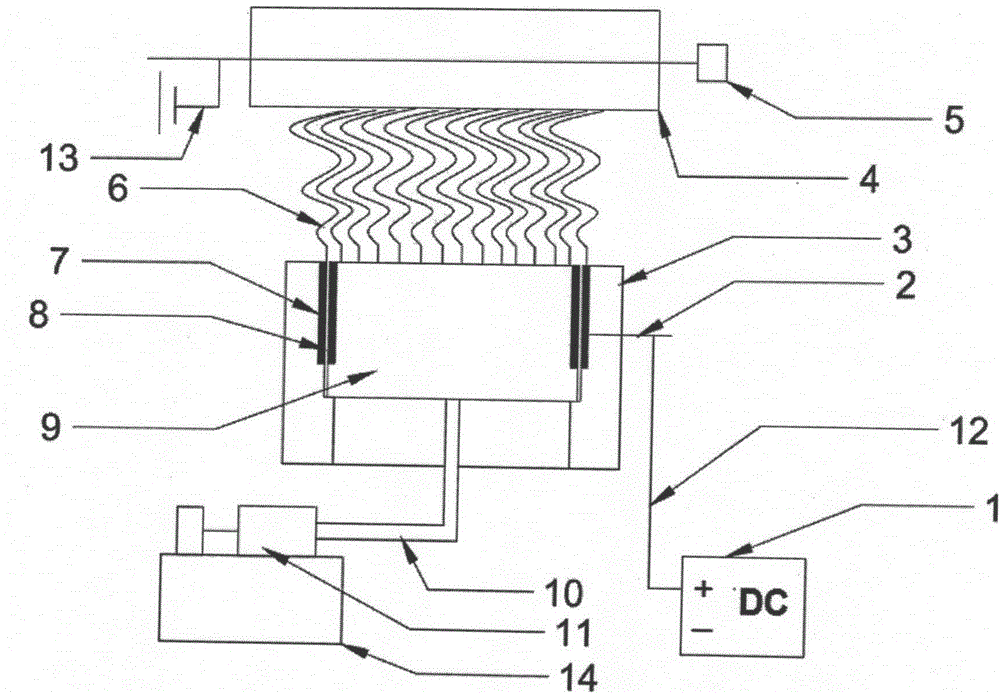

Double-circular-ring-shaped slit type electrostatic spinning device and method

An electrospinning, ring-shaped technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of non-oriented nanofiber product structure, easy large amount of solvent volatilization, insufficient solution utilization, etc. Achieve the effect of realizing industrialized preparation, solving the problem of easy volatilization of solvents and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare nanofibers by preparing polymer solution with polyacrylonitrile (PAN) and N,N dimethylformamide (DMF):

