Patents

Literature

39results about How to "Many controllable parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for evaluating pilling resistance of yarn by on-line inlet and outlet measurement mode

InactiveCN102323120ARepresentativeMeasurement is highly targetedPreparing sample for investigationMaterial analysis by optical meansYarnTest sample

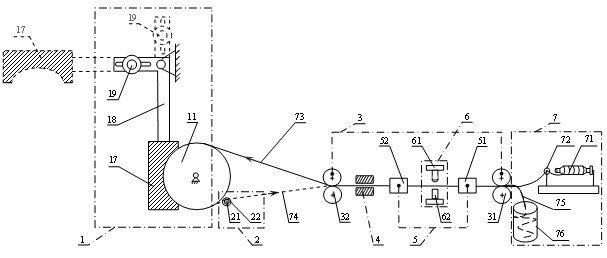

The invention relates to a method and a device for evaluating the pilling resistance of a yarn by an on-line inlet and outlet measurement mode. The method comprises the steps of input pre-evaluation, uniform winding forming, preparation of a test sample by carrying pressurizing friction, stable backing-off and on-line measurement, comparison and evaluation. The device comprises a yarn supply and recovery device, a yarn pilling condition measurement device and a winding friction mechanism. The yarn pilling condition measurement device comprises a capacitor plate, a static electricity generation device and a yarn hairness measurement system. The static electricity generation device comprises a prepositive static electricity generator and a post static electricity generator. The prepositive static electricity generator and the post static electricity generator are respectively arranged at both sides of the yarn hairness measurement system. The capacitor plate is arranged at the rear sideof the post static electricity generator. The winding friction mechanism comprises a winding drum. The separation position of the unwound yarn and the winding drum is provided with a backing-off tension measurement mechanism. The winding friction mechanism is connected with a reciprocating mechanism. In the invention, the yarn is used for directly testing and panel knitting is not used; and by taking a base yarn as the contrast, the method and the device are more accurate.

Owner:DONGHUA UNIV

Preparation method for polycarboxylic acid high-performance water reducer

The invention discloses a preparation method of a poly-carboxylic acid water reducing agent with high performance, the water reducing agent is made in simple process with low mixing amount and high dispersive property. The technical proposal is as the follow: A) methacrylic acid and methoxy polyethylene glycol with a mole ratio of 1 to 1.2: 1 are put into a reactor with catalyst, polymerization inhibitor and water carrying agent being added to be mixed and heated to 100 to 150 DEG C and kept reacting within 8 to 12 hours to obtain polyoxyethylene methacrylate; B) water and initiator are added into the reactor, then a mixing solution containing sodium allylsulfonate, the polyoxyethylene methacrylate and the methacrylic acid is added drop by drop slowly into the reactor, wherein the weight proportion of the water and the mixing solution is 2: 1 to 1.2, the solution is mixed and heated to the temperature of 80 to 120 DEG C. Chain transfer agent is added after reaction of 4 to 6 hours and the adding drop by drop being finished, and the solution is discharged after being kept mixing with heat preserved for 1 to 2 hours, the poly-carboxylic acid water reducing agent with high performance is obtained.

Owner:JIANGSU CHEM RES INST

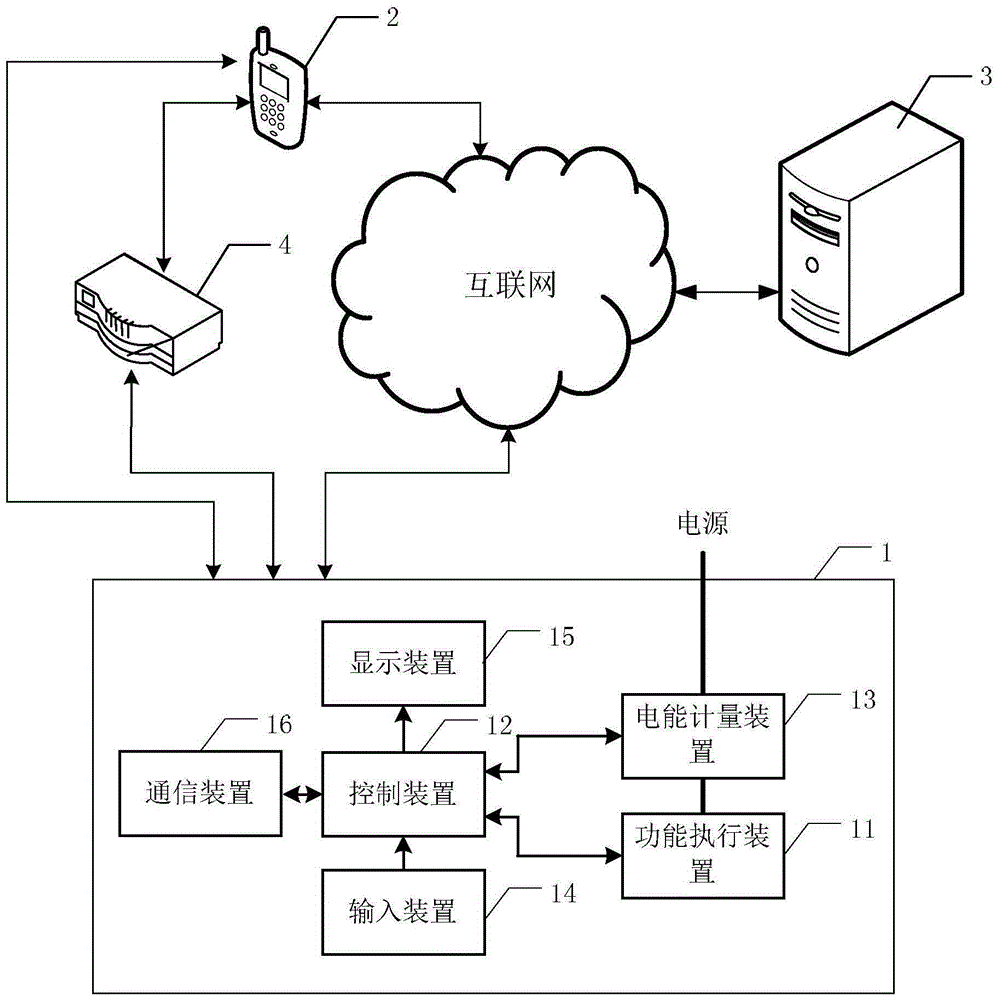

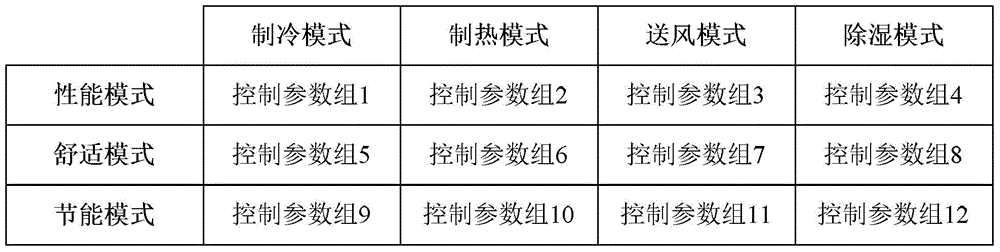

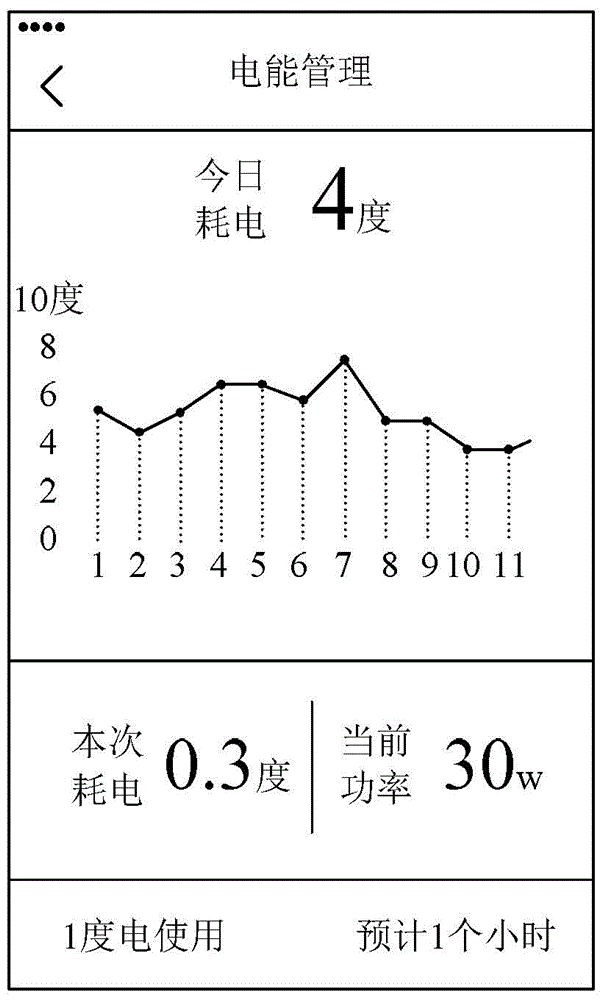

Household appliance, as well as control method and control system for same

ActiveCN105180365AMany controllable parametersVarious control modesSpace heating and ventilation safety systemsLighting and heating apparatusEmbedded systemControl mode

The invention discloses a household appliance, as well as a control method and a control system for the same. Control on a power supply and a power consumption state is added while function control is carried out by controlling a function execution device of the household appliance according to the selected power supply management mode and function control mode, thus providing more abundant control modes for a user, and providing more user-controllable parameters.

