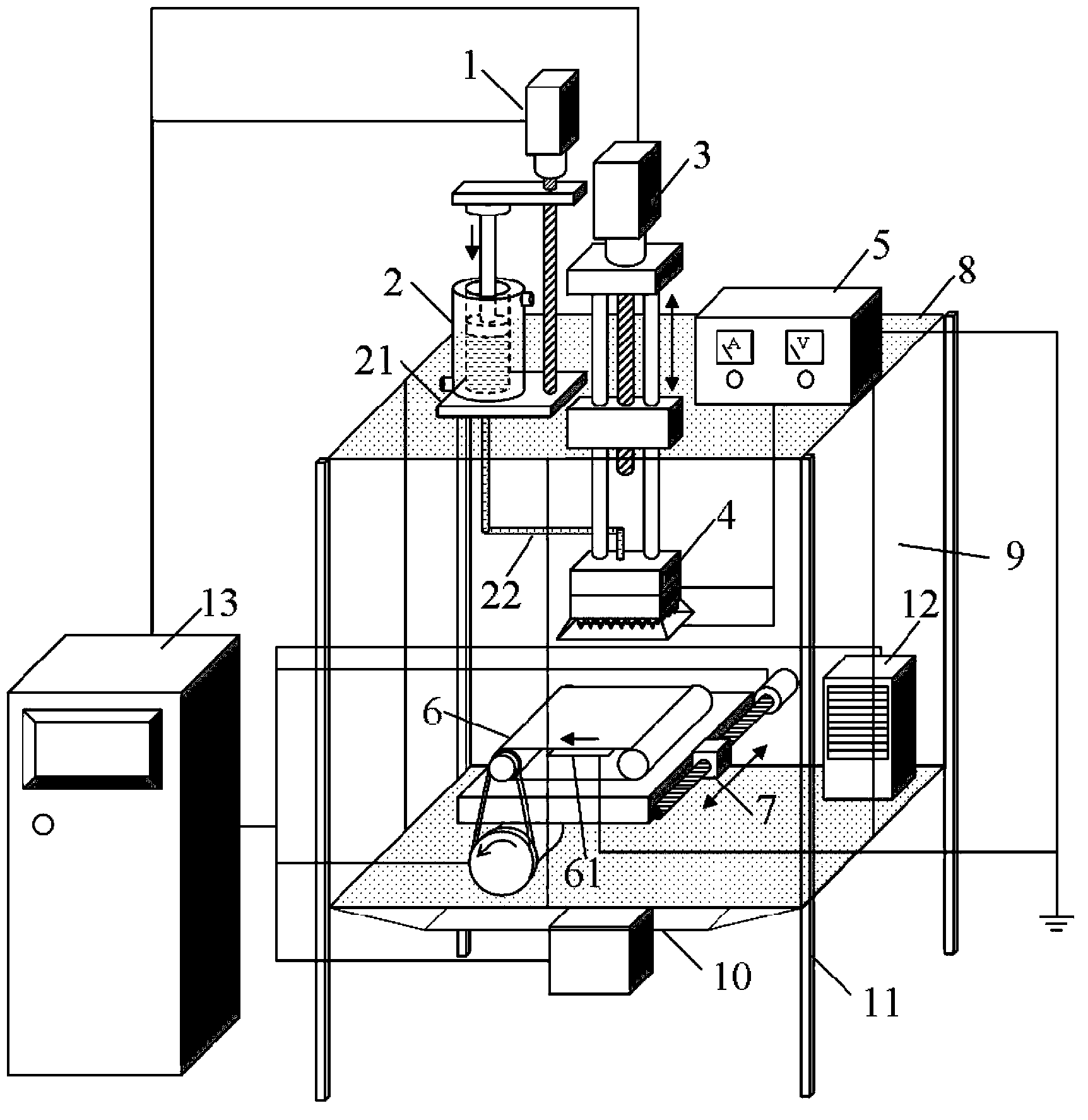

Multi-spraying-nozzle electrostatic spinning device with controllable spinning environment

An electrospinning and multi-nozzle technology, which is applied in the direction of spinneret assemblies, textiles and papermaking, filament/thread forming, etc., can solve problems such as electrostatic field interference of spinnerets, and achieve improved spinning efficiency and good industrialization The effect of production application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

