Immersion type ultra-filtration system

An ultrafiltration system and immersion technology, applied in the field of water treatment, can solve the problems of increasing project land occupation, construction cost, operation and maintenance costs, etc., and achieve the effect of saving project area, strong pollution holding capacity, and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

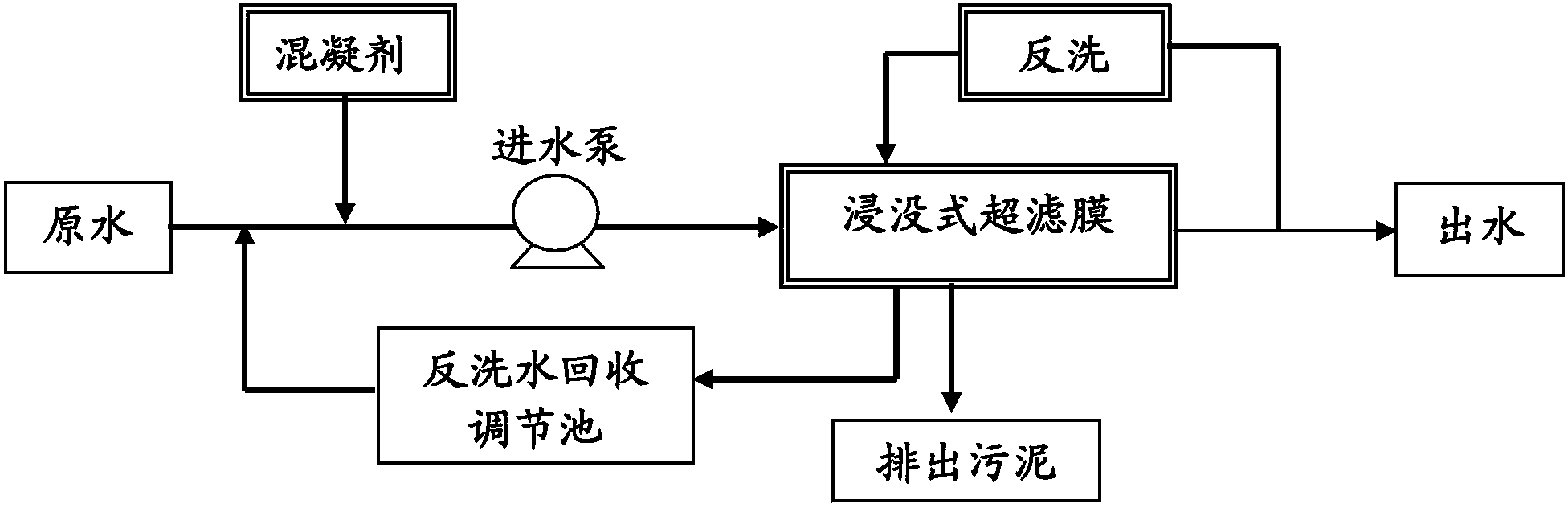

Method used

Image

Examples

Embodiment 1

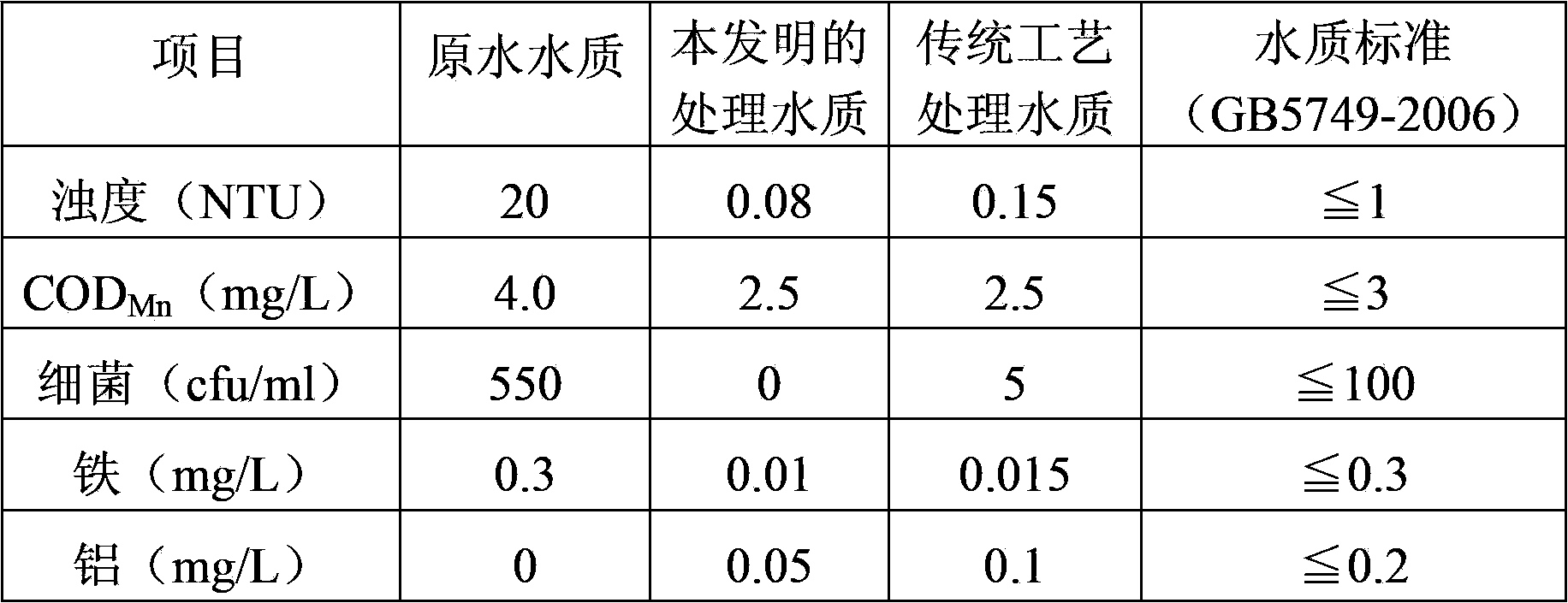

[0027] A water plant with a treatment scale of 400,000m 3 / d, the raw water is surface water, of which COD Mn It is 4mg / L, and the turbidity is 20NTU. The specific treatment process is as follows: the prepared coagulant is added to the 15cm upstream of the suction port of the self-priming ultrafiltration water inlet pump, and then enters the submerged ultrafiltration membrane pool. The coagulant is polyaluminum chloride. 2mg / L (calculated as aluminum). The ultrafiltration membrane is PVDF submerged ultrafiltration, the membrane pore size is 0.01 micron, and the membrane area is 20m 2 , The ultrafiltration membrane flux is 2.0m / d.

[0028] The operation mode of the ultrafiltration membrane is backwashing and air scrubbing after every 30 minutes of filtration. Among them, the backwashing water volume is 2.2m / d, and the washing time is 1min. The backwashing water enters the backwashing recovery through the backwashing outlet on the submerged membrane pool In the adjustment ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com