Owner:GREE ELECTRIC APPLIANCES INC

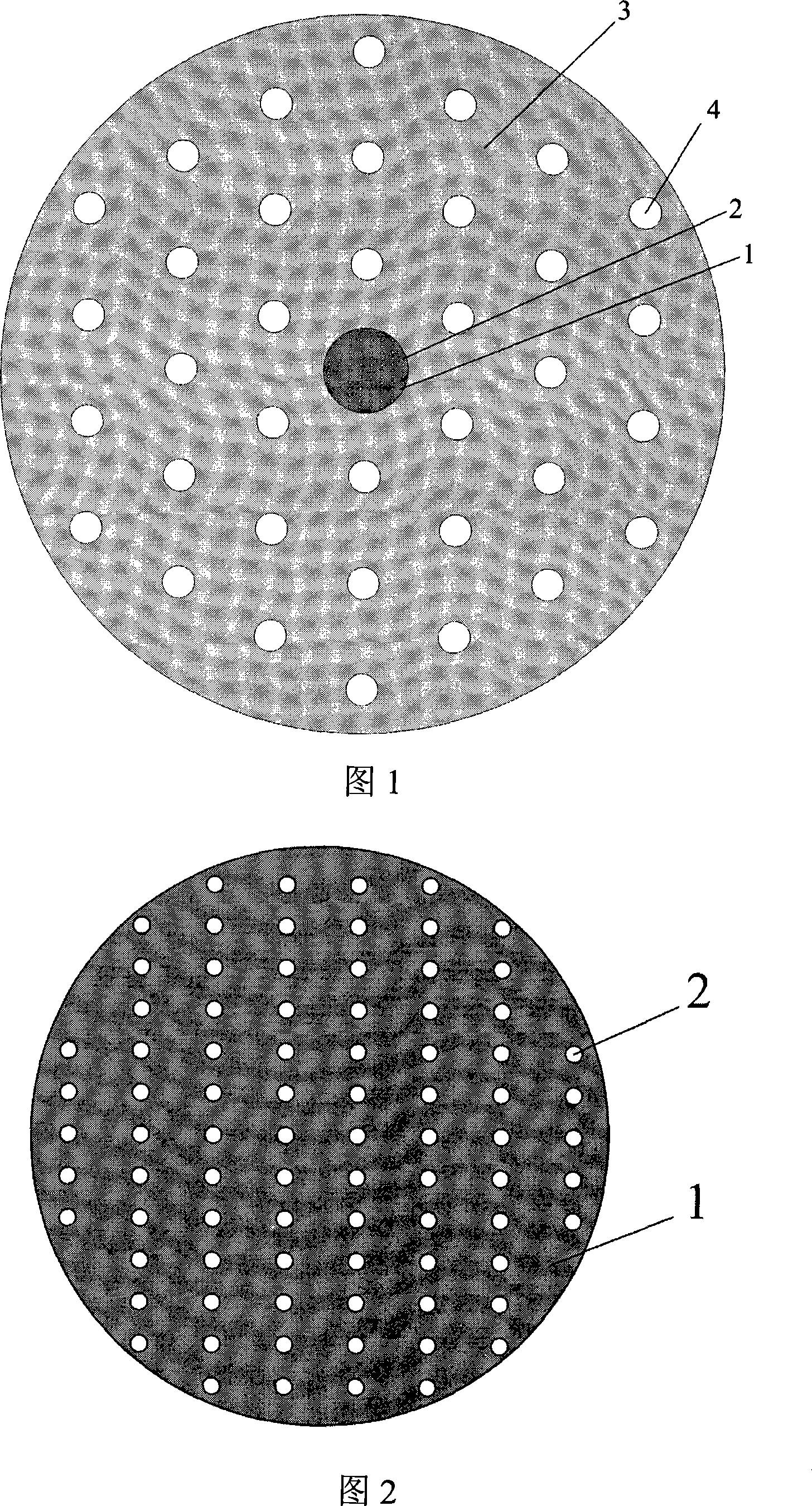

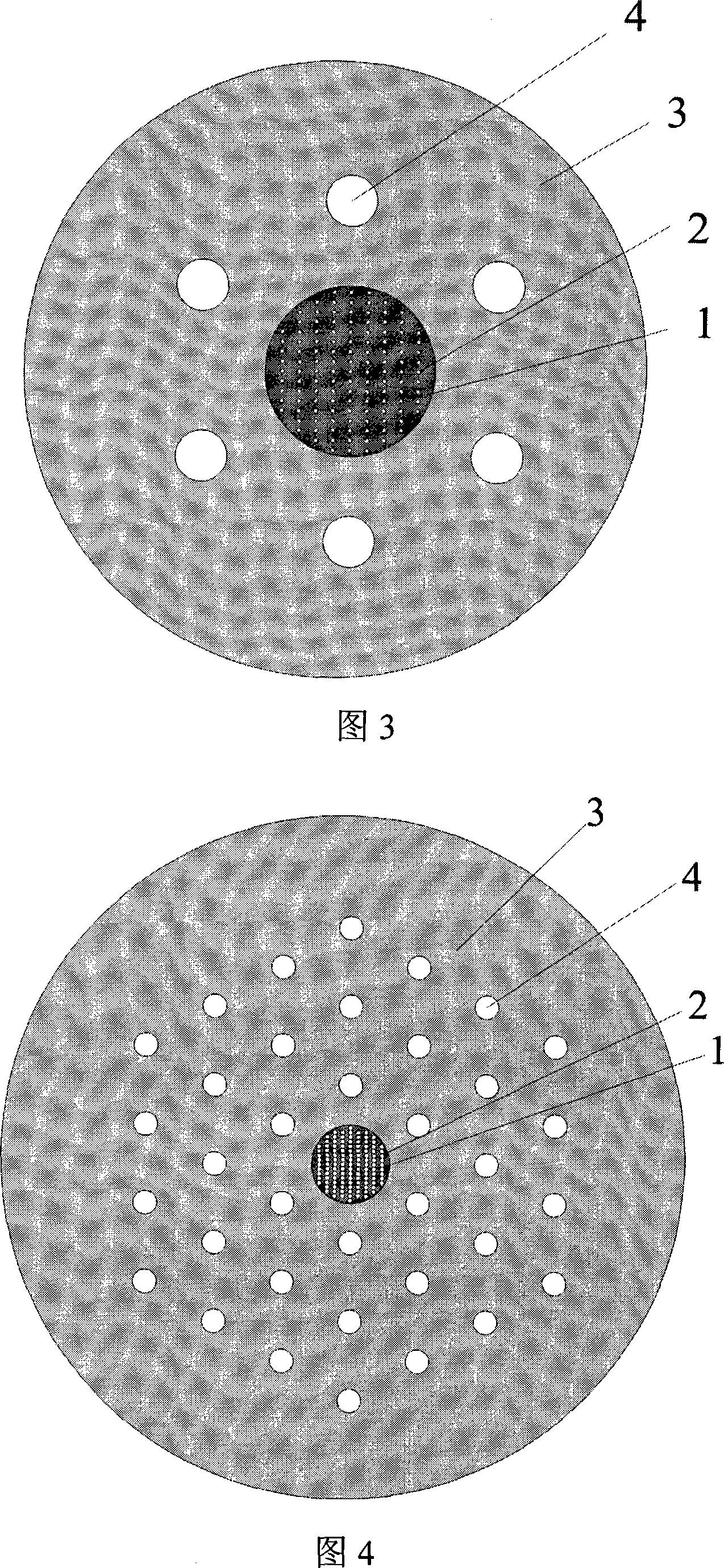

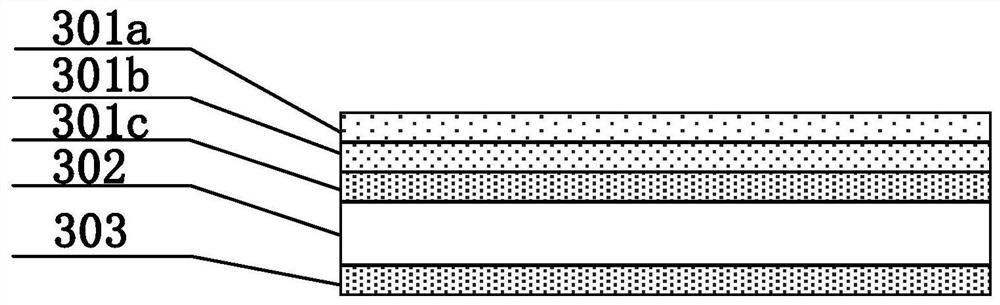

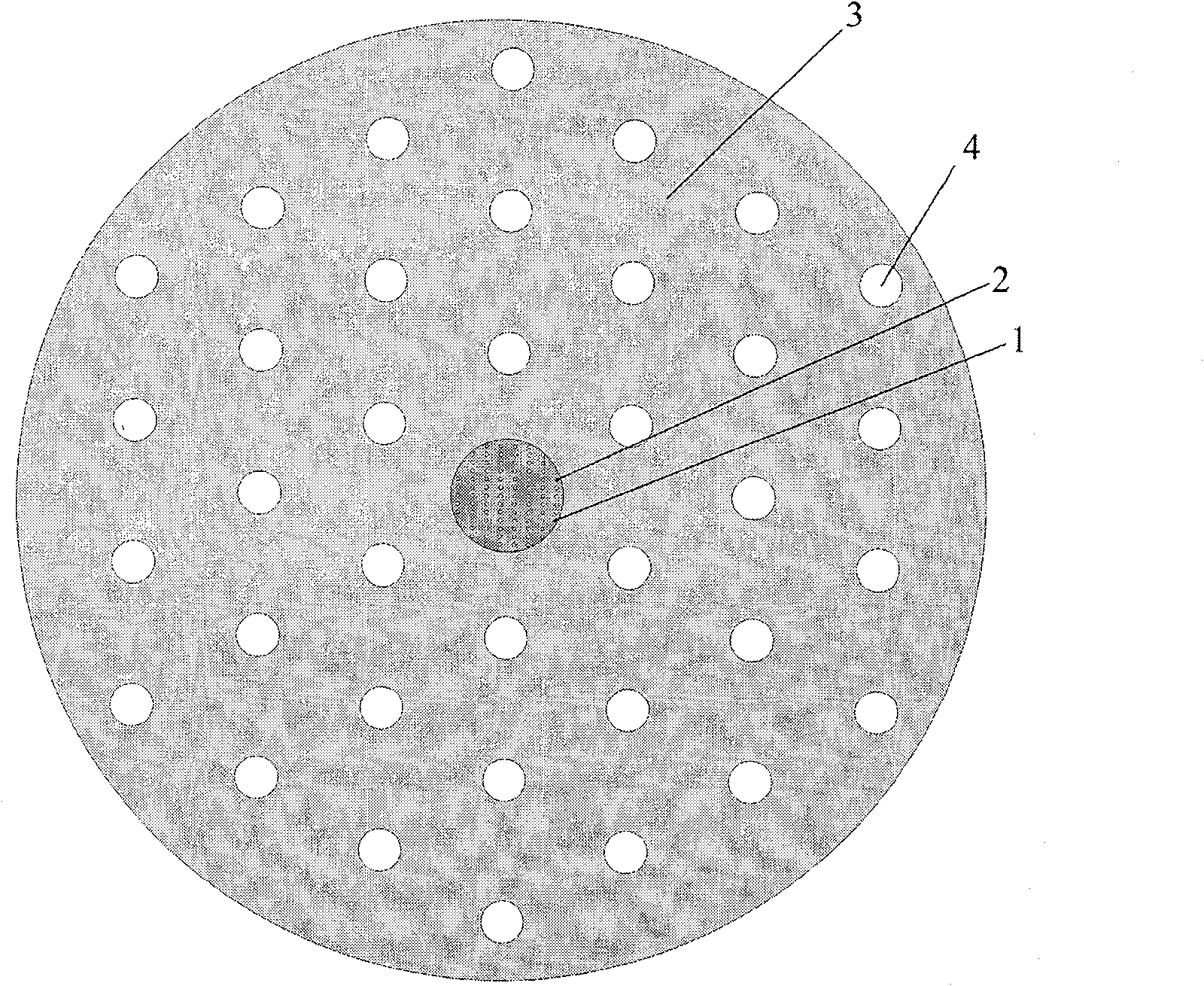

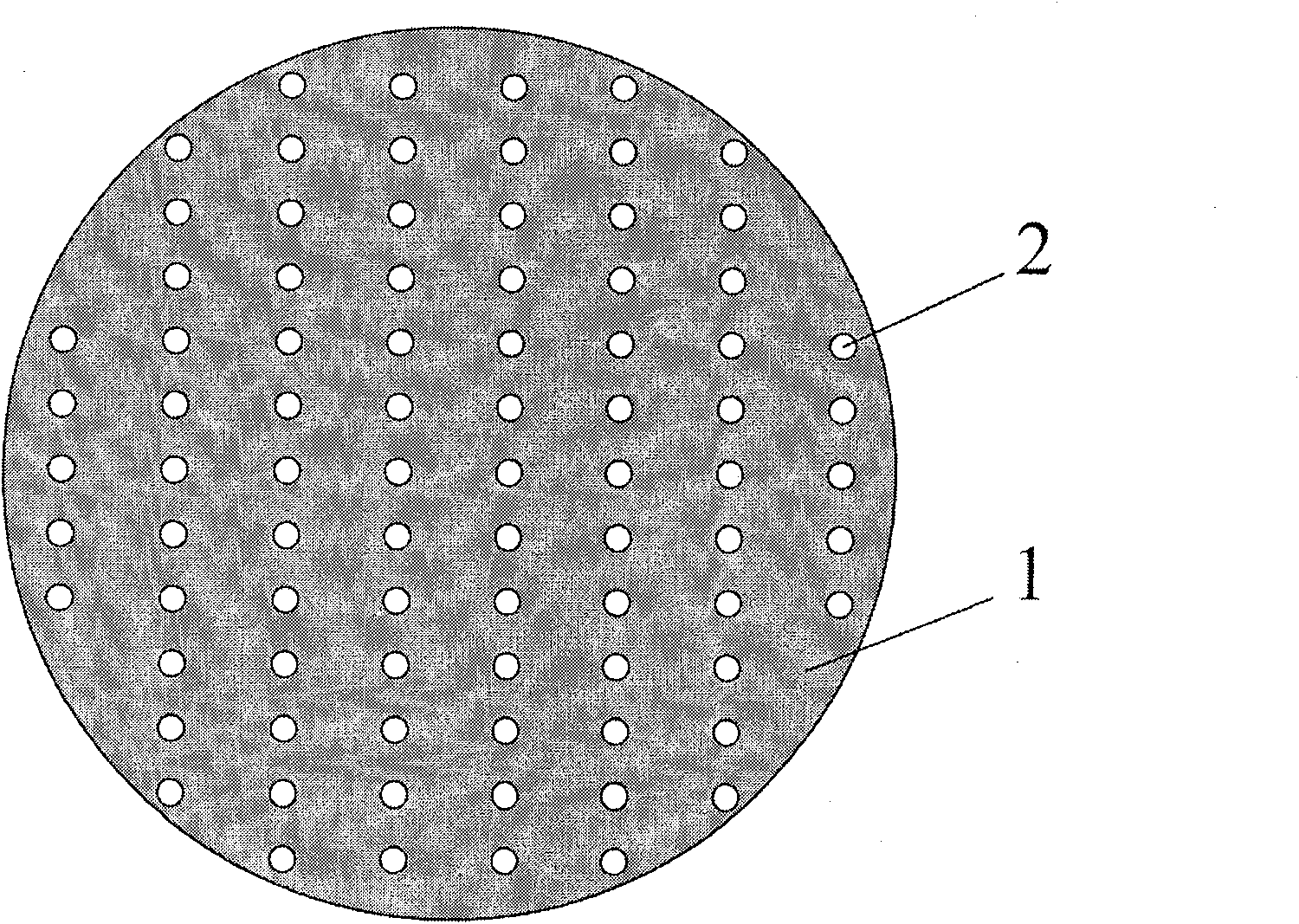

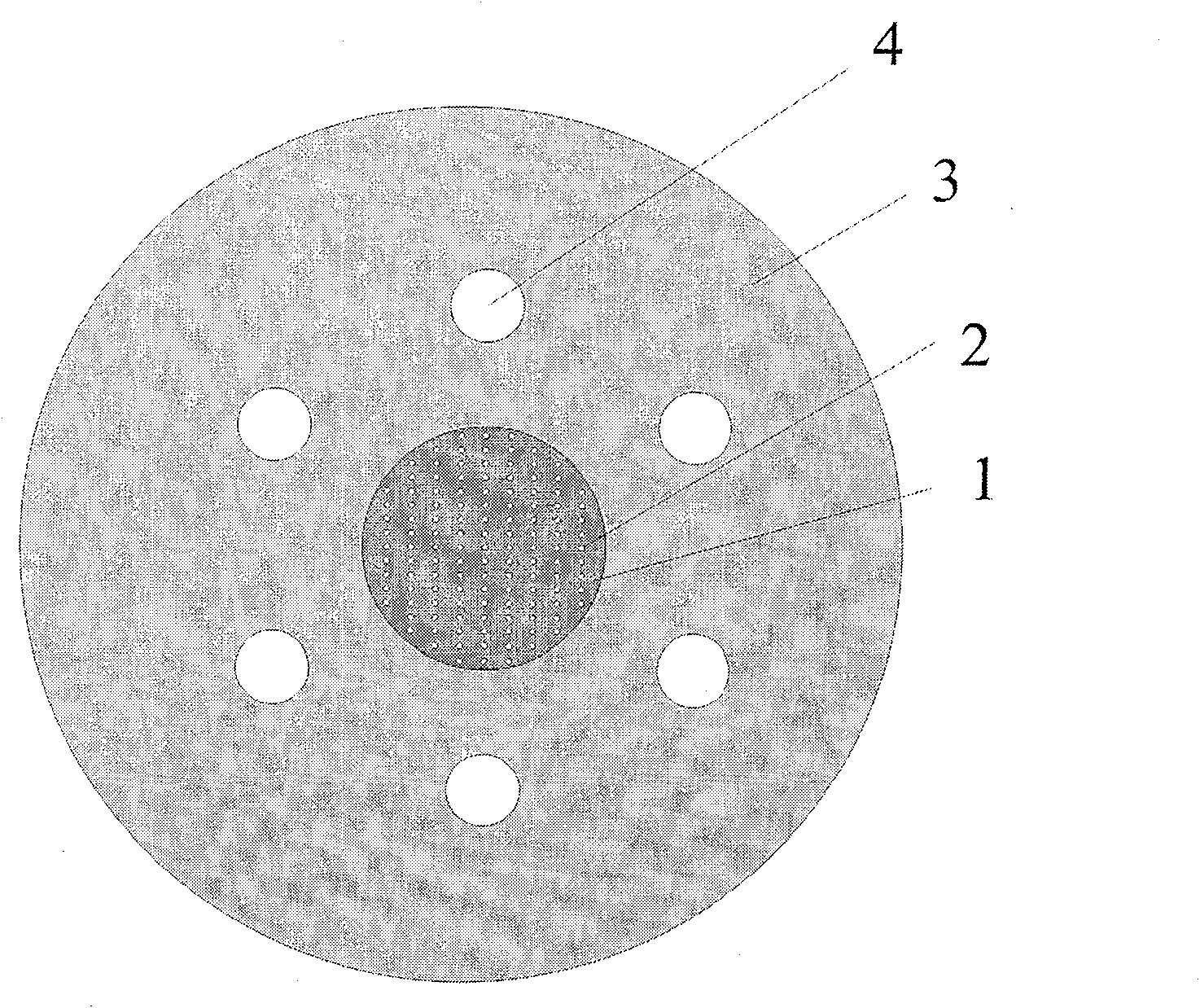

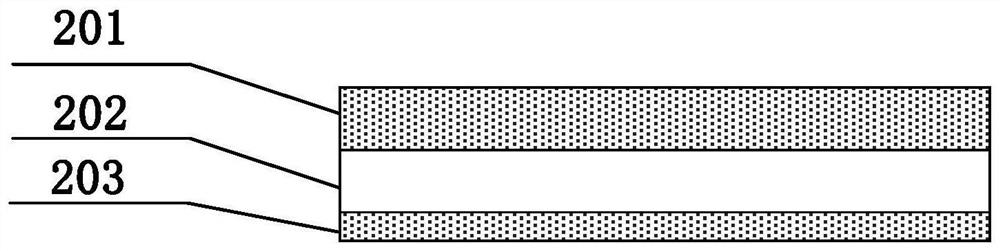

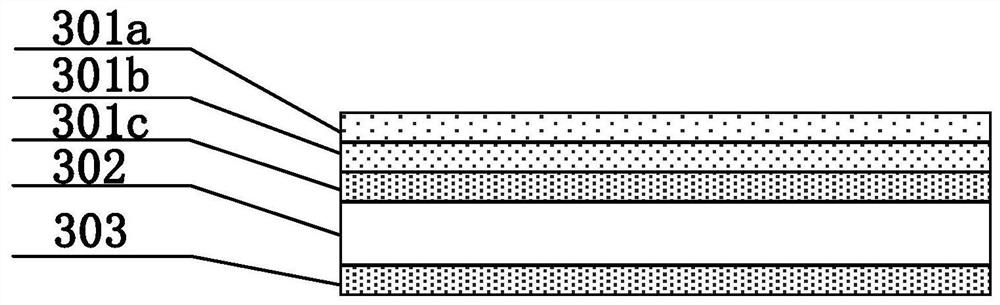

