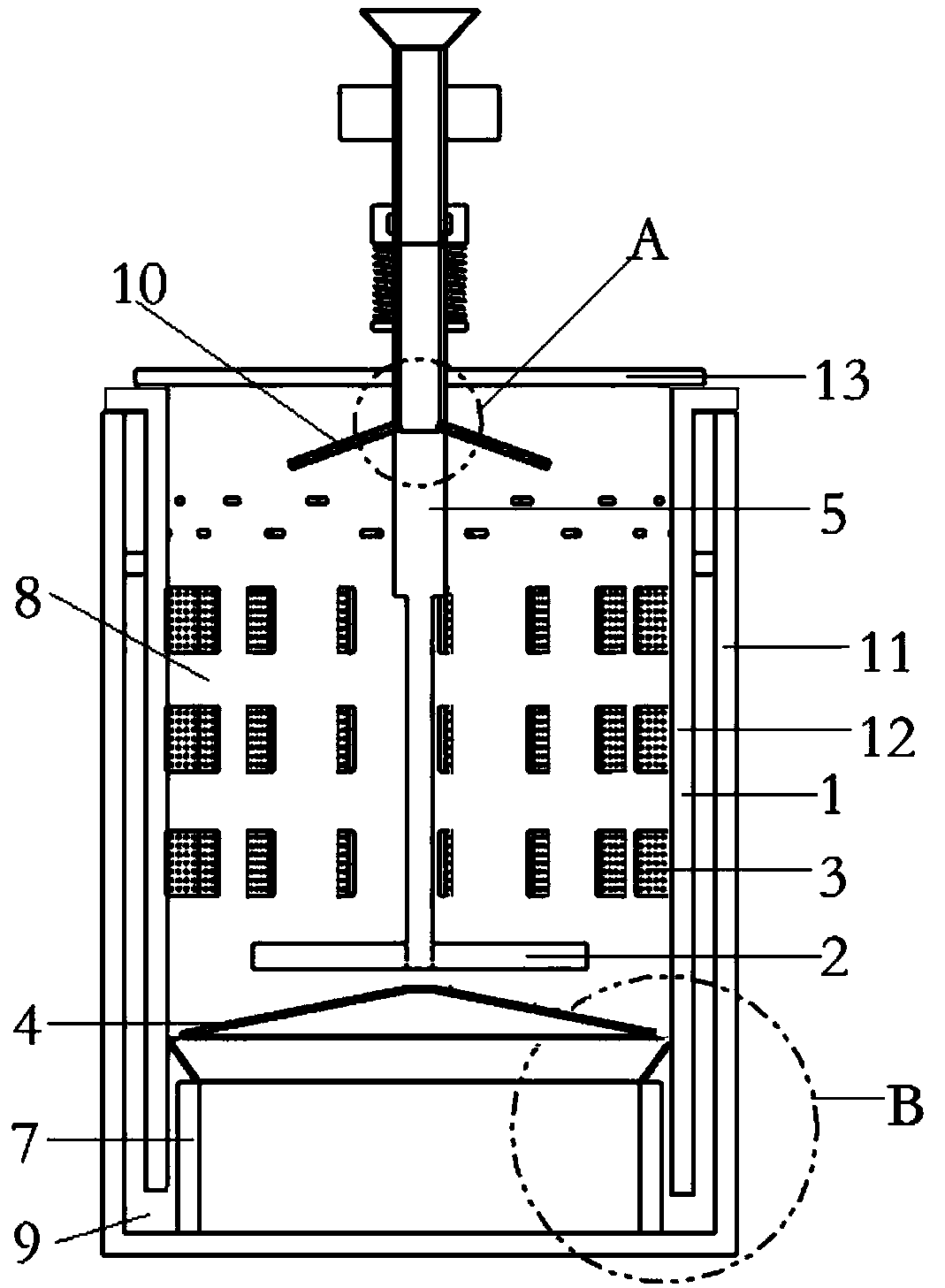

Dry-type dust separator for natural gas

InactiveCN104623986AGood filtration and separation effectEasy maintenance and operationDispersed particle separationGaseous fuelsThermodynamicsDust abatement

The invention discloses a dry-type dust separator for natural gas. The dry-type dust separator consists of a dust separator cylinder (1), a gas-liquid separation device (2), a cyclone assembly (3), a liquid collection chamber (4), a mixed high-efficiency demister (5) and an anti-vortex device (6). The dry-type dust separator disclosed by the invention has the beneficial effects that a multi-pipe cyclone advanced structure is adopted, the filtering and separating effect is good, and the operation and maintenance are convenient.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

