Preparation method of MOF (metal oxide framework)-loaded silver antibacterial scale-blocking ultrafiltration film and application thereof

A technology of ultrafiltration membrane and MOF, which is applied in the field of inorganic/organic hybrid separation, can solve problems not involved in the synthesis and application of MOF-loaded silver, and achieve good filtration and separation performance, high sterilization, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Dissolve or disperse PVDF with a molecular weight of 200,000 g / mol at a ratio of 100:1:3, MOF-loaded silver, and a pore-forming agent in dimethylacetamide to form a PVDF solution with a mass fraction of 20%, so that it is fully dissolved, Remove the insoluble matter by filtering and degassing, and mature in a constant temperature room at 60°C for 12 hours to obtain the casting solution; scrape the film on a clean glass plate with a scraper, and then immediately put the glass plate in deionized water for phase inversion, and the phase inversion is complete Afterwards, immerse in deionized water to remove residual solvent to obtain an ultrafiltration membrane.

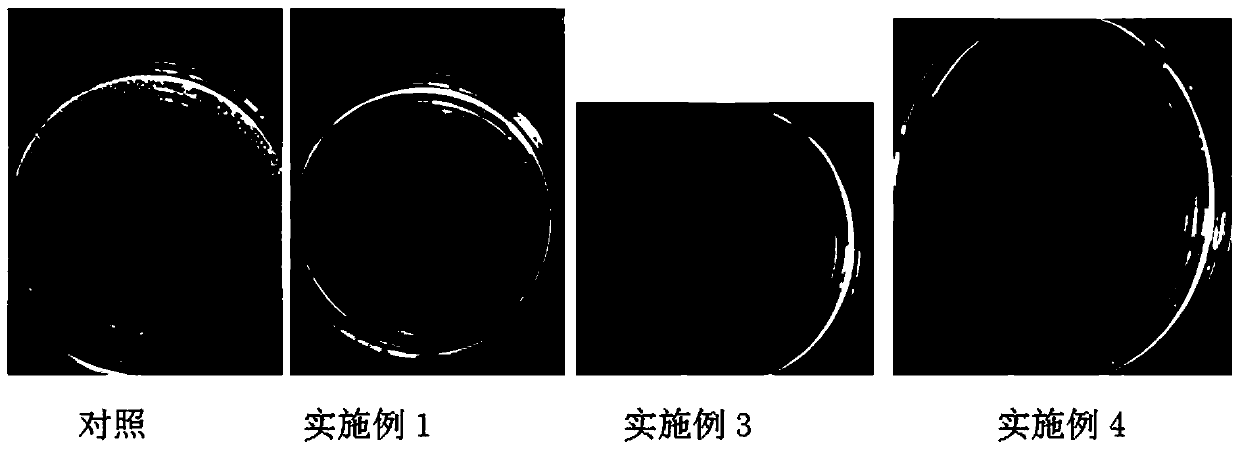

[0022] Antibacterial Performance Experiment of Antibacterial Ultrafiltration Membrane

[0023] In this experiment, Staphylococcus aureus was used to test the antibacterial performance of antibacterial ultrafiltration membrane.

[0024] The medium formula used in the experiment is as follows:

[0025] LB liquid m...

Embodiment 2

[0029] 1) Preparation of antibacterial ultrafiltration membrane:

[0030] Dissolve or disperse PVDF with a molecular weight of 200,000 g / mol at a ratio of 100:2:3, MOF-loaded silver, and a pore-forming agent in dimethylacetamide to form a PVDF solution with a mass fraction of 20%, so that it is fully dissolved, Remove the insoluble matter by filtering and degassing, and mature in a constant temperature room at 60°C for 12 hours to obtain the casting solution; scrape the film on a clean glass plate with a scraper, and then immediately put the glass plate in deionized water for phase inversion, and the phase inversion is complete Afterwards, immerse in deionized water to remove residual solvent to obtain an ultrafiltration membrane.

[0031] Antibacterial performance experiment of antibacterial ultrafiltration membrane. In this experiment, Staphylococcus aureus was used to test the antibacterial performance of antibacterial ultrafiltration membrane. The medium formula used in th...

Embodiment 3

[0034] 1) Preparation of antibacterial ultrafiltration membrane:

[0035] Dissolve or disperse PSF with a molecular weight of 200,000 g / mol at a ratio of 100:2:3, MOF-loaded silver, and a pore-forming agent in dimethylacetamide to prepare a PS solution with a mass fraction of 20%, so that it is fully dissolved. Remove the insoluble matter by filtering and degassing, and mature in a constant temperature room at 60°C for 12 hours to obtain the casting solution; scrape the film on a clean glass plate with a scraper, and then immediately put the glass plate in deionized water for phase inversion, and the phase inversion is complete Afterwards, immerse in deionized water to remove residual solvent to obtain an ultrafiltration membrane.

[0036] Antibacterial performance experiment of antibacterial ultrafiltration membrane. In this experiment, Staphylococcus aureus was used to test the antibacterial performance of antibacterial ultrafiltration membrane. The medium formula used in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com