Polarization maintaining optical fiber with microstructure

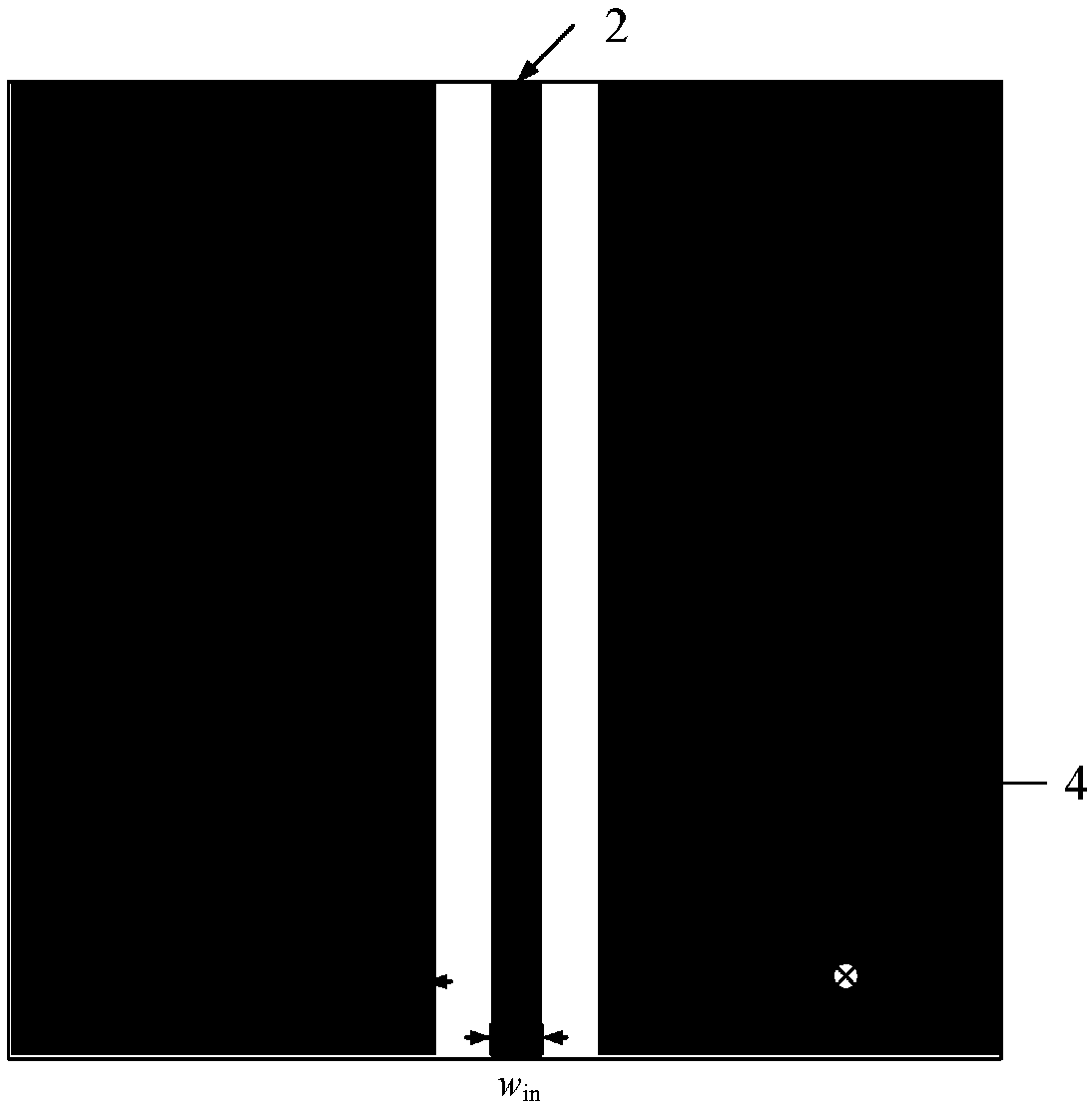

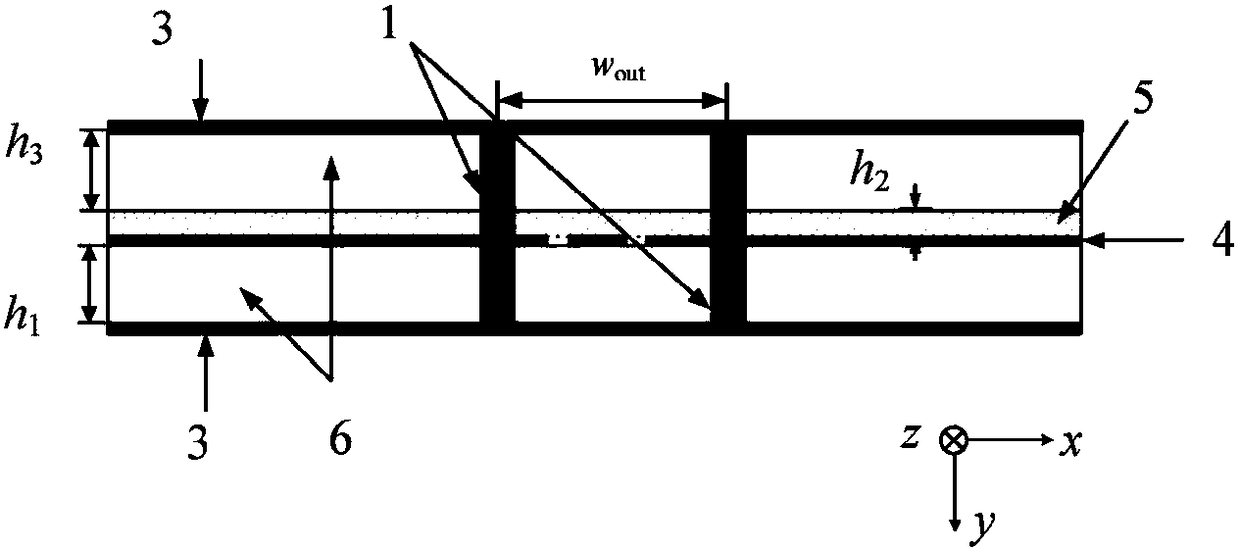

InactiveCN101093262ARefractive index adjustmentMany controllable parametersOptical fibre with polarisationOptical waveguide light guideRefractive indexPolarization-maintaining optical fiber