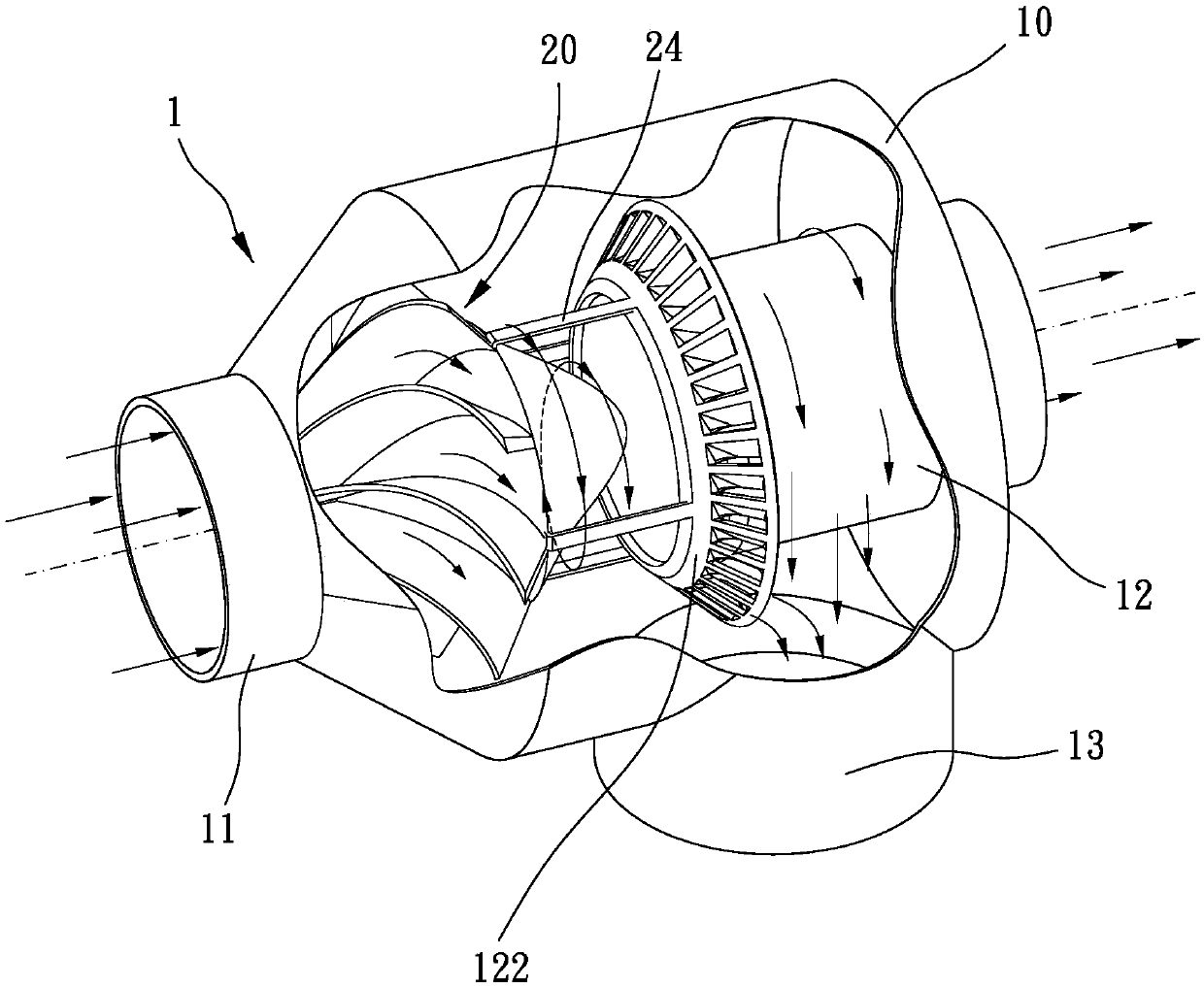

Filtering system

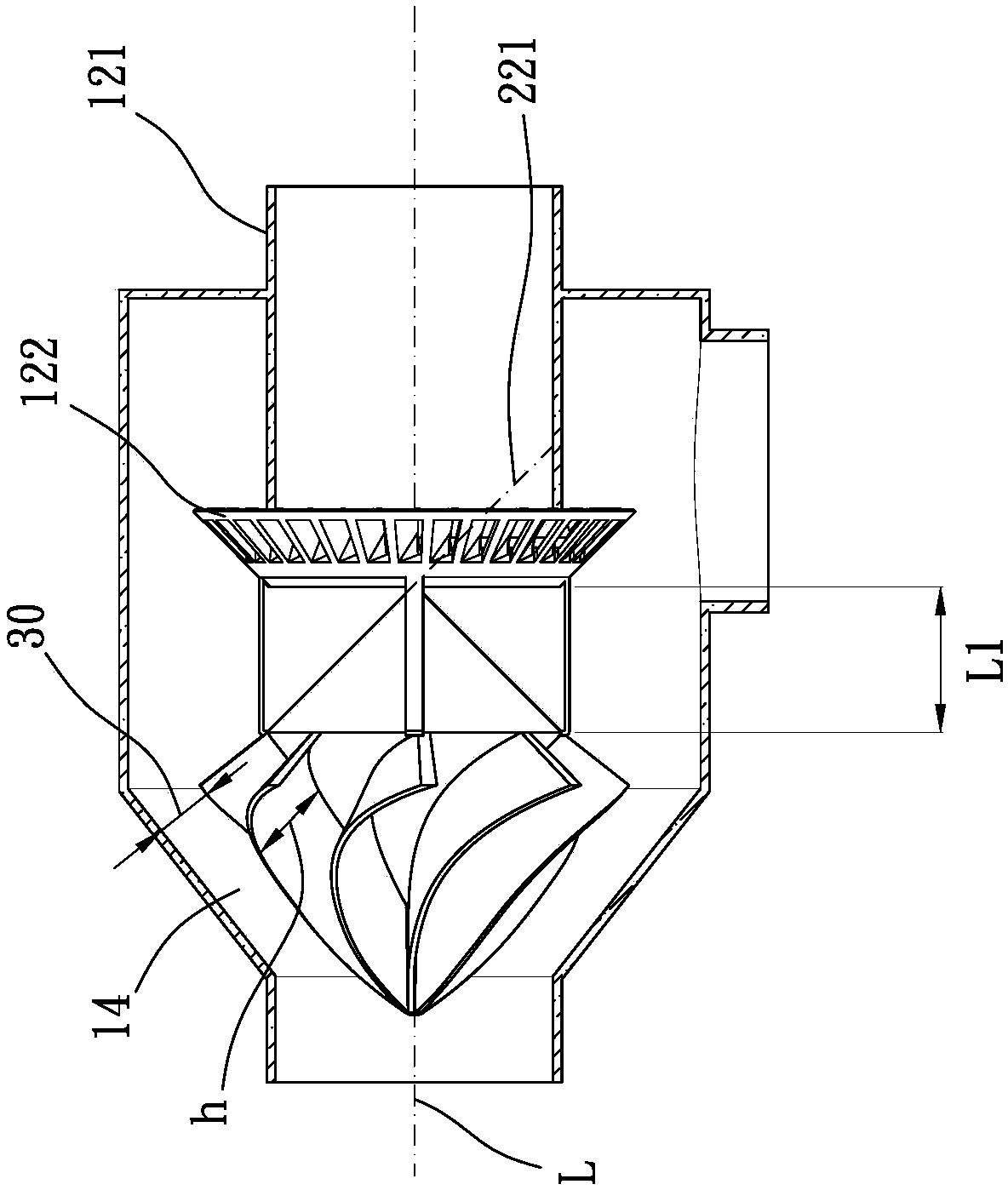

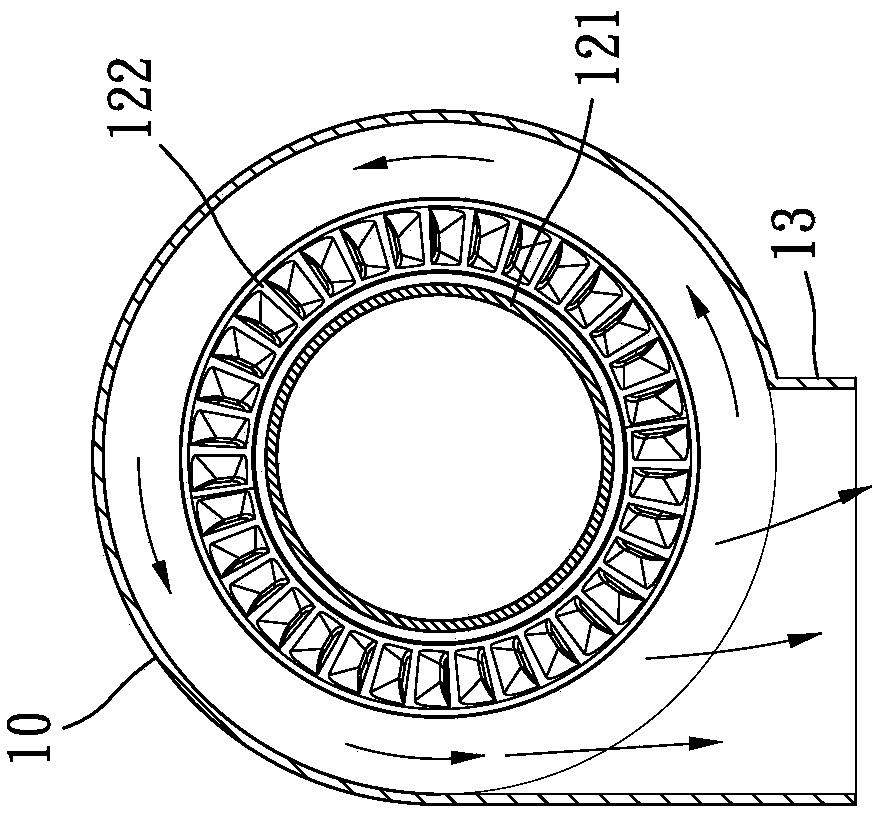

The invention provides a filtering system, which comprises: a shell, wherein the shell comprises an inlet channel and an outlet channel, and the inlet channel and the outlet channel are positioned onthe same extension line; and a flow guide mechanism, wherein the flow guide mechanism comprises a first gradually-reduced part gradually reduced towards the inlet channel, a second gradually-reduced part gradually reduced towards the outlet channel and a plurality of blades, the blades spirally extend to the first gradually-reduced part relative to the extension line, a gap is formed between the blade and the inner wall of the shell, and the height of the gap is smaller than the height of the blade relative to the surface of the first gradually-reduced part. According to the invention, the volume of the filtering system can be reduced, and the good filtering and separating effect is achieved; furthermore the three-dimensional cycloid is applied to the blade, and any cross sections, parallel to the surface of the first gradually-reduced part, of each blade are respectively located on a cycloid, so that after dust-containing gas enters from the inlet channel, the dust-containing gas moves on the blades along the path with the shortest residence time so as to reduce the kinetic energy loss caused by friction force; and the filtering system can achieve the excellent centrifugal separation effect and reduce the power required for feeding dust-containing gas into the filtering system by the power source.

Owner:孙正和 +1

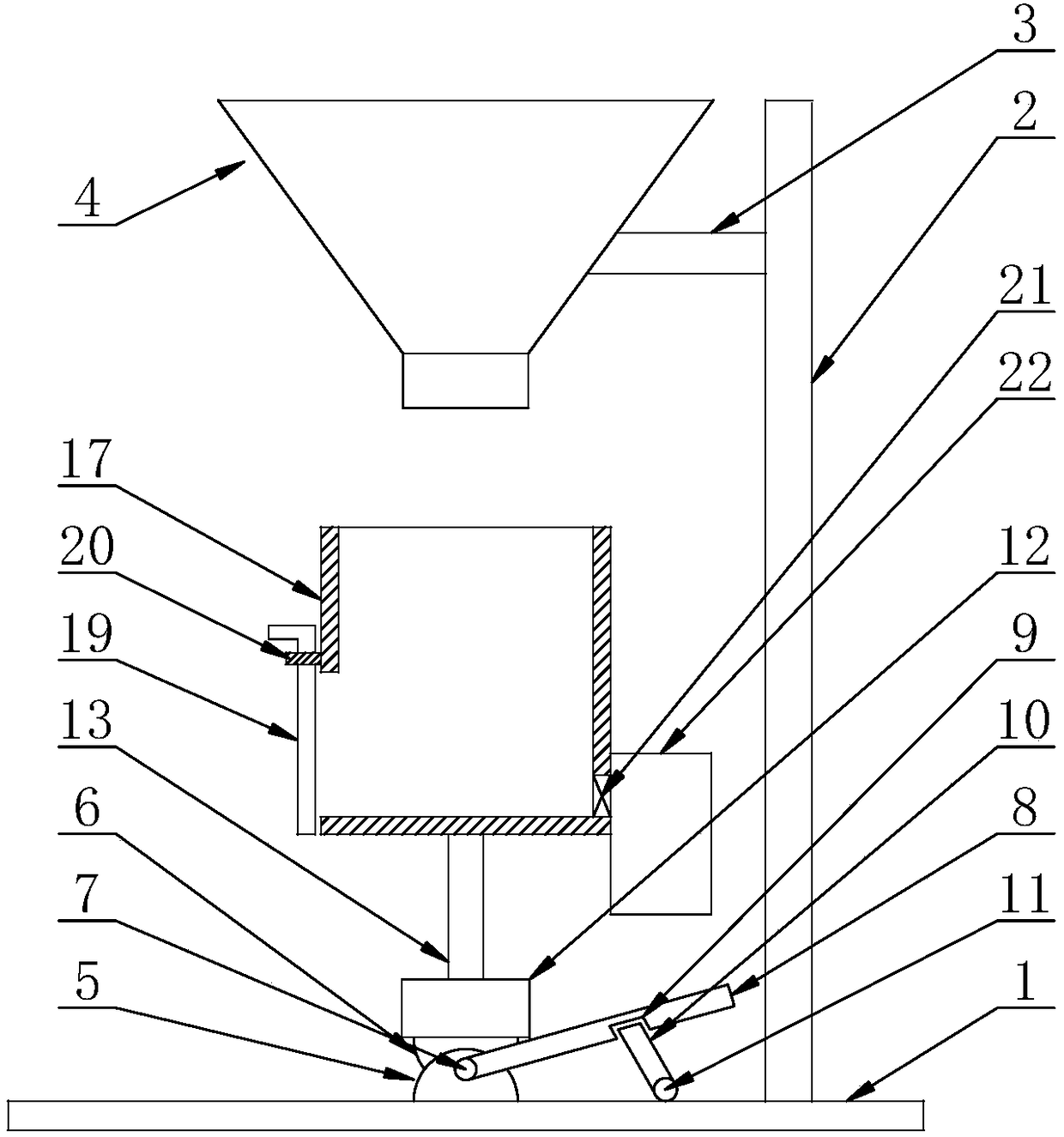

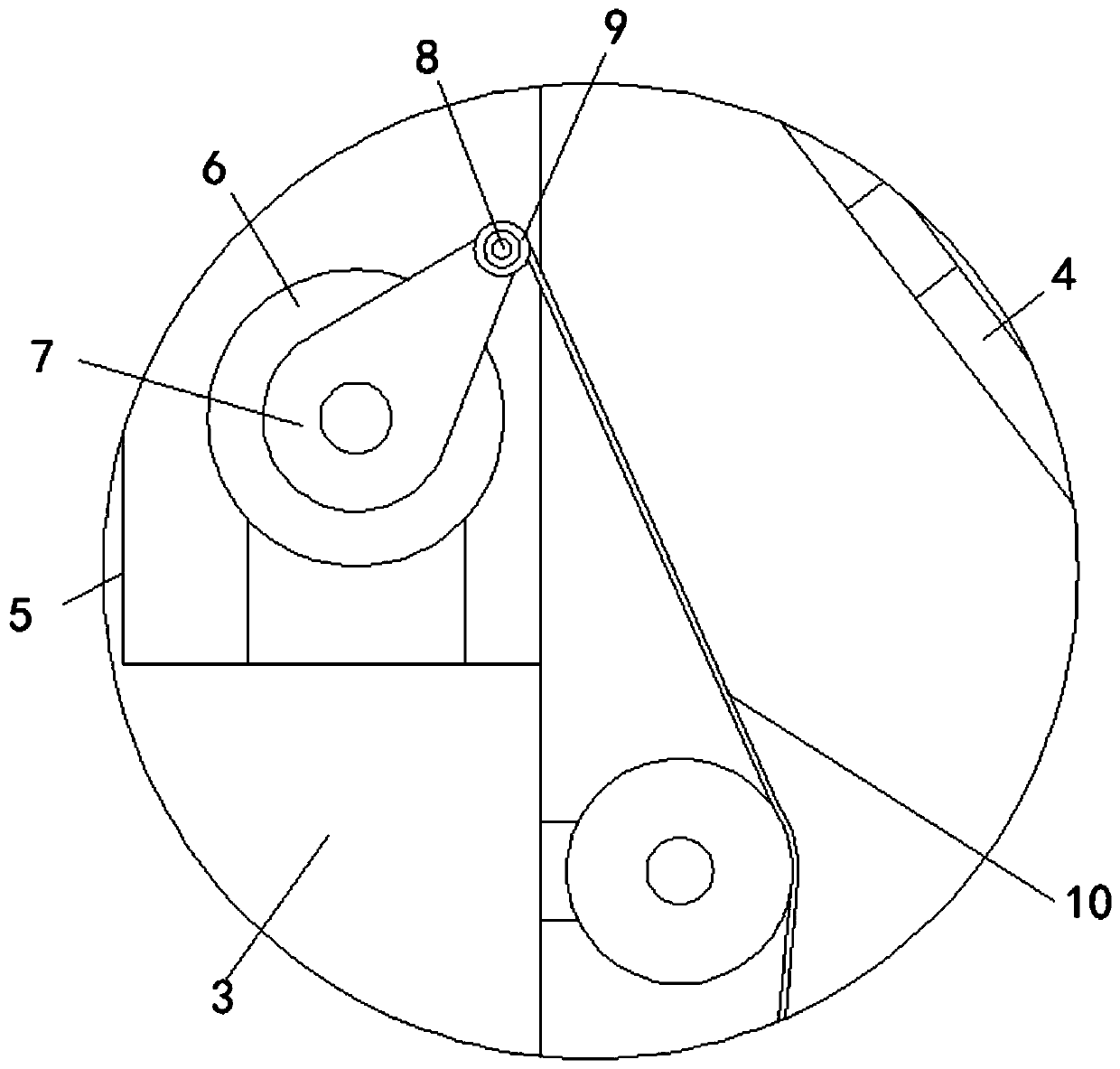

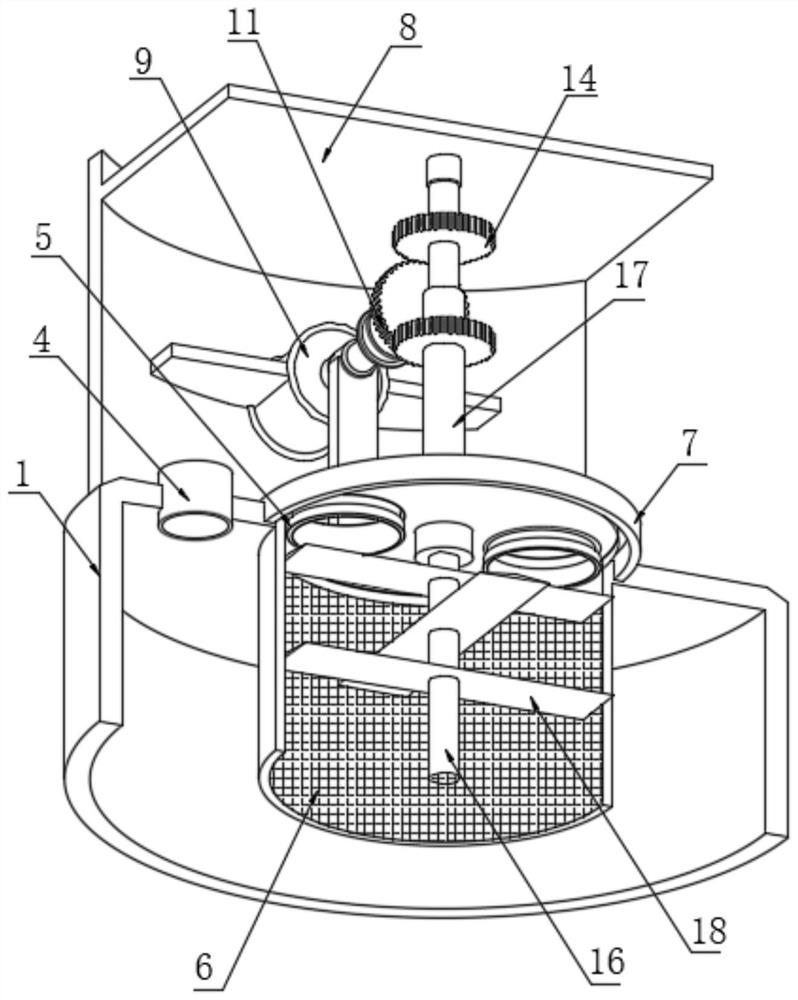

Centrifugal slurry separator

ActiveCN108126401AGood filtration and separation effectSimple structureMoving filtering element filtersHome useFiltration

The invention discloses a centrifugal slurry separator. The centrifugal slurry separator comprises an operating platform, wherein a support rod is fixedly connected to the part, near the right side, of the top of the operating platform, a connecting rod is fixedly connected to the part, near the top, of the left side of the support rod, and the operating platform is fixedly connected with a concave block; one end of a pin shaft penetrates through the front end surface of the concave block and extends to the outside of the concave block, a rotary shaft is fixedly connected to the top of the operating platform, and the top of a bump is fixedly connected with a first motor; the power output end of the first motor is fixedly connected with the bottom of a cylinder, a mobile plate is arranged at an opening in the left side of the cylinder, a filter screen is arranged at an opening in the right side of the cylinder, and a material storage tank is fixedly connected with the opening in the right side of the cylinder. The centrifugal slurry separator has the characteristics of convenient manual operation and good effects of separation and filtration, and is suitable for home use.

