Method and device for evaluating pilling resistance of yarn by on-line inlet and outlet measurement mode

A technology for pilling and evaluating devices, which is used in measurement devices, preparation of test samples, material analysis by optical means, etc., can solve the problems of inability to obtain the appearance and morphological characteristics of hairiness and hairballs, inability to observe, and to be different. , to achieve the effect of fast measurement, strong contrast and land saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

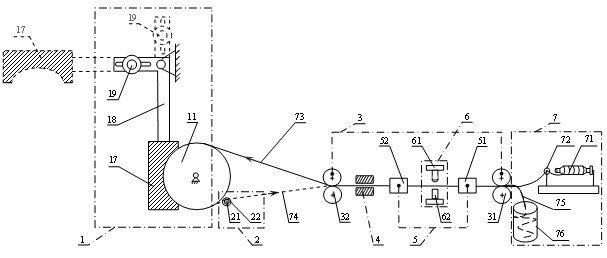

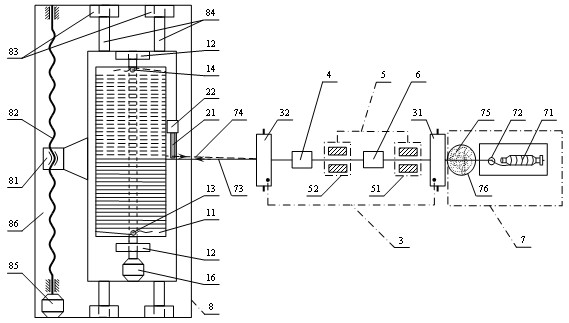

[0037] Such as figure 1 As shown, it is a side view of the yarn pilling evaluation device with in-line and out-of-line measurement, figure 2 Its top view, the described yarn fluffing and pilling evaluation device with double measurement in and out of line is composed of a yarn winding friction mechanism 1, an unwinding tension measuring mechanism 2, a yarn feeding and unwinding mechanism 3, a capacitor plate 4, and an electrostatic generating device 5 , yarn hairiness measurement system 6, yarn supply and collection device 7, reciprocating mechanism 8 and data acquisition and control system 9.

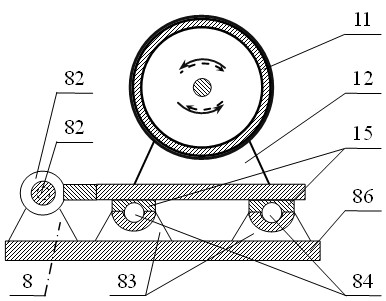

[0038] The yarn winding friction mechanism 1 consists of a yarn winding bobbin 11, a winding bobbin support 12, a left yarn end fixer 13, a right yarn end fixer 14, a double slide bar bushing 15, a yarn winding bobbin stepping motor 16, a friction Block 17, right angle bar 18 and pressure weight 19 form. The lower side of the winding bobbin support 12 is fixedly connected with the d...

Embodiment 2

[0064] Adopt the yarn pilling and pilling evaluation device of online in-out double measurement described in embodiment 1, to 32 S The pilling property of wool yarn is measured.

[0065] The whole measurement and evaluation method is to first measure the thickness and unevenness of the yarn and the fluff and pilling amount of the yarn online, and then measure the thickness and unevenness of the yarn after winding forming, friction sample preparation and smooth unwinding And the fluff and pilling amount of the yarn, that is, the in-situ measurement, and compare the two sets of measured data to give the evaluation of the yarn fluff and pilling.

[0066] The specific implementation steps are:

[0067] Step 1: input the prediction evaluation, the yarn is withdrawn from the bobbin 71, fluffed by the yarn guide hook 72, the front clamping roller 31, and the front electrostatic generator 51, and enters the yarn hairiness measurement system 6 prediction evaluation The diameter o...

Embodiment 3

[0075] Adopt the device identical with embodiment 2 and similar method, same yarn sample (32 S Wool yarn), the same way of clamping and loading the yarn, the same measurement and measurement content, but the asymmetric rotation in the reciprocating rotation of the winding bobbin 11 is adopted, that is, the forward rotation angle is 60o, and the reverse rotation angle is 54o , the supporting reciprocating movement distance is 8cm, so that the friction block 17 applies friction to the yarn around the yarn bobbin 11 for a whole week, and the asymmetric overall rotation is 6 circles, which is equivalent to 60 times of friction at each point. It is equivalent to the friction effect of Example 2. The frequency of the reciprocating rotation is 0.2 Hz, which is the same as in Embodiment 2.

[0076]

[0077] Note: * means that the average tension cannot be carried out in the pre-evaluation measurement, so the average tension data of unwound yarn in the ungrinded area is used for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com