Separating membrane pollution controlling and cleaning method

A technology for pollution control and separation membranes, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

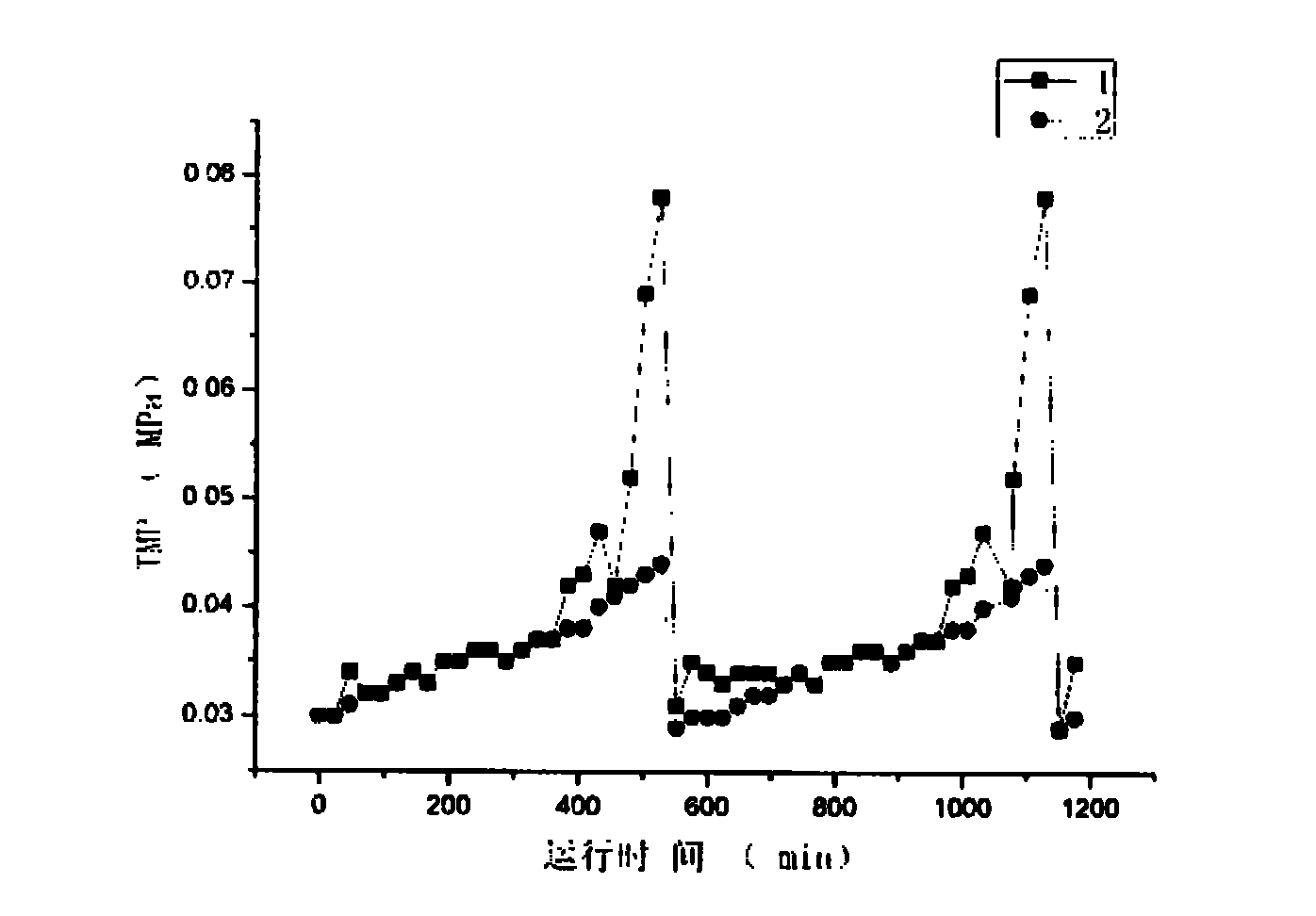

[0020] Embodiment: Also adopt the effluent of the secondary settling tank of a certain urban sewage treatment plant as raw water, adopt polyvinylidene fluoride hollow fiber membrane modules (0.22 micron pore size), the operating process of the membrane filtration device is the same as that of the comparative example, and the constant flux mode is adopted for operation. The volume is 50L / m2.h, and it operates in a cycle of 29 minutes of filtration and 1 minute of air-water double washing. The difference from the comparative example is that in the raw water circulation tank, diatomaceous earth (SiO 2 The particle size is 38 microns, Beijing Wancheng Yuanxing Chemical Products Co., Ltd.), and the diatomite loading per unit membrane area is 50mg / m 2 . After air-water cleaning, pass through a 200-mesh pipeline filter, filter out and collect diatomite from the discharged sewage, and return the collected diatomite to the raw water circulation tank to repeat the experiment. See the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com