Owner:枞阳县田园面业有限责任公司

A kind of method of producing anhydrous magnesium carbonate with magnesium-containing mother liquor

ActiveCN105540625BAvoid generatingStable in natureAmmonium nitratesMagnesium carbonatesGranularitySlurry

A method for preparing anhydrous magnesium carbonate through a magnesium-containing mother solution includes the following steps of firstly, adjusting the pH value, wherein ammonia gas is introduced into the magnesium-containing mother solution till the pH value is 10.0-12.0 to obtain Mg(OH)2 slurry; secondly, conducting CO2 carbonizing, wherein CO2 is introduced till the pH value is 7.5-8.0 to obtain a carbonized mother solution; thirdly, conducting pyrolysis separation, wherein the carbonized mother solution is heated and decomposed to separate solid and liquid and obtain MgCO3.3H2O solid salt and a pyrolysis separation mother solution; fourthly, conducting calcining, wherein MgCO3.3H2O is calcined to obtain anhydrous magnesium carbonate. Calcining is further conducted to obtain magnesium oxide. The MgCO3.3H2O obtained through pyrolysis separation is large in granularity, the filter separation performance is good, the carrying amount of the mother solution is small, the MgO content reaches up to 47.3%, and the total yield of magnesium ions reaches up to 92.8%; the purity of the MgO product is high, and inorganic ammonium salt type by-products can be co-produced; the method is simple in process, beneficial to industrial production, low in cost, green and environmentally friendly.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

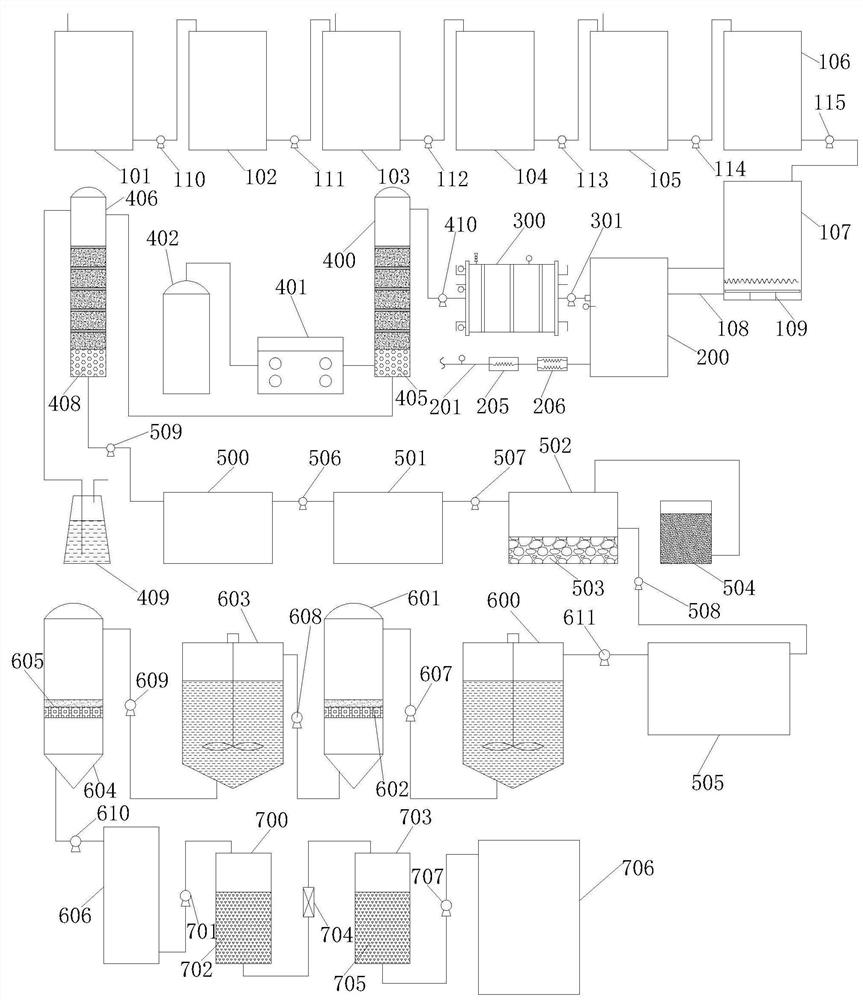

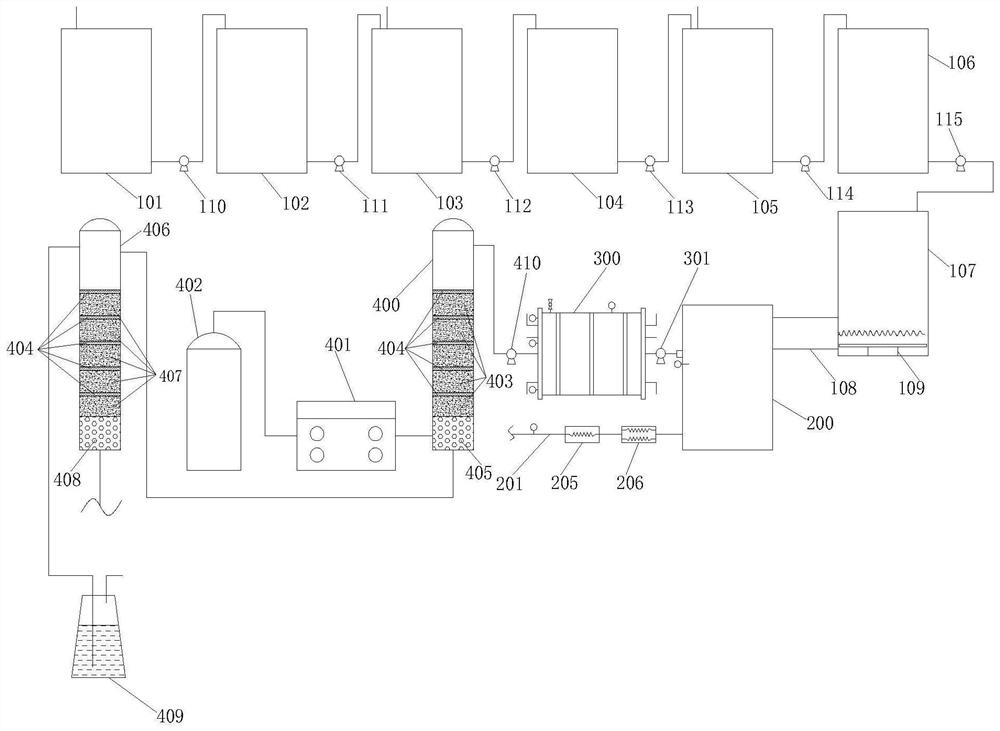

Method and device for treating high-salt organic wastewater in chemical production

PendingCN113754191ASettling Time GuaranteeEasy to separateSolid waste disposalWater contaminantsSaline waterCatalytic oxidation

The invention relates to the technical field of environmental protection, and particularly discloses a method and a device for treating high-salt organic wastewater in chemical production. The method comprises the following steps: (a) salt washing; (b) salt dissolving; (c) treatment via a nanofiltration membrane; (d) catalytic oxidation treatment; (e) phosphorus removal and flocculation; (f) settling: (f1) feeding saline water into a first settling cylinder; (f2) feeding saline water in a first settling cylinder into a first double-layer filter cylinder; (f3) feeding the saline water in the first double-layer filter cylinder into a second settling cylinder; (f4) feeding the saline water in the second settling cylinder into a second double-layer filter cylinder; (f5) feeding the saline water in the second double-layer filter cylinder into a purification cylinder; and (g) adsorption: (g1) feeding the saline water in the purification cylinder into a first adsorption cylinder; (g2) starting a pressurizing device on a liquid inlet pipeline of the first adsorption cylinder; (g3) starting a pressure reducing device on a liquid inlet pipeline of the second adsorption cylinder; and (g4) feeding the saline water into a refined brine storage tank. The device and the method invention have the characteristics of better settling separation effect, shorter adsorption time and better adsorption effect.

Owner:叶婷婷

Method for extracting lithium from salt lake and brine

PendingCN114381614ASimple structureFunction increaseProcess efficiency improvementSalt lakeControl system

The invention discloses a method for extracting lithium from a salt lake and brine, which comprises the following steps: 1) separation of high-valence ion impurities: adding strong base or acid into the salt lake and the brine according to the water quality condition of the salt lake and the brine to adjust the pH value so as to generate insoluble substances, separating through a separation membrane, and collecting filtrate, namely a high-lithium solution; 2) recovery of lithium precipitation mother liquor: adding fully excessive Na2CO3 into the high-lithium solution in the step 1) to carry out lithium precipitation reaction, and collecting filtrate, namely the lithium precipitation mother liquor; and separating and recycling the lithium precipitation mother liquor through a separation membrane. The method for extracting the lithium from the salt lake and the brine is simple in structure and feasible in function, the process is greatly simplified, and a control system adopts full-automatic control; energy is saved, the water content of filter residues is low, and zero emission can be achieved according to technological requirements; the investment cost is reduced after the process is simplified; the system is low in operation pressure and low in operation cost, and agent use is reduced; operation is simple, and the production period is short.

