Degerming, antibacterial and antiviral coating

An anti-virus and coating technology, applied in epoxy resin coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve problems such as affecting mixing efficiency, low mixing efficiency, and insufficient mixing, to improve the system Stability, improve stirring efficiency, improve the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

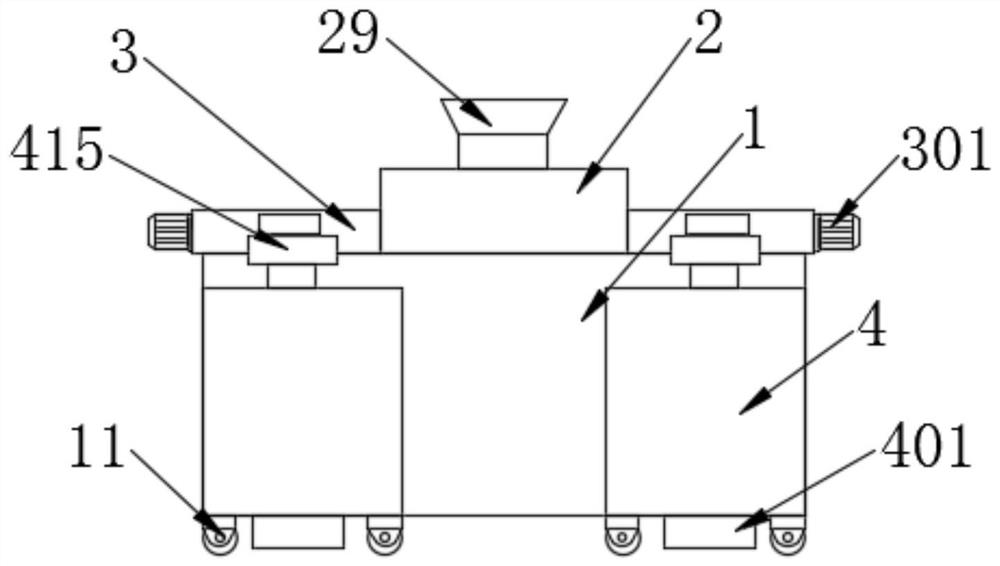

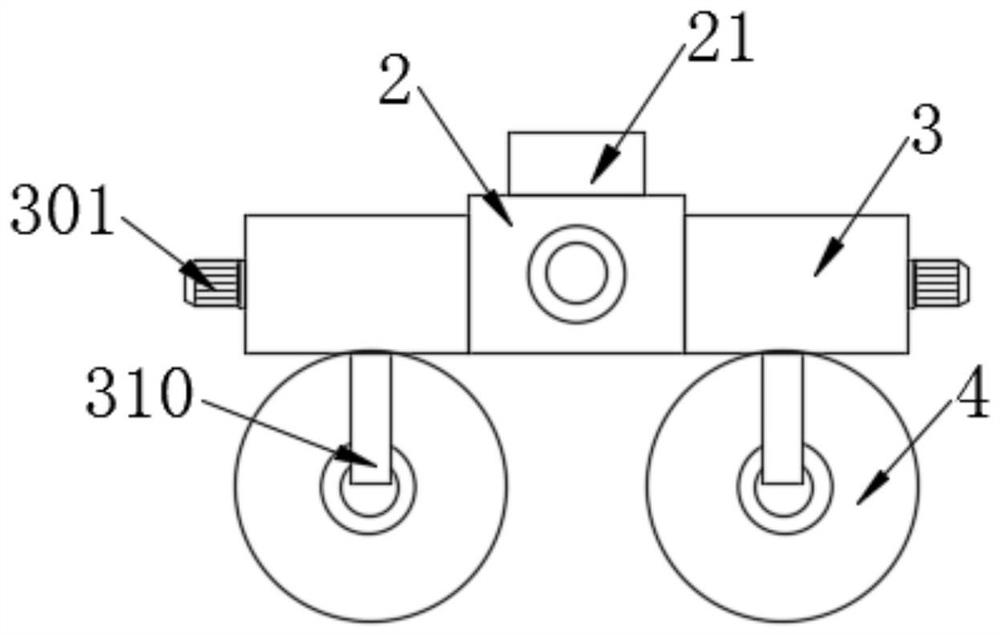

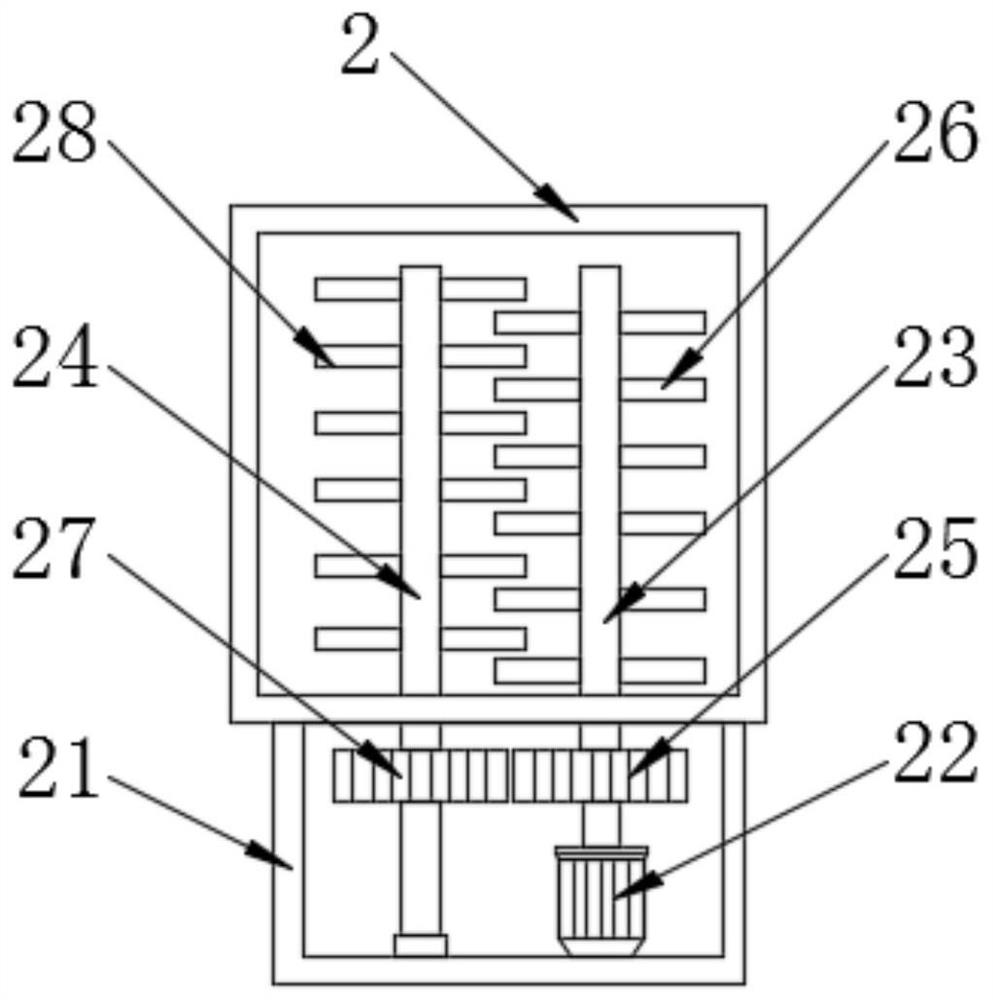

Image

Examples

Embodiment 1

[0051] A kind of bactericidal antibacterial antiviral coating, the preparation method of this bactericidal antibacterial antiviral coating comprises the steps:

[0052] S1, prepare raw materials, take the following raw materials by weight: 50 parts of film-forming resins, 40 parts of film-forming emulsions, 40 parts of auxiliary agents, 20 parts of Chinese herbal medicine extracts, 2 parts of dispersants and 10 parts of fillers;

[0053] S2. Mix the film-forming resin and additives to obtain materials, put them into a mixing and stirring equipment, stir for 40 minutes at a temperature of 75°C, and cool to room temperature to obtain a mixture A;

[0054] S3. Mix the film-forming emulsion and the mixture A into the mixing and stirring equipment and continue to stir for 30 minutes to obtain the mixture B;

[0055] S4. Mix the Chinese herbal medicine extract and the mixture B into a mixing and stirring device, and stir for 30 minutes at a temperature of 60° C. to obtain a mixture ...

Embodiment 2

[0064] A kind of bactericidal antibacterial antiviral coating, the preparation method of this bactericidal antibacterial antiviral coating comprises the steps:

[0065] S1, prepare raw material, take the raw material of following weight portion: 60 parts of film-forming resins, 45 parts of film-forming emulsions, 50 parts of auxiliary agents, 30 parts of Chinese herbal medicine extracts, 3 parts of dispersants and 12 parts of fillers;

[0066] S2. Mix the film-forming resin and the auxiliary agent to obtain the material, put it into a mixing and stirring device, stir for 45 minutes at a temperature of 80° C., and cool to room temperature to obtain a mixture A;

[0067] S3. Mix the film-forming emulsion and the mixture A into the mixing and stirring equipment and continue to stir for 35 minutes to obtain the mixture B;

[0068] S4. Mix the Chinese herbal medicine extract and the mixture B into a mixing and stirring device, and stir for 35 minutes at a temperature of 65° C. to o...

Embodiment 3

[0077] A kind of bactericidal antibacterial antiviral coating, the preparation method of this bactericidal antibacterial antiviral coating comprises the steps:

[0078] S1, prepare raw materials, take the following raw materials by weight: 70 parts of film-forming resins, 50 parts of film-forming emulsions, 60 parts of auxiliary agents, 45 parts of Chinese herbal medicine extracts, 4 parts of dispersants and 14 parts of fillers;

[0079] S2. Mix the film-forming resin and additives to obtain materials, put them into a mixing and stirring equipment, stir for 50 minutes at a temperature of 85°C, and cool to room temperature to obtain a mixture A;

[0080] S3, mixing the film-forming emulsion and the mixture A into the mixing and stirring equipment and continuing to stir for 40 minutes to obtain the mixture B;

[0081] S4. Mix the Chinese herbal medicine extract and the mixture B into a mixing and stirring device, and stir for 40 minutes at a temperature of 70° C. to obtain a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com