Preparation method of multilayer-structure nano fiber composite membrane for filtering particulates in air

A nanofiber membrane and nanofiber technology, which is applied in the direction of dispersed particle filtration, fiber treatment, separation methods, etc., can solve the problems of reducing filtration performance, affecting the filtration efficiency of particle filtration membranes, and reducing filtration efficiency, so as to reduce filtration air resistance, High particle filtration efficiency, effect of improving blocking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

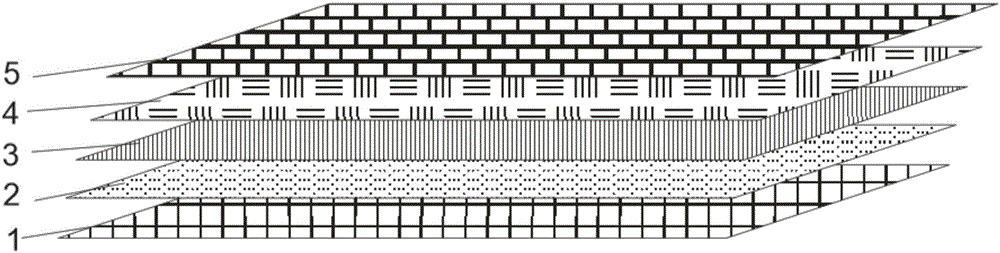

[0035] A preparation method for a multi-layer structure nanofiber composite membrane used for filtering particulate matter in the air, comprising the following steps:

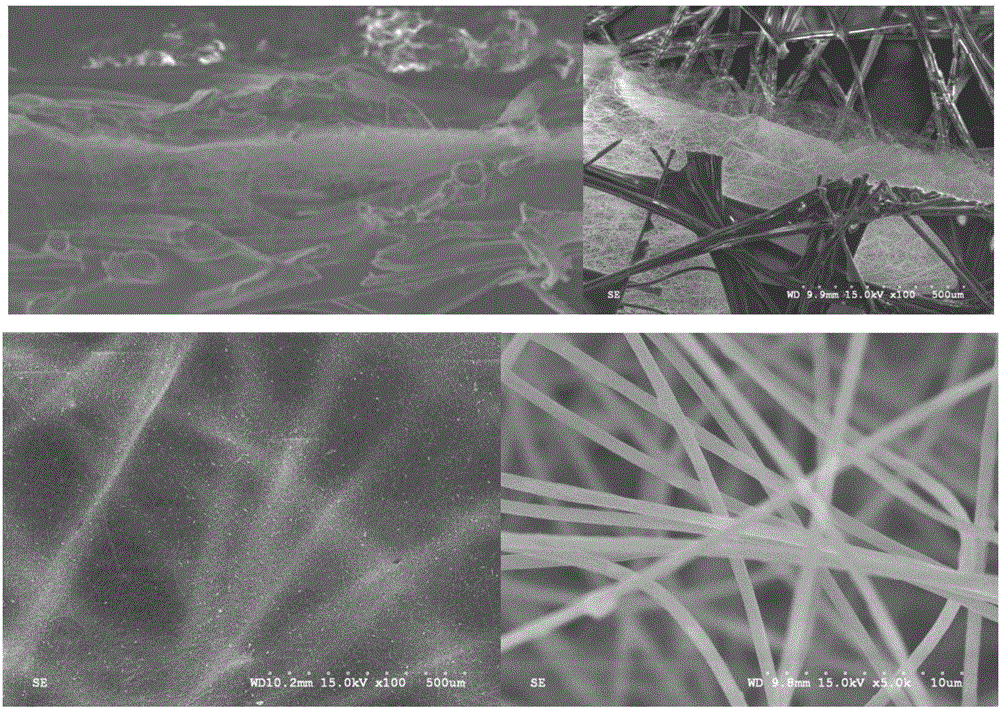

[0036] (1) In PP nonwoven fabric (weight is 30g / m 2 ) substrate is spun into the first nanofiber film layer——PAN nanofibers by electrospinning. The receiving device used in electrospinning is a drum-type receiving device. The drum speed is 30r / min and the voltage is 18KV. The distance from the nozzle to the receiving template is 12cm, the ambient temperature is 26°C, and the relative humidity is 40%;

[0037] (2) The upper surface of the first nanofiber film layer and the exposed surface of each nanofiber film layer are covered with PP filament nonwoven fabric by electrospinning to obtain semi-finished product I, and the nanofiber film protective layer Surface density is 20g / m 2 ;

[0038] (3) The semi-finished product I is impregnated, loaded with 5% granular activated carbon, the impregnation time is 10min...