Owner:HENGXINGRUNFENG TECH DEV BEIJING

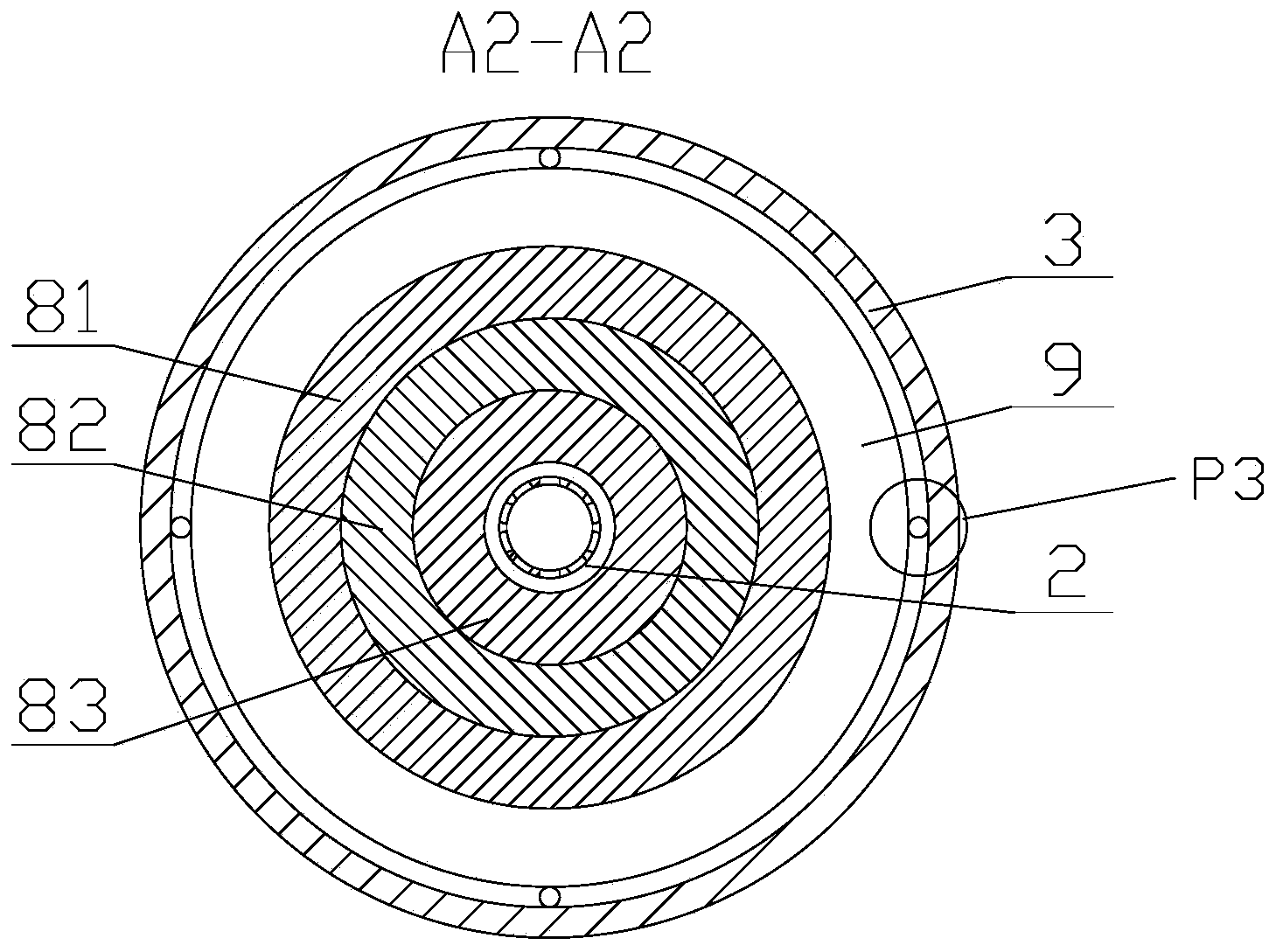

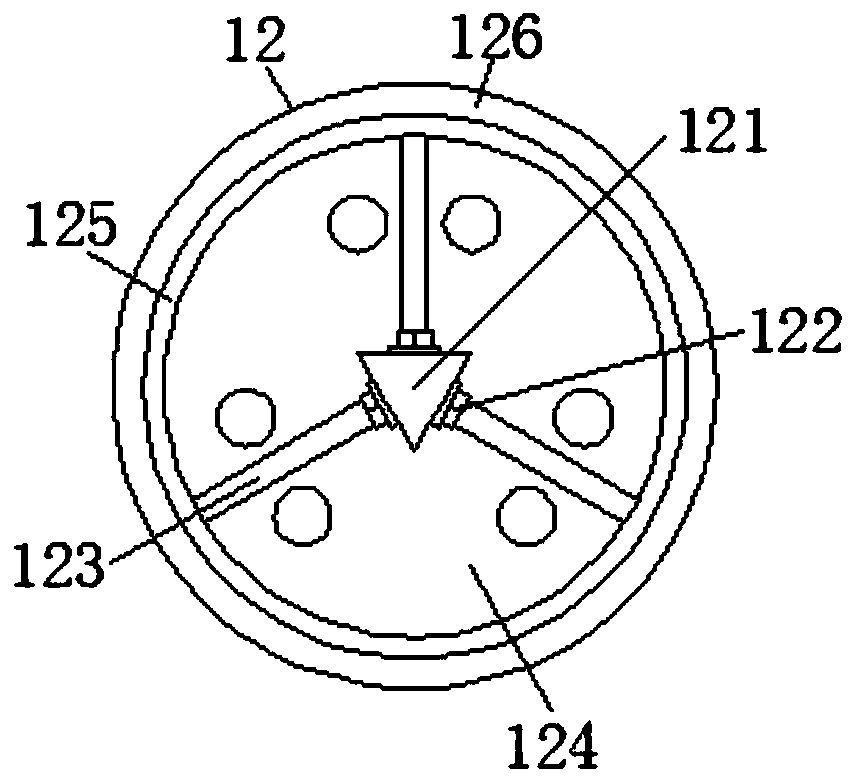

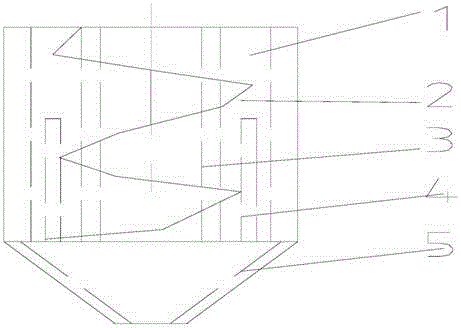

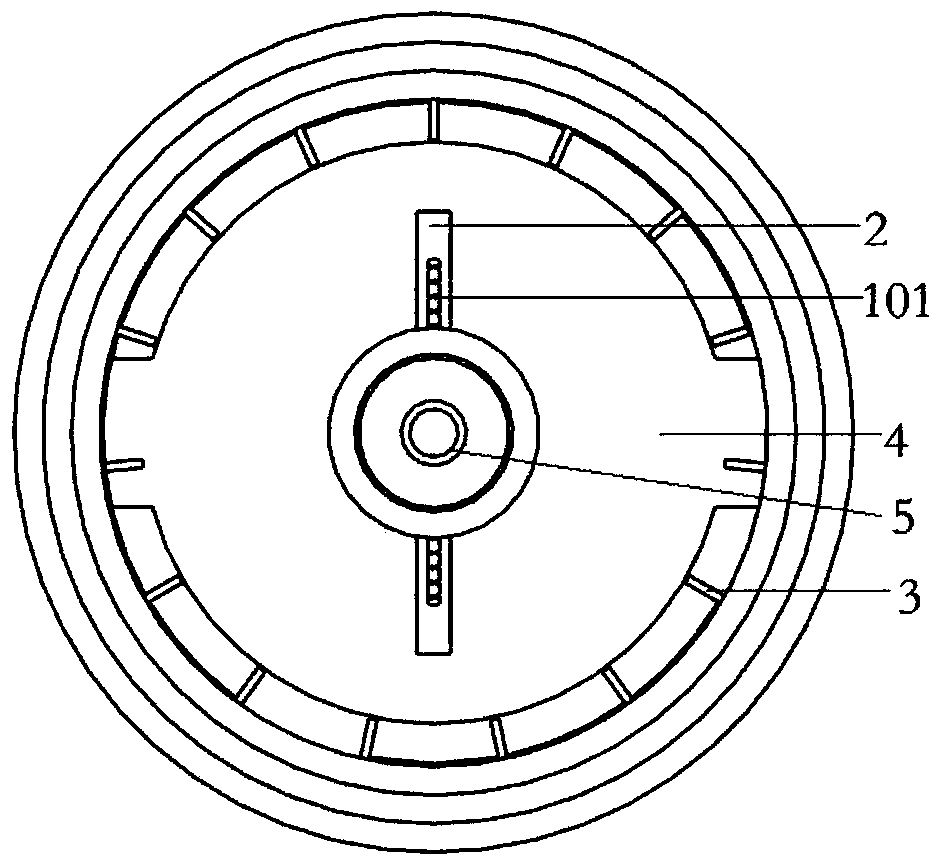

Cyclone component of natural gas dry type dedusting separator

InactiveCN104624404AGood filtration and separation effectReversed direction vortexGaseous fuelsThermodynamicsEngineering

The invention discloses a cyclone component of a natural gas dry type dedusting separator. The cyclone componentconsists of an ascending gas pipe (1), spiral guide blades (2), an inner pipe (3), an outer pipe (4) and a cone body (5). The cyclone component is characterized in that the ascending gas pipe (1) is installed on the end part of the inner pipe (3); the excircle parts of the spiral guide blades (2) are provided with outer spiral angles of 45 degrees-48 degrees; the outer pipe (4) is internally provided with the inner pipe (3). The cyclone component has the beneficial effects that the outer spiral angles enable the filtering and separation effect of gas and dust of natural gas to be optimal.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

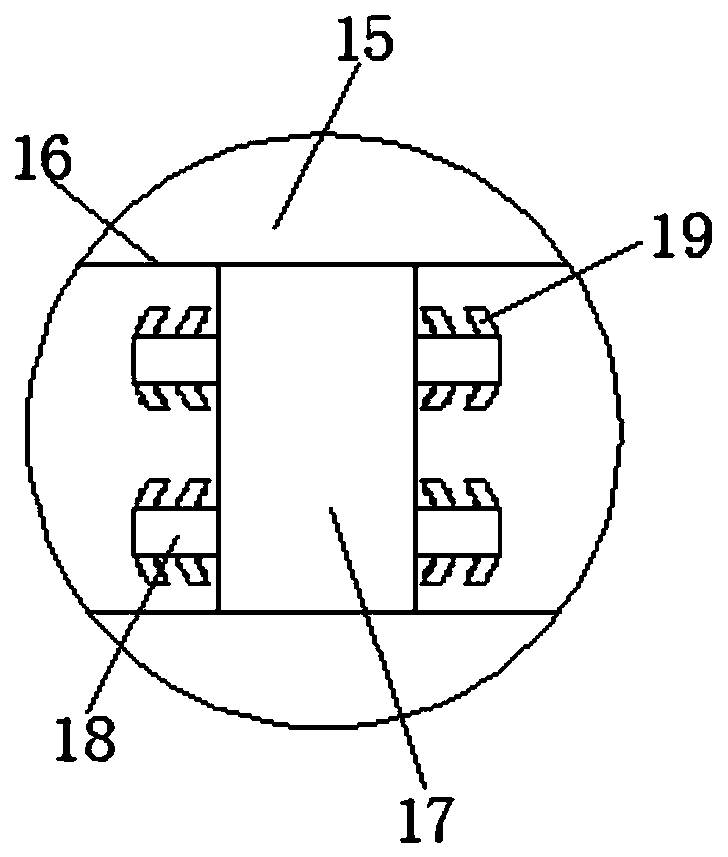

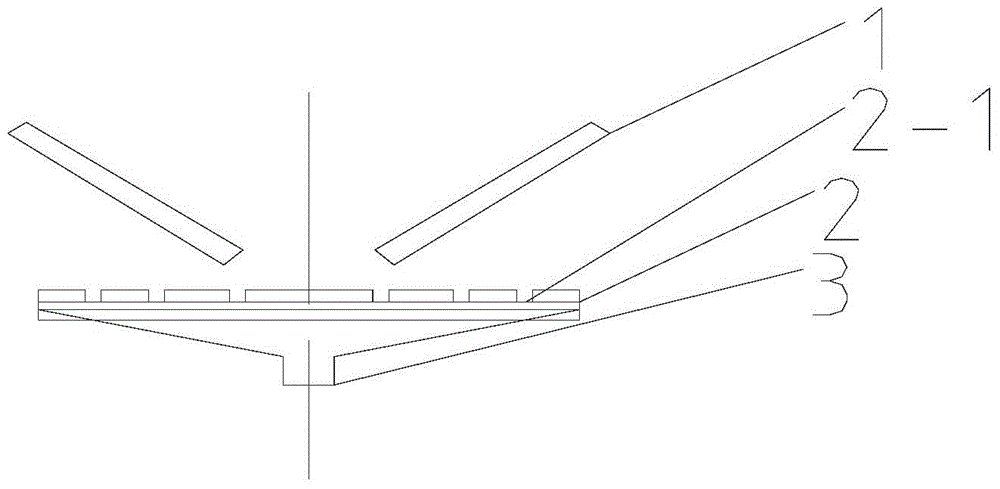

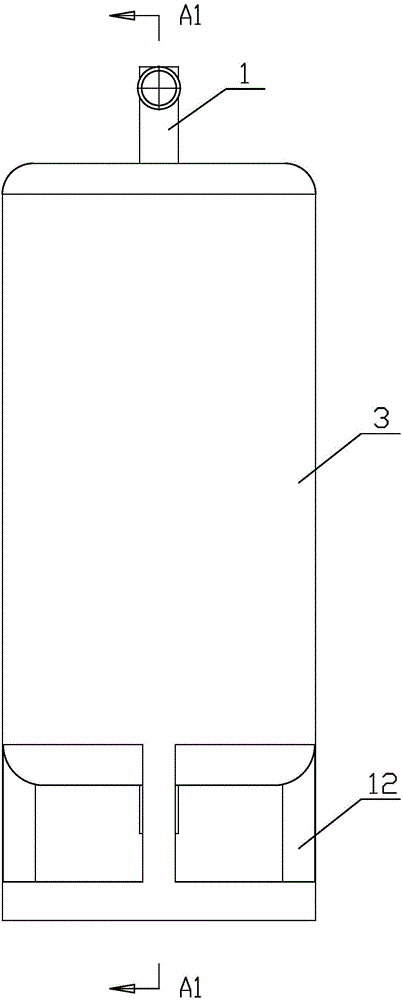

Gas-liquid isolating device of dry dust removal separator for natural gas

InactiveCN104623984AGood filtration and separation effectGaseous fuelsDispersed particle separationDust controlMechanical engineering

The invention relates to a gas-liquid isolating device of a dry dust removal separator for natural gas. The gas-liquid isolating device comprises baffle plates (1), a filler plate (2) and a liquid discharge pipe (3). The gas-liquid isolating device is characterized in that the baffle plates (1) are arranged on the upper surface of the filler plate (2), and the lower surface of the filler plate (2) is connected with the liquid discharge pipe (3); two baffle plates (1) are symmetrically distributed; and the filler plate (2) is provided with a plurality of overflow grooves (2-1), and the overflow grooves (2-1) are connected with the liquid discharge pipe (3) after being converged. The gas-liquid isolating device disclosed by the invention has the beneficial effects of achieving an optimal filtering separation effect of the natural gas and liquid by integrally applying a baffle separation principle and a filling separation principle.

