A kind of antibacterial ultrafiltration membrane and its preparation method and membrane regeneration method

A technology of ultrafiltration membrane and repeating unit, which is applied in the field of antibacterial ultrafiltration membrane and its preparation, can solve the problems of easy harm to the environment, easy loss, and drug resistance, and achieve good filtration and separation performance, environmental friendliness, high Bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

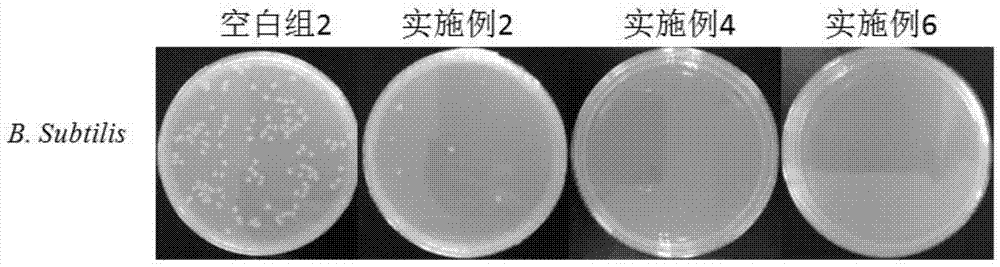

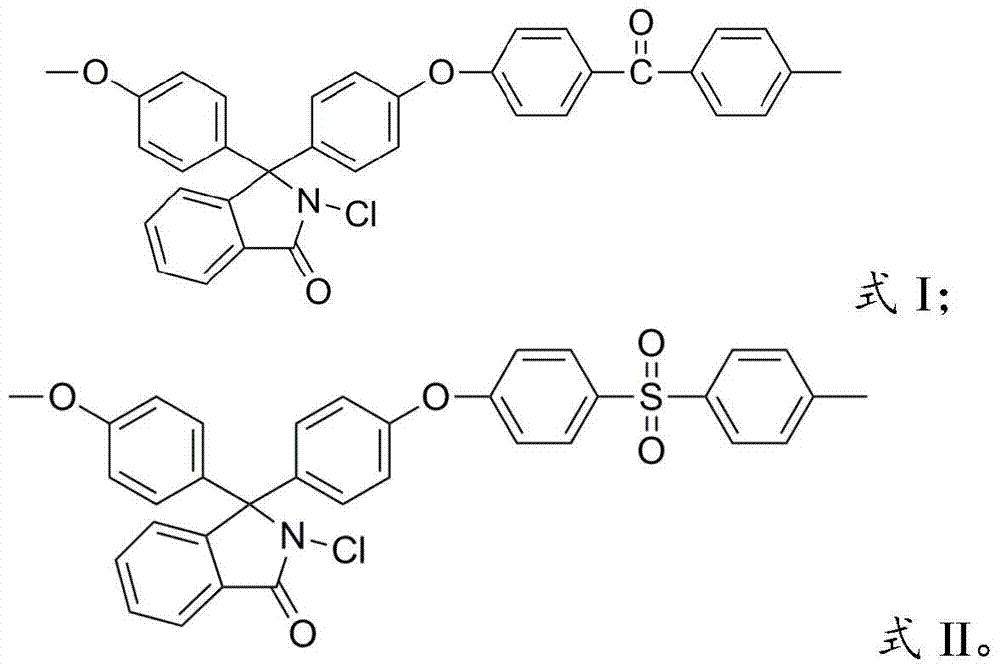

[0031] The present invention provides a kind of preparation method of antibacterial ultrafiltration membrane described in above-mentioned technical scheme, comprises the following steps:

[0032] The ultrafiltration membrane is obtained by a phase inversion method, and the materials used to prepare the ultrafiltration membrane include polyarylether ketone or polyaryl ether sulfone, and the polyarylether ketone has a repeating unit shown in formula III:

[0033]

[0034] The polyarylethersulfone has a repeating unit represented by formula IV:

[0035]

[0036] The ultrafiltration membrane is contacted with a chlorine solution to react to obtain an antibacterial ultrafiltration membrane.

[0037] The preparation method provided by the invention has simple process, mild reaction conditions and low cost.

[0038] The present invention adopts a phase inversion method to obtain an ultrafiltration membrane, and the materials used to prepare the ultrafiltration membrane include...

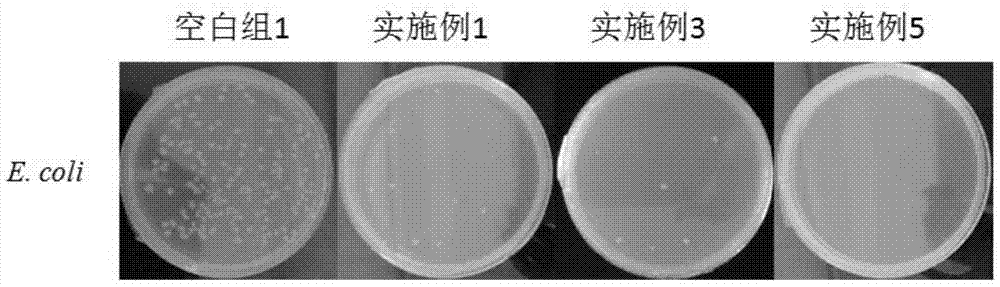

Embodiment 1

[0063] 1) Preparation of antibacterial ultrafiltration membrane:

[0064] Dissolve polyaryletherketone with a molecular weight of 200,000 g / mol in dimethylacetamide to form a polyaryletherketone solution with a mass fraction of 18%, fully dissolve it, filter to remove insoluble matter and defoam at 30°C Mature in a constant temperature room for 12 hours to obtain the casting solution; use a scraper to scrape the film on a clean glass plate with a slit of 150 μm, then immediately put the glass plate in deionized water for phase inversion, after the phase inversion is complete, soak in deionized water Remove residual solvent to obtain ultrafiltration membrane;

[0065] Soak the prepared ultrafiltration membrane in sodium hypochlorite solution (mass concentration 1%) for 5 min. Wash the residual sodium hypochlorite with water at 30°C, and constantly replace the water to remove a small amount of sodium hypochlorite remaining in the membrane to obtain an antibacterial ultrafiltrat...

Embodiment 2

[0075] 1) Preparation of antibacterial ultrafiltration membrane:

[0076] Dissolve polyaryletherketone with a molecular weight of 120,000 g / mol in dimethylacetamide to form a polyaryletherketone solution with a mass fraction of 15%, fully dissolve it, filter to remove insoluble matter and defoam at 30°C Mature in a constant temperature room for 12 hours to obtain a casting solution; use a scraper to scrape the film on a clean glass plate with a slit of 200 μm, and immediately put the glass plate in deionized water for phase inversion. After the phase inversion is complete, soak in deionized water Remove residual solvent to obtain ultrafiltration membrane;

[0077] Soak the prepared ultrafiltration membrane in sodium hypochlorite solution (mass concentration 5%) for 30min, wash the residual sodium hypochlorite with water at 30°C and soak in water for one day, and constantly replace the water to remove a small amount of sodium hypochlorite remaining in the membrane to obtain ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com