Cutting fluid purifying apparatus capable of treating residues on line

A technology for purifying equipment and cutting fluids, applied in chemical instruments and methods, filtration and separation, lubricating compositions, etc., can solve the problems of cleaning up and single-handedness that must be stopped, and achieve enhanced processing capacity, high work efficiency, and filtration and separation effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

Specific examples:

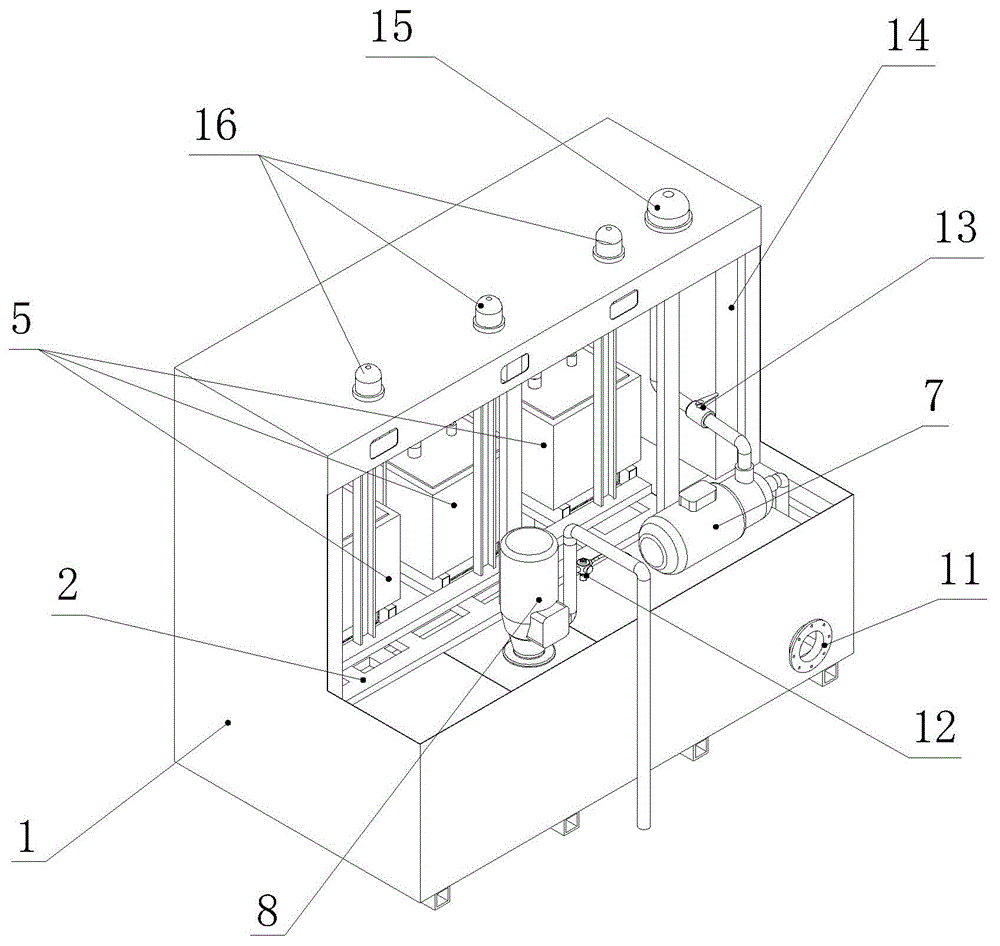

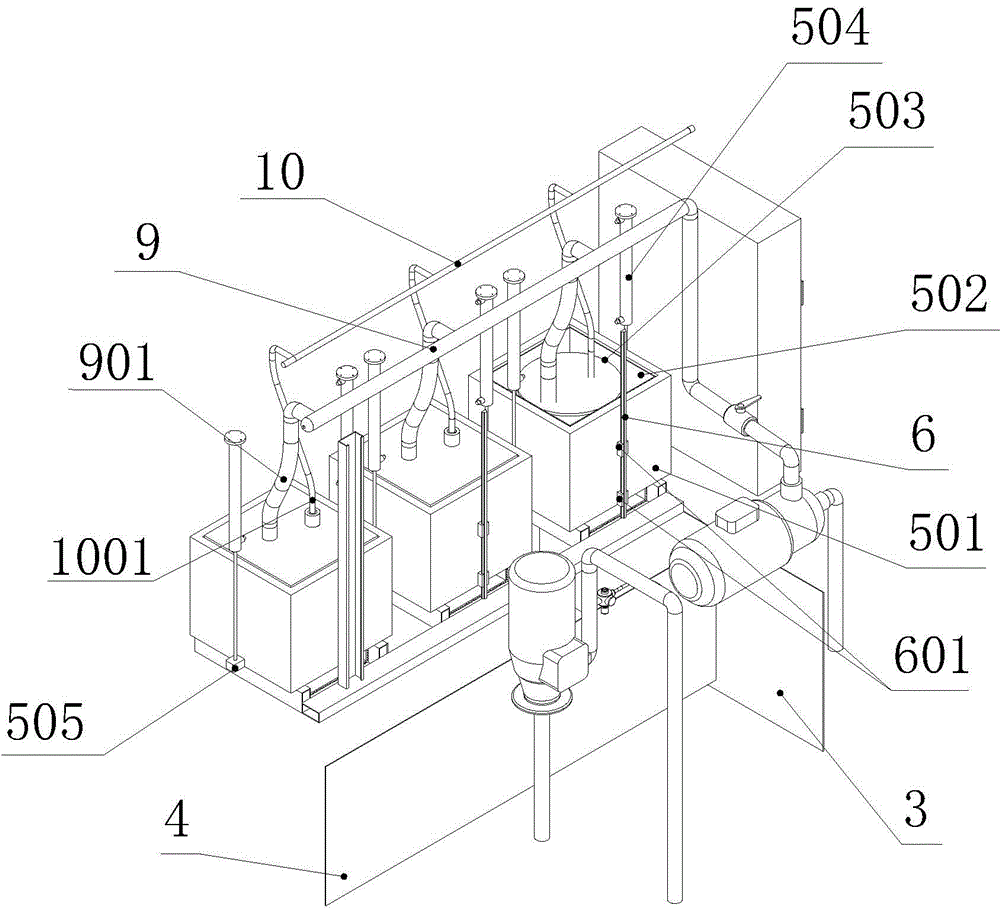

[0021] refer to figure 1 and figure 2 , a cutting fluid purification device capable of processing residues online, comprising a casing 1 and a waste liquid filtration and separation system disposed in the casing 1, the waste liquid filtration and separation system includes a waste liquid separation unit, a liquid storage tank, and a liquid supply pipeline , an air supply pipeline, an inlet pump 7 and an outlet pump 8, the housing 1 is provided with a frame 2, and the frame 2 is welded by several horizontal bars and vertical bars; the waste liquid separation unit is located in the housing 1, the liquid storage tank is located at the lower part of the shell 1; the liquid storage tank is provided with a blocking steel plate 3 that divides the liquid storage tank into a first zone and a second zone, and the first zone is a waste liquid pool, the second zone is a filtrate pool, and the filtrate pool includes a primary filtrate pool and a secondary filtrate po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com