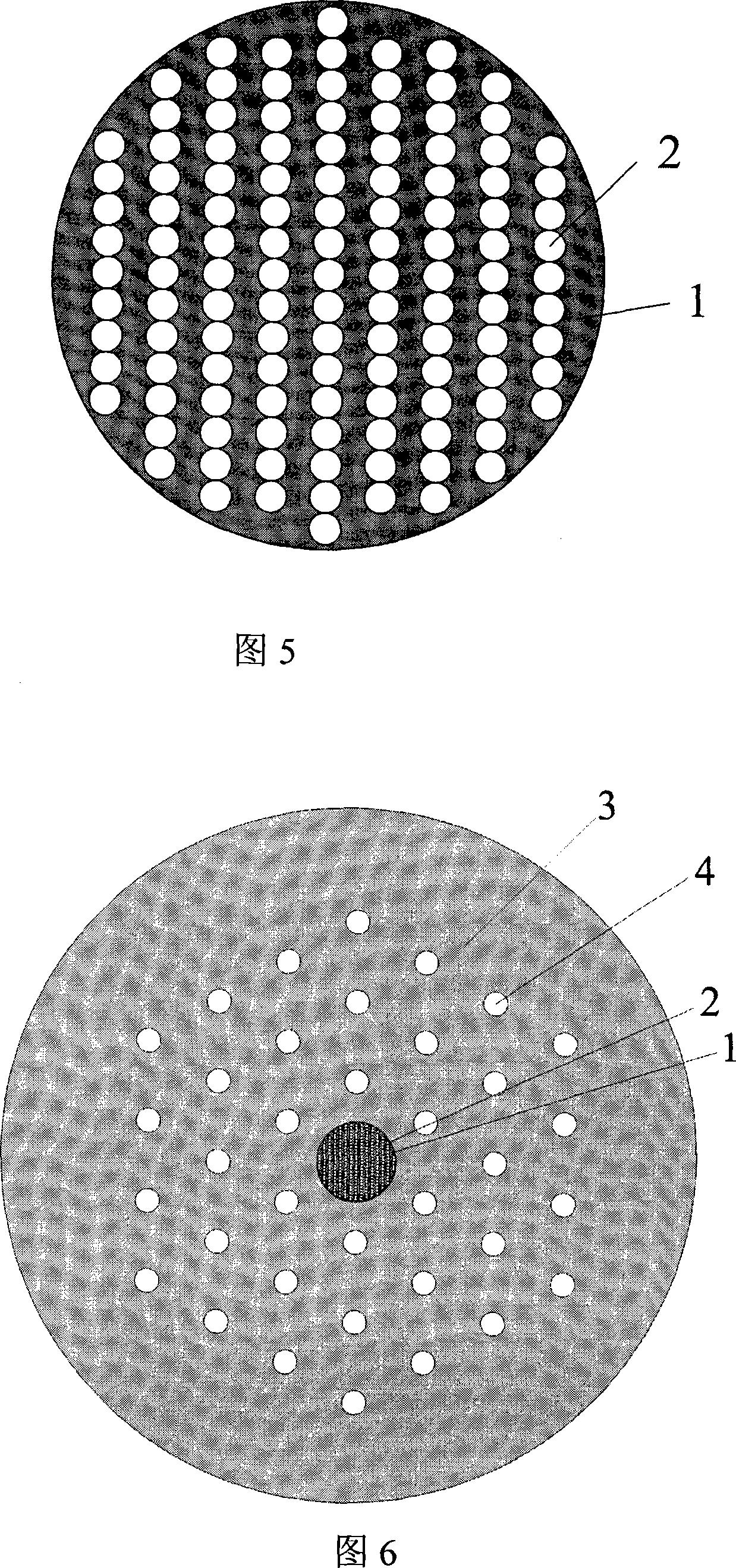

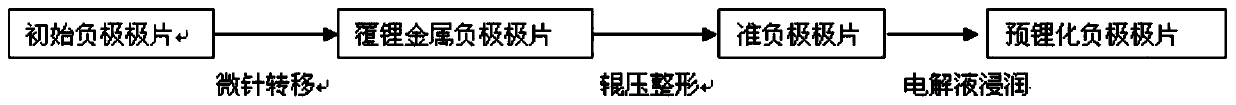

A polarization preserving fiber of microstructure mode is prepared for forming fiber core by media material 1 and hole 2 being cyclically arranged, obtaining refractivity relation of n1 >n3 >n2 for media material 3 when cladded layer is only prepared by media material 3 and obtaining refractivity relation of n3 >n4 and n1>n3 >n2 for media material 3 and hole 4 being cyclically arranged when cladded layer is prepared by media material 3 and hole 4 being cyclically arranged.

Owner:JIANGSU UNIV

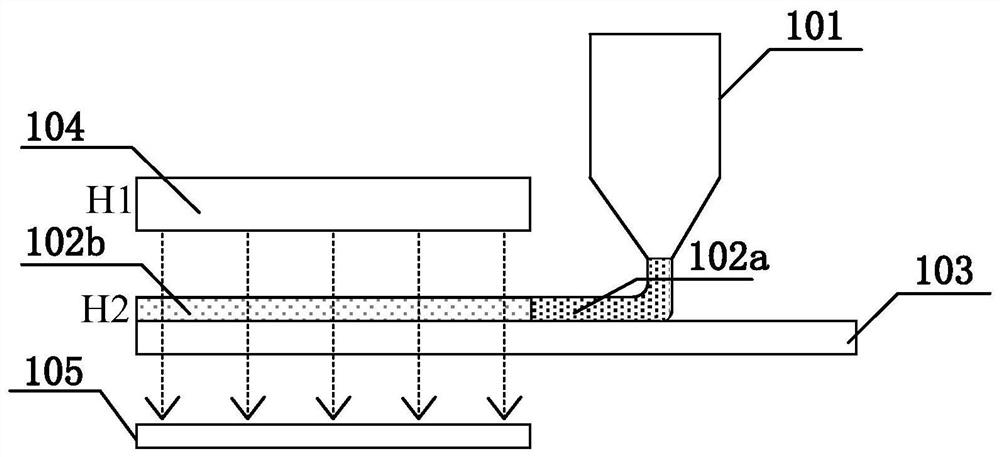

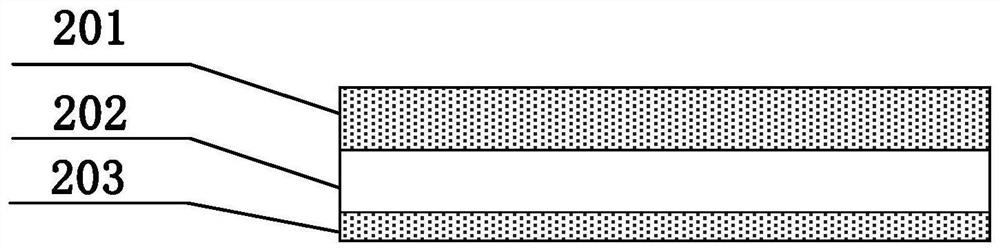

Pre-lithiation process of negative pole piece

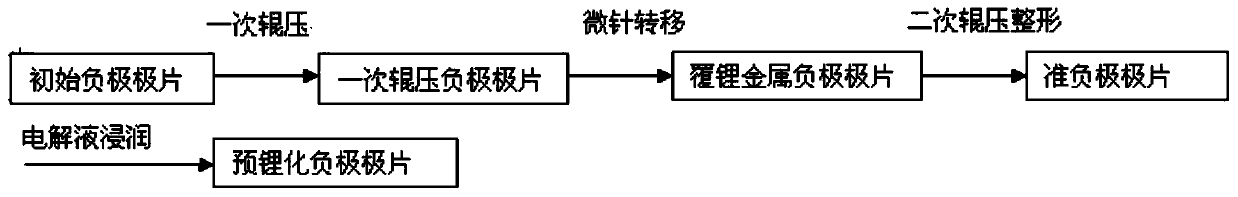

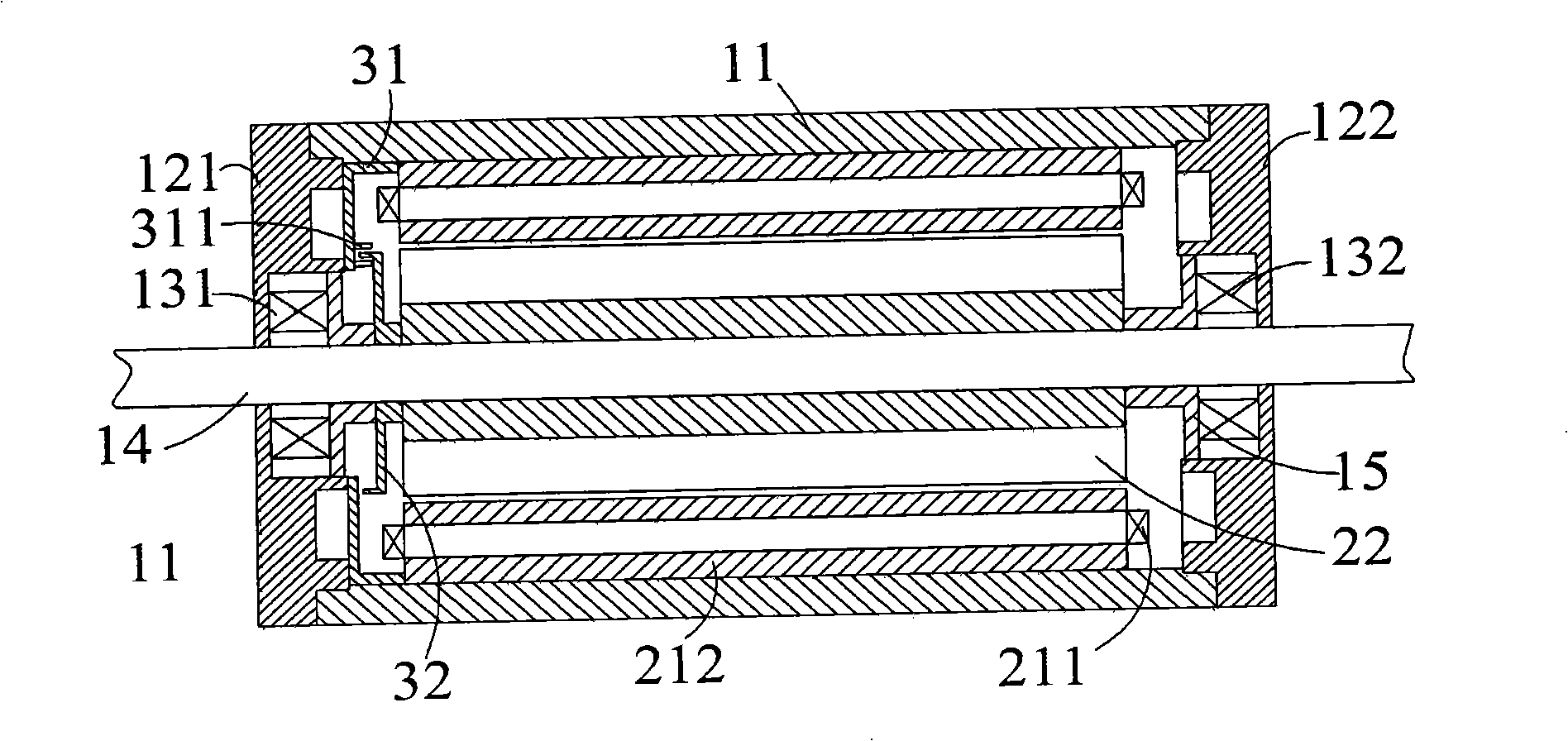

ActiveCN111276669AEasy to enlarge operationLow costSecondary cellsElectrode collector coatingElectrolytic agentLithium metal

The invention provides a pre-lithiation process of a negative pole piece, which comprises the following steps: mixing 80-98% of a negative active substance, 0.5-8% of a binder and 0.5-10% of a conductive agent to obtain a mixture, and coating the surface of a current collector with the mixture to obtain an initial negative pole piece; covering the initial negative pole piece with the lithium foilor lithium alloy coated with the base layer, and transferring the initial negative pole piece to the surface and the interior of the initial negative pole piece through a microneedle to obtain a lithium-coated metal negative pole piece; wherein the microneedle transfer mode is selected from one or more times of grinding, extrusion or extrusion-standing; wherein the density of the microneedles is 10-10,000 needles / cm<2>, and rolling the lithium-coated metal negative pole piece, and infiltrating the lithium-coated metal negative pole piece into the electrolyte to obtain the pre-lithiated negative pole piece. A numerous tensioning and deviation rectifying device is not needed, and the pre-lithiation process is simple, environmentally friendly and low in cost. According to the pre-lithiation process, no toxic substance is introduced, the process time is short, controllable parameters are rich, pre-lithiation can be carried out on different types of negative electrode materials, and the pre-lithiation process has an industrial application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