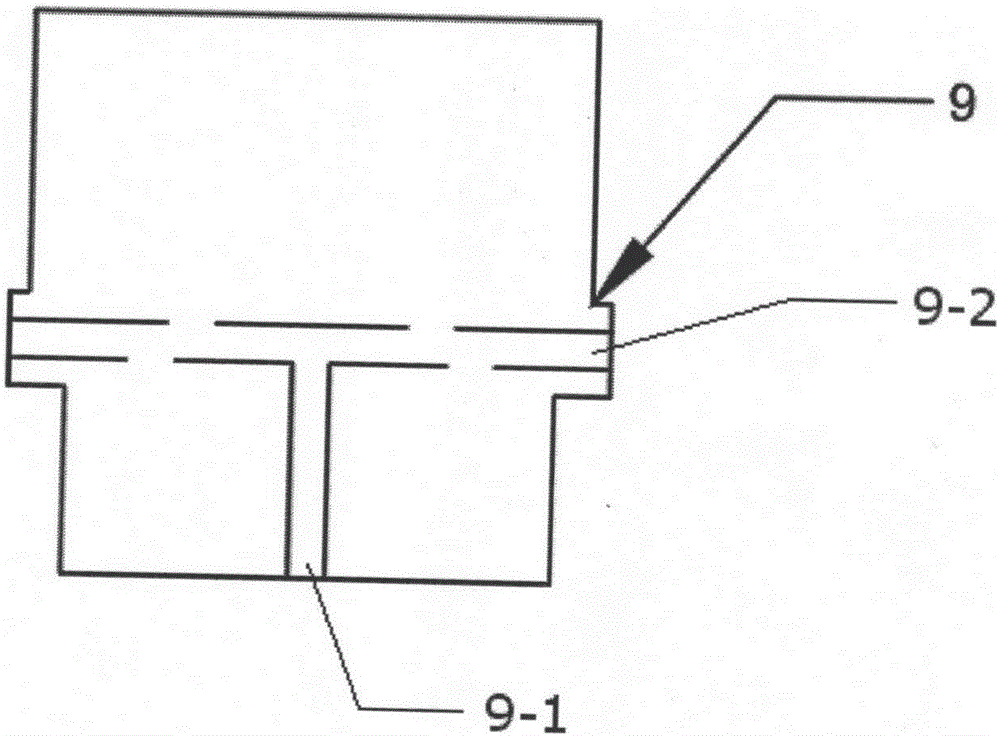

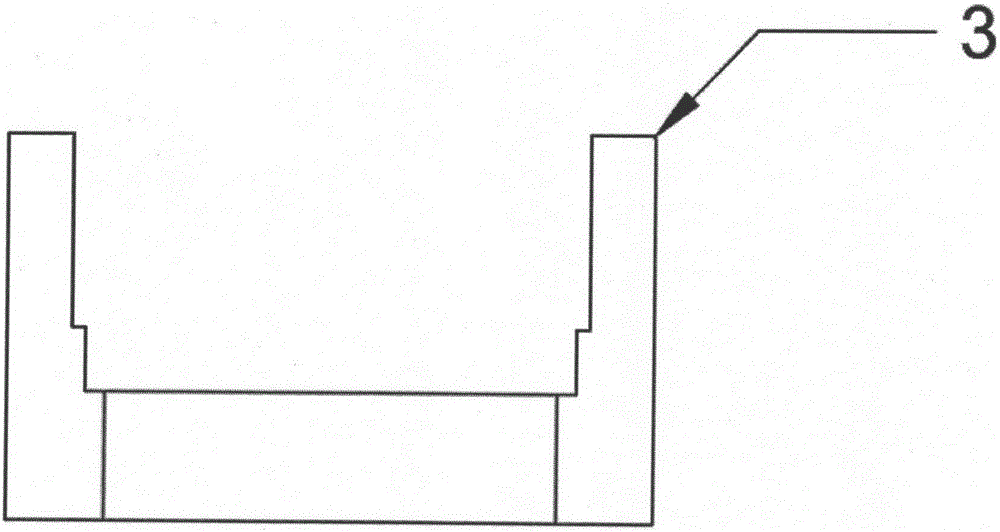

[0035] The mass fraction of the prepared PAN polymer solution is 10%. Put the configured PAN polymer solution into the syringe 11, set the distance from the main shaft of the metal roller 4 to the upper plane of the double-circular slit nozzle system to 300mm, turn on the speed regulating motor 5, and drive the metal roller 4 Rotate, adjust the rotating speed of the metal roller to 50r / min, the polymer solution flows into the tiny channel 9-2 inside the inner core 9 through the infusion tube 10, and finally enters the slit; turn on the high-voltage electrostatic generator 1, slowly increase the voltage, when the voltage After exceeding a certain value, multiple jets 6 will appear in the slit, the solvent of the jets 6 will volatilize during flight, and the high polymer will solidify to form nanofibers and deposit on the metal roller 4 .

Embodiment 2

[0037] The difference from Example 1 is that the rotational speed of the metal roller is 300r / min.

Embodiment 3

[0039] The difference from Example 1 is that the rotational speed of the metal roller is 800r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com