Floating filter material filtering device

A technology of floating filter material and filter device, applied in the direction of loose filter material filter, filtration separation, filter circuit, etc., can solve the problems of high energy consumption and low filtration efficiency, achieve good effect, reduce cleaning amount, filter material The effect of energy saving in the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

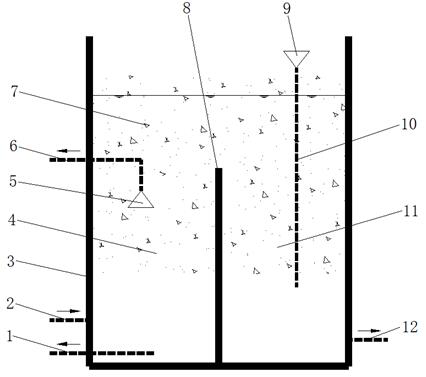

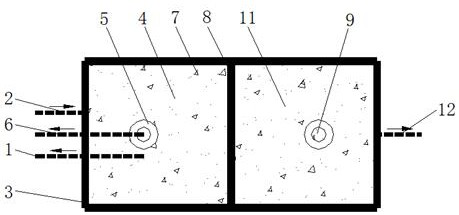

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The floating filter material filtering device provided by the present invention comprises: a filter tank 3 with a cavity inside and a water inlet device 2 and a water outlet device 12 arranged thereon. The plate 8 divides the cavity into the water inlet pool 4 with the water inlet device 2 and the water outlet pool 11 with the water outlet device 12. The water inlet pool 4 and the water outlet pool 11 are connected by the overflow port on the partition plate 8 which is lower than the top of the pool. , the outlet pool 11 is provided with a filter material input device 10, the water inlet pool is provided with a filter material output device 6, and the input floating filter material 7 floats on the upper part of the cavity.

[0025] The solid-liquid separation process of the mixed liquid during the operation is as follows: the mixed liquid enters the sedimentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com