A linear trough-shaped needle-free electrospinning device and spinning method

An electrospinning, straight-line technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problem of the stability of nanofiber preparation that affects the concentration of spinning solution, the preparation of nanofibers is not smooth, and the design process is complicated and other problems, to achieve the effect of solving the complex structure design of the nozzle, realizing automatic and accurate supply, and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

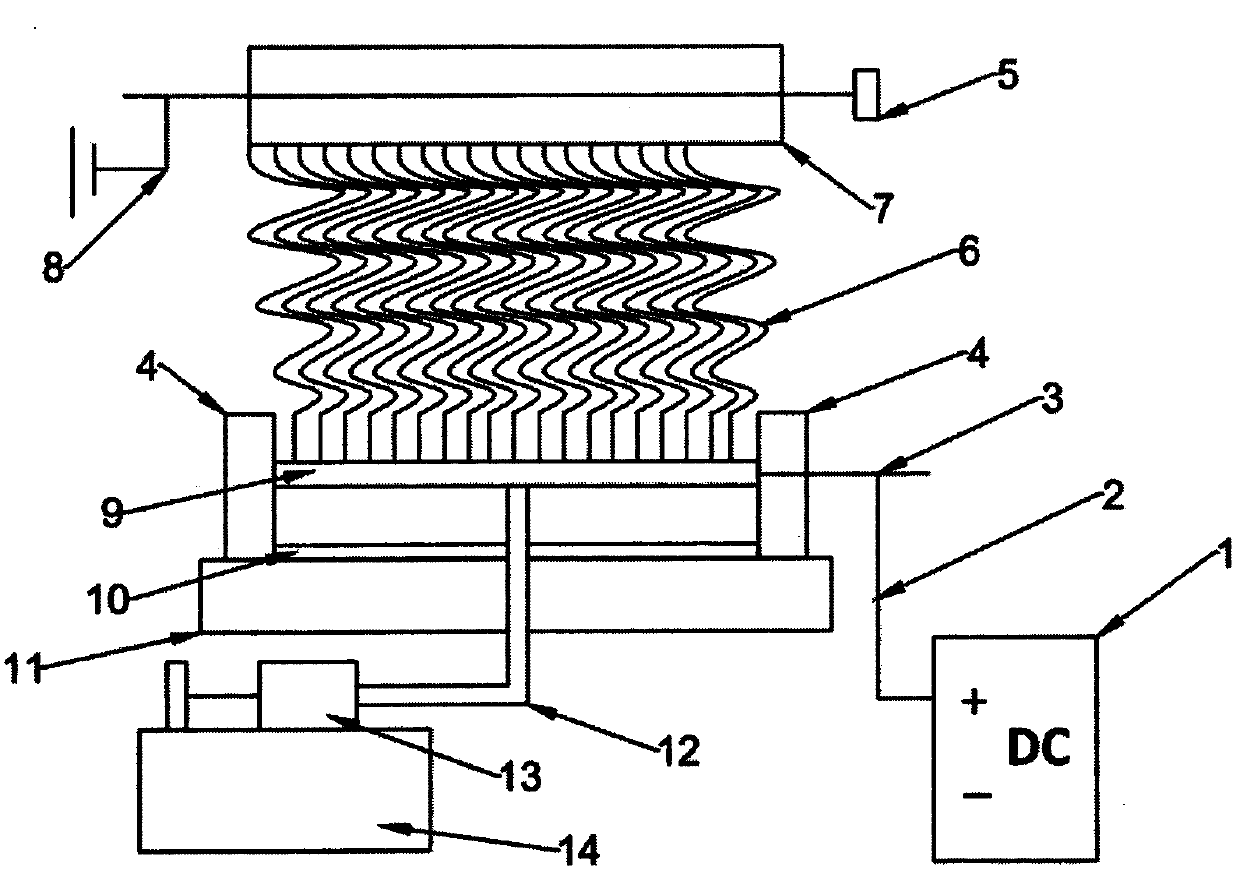

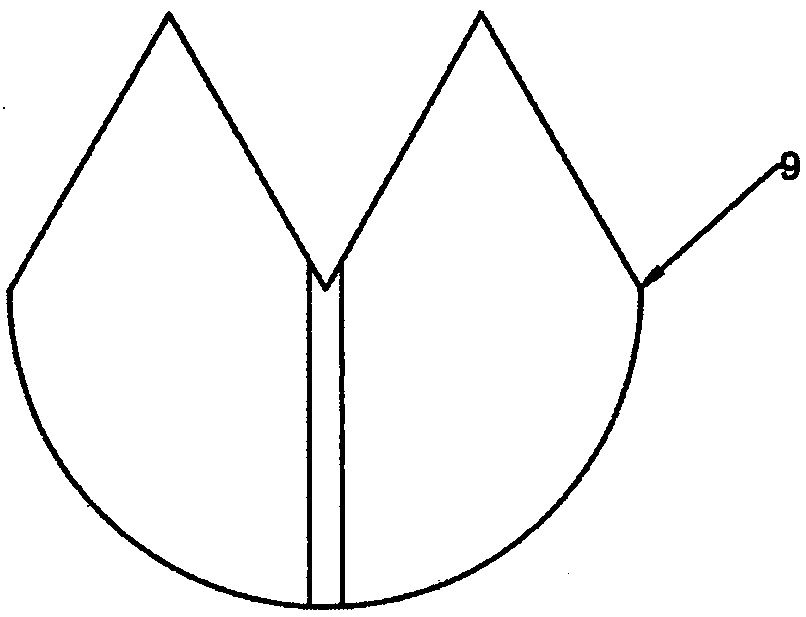

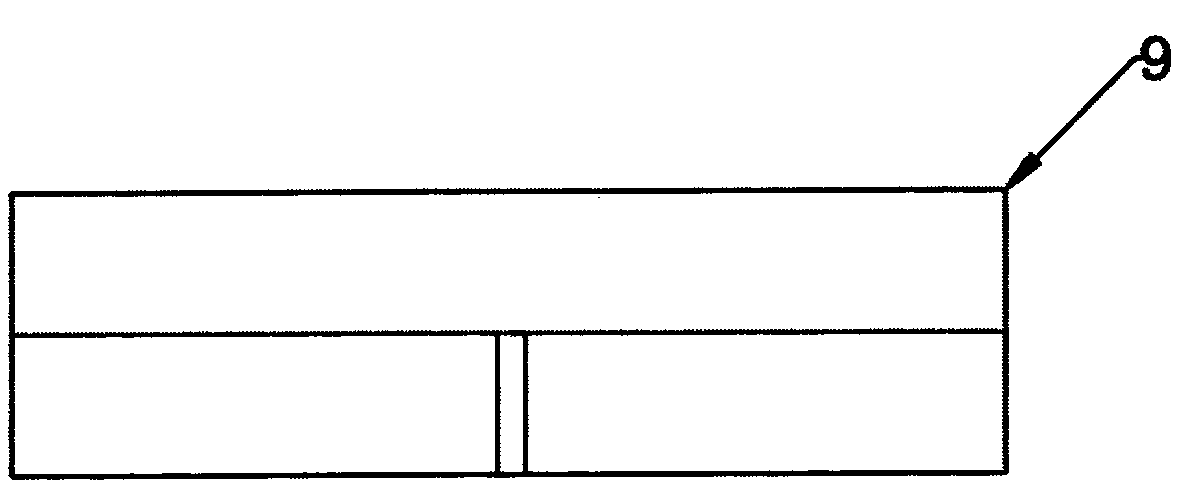

[0046] Next, nanofibers are prepared by using a polymer solution prepared from polyacrylonitrile (PAN) and N,N dimethylformamide (DMF). The mass fraction of the prepared PAN polymer solution is 12%. Fix the linear groove-shaped nozzle 9 horizontally on the brackets 4 at both ends, and fix the brackets 4 at both ends vertically on the polytetrafluoroethylene plate 11, place the solution recovery tank 10 directly below the linear groove-shaped nozzle 9, and metal screws 3 is connected to the linear groove-shaped nozzle 9, the metal screw 3 is connected to the positive electrode of the high-voltage electrostatic generator 1 through the metal wire 2, one end of the infusion tube 12 is connected to the micropore at the bottom center of the linear groove-shaped nozzle 9, and the other end is connected to the medical syringe 13 is connected, and the solution flow rate of the medical syringe 13 is controlled by the micro-injection pump 14. The cylindrical metal roller 7 for collectin...

Embodiment 2