Owner:NINGXIA ZHONGYUAN TIANSHENG TECH

A kind of antibacterial ultrafiltration membrane and its preparation method and membrane regeneration method

ActiveCN105289339BImprove the bactericidal effectGood filtration and separation effectSemi-permeable membranesEscherichia coliUltrafiltration

The invention provides a kind of antibacterial ultrafiltration membrane and its preparation method and membrane regeneration method, and this antibacterial ultrafiltration membrane is prepared from the ultrafiltration membrane material with the repeating unit shown in formula I or formula II, and described formula I or The repeating unit shown in formula II contains N-Cl bond, so that the antibacterial ultrafiltration membrane prepared from the ultrafiltration membrane material having the repeating unit shown in formula I or formula II has higher bactericidal properties. In addition, the antibacterial ultrafiltration membrane has good filtration and separation performance; it can exist stably in air and water; it can be recycled; it is environmentally friendly and non-corrosive. Experimental result shows: antibacterial ultrafiltration membrane provided by the present invention has a bactericidal rate of 90% to 100% to Escherichia coli or Bacillus subtilis; 100%; the rejection rate of bovine serum albumin is above 99.2%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

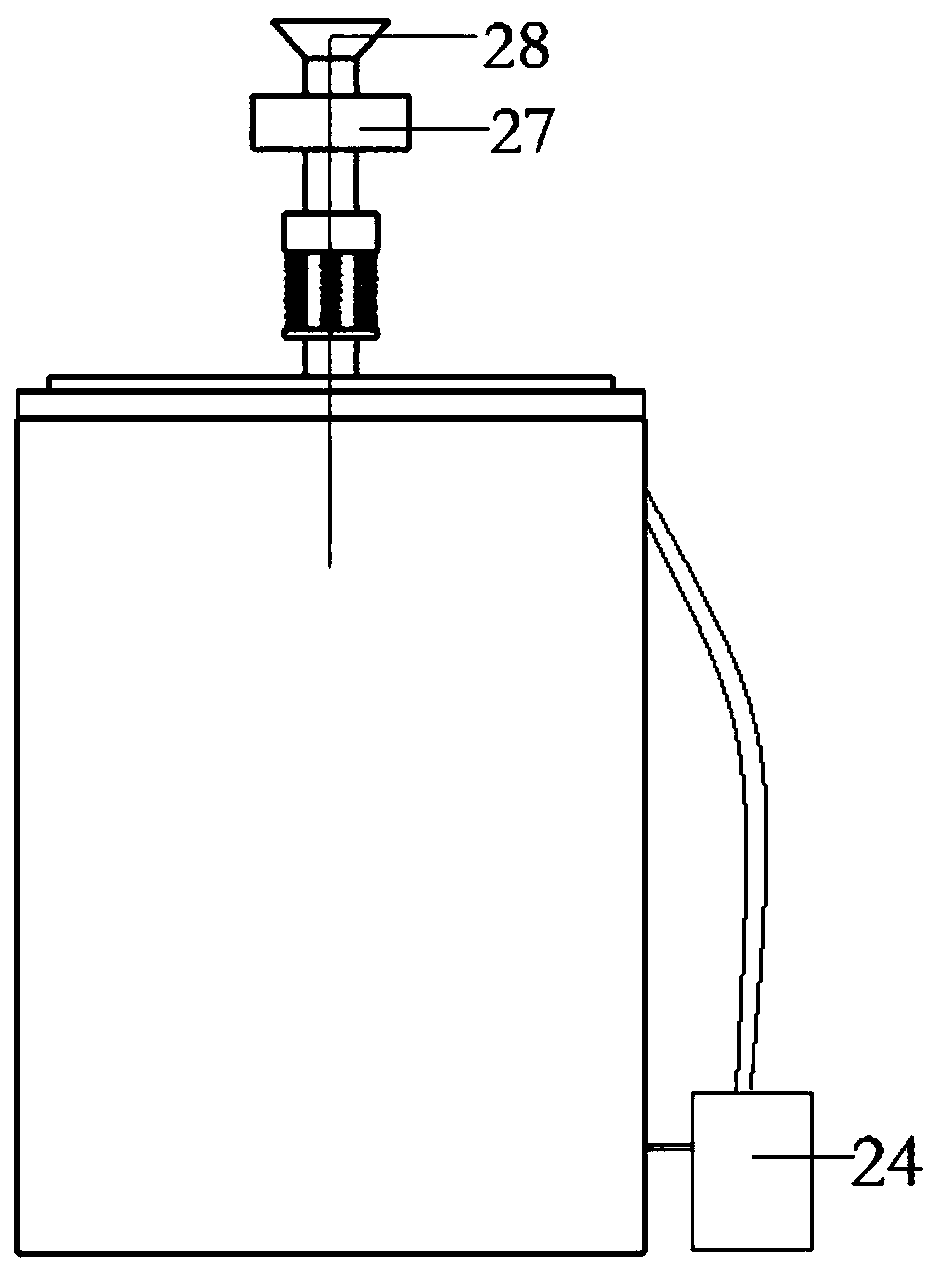

Oil drilling fluid filtration recovery device

ActiveCN107998744BEasy to recycleGood filtration and separation effectFiltration circuitsCooling effectOil drilling

The invention relates to the technical field of oil equipment, and discloses an oil drilling fluid filtration recovery device. The device comprises a base, a support column is fixedly connected to theupper surface of the base, the top of the support column is fixedly connected with the bottom surface of a filter box, the top of the interior of the filter box is provided with a first filter, mounting grooves are formed in the inner walls of the left and right sides of the filter box and located below the first filter, a first motor is fixedly connected into each mounting groove, and a cam is fixedly connected to an output shaft of each first motor. By means of the oil drilling fluid filtration recovery device, the temperature of an oil drill pipe after filtration can be reduced, not only is the cooling effect good, but also the cooling speed is higher, the recovery of oil drill pipe fluid is more convenient, the situation can be avoided that the oil drill pipe fluid is difficult to recover due to high temperature, impurities in the oil drill pipe fluid can also be separated, the filtration and separation effect is better, the oil drill pipe fluid can be more conveniently recycled and utilized, and the mining cost is reduced.

Owner:海安发达石油仪器科技有限公司

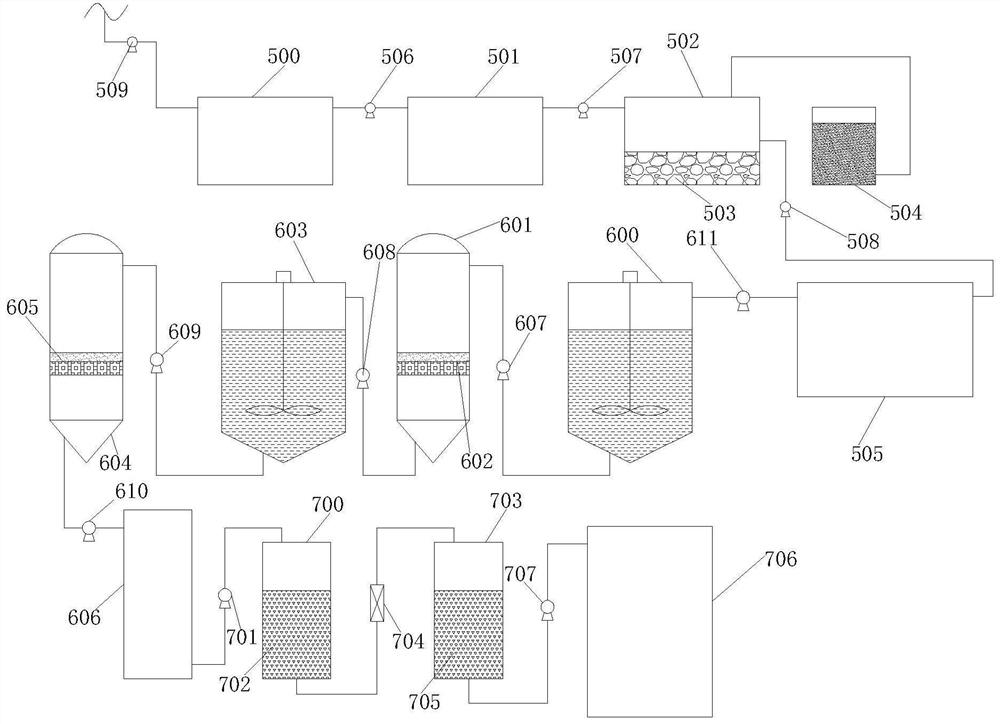

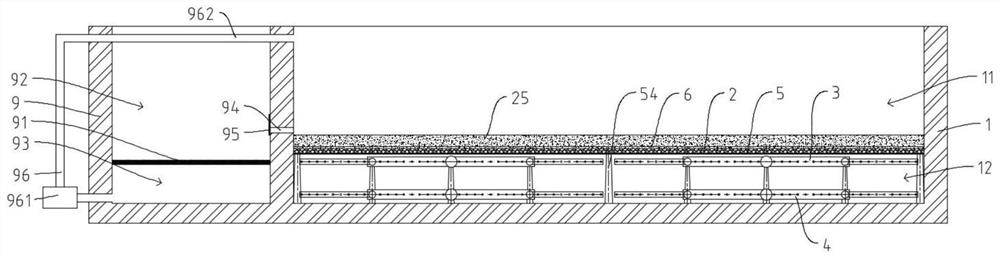

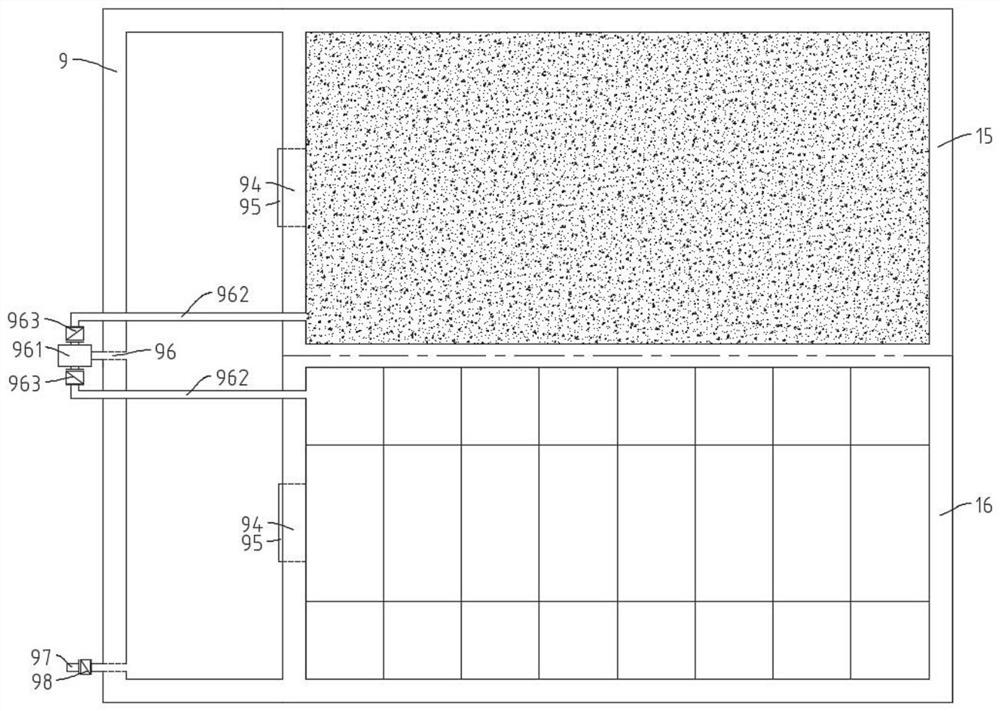

Blast furnace slag bottom filter tank system and blast furnace slag bottom filter method treatment process

PendingCN114011154ARecycleReduce the amount of sedimentDispersed particle filtrationSpecific water treatment objectivesWater storageWater storage tank

