Filtering system

A filtration system and outlet channel technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as poor configuration, inability to effectively utilize gas cyclone, poor filtration effect, etc., and reduce kinetic energy loss. , reduce power, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples illustrate possible implementations of the present invention, but are not intended to limit the protection scope of the present invention.

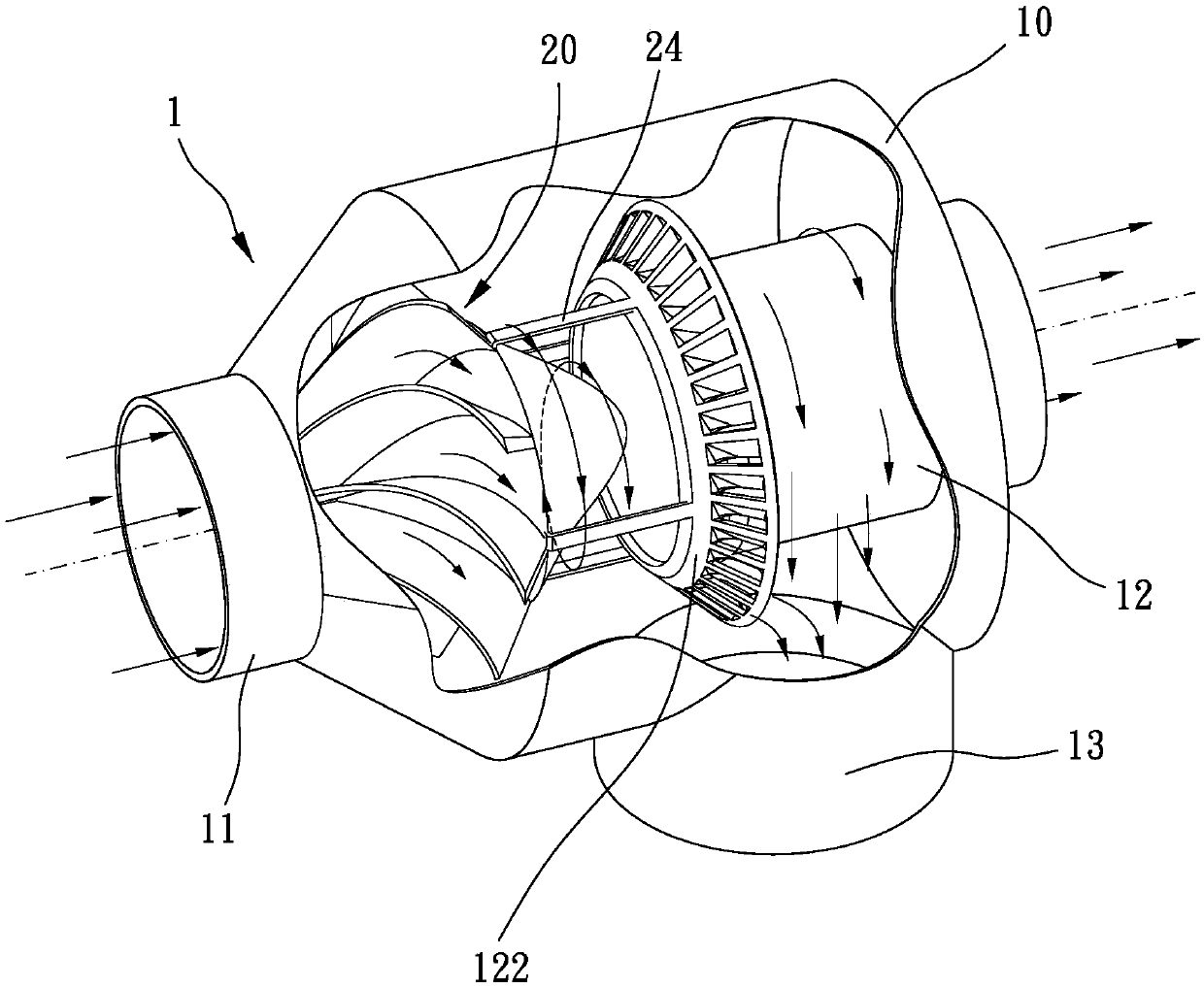

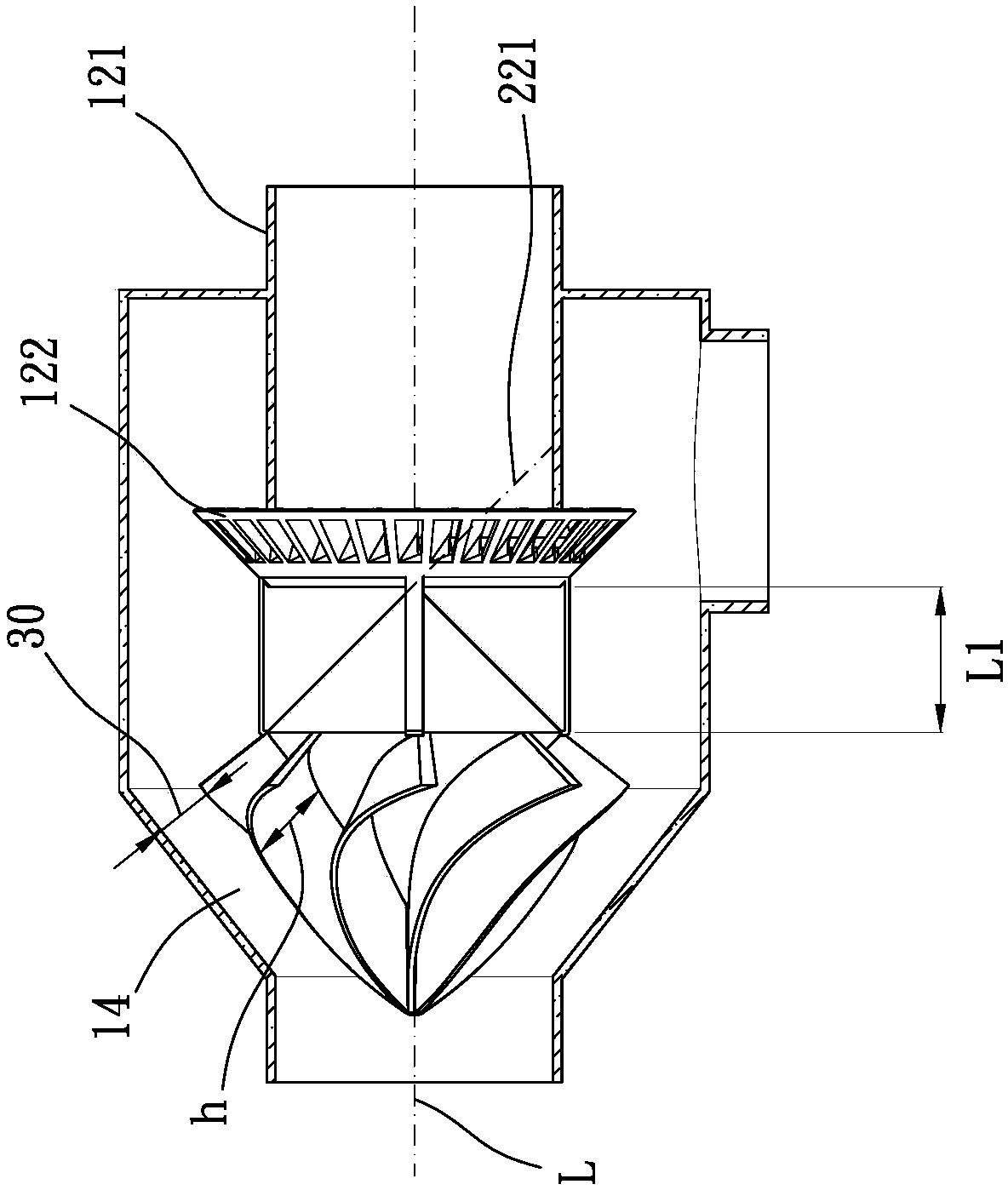

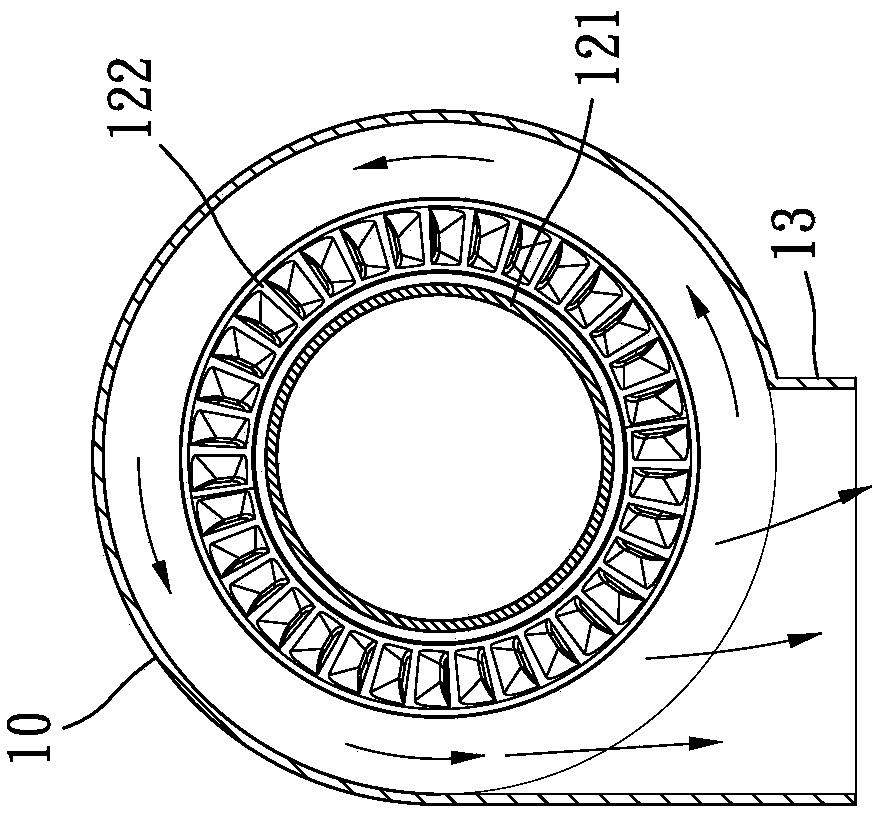

[0030] like Figure 1 to Figure 5 As shown, which shows a preferred embodiment of the present invention, the filter system 1 of the present invention includes a housing 10 and a flow guiding mechanism 20 .

[0031] The housing 10 includes an inlet channel 11 and an outlet channel 12 located on the same extension line L; The second tapered part 22 tapered in the direction of 12 and a plurality of blades 23, the plurality of blades 23 extend helically on the first tapered part 21 relative to the extension line L, the plurality of blades 23 and the housing 10 A gap 30 is formed between the inner walls of the vane 23 , and the gap 30 is smaller than a height h of the vane 23 relative to the surface of the first tapered portion 21 . The housing 10 , the inlet channel 11 , the outlet channel 12 , the first tapere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com