Method for preparing high-temperature resistant anti-corrosion ablation microfiber

An anti-corrosion and ablative technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve problems such as high price, low cost performance, poor separation effect, etc., to improve product quality, environmental protection, and technical level High, excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] 1. The composition selection of glass microfiber raw cotton

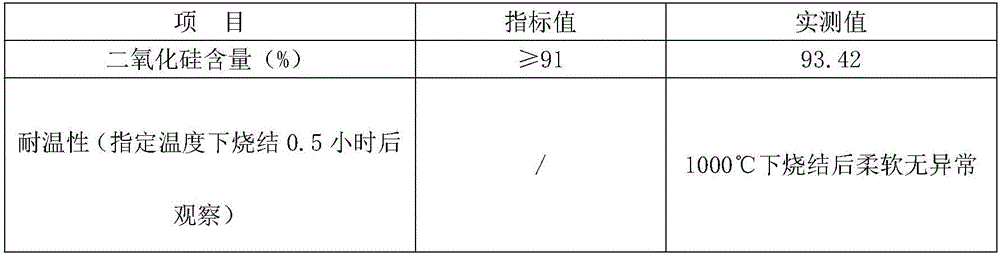

[0031] The microfiber provided by the present invention must contain a microporous structure in order to reflect its filtering function. The choice of raw cotton should first consider the material that can obtain microporous structure after acid leaching (hot acid leaching and water washing leaching). There are many types of glass fiber cotton suitable for acid leaching to obtain microporous structure. Commonly used Glass wool includes alkali-free glass wool, sodium borosilicate glass wool, sodium silicate and the like. After acid leaching of glass wool with different components, the size of micropores formed in the glass structure is quite different, and the content of silicon dioxide in different glass wools after acid treatment is different, resulting in differences in temperature resistance. The composition of the microfiber raw cotton is selected to obtain the filter material that can meet the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com