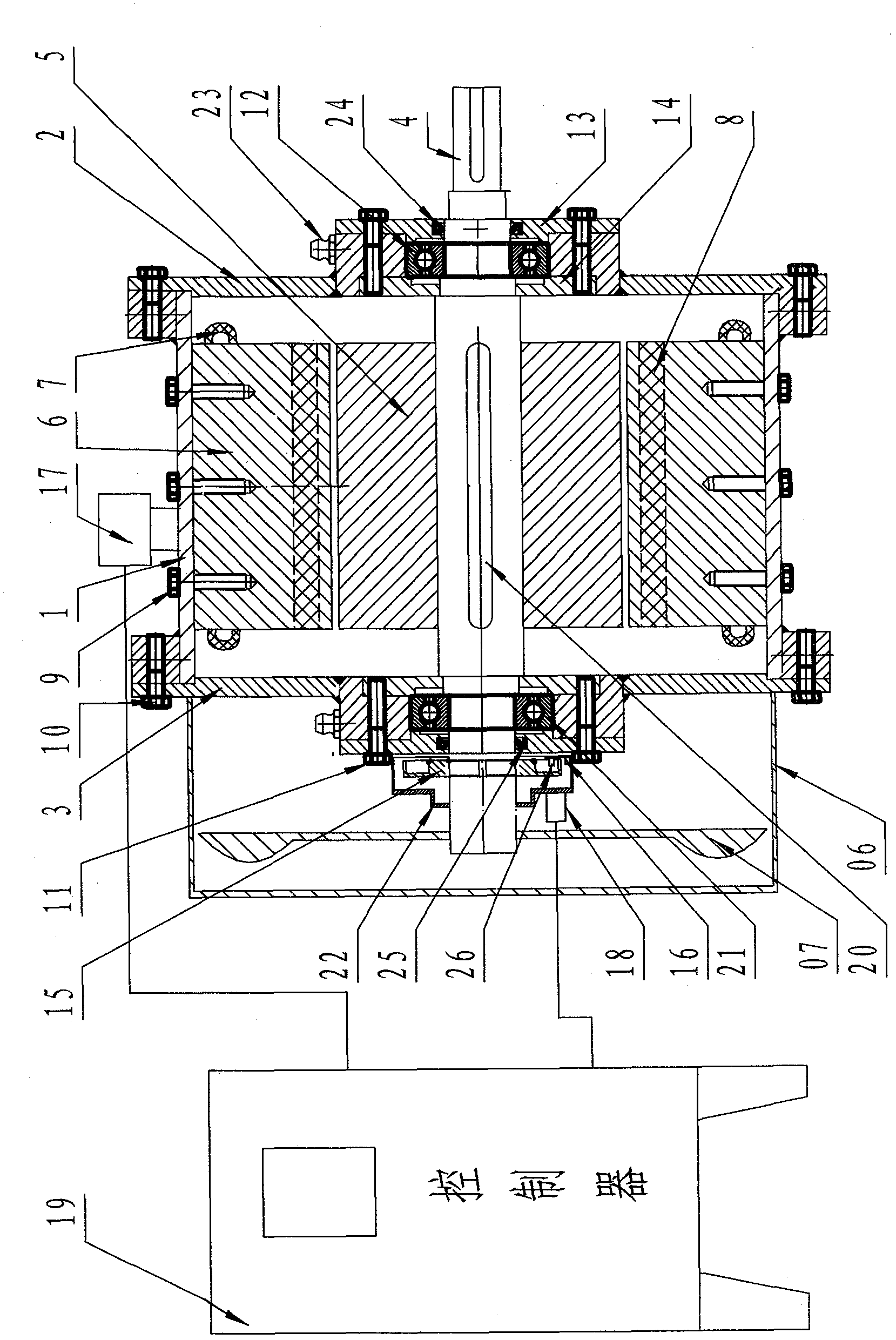

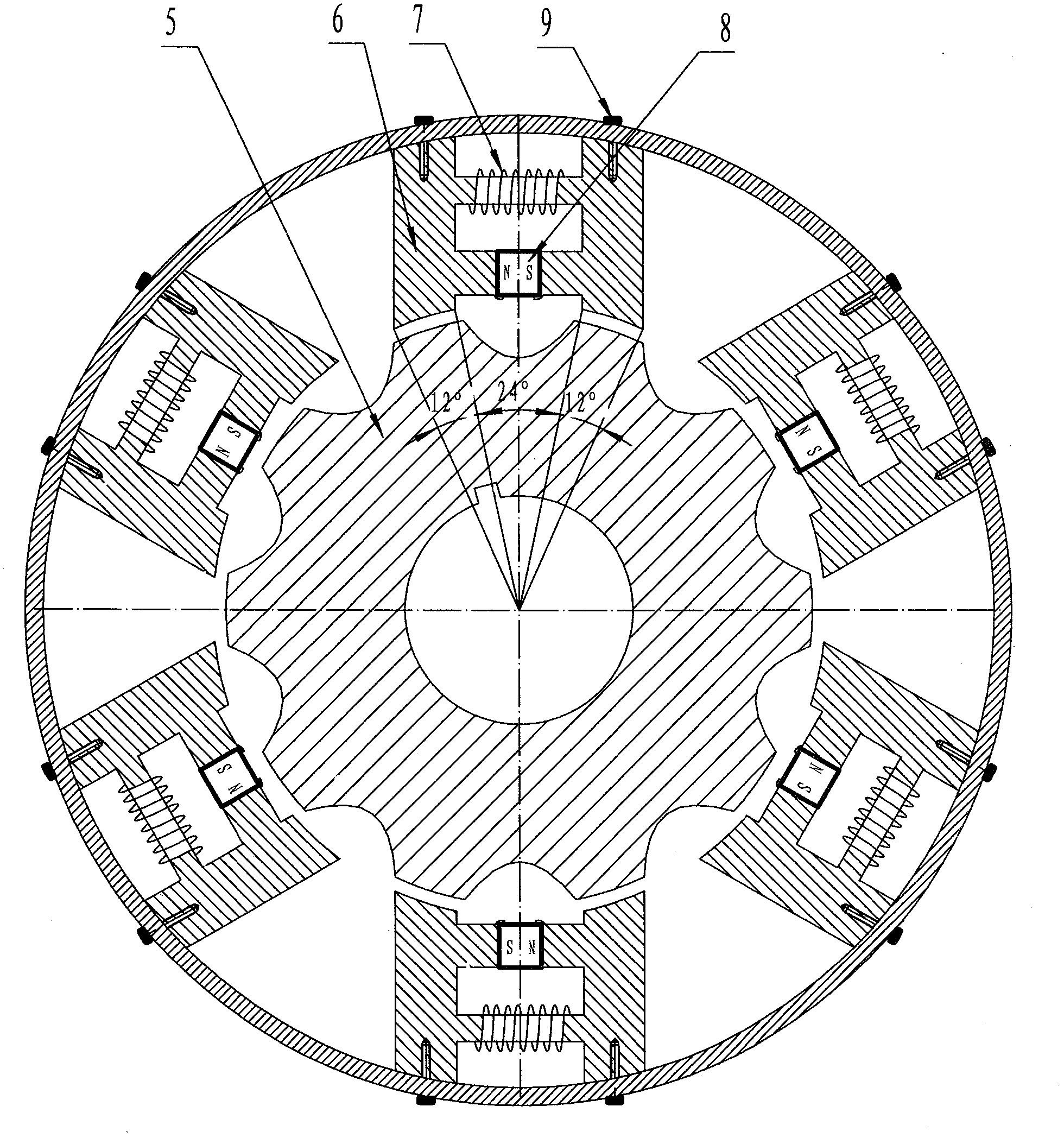

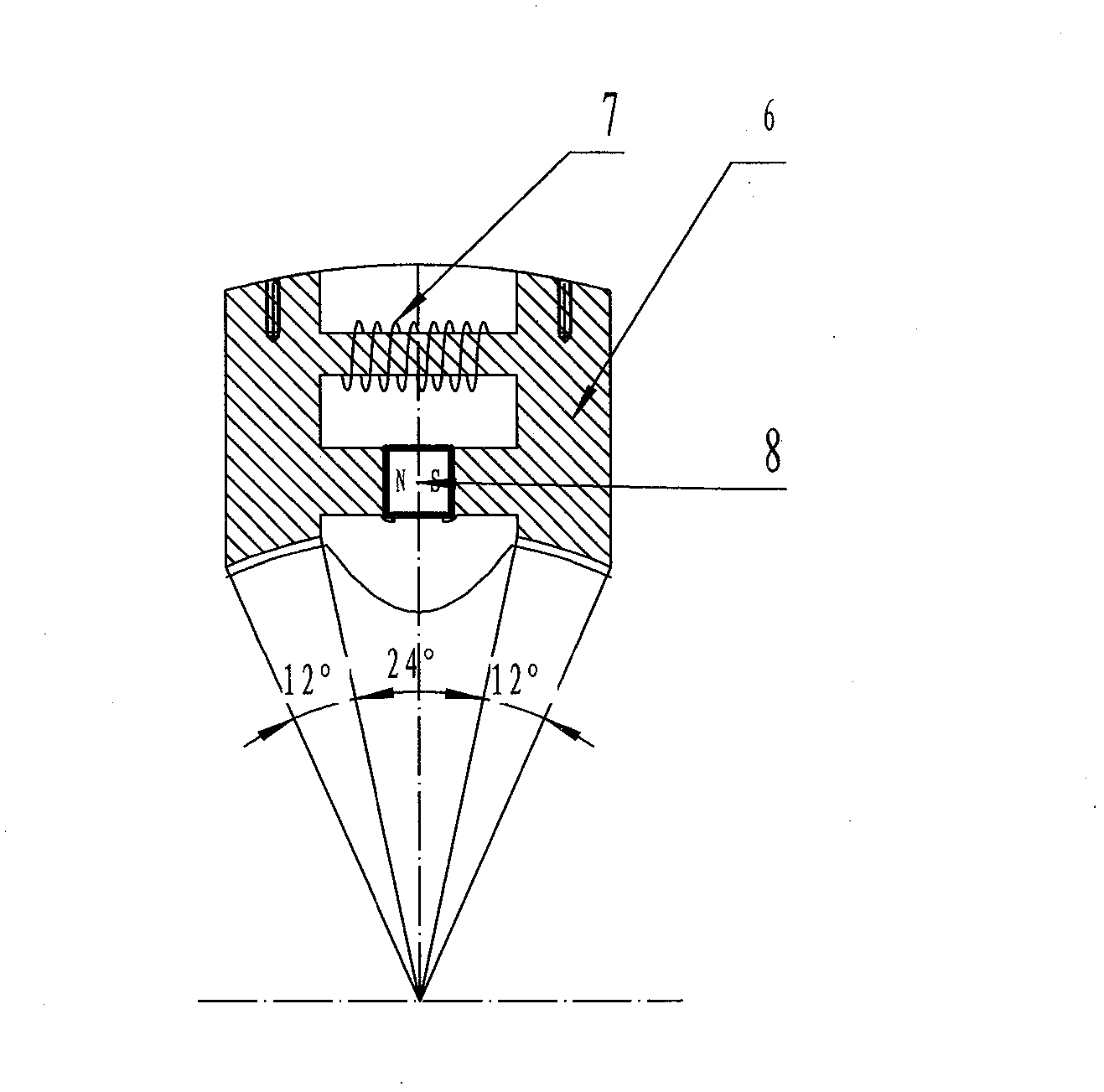

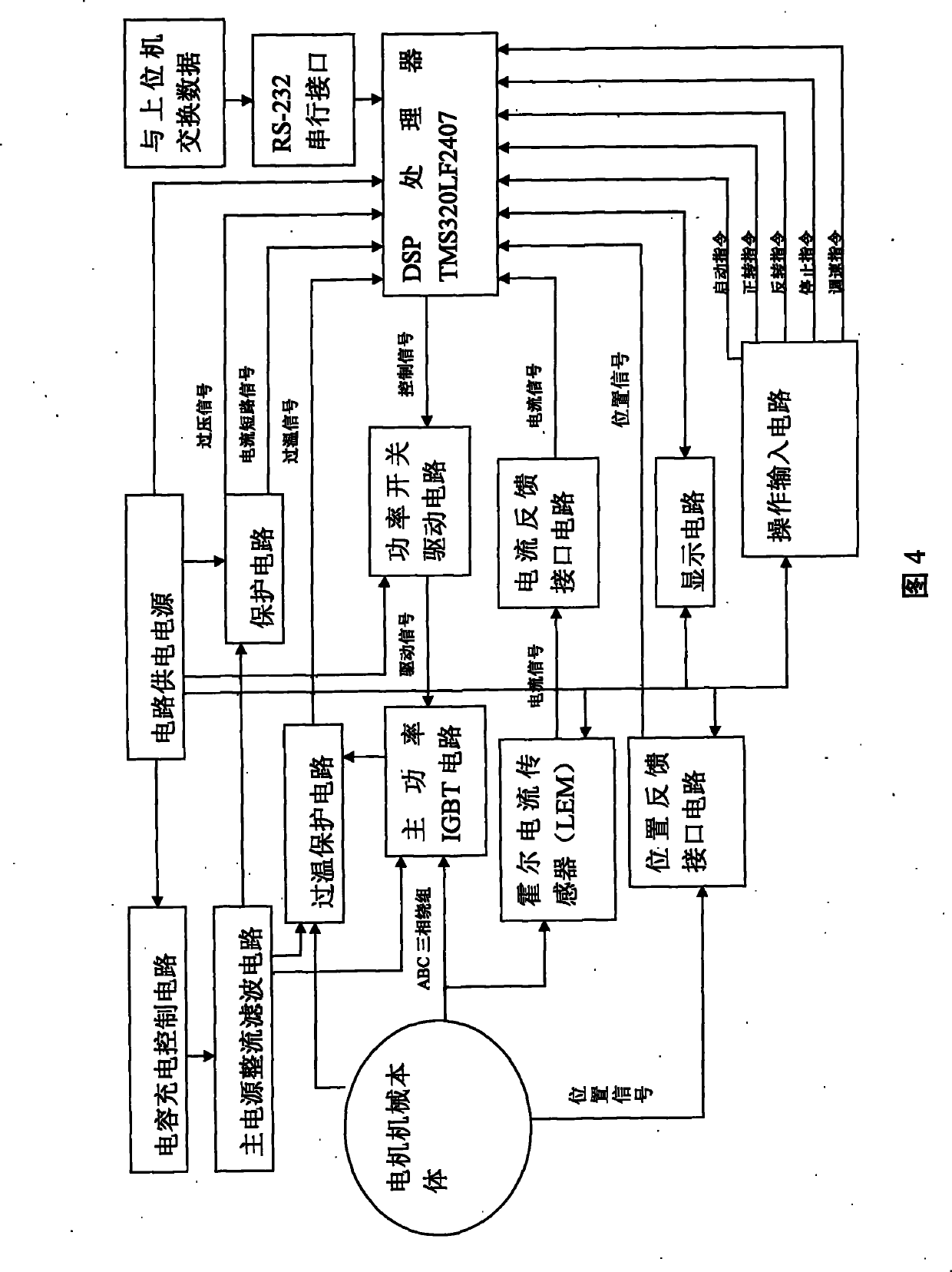

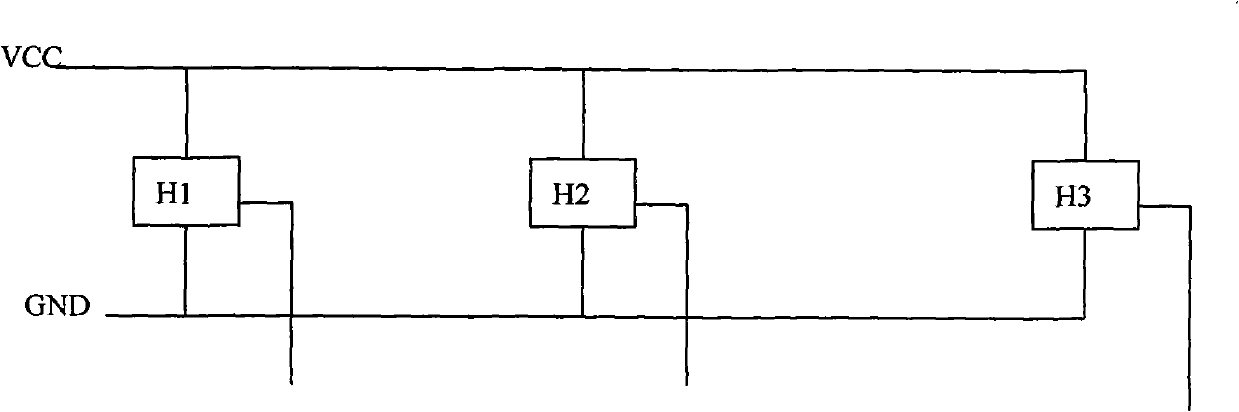

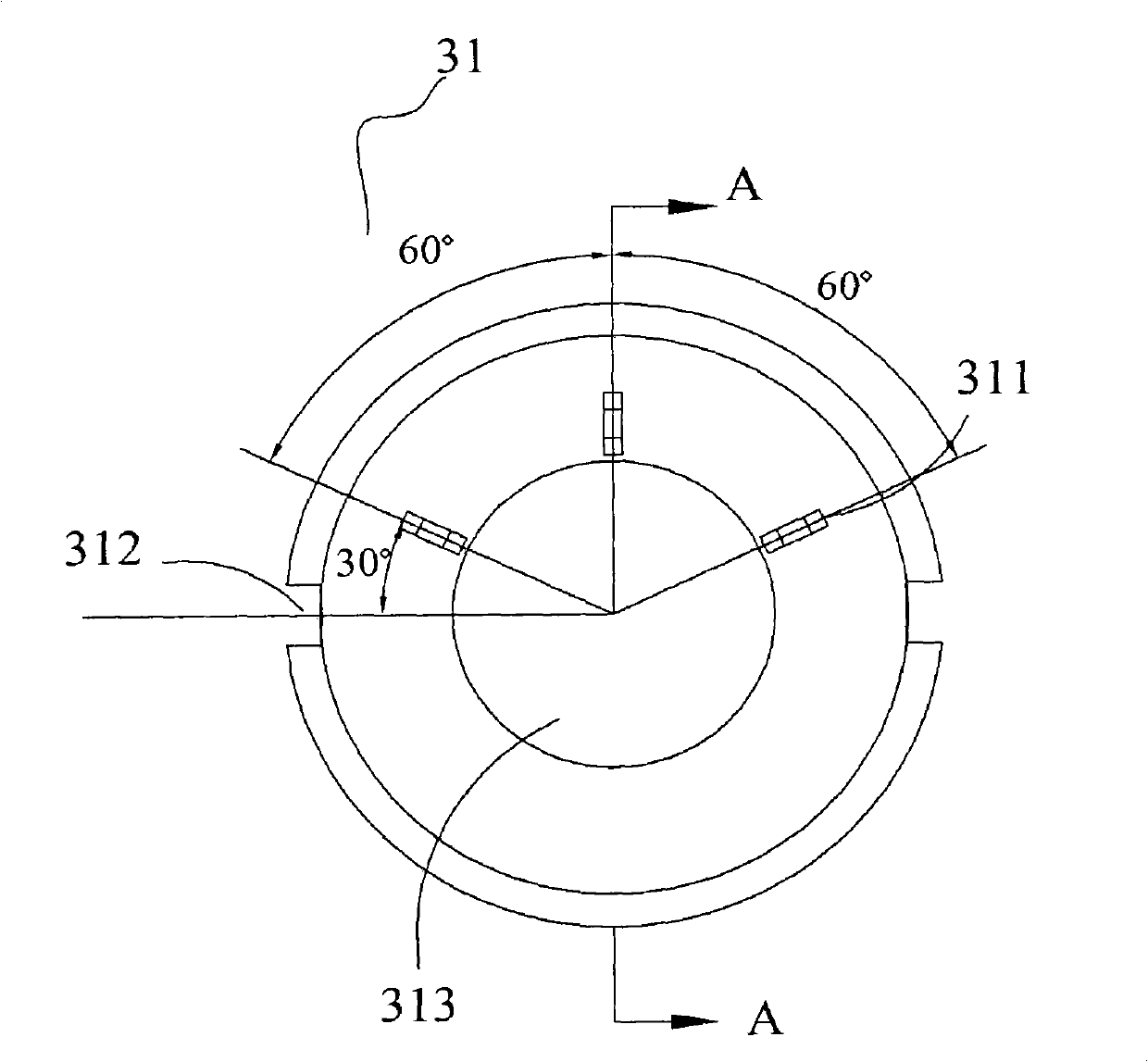

High-efficiency energy-saving double-salient-pole synchronous reluctance motor

ActiveCN101409471ASimple structureLow costMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous reluctance motorMotor control

The invention provides an efficient energy-saving dual salient pole synchronous reluctance motor, comprising a motor mechanical body and a motor control part; wherein, the motor mechanical body comprises a motor shell, a stator which is arranged on the internal wall of the motor shell and a rotor which is arranged at the center in the motor shell; the rotor is arranged on a motor shaft; the motor mechanical body also comprises a motor end cover which is arranged at the two ends of the motor shell; the motor shaft is connected with the motor end cover by a bearing; a shaft sleeve and an oil seal are arranged between the internal end surface of the bearing and the rotor; wherein, the rotor is provided with 8 salient poles; the stator is provided with 12 salient poles and 12 winding coils which are corresponding to the 12 salient poles.