The invention discloses a blast furnace slag bottom filter tank system and a blast furnace slag bottom filter method treatment process, and relates to the field of metal smelting equipment. The blast furnace slag bottom filter tank system comprises a water storage tank and at least one bottom filter tank. A modular filter layer is arranged in the bottom filter tank, and the bottom filter tank is divided into a slag grabbing area and an after-filtration settling area through the modular filter layer. A stored water filter layer is arranged in the water storage tank, and the water storage tank is divided into an overflow area and a filtered water storage area through the stored water filter layer. The overflow area is communicated with the slag grabbing area through an overflow channel. The filtered water storage area is communicated with the slag grabbing area through a water return pipeline. Flushing sewage can be treated through the water storage tank, and the service life of the modular filter layer is further prolonged. The invention also discloses a blast furnace slag bottom filtration method treatment process, which comprises a slag flushing process, a filtering process, a slag grabbing process and a back-washing process. The blast furnace slag bottom filtration method treatment process can realize a continuous slag tapping production process.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

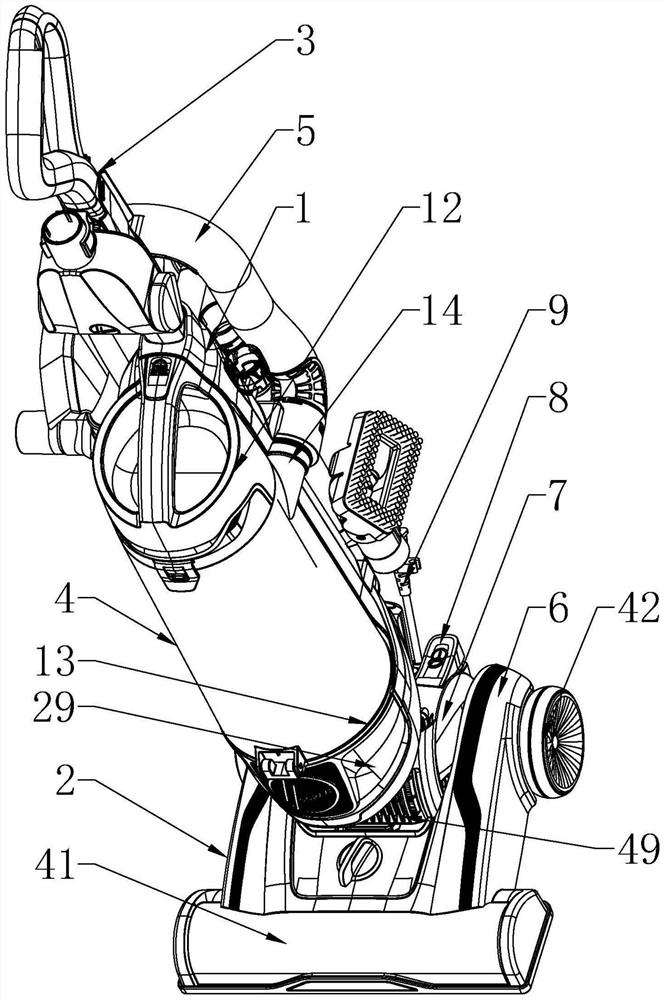

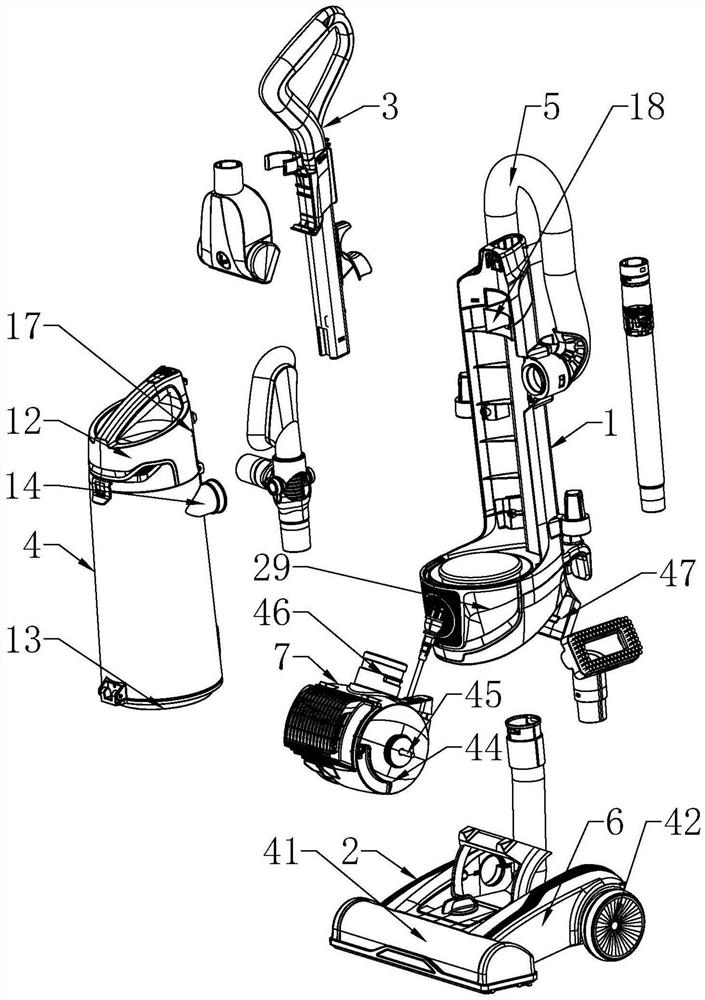

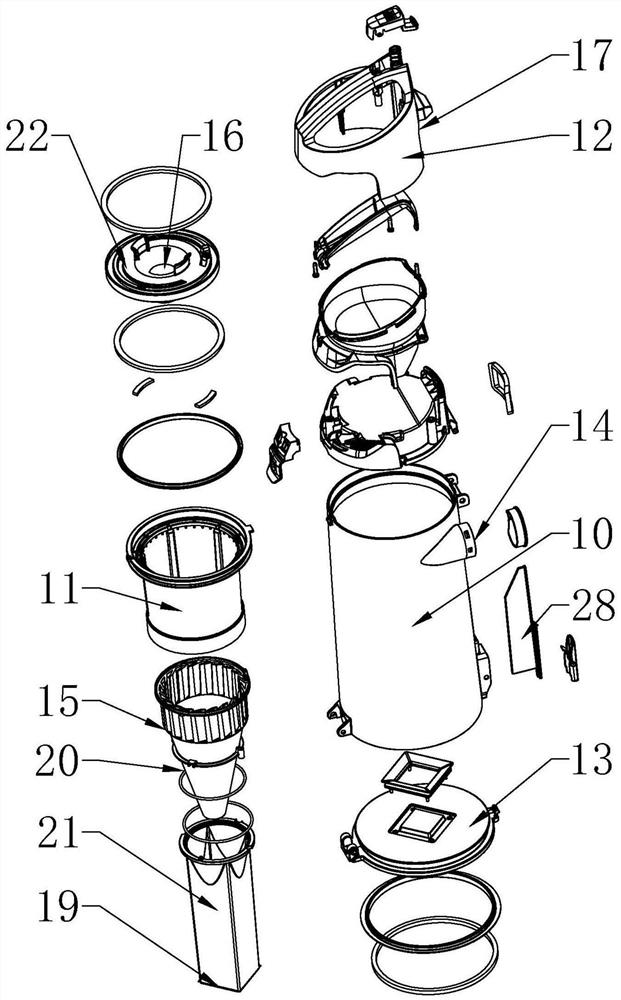

Structure of dust collector

The invention discloses a structure of a dust collector, and aims to provide a structure of a dust collector convenient for wiring. The bottom of the machine body is detachably connected with a mop, the top of the machine body is connected with a handle, the machine body is provided with a dust cup assembly and a hose, the dust cup assembly and the hose are both detachably connected with the machine body, the mop is communicated with the dust cup assembly through the hose, the mop comprises a bracket, a rolling brush and a motor assembly, and the rolling brush and the motor assembly are both detachably connected with the bracket. The rolling brush is driven by the motor assembly to be rotationally connected with the bracket, a foot switch and a power line are arranged on the motor assembly, and the foot switch and the power line are both electrically connected with the motor assembly. The beneficial effects of the invention are that wiring is convenient; the use is convenient; heat dissipation of the motor body is facilitated, and the service life of the motor body is prolonged; dust in the dust cup body can be conveniently cleaned, meanwhile, the dust generation amount can be reduced, and human health is facilitated; the dust filtering and separating effect is good; and noise reduction is facilitated.

Owner:NINGBO DECHANG ELECTRICAL MACHINERY MFG CO LTD

High-efficiency filtration and separation device and method for sewage

InactiveCN108264161BEasy to separateSimple structureWater/sewage treatment by centrifugal separationTreatment involving filtrationFiltrationEngineering

The invention discloses a sewage efficient filtering and separation device and method. The sewage efficient filtering and separation device comprises a tube body container, a layering plate, an adsorbent adding assembly and a vortex generation assembly, wherein the layering plate is erected in the tube body container; the outer contour edge of the layering plate and the inner wall of the tube bodycontainer are in gap arrangement; the tube body container is separated into a separation cavity and a settling cavity in vertical mutual communication by the layering plate; the vortex generation assembly is arranged in the separation cavity; the vortex generation assembly is arranged above the layering plate; through the vortex generation assembly, sewage solution in the separation cavity rotates at high speed to form vortex; the adsorbent adding assembly is arranged in an opening part of the top end of the tube body container; the adsorbent adding assembly is filled with adsorbents. The sewage efficient filtering and separation device and method provided by the invention have the advantage that the sewage solution is effectively filtered.

Owner:绍兴三杰纺织印染有限公司

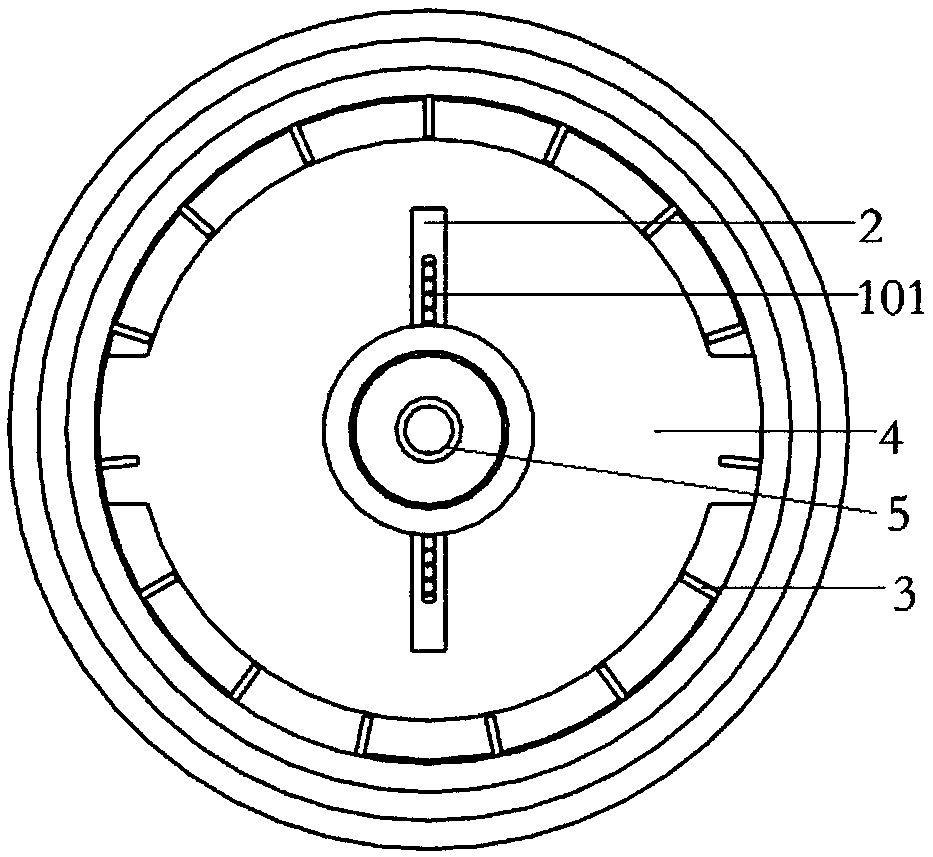

Foam metal filtering type oil separator

InactiveCN103736331BIncrease the passing areaStrong irregularityDispersed particle filtrationGuide tubeMetal

The invention discloses a foam metal filtering type oil separator. The oil separator comprises an outer barrel, wherein an air inlet connector and an air exhausting duct are arranged at the top of the outer barrel; the bottom end of the air exhausting duct extends into a cavity in the outer barrel; the cavity and an oil collecting chamber below the cavity are separated by an oil falling umbrella; an oil falling hole is formed below the oil falling umbrella; an oil outlet is formed in the center of the bottom surface of the oil collecting chamber; three foam metal filtering layers are sequentially arranged in the outer barrel from top to bottom; a plurality of annular oil guiding grooves and centripetal oil guiding grooves are formed between every two foam metal filtering layers; oil guiding pipes, the top ends of which are sealed, extend to openings in the bottom end in the cavity and are provided with oil storing elbows; the oil guiding pipes are respectively communicated with the centripetal oil guiding grooves. As the oil separator is used, airflows mixed with oil drops are filtered by the three foam metal filtering layers, the airflows in which the majority of oil drops are filtered are exhausted by the air exhausting duct while the filtered oil drops fall onto the oil falling umbrella through the annular oil guiding grooves, the centripetal oil guiding grooves and the oil guiding pipes, then reach the oil collecting chamber through the oil falling hole and finally are discharged through the oil outlet.

