Oilfield poly-surfactant flooding sewage treatment process

A technology of sewage treatment and polysurfactant, which is applied in the field of sewage treatment process produced by polysurfactant flooding, can solve the problems of long running time, high investment cost, large floor area, etc., and achieves short treatment time, low investment cost, The effect of water stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

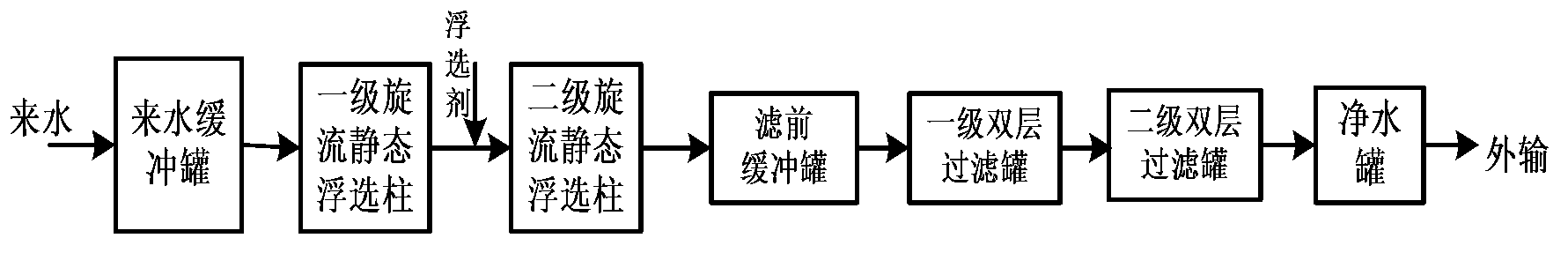

[0032] First, the incoming water from the sewage settling tank of the oil station has a water temperature of 39°C, a pH value of 7.8, a viscosity of 2.4 mPa.s, a polysurfactant content of 390mg / L, an oil content of 2200mg / L, and a suspended solid of 80mg / L. The incoming water buffer tank stays hydraulically for 1 hour to remove most of the slick oil in the water; then the effluent is lifted by the pump and then enters the first-stage cyclone static flotation column, which generates a swirl through tangential water inflow to increase the separation of oil and water, and at the same time It is fully mixed with the dissolved air water whose circulation volume is 2 to 3 times of the influent water volume, so that the micro-bubbles in the water fully contact with the oil beads and suspended particles, and the oil beads and suspended particles are carried to the column through the static flotation section of the flotation column The upper part of the flotation tank is discharged, and...

Embodiment 2

[0034] First, the incoming water from the sewage settling tank of the oil station has a water temperature of 39°C, a pH value of 7.7, a viscosity of 3.3 mPa.s, a polysurfactant content of 620mg / L, an oil content of 2600mg / L, and a suspended solid of 120mg / L. The incoming water buffer tank stays hydraulically for 1 hour to remove most of the slick oil in the water; then the effluent is lifted by the pump and then enters the first-stage cyclone static flotation column, which generates a swirl through tangential water inflow to increase the separation of oil and water, and at the same time It is fully mixed with the dissolved air water whose circulation volume is 2 to 3 times of the influent water volume, so that the micro-bubbles in the water fully contact with the oil beads and suspended particles, and the oil beads and suspended particles are carried to the column through the static flotation section of the flotation column The upper part of the flotation tank is discharged. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com