Embodiment 2

[0043] A preparation method for a multi-layer structure nanofiber composite membrane used for filtering particulate matter in the air, comprising the following steps:

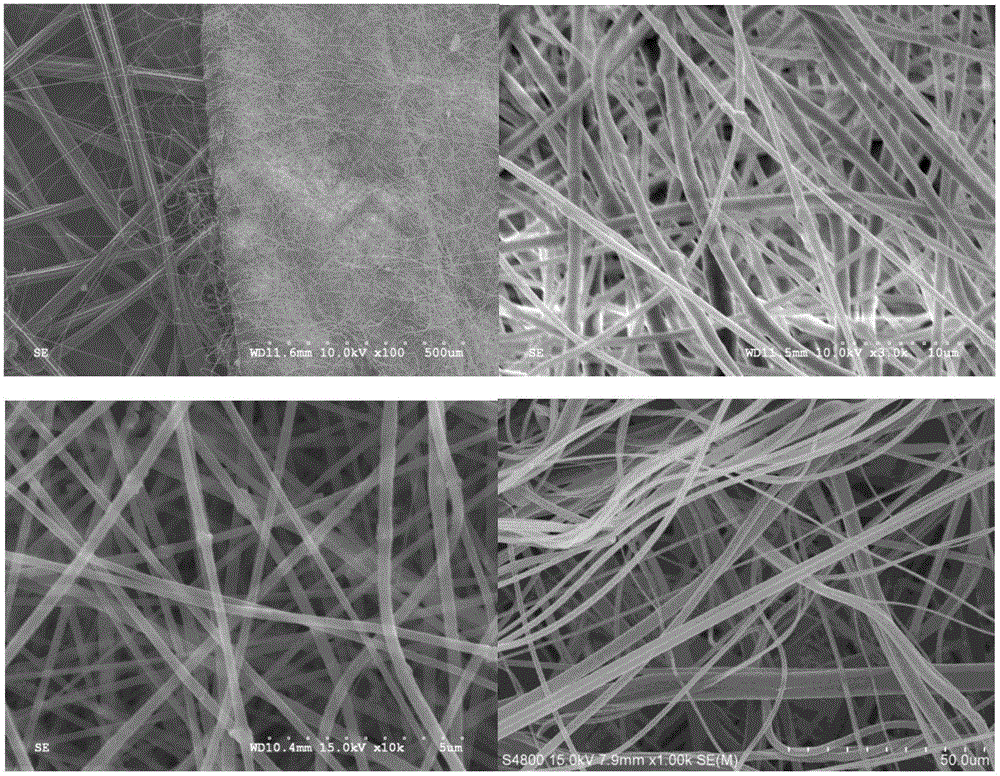

[0044] (1) The first nanofiber film layer and the second nanofiber film layer are sequentially spun into the woven fabric by electrospinning. The receiving device used in electrospinning is a drum receiving device, and the drum speed is 35r / min. , the voltage is 42KV, the distance from the needle to the receiving template is 11.2cm, the ambient temperature is 37°C, and the ambient relative humidity is 25%;

[0045] (2) The first nanofiber film layer is obtained by mixing PES with 3% TiO 2 Nano particle additives are prepared by electrospinning. Among them, TiO 2 The average diameter of the nanoparticles is 25 nm. The average fiber diameter is 350 nm. The second nanofibrous membrane layer is made of PVDF with 3% TiO 2 Nano particle additives are prepared by electrospinning. Among them, TiO 2 The average d...

Embodiment 3

[0051] A preparation method for a multi-layer structure nanofiber composite membrane used for filtering particulate matter in the air, comprising the following steps:

[0052] (1) at 20g / m 2 The PP filament non-woven fabric is spun into the first nanofiber film layer and the second nanofiber film layer sequentially by electrospinning. The receiving device used in electrospinning is a drum type receiving device, and the drum speed is 40r / min. , the voltage is 44KV, the distance from the needle to the receiving template is 11.5cm, the ambient temperature is 37°C, and the ambient relative humidity is 30%;

[0053] (3) The fabrication process of the first nanofiber film layer is prepared by electrospinning PVDF and 20% ZnO nanoparticle precursor additives, and subjecting the nanofiber film to 120° heat treatment. Wherein, the average diameter of the ZnO nanoparticles in the PVDF fiber is 20nm, and the average diameter of the fiber is 1.5um. The second nanofiber film layer is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com