Membrane bioreactor using non fabric filtration

A membrane bioreactor and non-fabric technology, applied in the field of submerged membrane bioreactors, can solve the problems of high initial cost, high quality requirements of influent water, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

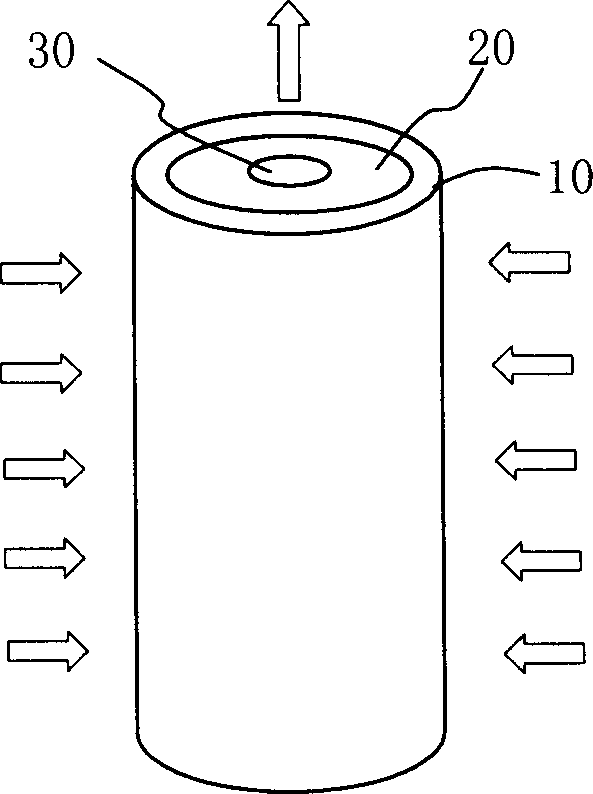

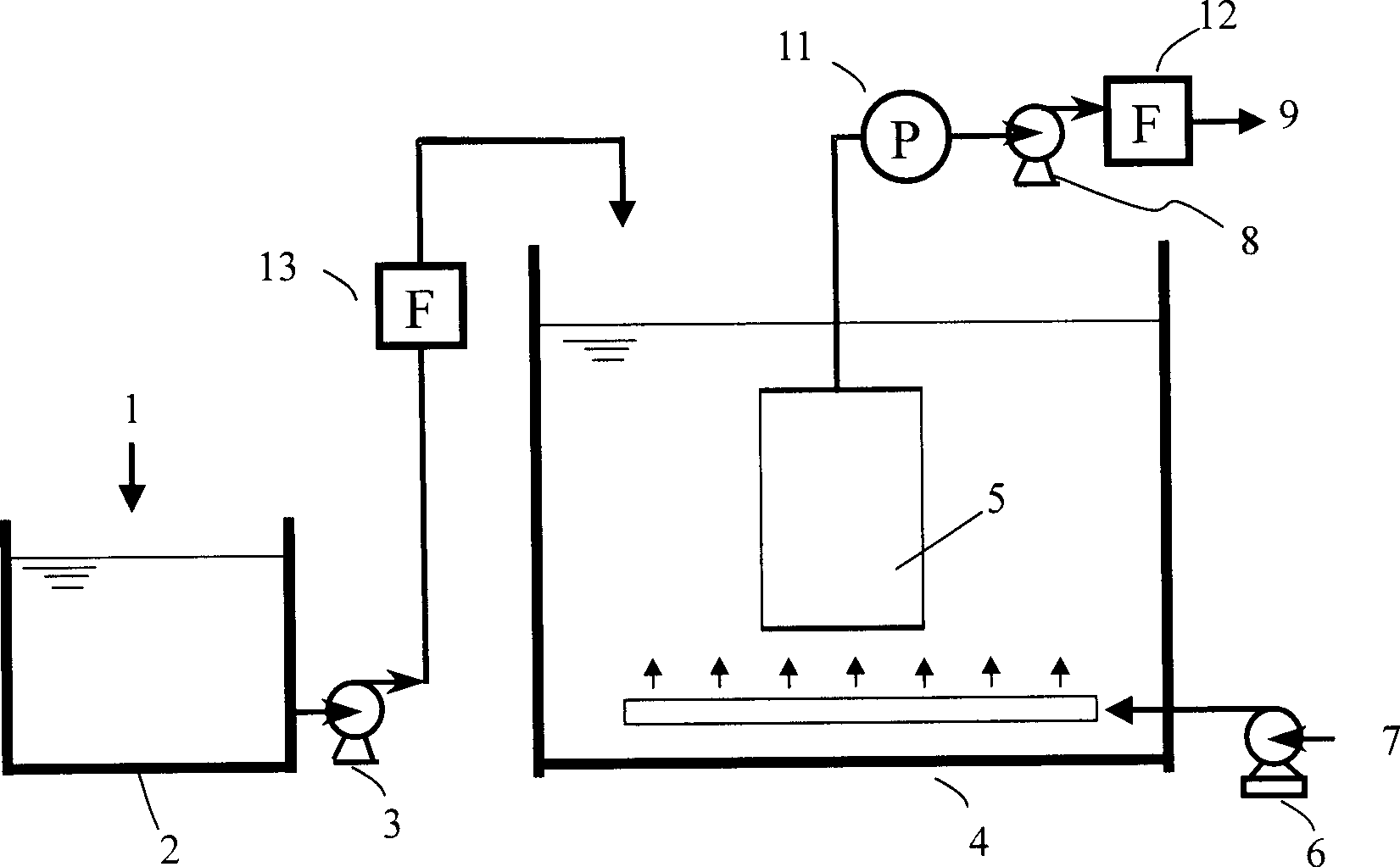

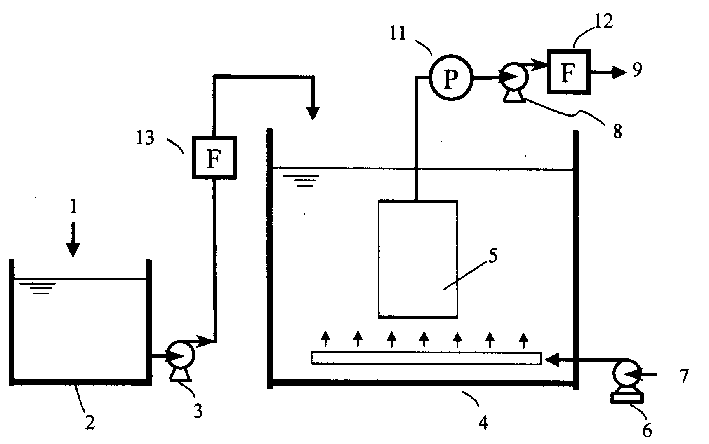

[0032] This example uses something like figure 2The submerged membrane bioreactor system was used for experiments. This embodiment takes sodium citrate as the main component of artificially prepared wastewater as the treatment object, and additionally adds trace components such as urea, phosphoric acid and ferric chloride to provide sufficient nutrients for microorganisms. The artificially synthesized matrix components are shown in Table 1. The non-fabric membrane used in the filter module is polypropylene non-fabric with a thickness of 0.3mm and a surface area of 0.1m 2 , with an average pore size of 39 μm. The polypropylene non-woven fabric is made hydrophilic by surface treatment of plasma activated grafting of acrylic monomers. The hollow tubular support material used in the filter module is polypropylene non-woven fabric with a thickness of 6 mm and a central hole diameter of 20 mm.

[0033] The operating conditions of the membrane bioreactor tank are controlled as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com