Preparation method and application of polydopamine modified ZIF-8 functionalized nanofiber membrane

A ZIF-8, nanofiber membrane technology, applied in chemical instruments and methods, fiber types, fiber processing, etc., can solve the problems of poor practical applicability of adsorbents, complicated use of adsorbents, and inability to reuse them. Application prospect, low cost, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

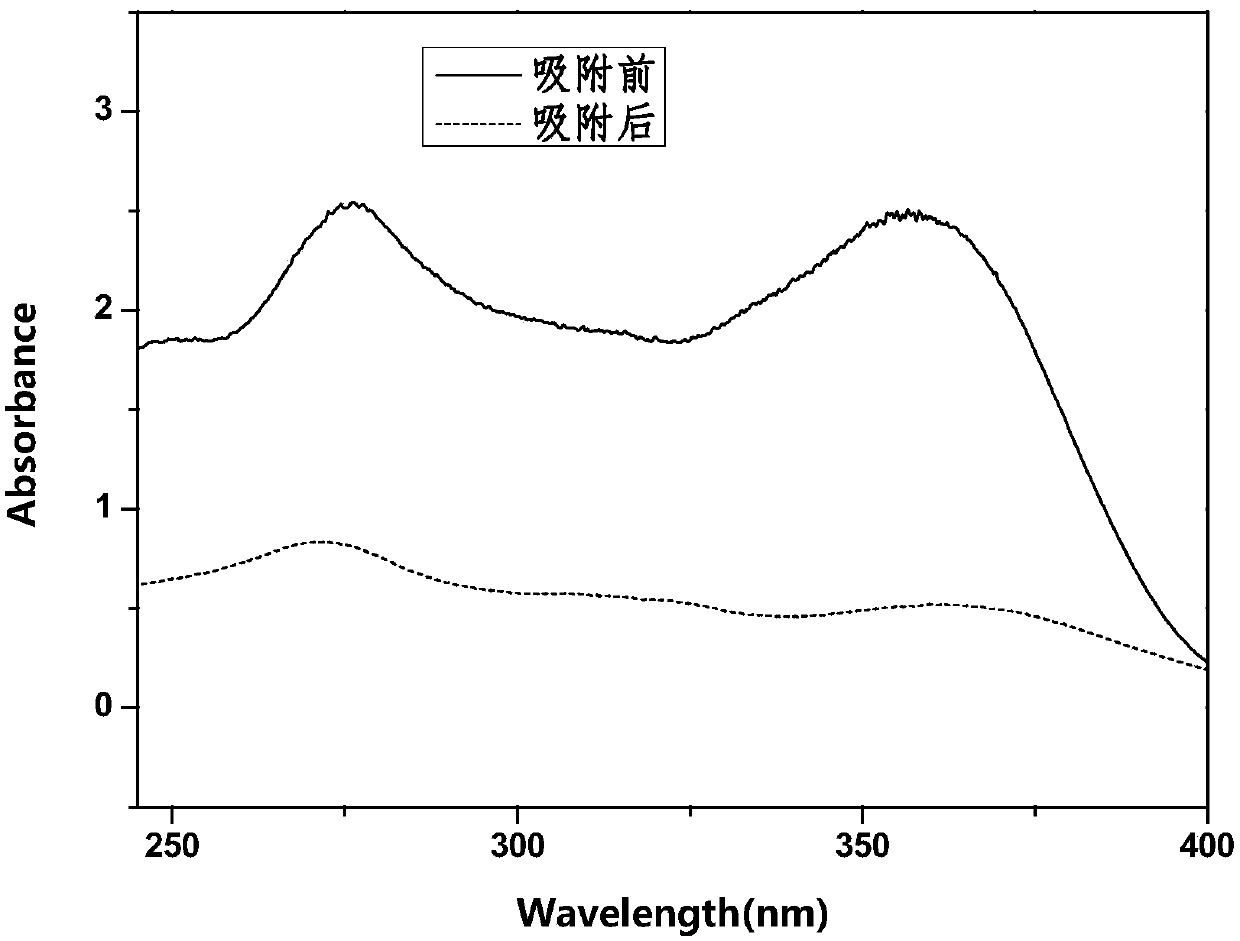

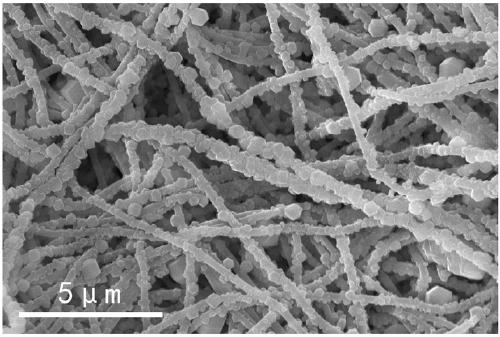

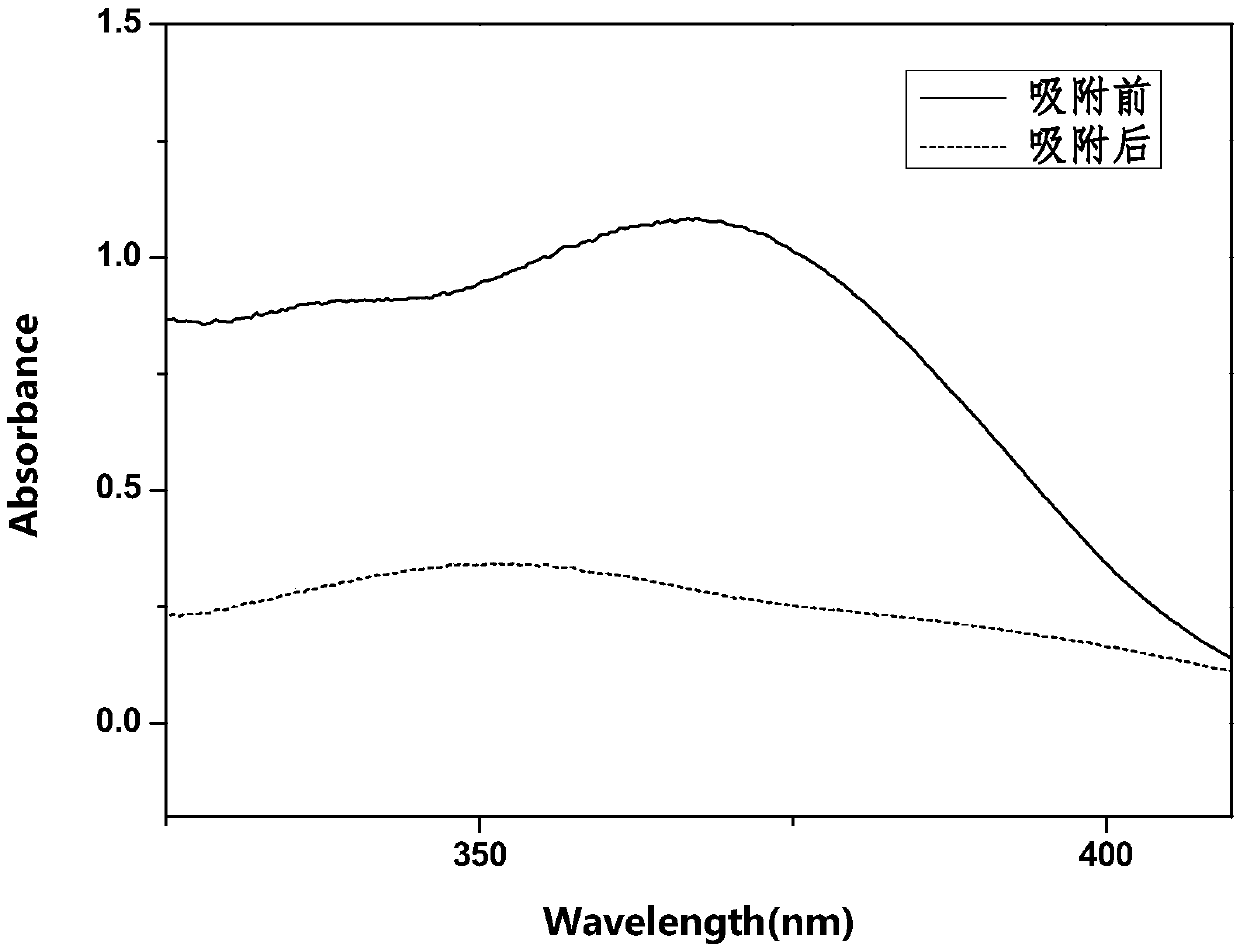

[0029]Dissolve polyacrylonitrile in the solvent N,N-dimethylformamide, heat and stir at 70°C until completely dissolved, wherein the mass fraction of polyacrylonitrile is 8.5wt%; after the solution is completely dissolved, a spinning solution is obtained, Electrospin the spinning solution; take 80mL of 50mM tris(hydroxymethyl)aminomethane hydrochloride buffer solution, adjust the pH to 8.5 with 0.1M HCl and 0.1M NaOH, then add 180mg of dopamine hydrochloride to obtain a mixed solution . The obtained 120mg electrospun nanofibers were soaked with absolute ethanol and placed in the mixed solution, heated and stirred at 45°C for 24h, then