Method and device for treating high-salt organic wastewater in chemical production

A technology for organic wastewater treatment and chemical production, applied in the direction of biological water/sewage treatment, oxidized water/sewage treatment, multi-stage water treatment, etc., can solve the problems of long adsorption time, poor sedimentation separation effect, poor adsorption effect, etc., to achieve Good adsorption effect, good filtration and separation effect, appropriate speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

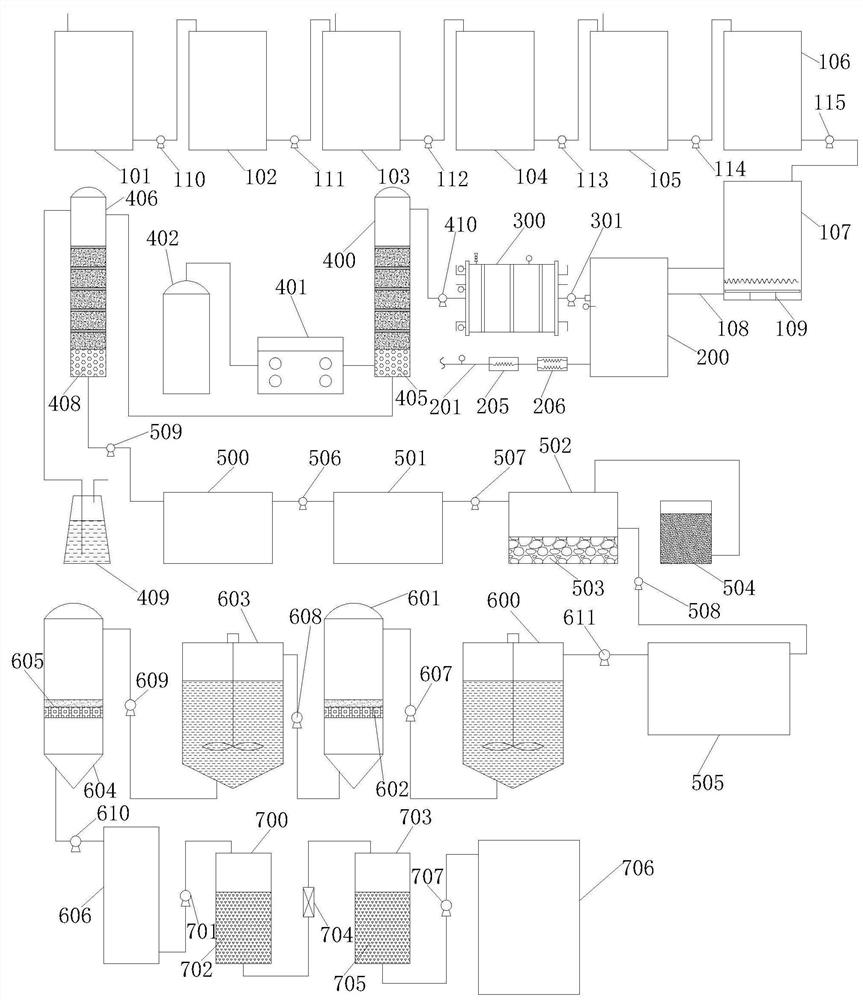

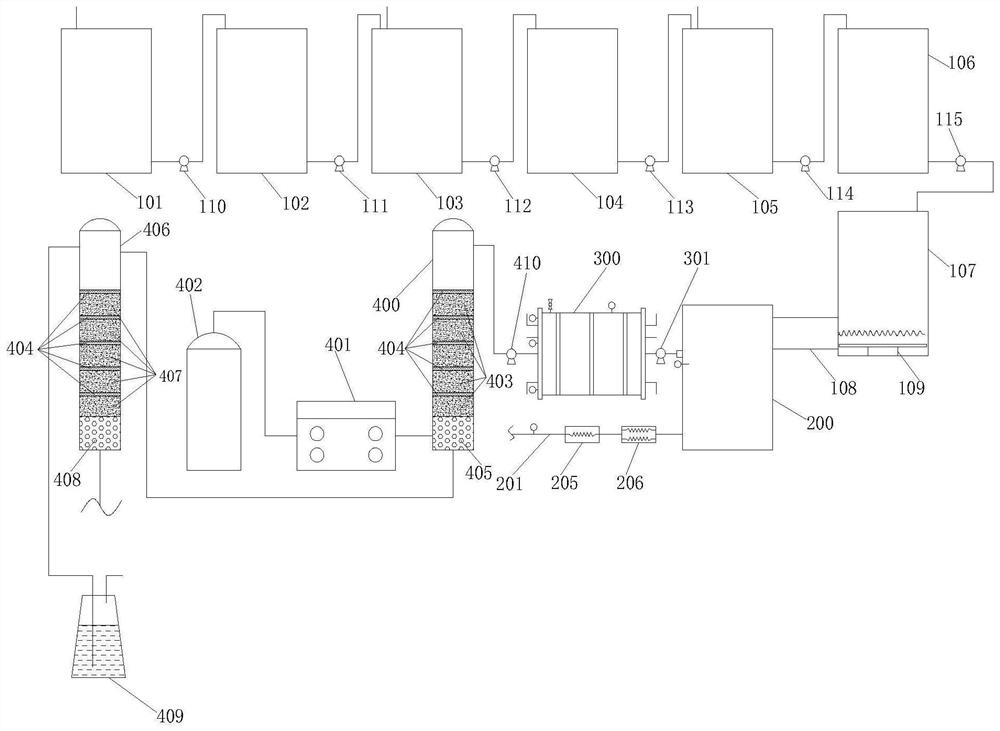

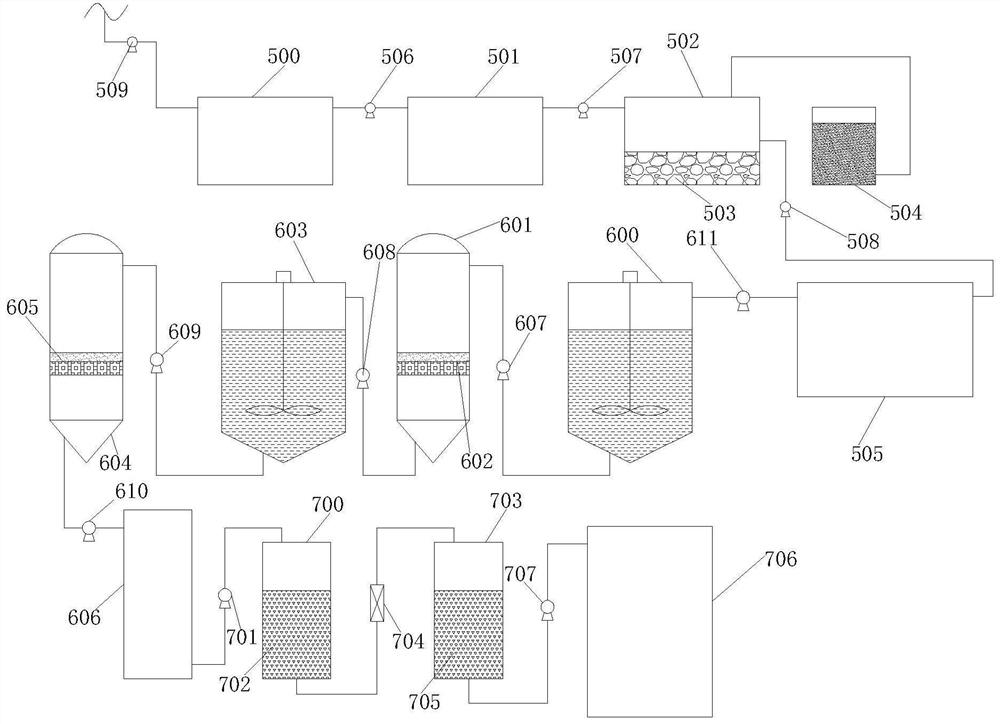

[0068] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but it is not used as a basis for limiting the present invention.

[0069]A method for treating high-salt organic wastewater in chemical production, comprising the following steps,

[0070] (a) washing salt

[0071] Cleaning the solid waste salt to be treated with a cleaning agent to obtain cleaning salt;

[0072] (b) Salt

[0073] Send the cleaning salt into the salt tank for salting;

[0074] (c) Nanofiltration membrane treatment

[0075] The brine after desalting in step (b) is sent in the nanofiltration tank and carries out nanofiltration;

[0076] (d) Catalytic oxidation treatment

[0077] The brine in step (c) nanofiltration tank is carried out catalytic oxidation treatment using ozone and solid-phase catalyst;

[0078] (e) Phosphorus removal flocculation

[0079] Adding a phosphorus removal flocculant to the brine after catalytic oxidation i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com