Owner:黑龙江三众科技有限公司

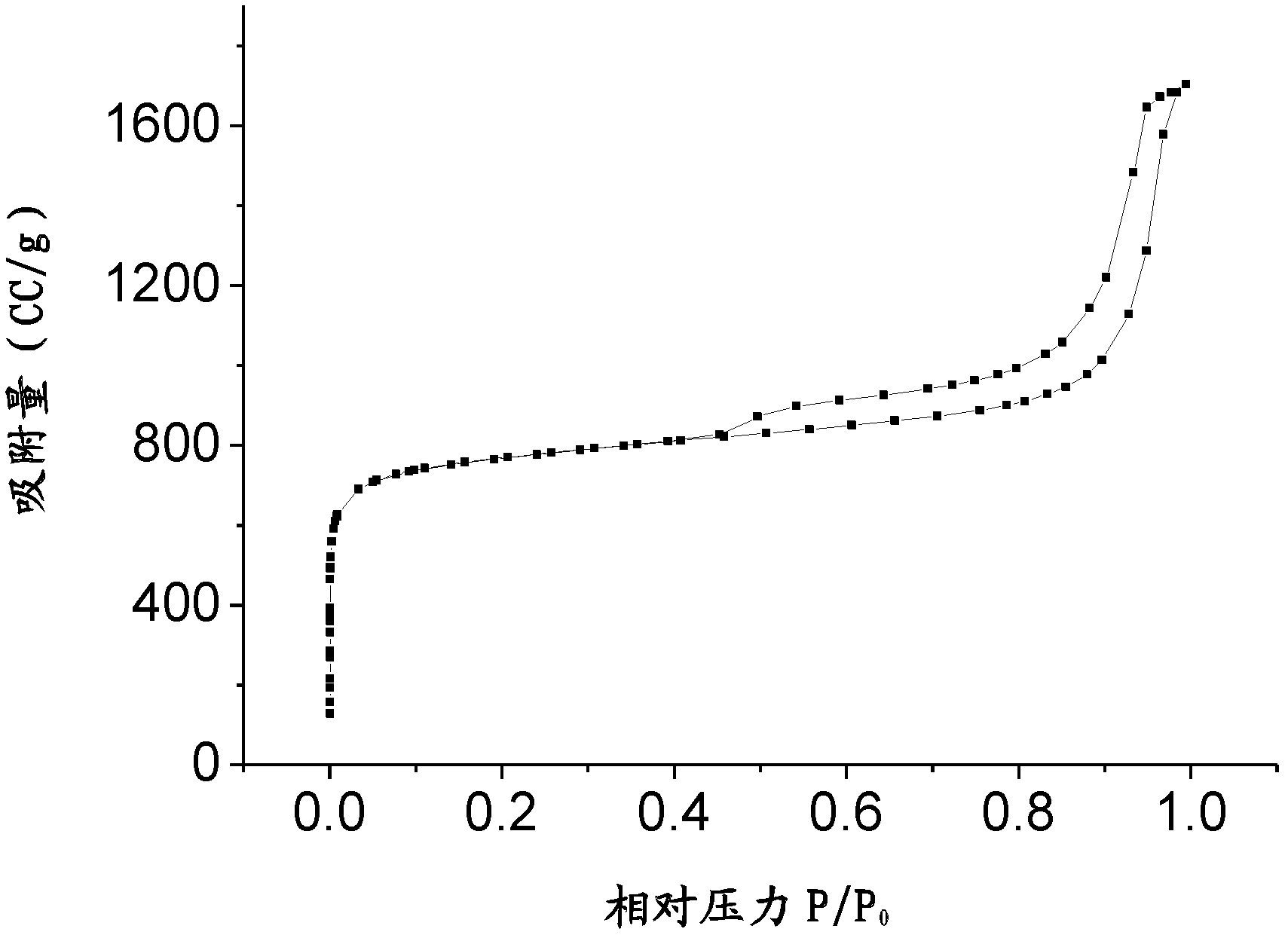

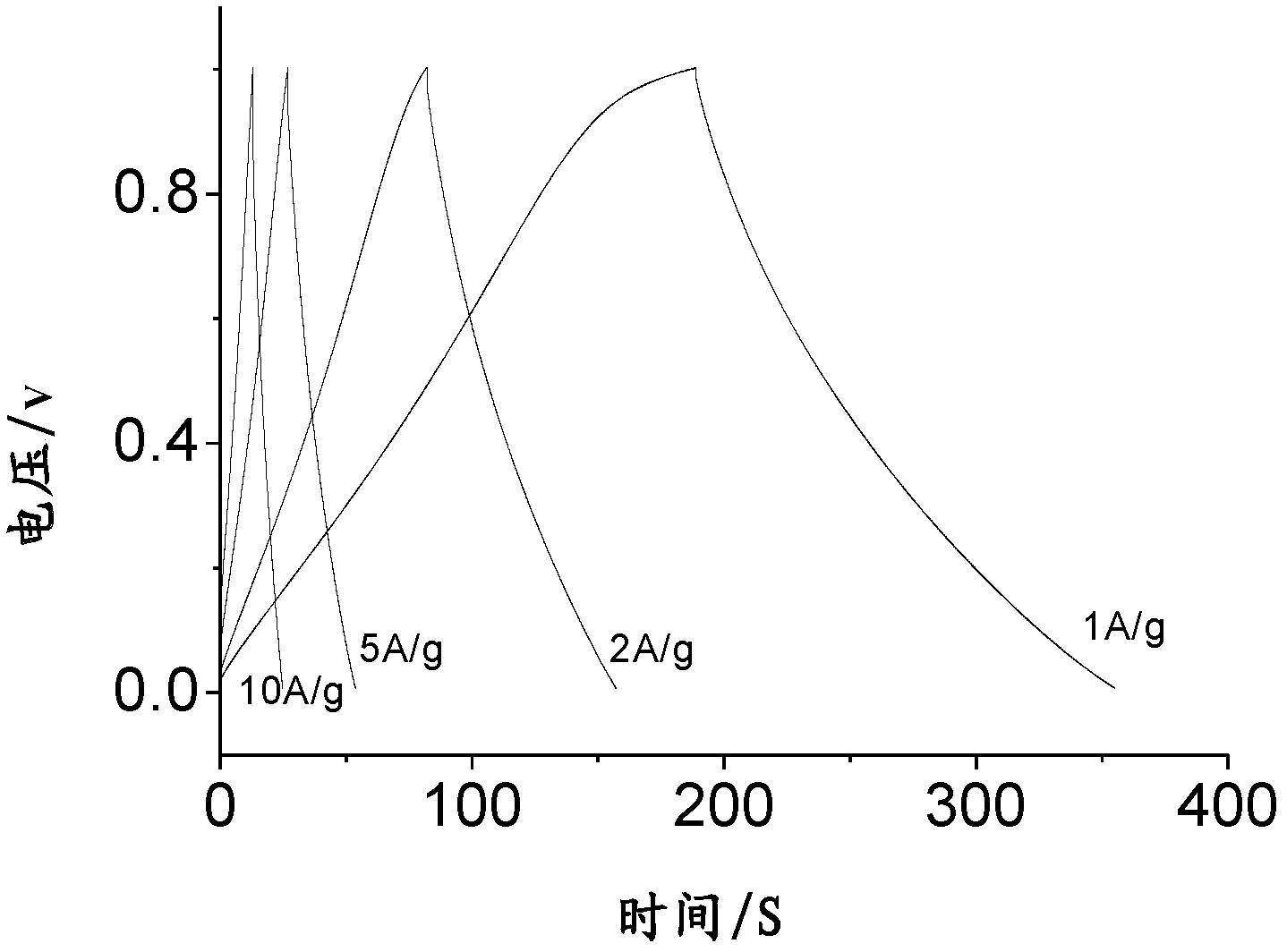

Method for preparing hierarchical porous nano carbon materials

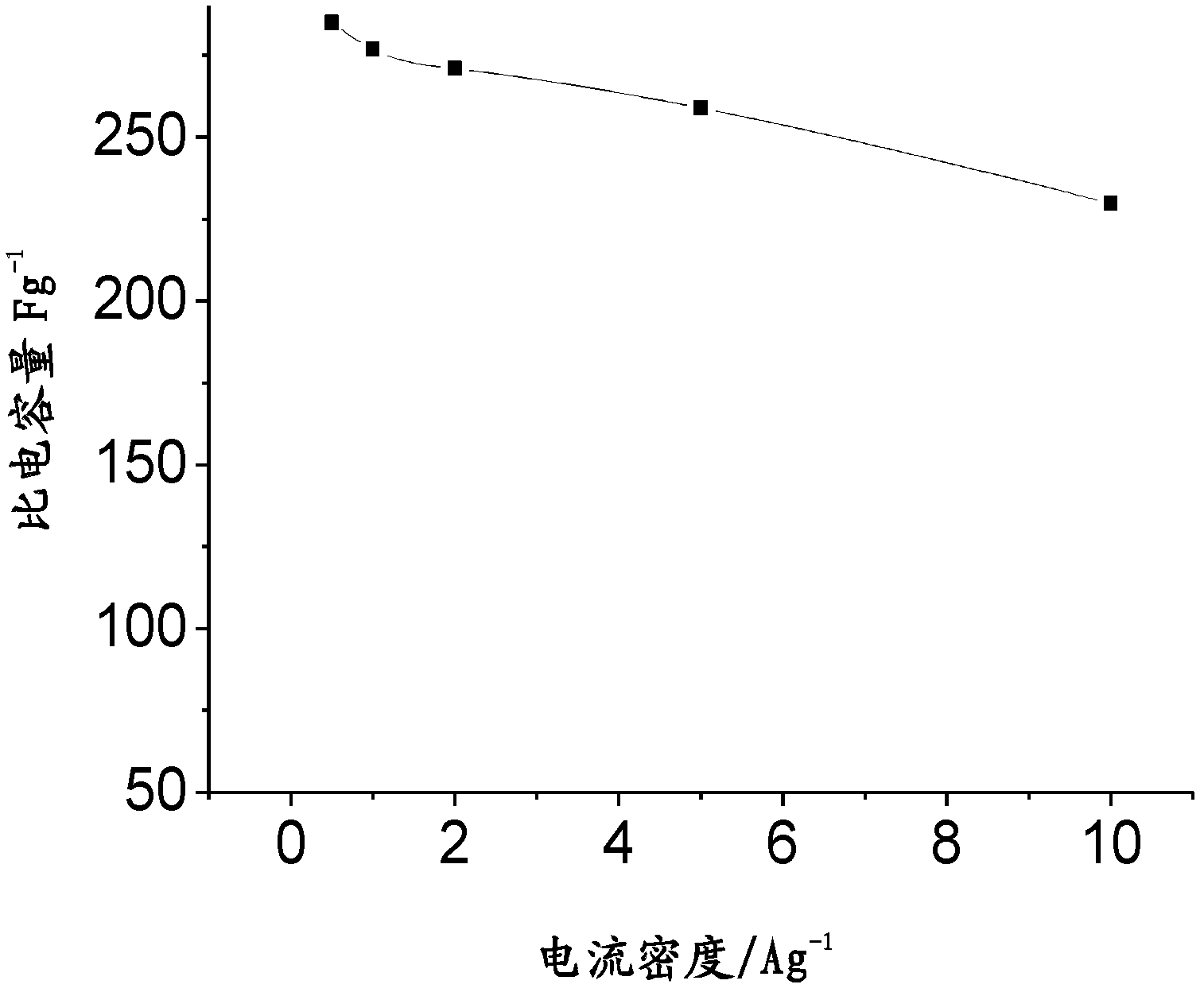

InactiveCN102874791APrecise control of specific surface areaLarge specific surface areaNanotechnologyNano-carbonCapacitanceCarbonization

The invention belongs to the technical field of materials, in particular to a method for preparing hierarchical porous nano carbon materials. The method comprises the following steps of: (1) preparing organosol; (2) aging the organosol prepared in the step (1) to prepare an organic aerogel; (3) vacuumizing the organic aerogel prepared in the step (2), keeping constant temperature and drying; (4) performing primary carbonization on a product prepared in the step (3); (5) performing ball milling on a product prepared in the step (4); (6) soaking a product prepared in the step (5) in a mixed acid solution, washing until the pH value is 6 to 7, filtering, vacuumizing, keeping constant temperature and drying; (7) adding a KOH solid and deionized water into a product prepared in the step (6) for mixing to obtain a paste, vacuumizing, keeping constant temperature and drying; and (8) performing secondary carbonization on a product prepared in the step (7). By the method, the specific surface area of a carbon aerogel material can be obviously increased, the pore diameter distribution is improved, and the specific capacitance and high-power charge-discharge performance of a carbon aerogel electrode material are improved.