Owner:TIANJIN UNIV

Floating filter material filtering device

PendingCN114570075AAdapt to the needs of productionEasy to manageEnergy based wastewater treatmentLoose filtering material filtersEnvironmental engineeringFilter material

The invention provides a floating filter material filter device, which comprises a filter tank provided with a cavity inside and provided with a water inlet device and a water outlet device, and is characterized in that a partition plate is arranged in the cavity of the filter tank and divides the cavity into a water inlet tank with the water inlet device and a water outlet tank with the water outlet device; the water inlet tank and the water outlet tank are communicated through an overflow port lower than the tank top, the water outlet tank is provided with a filter material input pipe, the water inlet tank is provided with a filter material output pipe, and input floating filter materials float on the upper portion of the cavity. Through mutual independence of floating filter material adding, discharging and filtering operation, continuous operation of floating filter material adding, discharging and filtering operation and off-line flushing of the filter material, the precipitation and filtering separation effects of the mixed liquid are greatly improved, and the device has the characteristics of low energy consumption, low investment and operation cost, simplicity in control and management and the like.

Owner:KUNMING ENG & RES INST OF NONFERROUS METALLURGY

Environmental protection wastewater treatment equipment

InactiveCN112499835AReach water quality requirementsReduce flow rateSpecific water treatment objectivesTreatment involving filtrationFiltrationSewage outfall

The invention relates to environmental protection wastewater treatment equipment which comprises a primary treatment box, a disinfection tower, a filter tower and a water quality purifier, a filter screen is connected to the top of the inner cavity of the primary treatment box, at least three grating plates are arranged below the filter screen, and the grating plates are obliquely connected to theinner side of the primary treatment box in a mutually staggered mode; the bottom of the primary treatment box is connected with a sewage draining exit, one side of the bottom of the primary treatmentbox communicates with a first water pump through a pipeline, a water outlet of the first water pump communicates with one side of the top of the disinfection tower through a pipeline, and a stirringmechanism is arranged in the inner cavity of the disinfection tower; wastewater sequentially passes through the primary treatment box, the disinfection tower, the filter tower and the water quality purifier, the procedures of impurity removal, pollution discharge, oxidation sterilization, layered filtration and water quality purification can be sequentially completed, the treated wastewater meetsthe recycled water quality requirement, an excellent filtering and separating effect is achieved, the workload of the subsequent water quality purifier is reduced, and the service life is prolonged.

Owner:阜阳三达环境检测有限公司

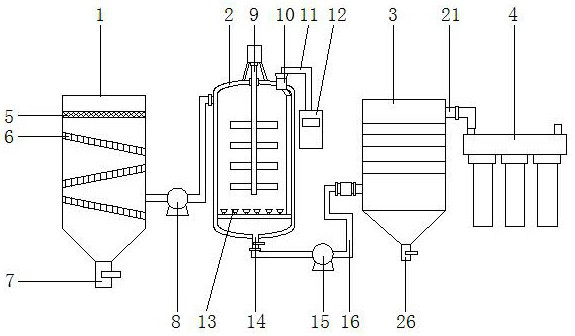

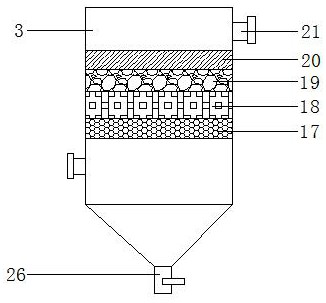

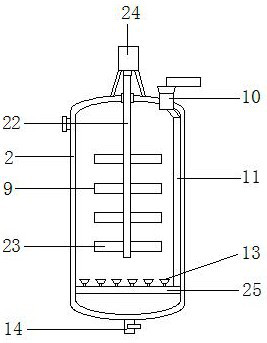

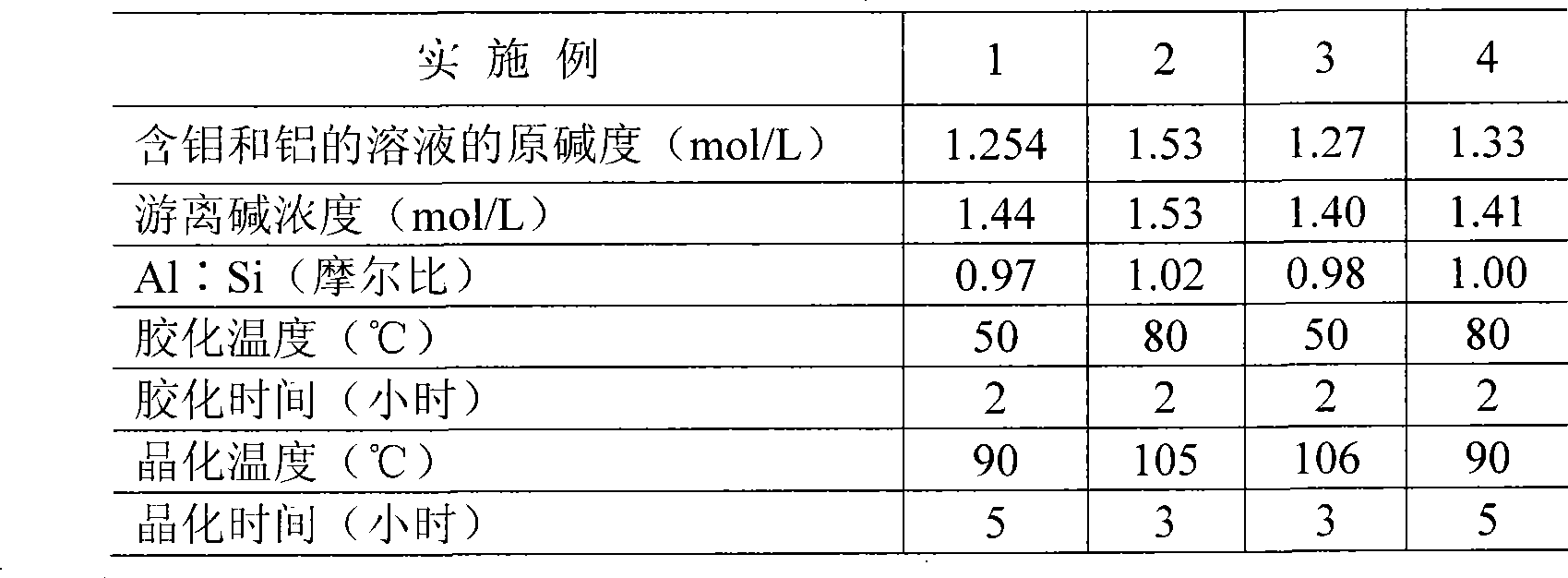

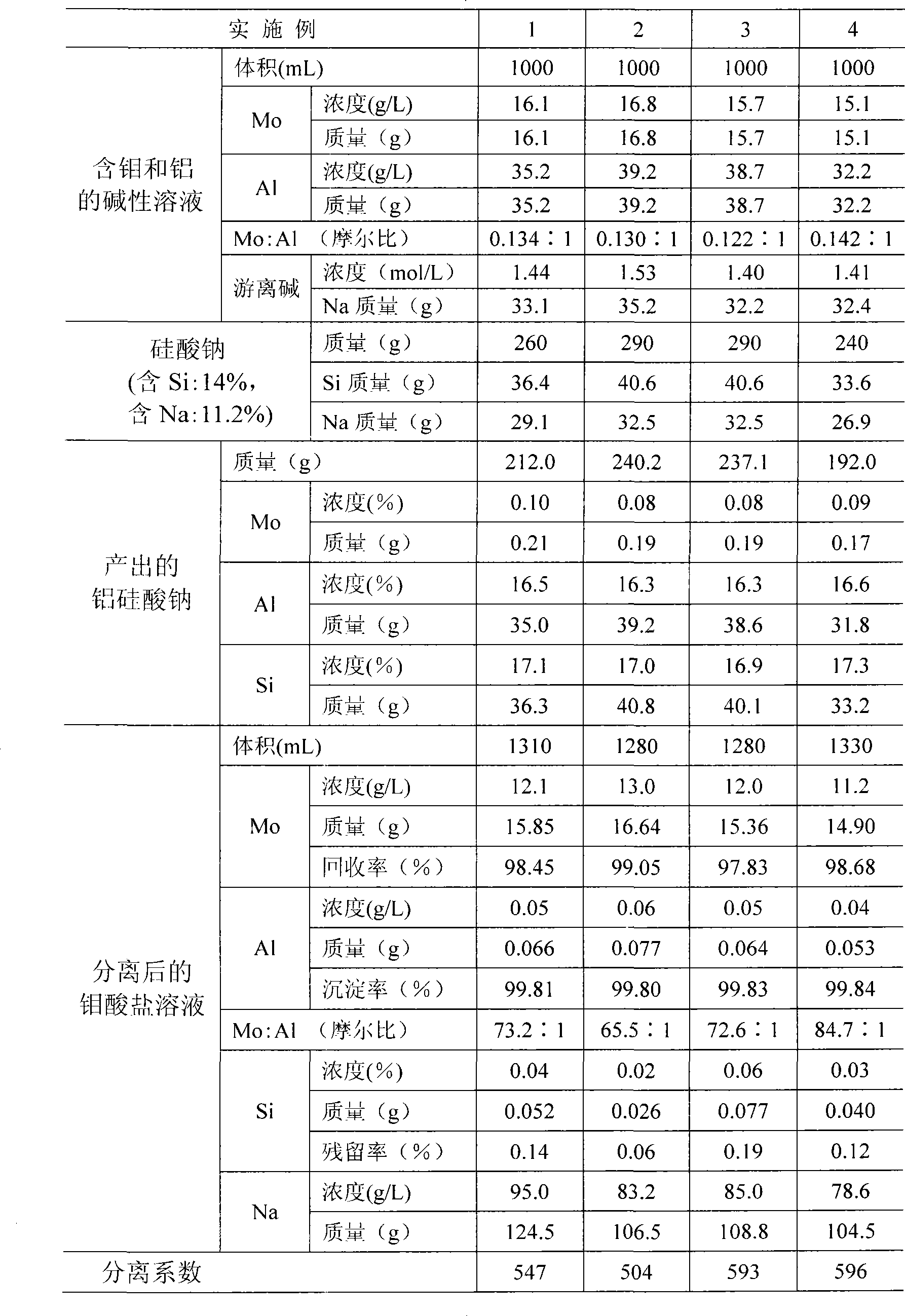

Method for separating molybdenum from aluminium in alkaline solution

InactiveCN101445875AGood filtration and separation effectGood separation factorProcess efficiency improvementAlkali hydroxideAluminium

The invention provides a method for separating molybdenum from aluminium in alkaline solution. The method is characterized in that alkali metal hydroxide is added; the consistency of free alkali is controlled within 1.20-1.80mol / L; according to the molar ratio of 0.95-1.05 of Al:Si, alkali metal silicate solution is added under mixing condition at the normal temperature within 3 hours; the mixing condition is kept, the temperature is increased to the gelatinizing temperature of 50-80 DEG C and the gelatinizing temperature is kept for 2 hours; subsequently, the temperature is increased to the crystallization temperature of 90-110 DEG C and the crystallization temperature is kept for 3-5 hours; after filtration and separation, aluminosilicate precipitate and molybdate solution are obtained; after separation, the content of molybdenum in the aluminosilicate precipitate is reduced to below 0.2%wt, the content of aluminium or silicon in the filtrate is reduced to below 0.5g / L, the precipitation rate of the aluminium or the silicon is more than 98%. More than 98% of the soluble molybdate in the molybdenum filtrate is remained, thus achieving good separation coefficient. The method is suitable for recovering molybdenum element from waste catalyst.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

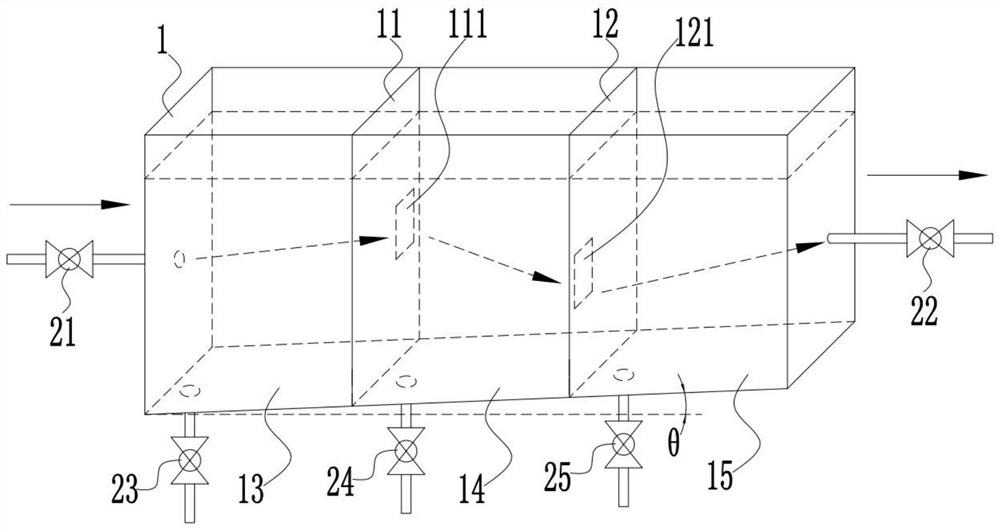

High-voltage cable crosslinking by-product filtering water tank

PendingCN113582361ASimple structurePlenty of time and enoughFatty/oily/floating substances removal devicesTreatment involving filtrationProcess engineeringElectric cables

The invention discloses a high-voltage cable crosslinking by-product filtering water tank, which comprises a water tank body, wherein at least two partition plates distributed at equal intervals are arranged in the water tank body in the vertical direction, each partition plate is provided with a through hole, and the through holes of the adjacent partition plates are arranged in an up-down staggered mode. According to the invention, the problem of accumulation of crosslinking by-products in circulating filtration water in high-voltage cable production is solved.