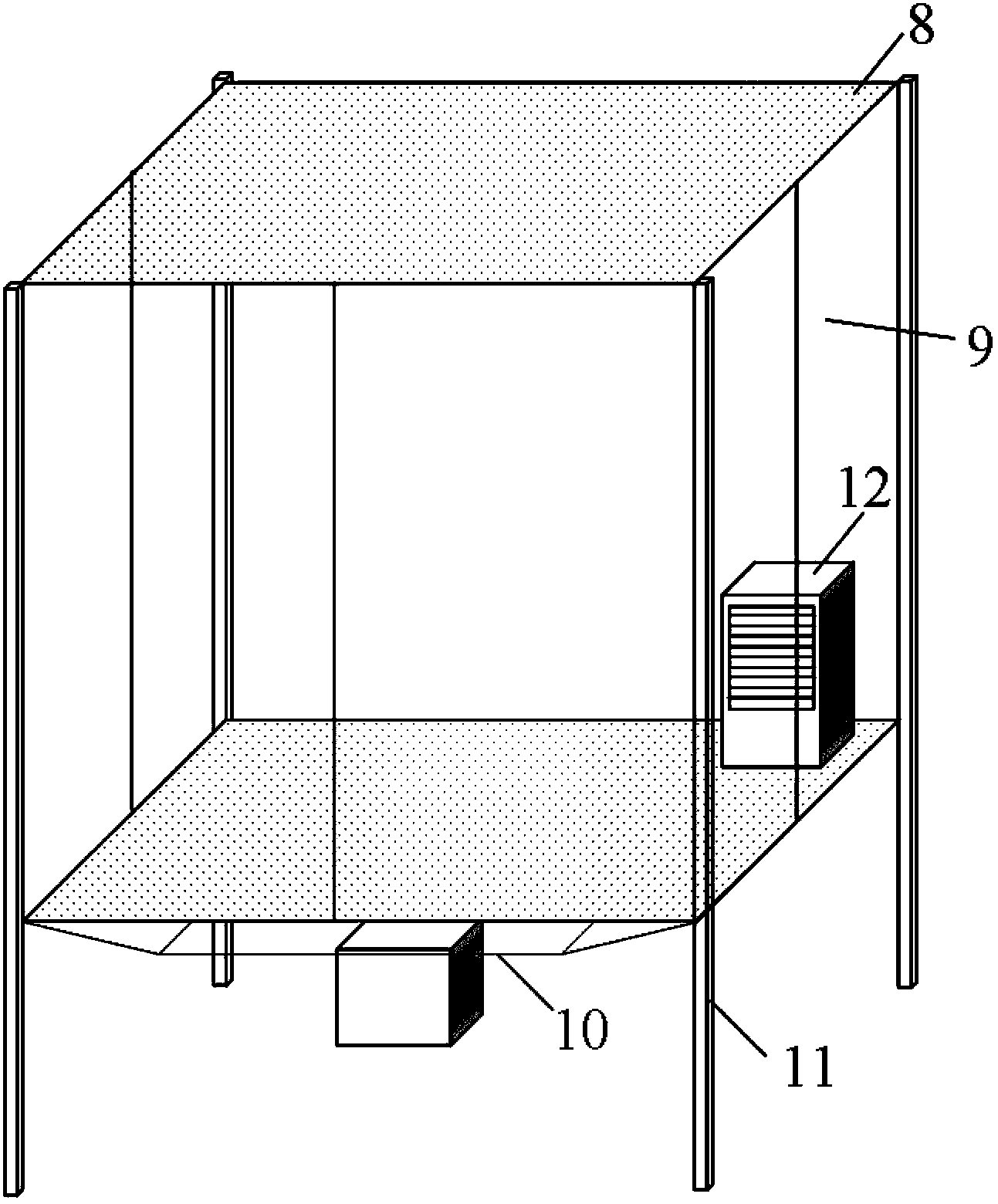

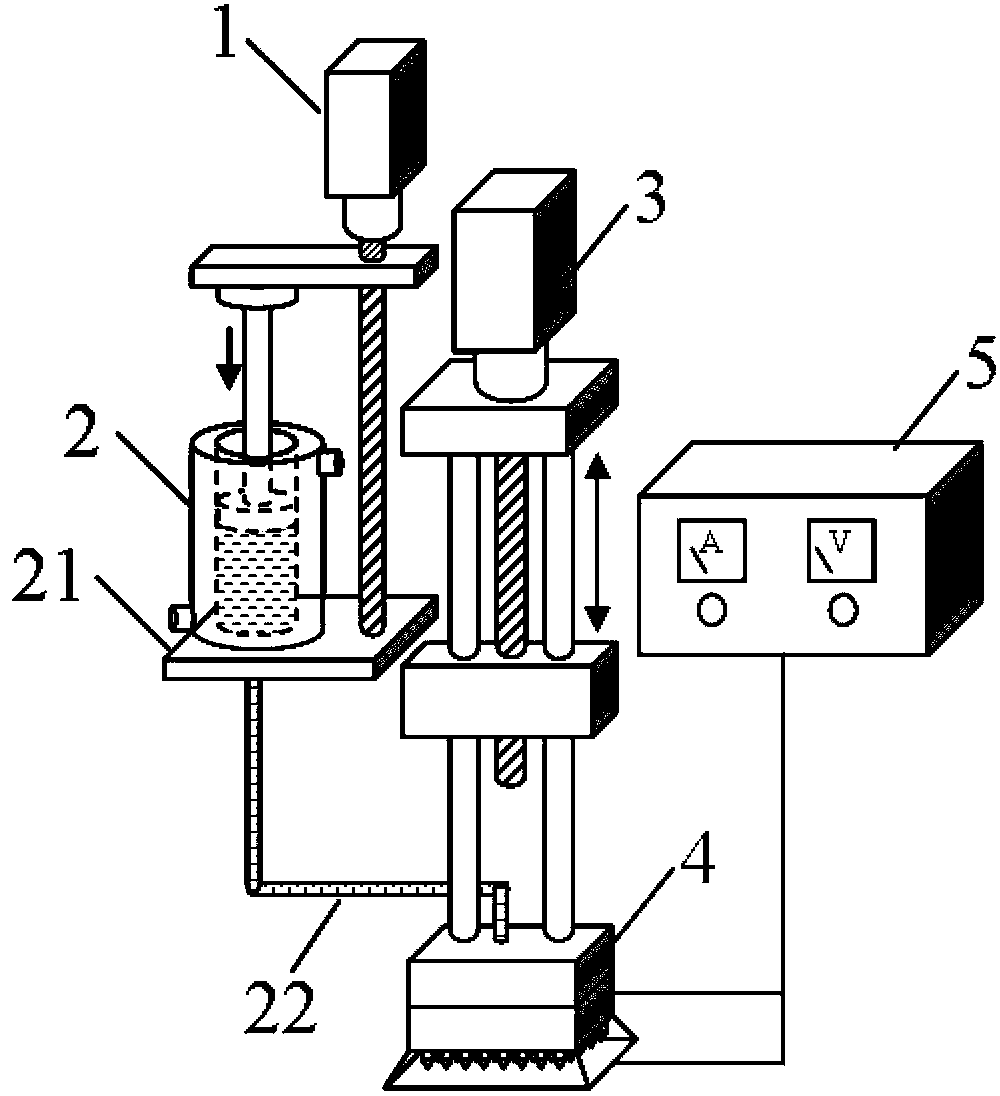

Method used

Image

Examples

Embodiment 1

[0039] It is worth mentioning that the present invention carries out electrospinning of aqueous polymer solution, and its spinning conditions are: spinning environment temperature is 25℃; spinning environment humidity is 55%RH; spinning solution advance speed is 16.0μL / min; The number of spinnerets is 10, the diameter of the spinneret capillary holes is 0.1mm, the height of the metal nozzle is 10mm, and the spinneret spacing is 1cm, distributed in a longitudinal row, perpendicular to the moving direction of the receiving track ; The applied electrostatic voltage is 45~75kV; the distance between the spinneret and the receiving surface is 150mm; the receiving surface is aluminum foil; the moving speed of the receiving crawler is 100mm / min; the horizontal moving speed of the receiving surface is 100mm / min; the horizontal moving distance of the receiving surface It is 200mm.

[0040] The spinning process is as follows: adding a 10wt% polyoxyethylene (PEO) aqueous solution with a wei...

Embodiment 2

[0043] It is worth mentioning that the present invention carries out electrospinning of aqueous polymer solution, and its spinning conditions are: spinning environment temperature is 35°C; spinning environment humidity is 50%RH; spinning solution advancing speed is 18.0μL / min; the number of spinnerets is 20, the pore diameter of the spinneret is 0.2mm, the height of the metal nozzle is 5-15mm, and the distance between the spinnerets is 1cm, distributed in