placed in a drying oven at 60°C for 8h; the obtained nanofiber membrane was immersed in Into 20mL of an aqueous solution containing 0.1095g of zinc nitrate hexahydrate, ultrasonically for 10min, and heated and stirred at 45°C for 30min, then add 20mL of an aqueous solution containing 2.2659g of 2-methylimidazole, and stand at 45°C for 30min; cool...

Embodiment 2

[0031] Dissolve polyacrylonitrile in the solvent N,N-dimethylformamide, heat and stir at 65°C until completely dissolved, wherein the mass fraction of polyacrylonitrile is 9wt%; after the solution is completely dissolved, a spinning solution is obtained, and the The spinning solution is electrospun; take 80mL of 45mM tris(hydroxymethyl)aminomethane hydrochloride buffer solution, adjust the pH to 8.0 with 0.1M HCl and 0.1M NaOH, and then add 200mg of dopamine hydrochloride to obtain a mixed solution. The obtained 200mg electrospun nanofibers were soaked with absolute ethanol and placed in the mixed solution, heated and stirred at 45°C for 24h, then placed in a drying oven at 60°C for 8h; the obtained nanofiber membrane was immersed in Into 40mL of an aqueous solution containing 0.2513g of zinc nitrate hexahydrate, ultrasonicated for 10min, heated and stirred at 45°C for 50min, then added 40mL of an aqueous solution containing 5.0132g of 2-methylimidazole, and kept at 45°C for 40...

Embodiment 3

[0033] Dissolve polyacrylonitrile in the solvent N,N-dimethylformamide, heat and stir at 70°C until completely dissolved, wherein the mass fraction of polyacrylonitrile is 8.5wt%; after the solution is completely dissolved, a spinning solution is obtained, Electrospin the spinning solution; take 80mL of 50mM tris(hydroxymethyl)aminomethane hydrochloride buffer solution, adjust the pH to 8.3 with 0.1M HCl and 0.1M NaOH, then add 220mg of dopamine hydrochloride to obtain a mixed solution . The obtained 150 mg electrospun nanofibers were soaked with absolute ethanol and placed in the mixed solution, heated and stirred at 45°C for 24 hours, then placed in a drying oven at 60°C for 8 hours; the obtained nanofiber membrane was immersed in Into 30mL aqueous solution containing 0.2945g zinc nitrate hexahydrate, ultrasonic 10min, and heated and stirred at 45°C for 1h, then add 30mL aqueous solution containing 4.9260g 2-methylimidazole, and stand at 45°C to continue heating for 1h; Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com