Owner:CHONGQING TAISHAN CABLE

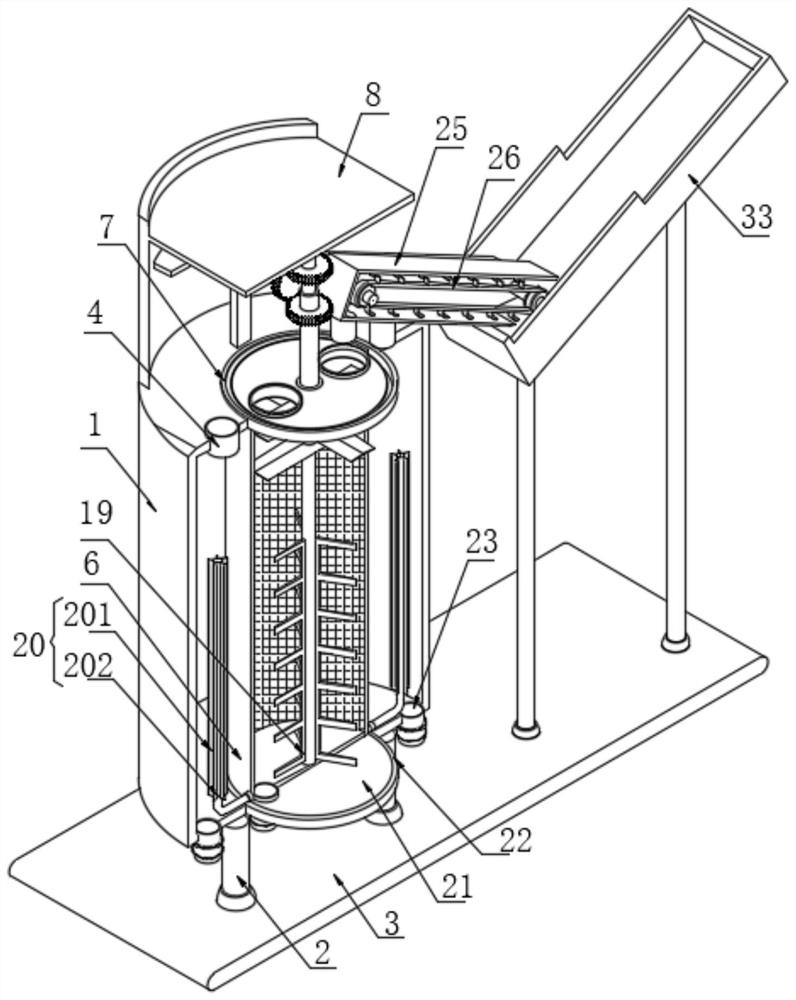

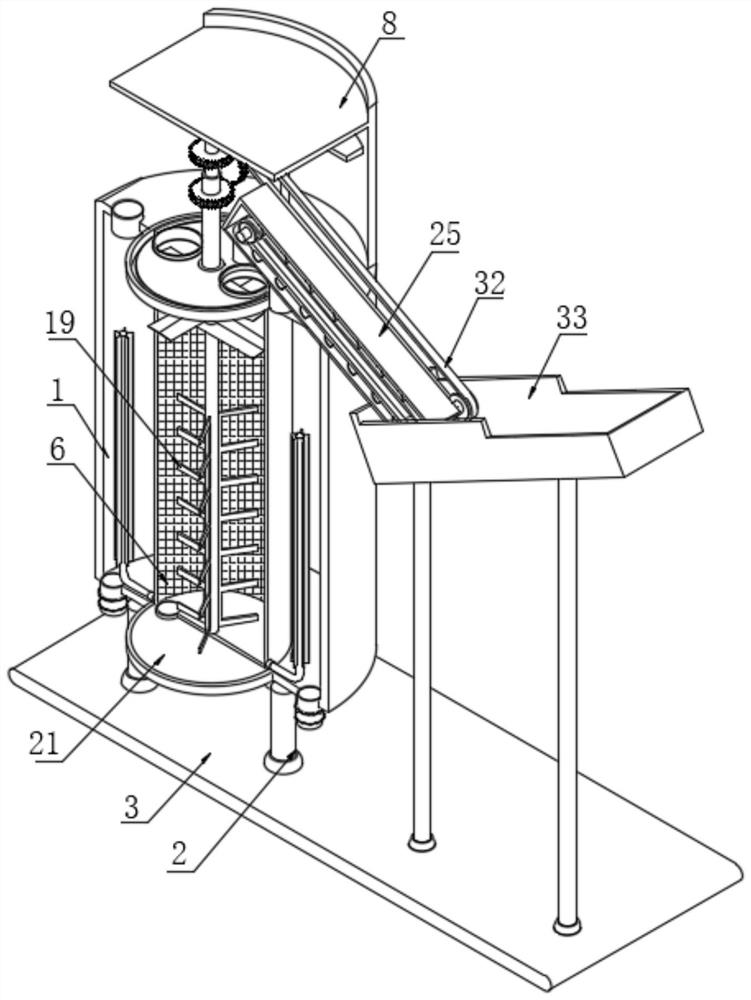

Hair cystine extraction equipment and process with impurity removal function

ActiveCN113713422BIncrease the hydrolysis areaGood for extraction workOrganic compound preparationSolid solvent extractionTransmission beltCystitides

The invention discloses a hair cystine extraction equipment and process with the function of removing impurities, which belongs to the technical field of cystine extraction, and comprises a tank body, the lower surface of the tank body is connected to the upper surface of the bottom plate by four supporting legs Fixedly connected, the left and right sides of the upper surface of the tank body are provided with liquid inlets, and the tank body is provided with a hollow cover. In the present invention, by setting the motor, transmission belt, push plate, shaft sleeve, rotating shaft, hollow cover, blade, stirring rod, blade and slag discharge valve, the hollow cover can rotate in reverse with the blade to fully mix and stir the solution, thereby further Improve the mixing effect. In the process of removing impurities, the hair is always in the hollow cover, and the filter is processed at the same time as the reaction, which reduces the workload of the personnel and the processing efficiency. The purpose of feeding, decomposition, mixing and filtering can be realized at the same time through a single motor drive. Effectively improve the applicability of the modified extraction equipment, which is beneficial to the extraction of cystine.

Owner:连云港华昌生物工程有限公司

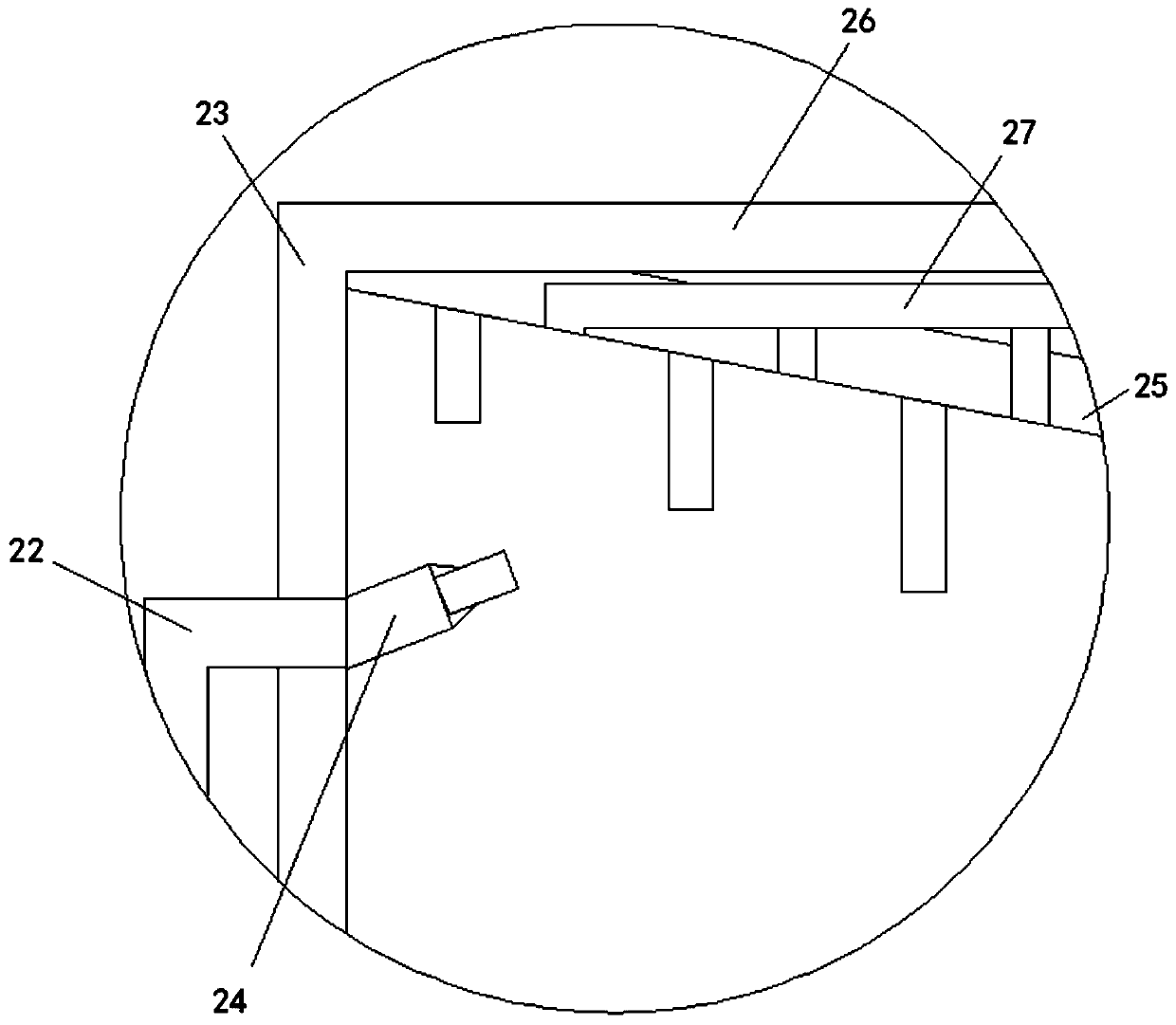

Cutting fluid purifying apparatus capable of treating residues on line

InactiveCN105327549AProcessing capacity can be adjustedEasy to handleFiltration circuitsLubricant compositionAfter treatmentStorage pool

The invention relates to the field of treatment of cutting fluids, specifically to a cutting fluid purifying apparatus capable of treating residues on line. The cutting fluid purifying apparatus comprises a shell and a waste fluid filtering and separating system arranged in the shell, wherein the waste fluid filtering and separating system comprises a waste fluid separating unit, a fluid storage pool, a fluid supplying pipeline, an air feeding pipeline, a water inlet pump and a water outlet pump. According to the invention, the apparatus has adjustable cutting fluid treating capability, can strengthen treating capability with increase of a treating amount, has good filtering and separating effect and high work efficiency, is capable of on-line cleaning cutting fluid residue left after treatment, greatly reduces work cost and is both energy-saving and environment-friendly.

Owner:DJTOL GRINDING MACHINE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com