two longitudinal rows, the distance between each row 3cm, and perpendicular to the moving direction of the receiving track; the applied electrostatic voltage is 60-100kV; the distance between the spinneret and the receiving surface is 150mm; the receiving surface is non-woven; the moving speed of the receiving crawler is 100mm / min; the receiving surface moves horizontally The speed is 100mm / min; the horizontal movement distance of the receiving surface is 200mm.

[0044] The spinning process is as follows: adding a polyvinyl al...

Embodiment 3

[0047] It is worth mentioning that the present invention carries out electrospinning of organic phase polymer solution, and its spinning conditions are: spinning environment temperature is 45℃; spinning environment humidity is 50%RH; spinning solution advancing speed is 16.0μL / min; the number of spinnerets is 50, the diameter of the spinneret capillary is 0.2mm, the height of the metal nozzle is 5-25mm, the spinneret spacing is 1cm, distributed in 5 columns, the distance between each column 2cm, and perpendicular to the moving direction of the receiving track; the applied electrostatic voltage is 55~85kV; the distance between the spinneret and the receiving surface is 200mm; the receiving surface is aluminum foil; the moving speed of the receiving crawler is 150mm / min; the horizontal moving speed of the receiving surface is 100mm / min; the horizontal movement distance of the receiving surface is 200mm.

[0048] The spinning process is as follows: the N,N-dimethylformamide (DMF) s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com