Electro-catalytic membrane wastewater treatment system and electro-catalytic membrane tube thereof

A wastewater treatment system, electrocatalytic membrane technology, applied in water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as high cost, difficult industrial application, low current efficiency, etc., to prevent Pollution, reduced treatment costs, reduced coagulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

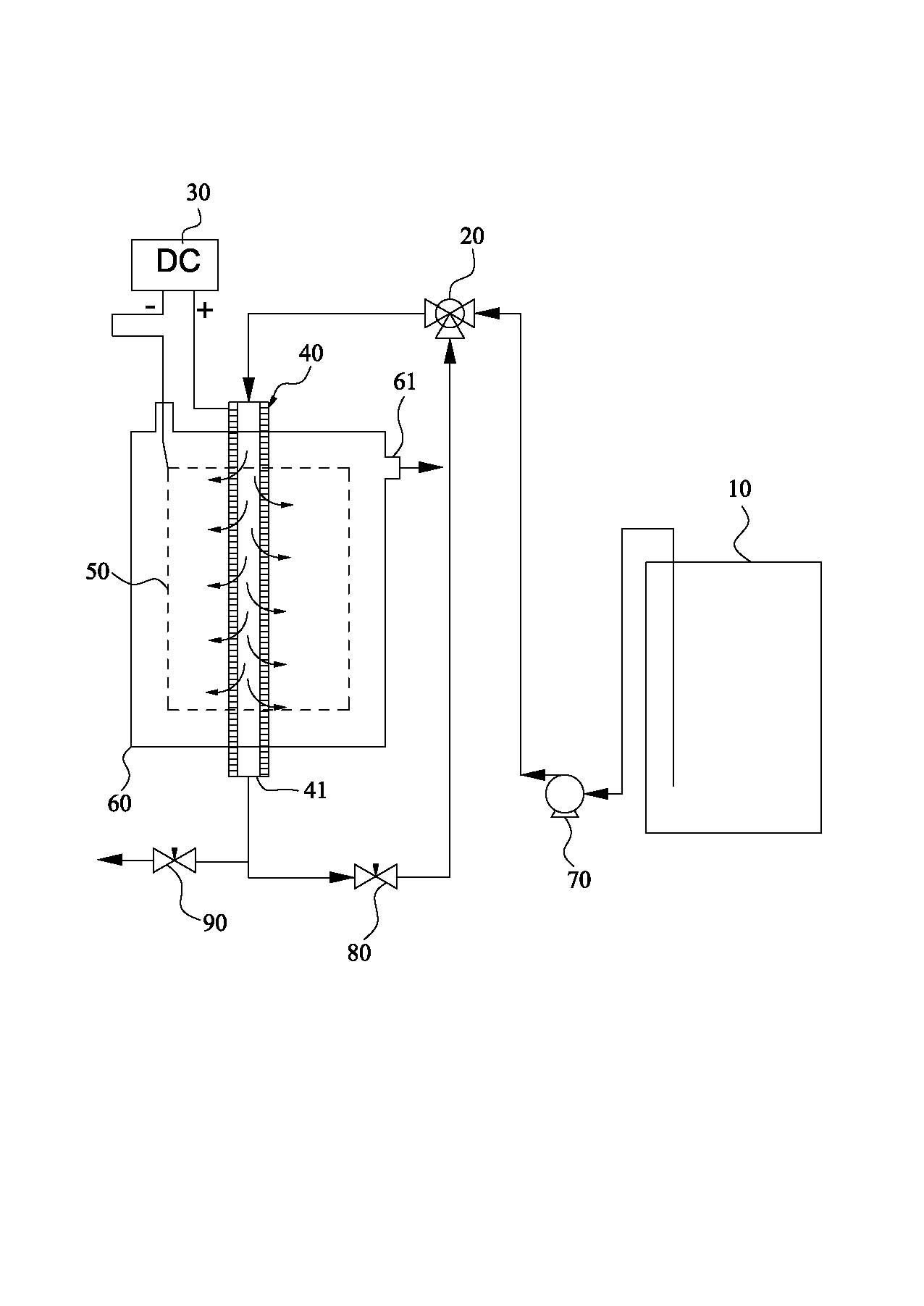

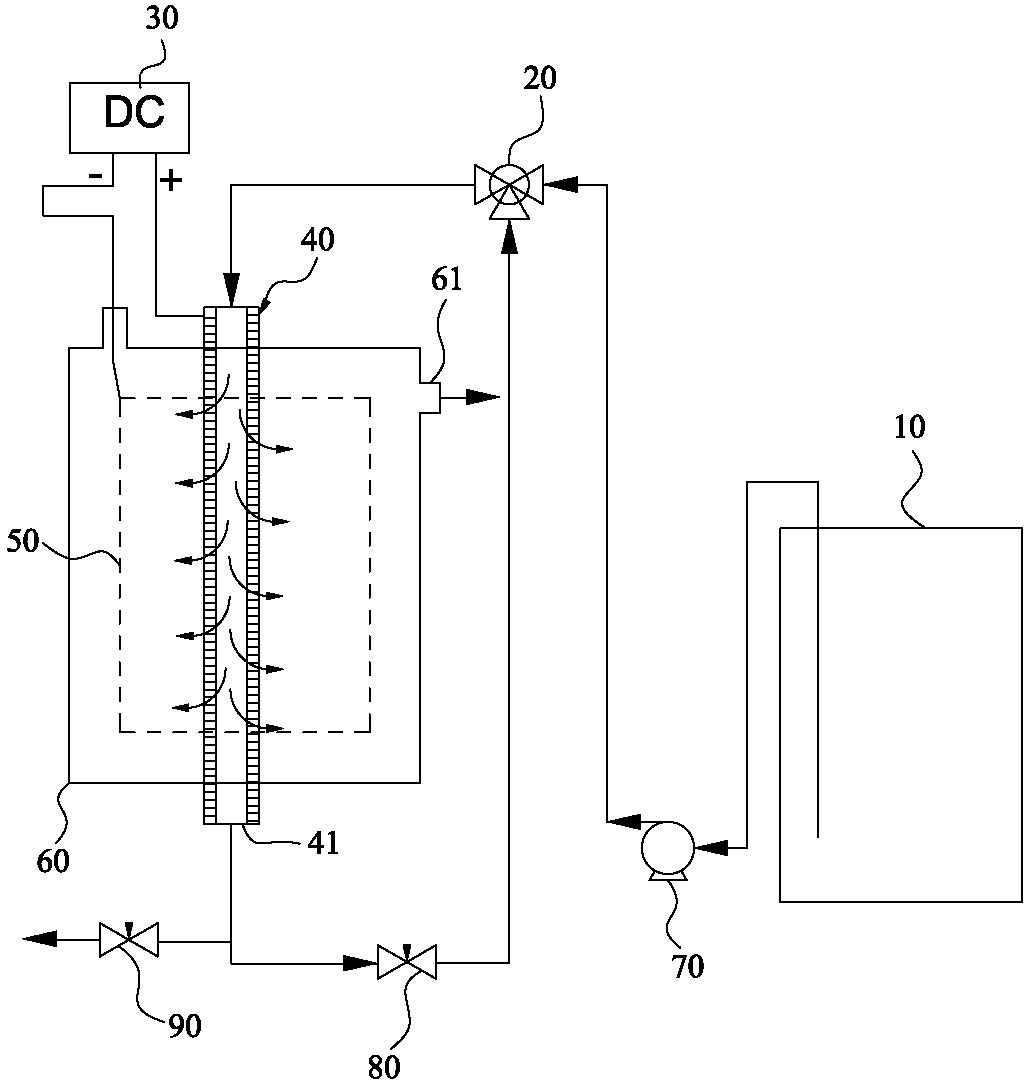

[0026] Please refer to figure 1 Shown, it has shown the concrete structure of the preferred embodiment of the present invention, comprises an organic waste water pool 10, a mixing valve 20, a DC stabilized voltage power supply 30, at least one electrocatalytic membrane tube 40, an auxiliary electrode 50 and A permeate tank 60, the electrocatalytic membrane tube 40 is installed in the permeate tank 60, the auxiliary electrode 50 surrounds the electrocatalyzed membrane tube 40 and keeps a distance from the electrocatalyzed membrane tube 40; The water outlet end is connected to the water inlet end of the mixing valve 20 through the metering pump 70, and the mixing valve 20 is connected to the electrocatalytic membrane tube 40 through the water inlet pipe, and the positive pole and the negative pole of the DC stabilized voltage power supply 30 are respectively connected to the electrocatalytic membrane tube through wires 40 and the auxiliary electrode 50 , the water outlet end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com