Separation method of effective components of rare earth tailings

A technology of rare earth tailings and effective components, applied in the direction of improving process efficiency, etc., can solve the problems of radioactive pollution, inability to recycle, high grade requirements of concentrate, etc., to reduce energy consumption and waste discharge, and to achieve good separation and filtration performance , high environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

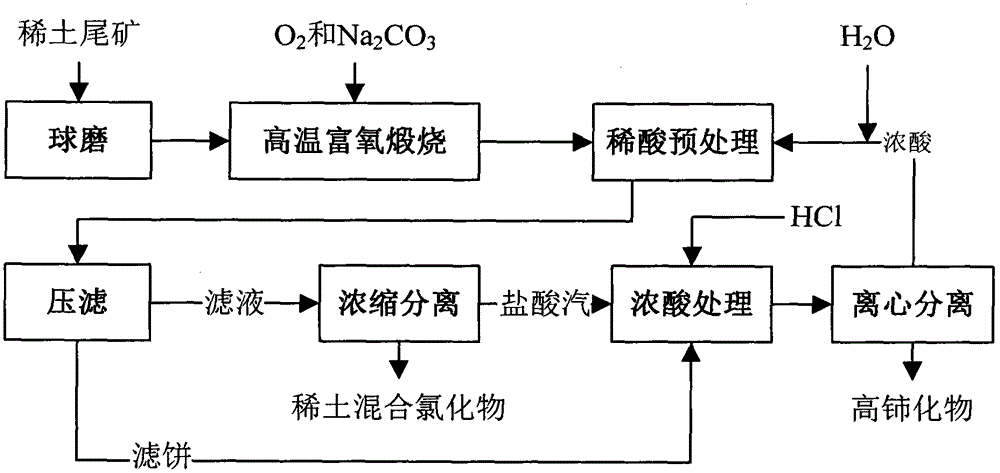

Method used

Image

Examples

Embodiment 1

[0028] The rare earth tailings are treated by ball milling, the particle size after ball milling is 150 mesh, and then the rare earth and sodium carbonate are uniformly mixed at a mass ratio of 1:0.3, and the temperature is controlled at 320°C, heated in a calciner, and oxygen is introduced at the same time, and the oxygen in the calciner The concentration is 40% vol. The mixed solid obtained by calcination was pretreated with dilute hydrochloric acid at 42° C., and the concentration of dilute hydrochloric acid used was 3.2 wt%. Then, the filter press liquid and the filter cake are obtained through filter press separation, and the filter press pressure is 2.8 bar. The filtrate is heated, concentrated and separated at a temperature of 94°C and a pressure of -0.8 bar, and the effective component rare earth mixed chloride will be precipitated in the form of crystals, and the total harvested amount is 80%. The hydrochloric acid vapor obtained during the concentration process beco...

Embodiment 2

[0030] The rare earth tailings are treated by ball milling, the particle size after ball milling is 165 mesh, and then the rare earth and sodium carbonate are uniformly mixed at a mass ratio of 1:0.7, and the temperature is controlled at 360°C, heated in a calciner, and oxygen is introduced at the same time, and the oxygen in the calciner The concentration is 53% vol. The mixed solid obtained by calcination was pretreated with dilute hydrochloric acid at 66° C., and the concentration of dilute hydrochloric acid used was 6.8 wt%. Then, the filter press liquid and the filter cake are obtained through filter press separation, and the filter press pressure is 4.2 bar. The filtrate is heated, concentrated and separated at a temperature of 110°C and a pressure of -0.6 bar, and the effective component rare earth mixed chloride will be precipitated in the form of crystals, and the total harvested amount is 75%. The hydrochloric acid vapor obtained during the concentration process bec...

Embodiment 3

[0032]The rare earth tailings are treated by ball milling, the particle size after ball milling is 170 mesh, and then the rare earth and sodium carbonate are uniformly mixed at a mass ratio of 1:0.5, and the temperature is controlled at 400°C, heated in a calciner, and oxygen is introduced at the same time, and the oxygen in the calciner The concentration is 62% vol. The mixed solid obtained by calcination was pretreated with dilute hydrochloric acid at 70° C., and the concentration of dilute hydrochloric acid used was 5.4 wt%. Then, the filter press liquid and the filter cake are obtained through filter press separation, and the filter press pressure is 3.6 bar. The filtrate is heated, concentrated and separated at a temperature of 115°C and a pressure of 0.2 bar, and the effective component rare earth mixed chloride will be precipitated in the form of crystals, and the total harvested amount is 81%. The hydrochloric acid vapor obtained during the concentration process becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com