[0048] Fix the linear groove-shaped nozzle 9 horizontally on the brackets 4 at both ends, and fix the brackets 4 at both ends vertically on the polytetrafluoroethylene plate 11, place the solution recovery tank 10 directly below the linear groove-shaped nozzle 9, and metal screws 3 is connected to the linear groove-shaped nozzle 9, the metal screw 3 is connected to the positive electrode of the high-voltage electrostatic generator 1 through the metal wire 2, one end of the infusion tube 12 is connected to the micropore at the bottom center of the linear groove-shaped nozzle 9, and the other end is connected to the medical syringe 13 is connected, and the solution flow rate of the medical syringe 13 is controlled by the micro-injection pump 14. The cylindrical metal roller 7 for collecting nanofibers is connected to the speed regulating motor 5 , and the cylindrical metal roller 7 is connected to the ground wire 8 . Set the vertical distance from the linear trough nozzle to the...

Embodiment 3

[0050] Fix the linear groove-shaped nozzle 9 horizontally on the brackets 4 at both ends, and fix the brackets 4 at both ends vertically on the polytetrafluoroethylene plate 11, place the solution recovery tank 10 directly below the linear groove-shaped nozzle 9, and metal screws 3 is connected to the linear groove-shaped nozzle 9, the metal screw 3 is connected to the positive electrode of the high-voltage electrostatic generator 1 through the metal wire 2, one end of the infusion tube 12 is connected to the micropore at the bottom center of the linear groove-shaped nozzle 9, and the other end is connected to the medical syringe 13 is connected, and the solution flow rate of the medical syringe 13 is controlled by the micro-injection pump 14. The cylindrical metal roller 7 for collecting nanofibers is connected to the speed regulating motor 5 , and the cylindrical metal roller 7 is connected to the ground wire 8 . Set the vertical distance from the linear trough nozzle to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com