Owner:TONGJI UNIV

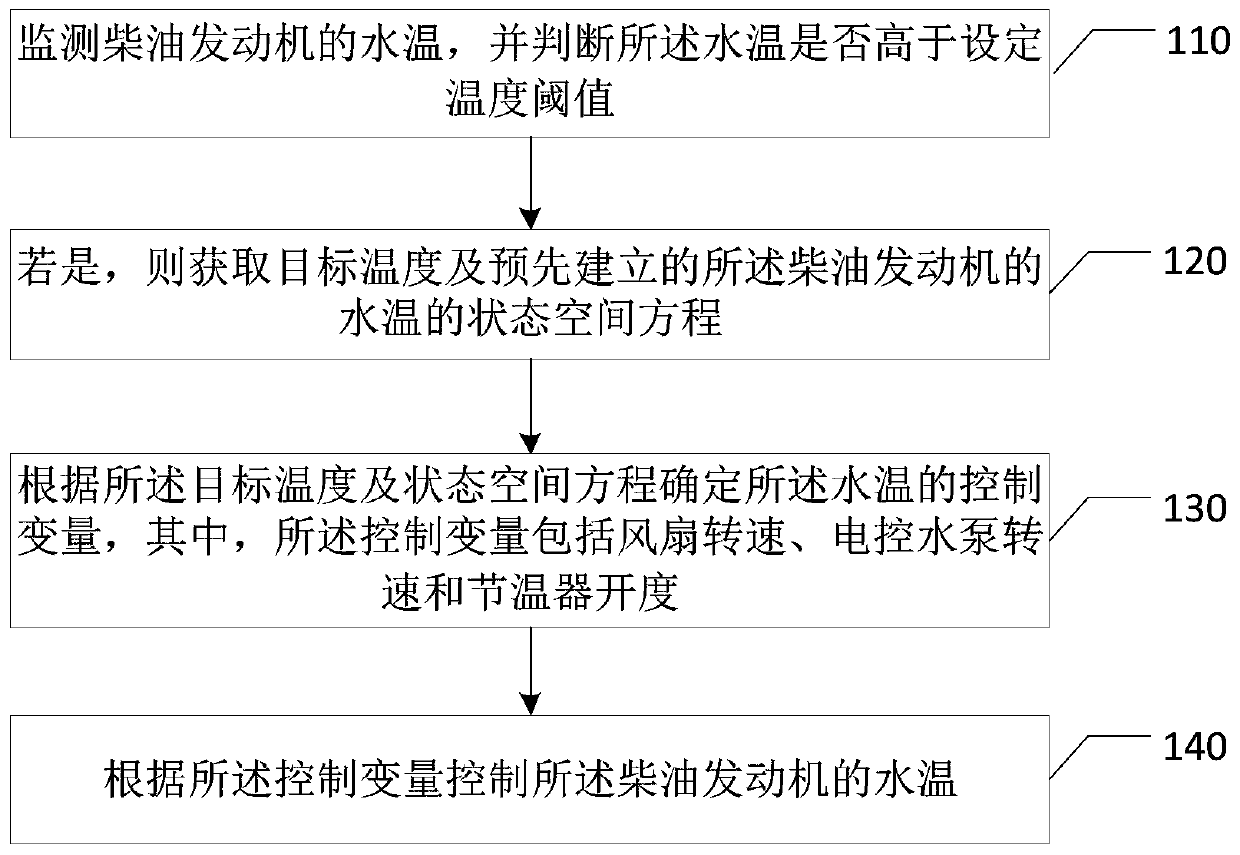

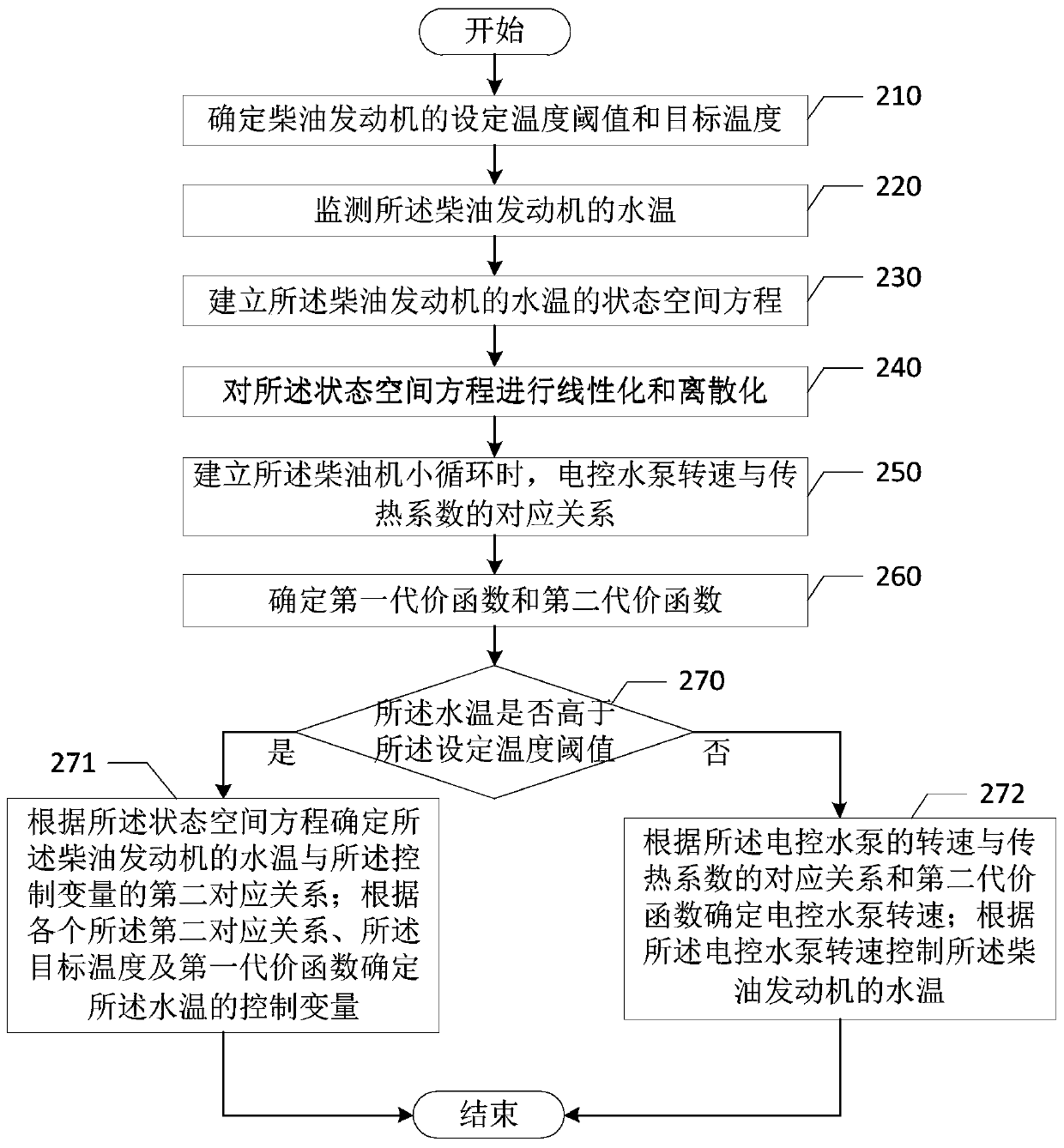

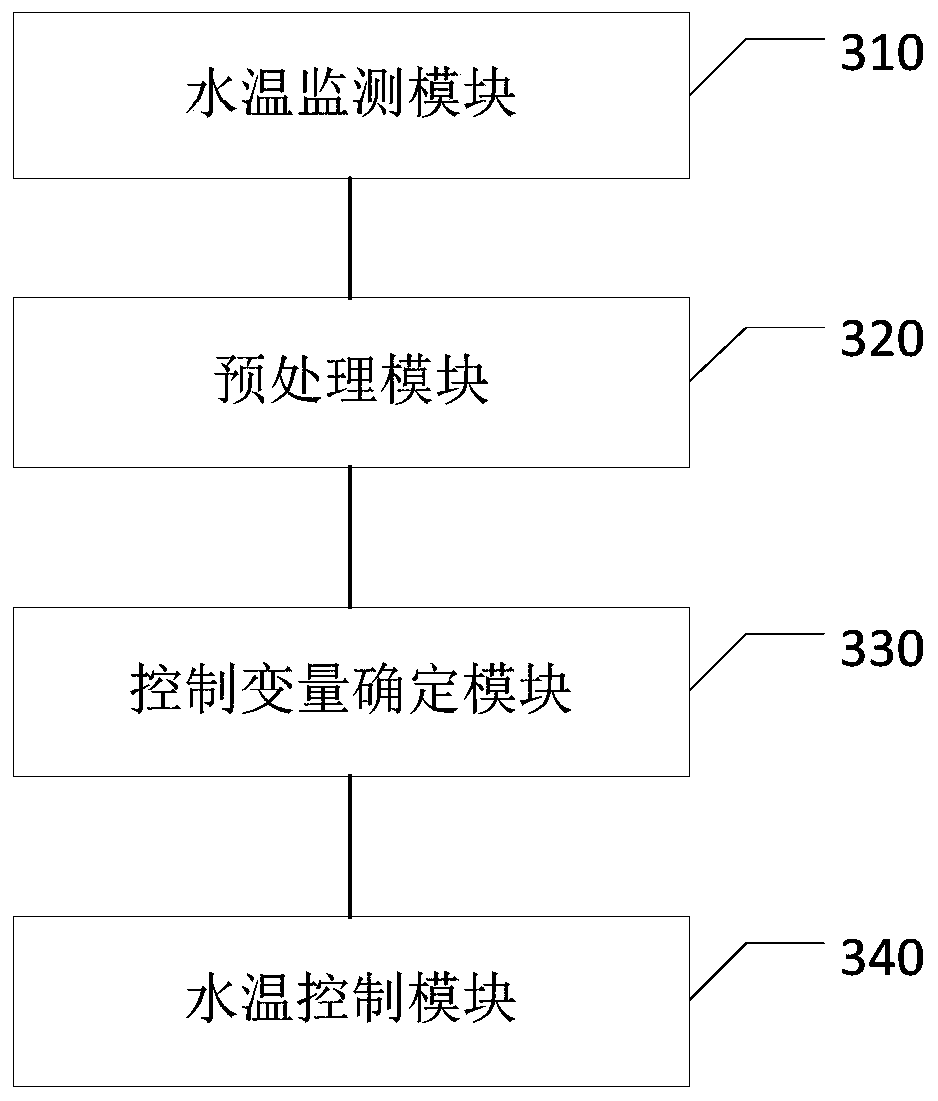

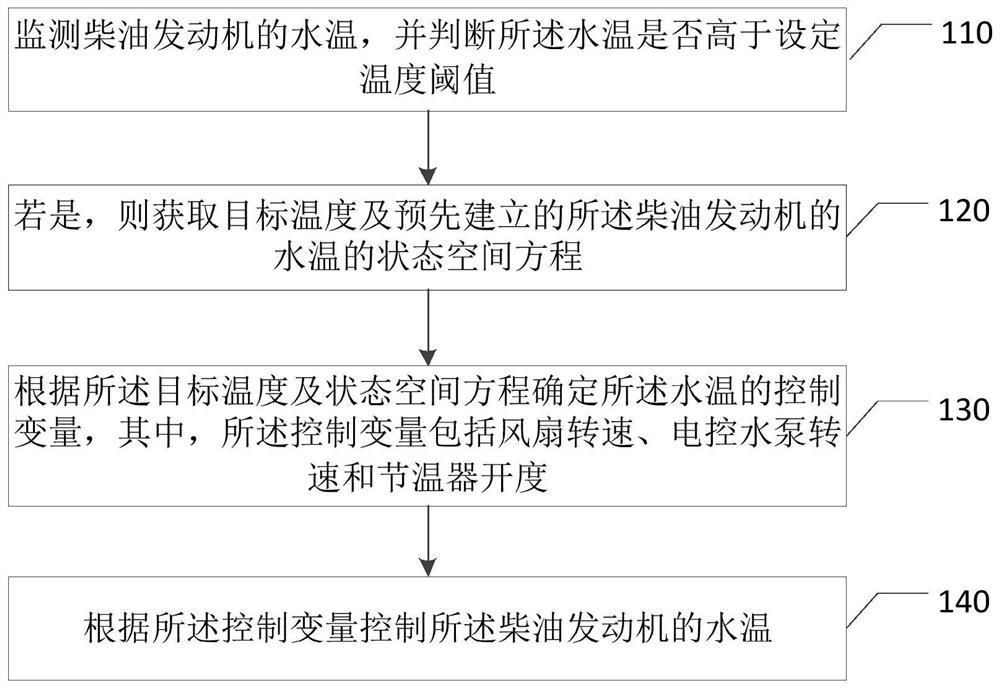

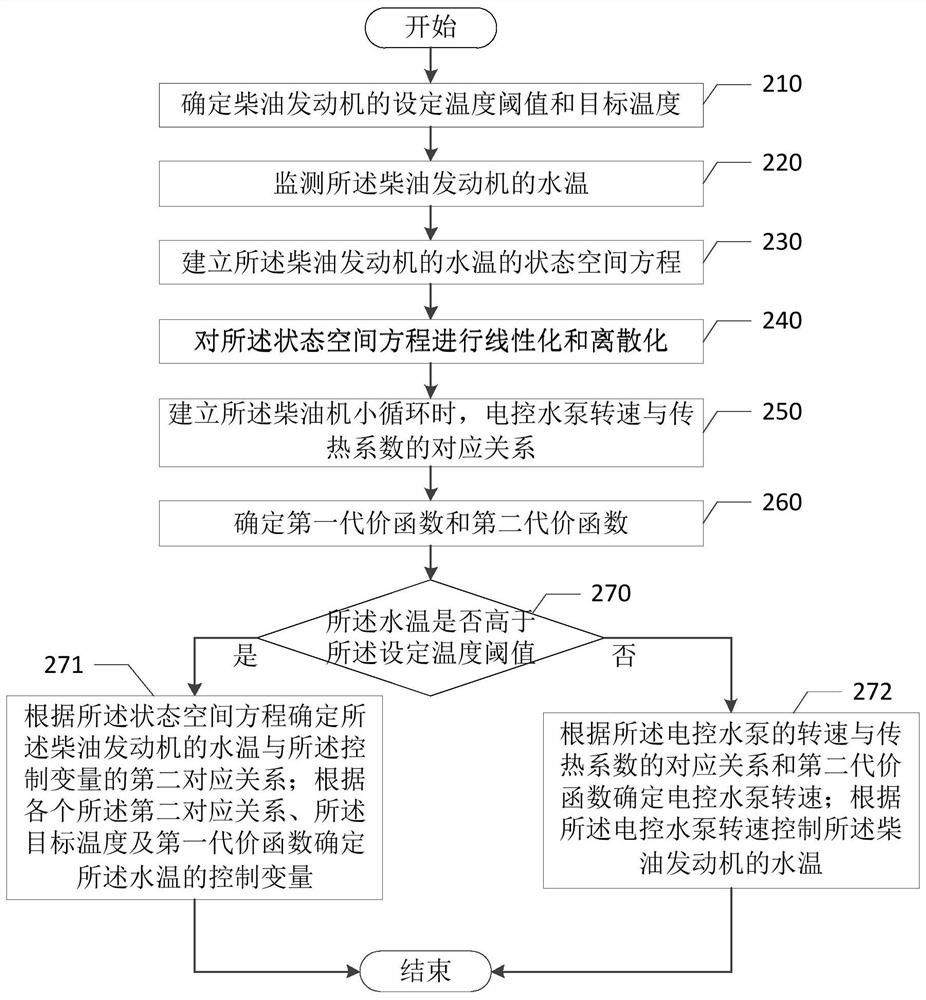

Water temperature control method and device, heat management system and storage medium

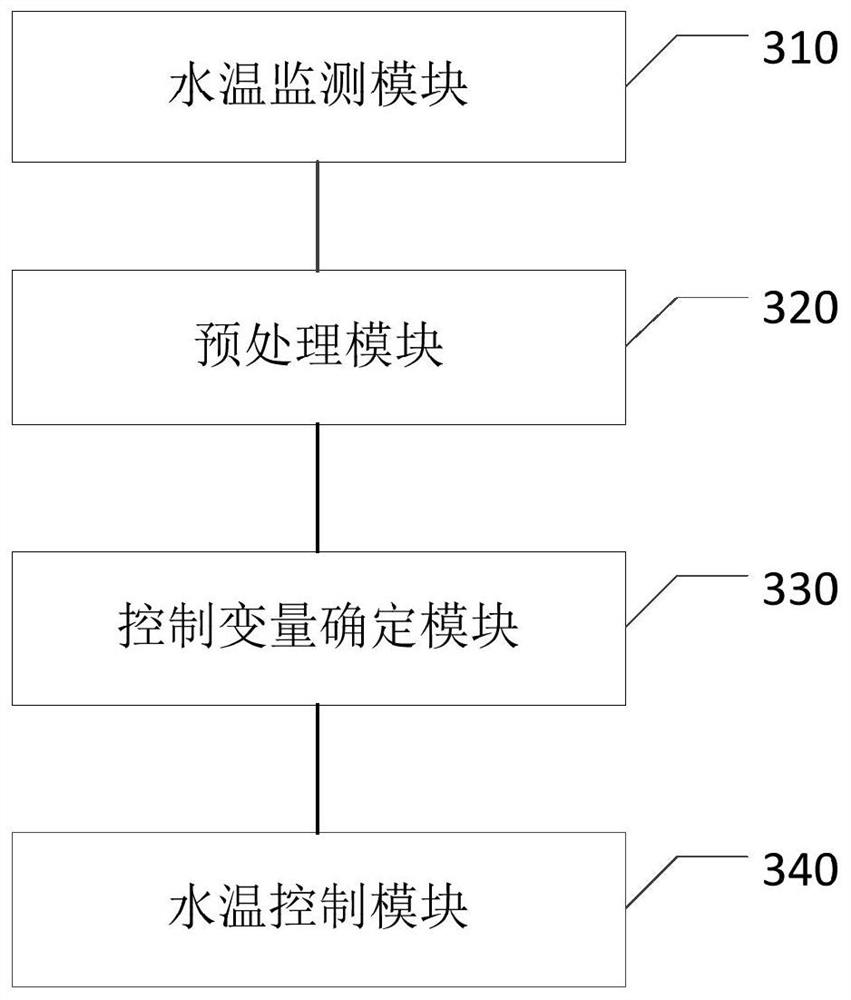

ActiveCN111005799AReduce lossImprove water temperature control accuracyCoolant flow controlMachines/enginesHeat managementEngineering

The invention discloses a water temperature control method and device, a whole vehicle heat management system and a storage medium. The water temperature control method comprises the steps that the water temperature of a diesel engine is monitored, and whether the water temperature is higher than a set temperature threshold value or not is judged; if yes, a target temperature and a pre-establishedstate space equation of the water temperature of the diesel engine are obtained; according to the target temperature and the state space equation, control variables of the water temperature are determined, wherein the control variables comprise the fan rotating speed, the electric control water pump rotating speed and the thermostat opening degree; and the water temperature of the diesel engine is controlled according to the control variables. According to the technical scheme, the water temperature is monitored in real time, the state space equation of the water temperature is established, the corresponding relation between the water temperature and the control variables is determined, the values of the control variables reaching the target temperature are determined according to the corresponding relation, the values of the control variables are optimized online, the water temperature control precision is improved, and the energy consumption of the system is reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

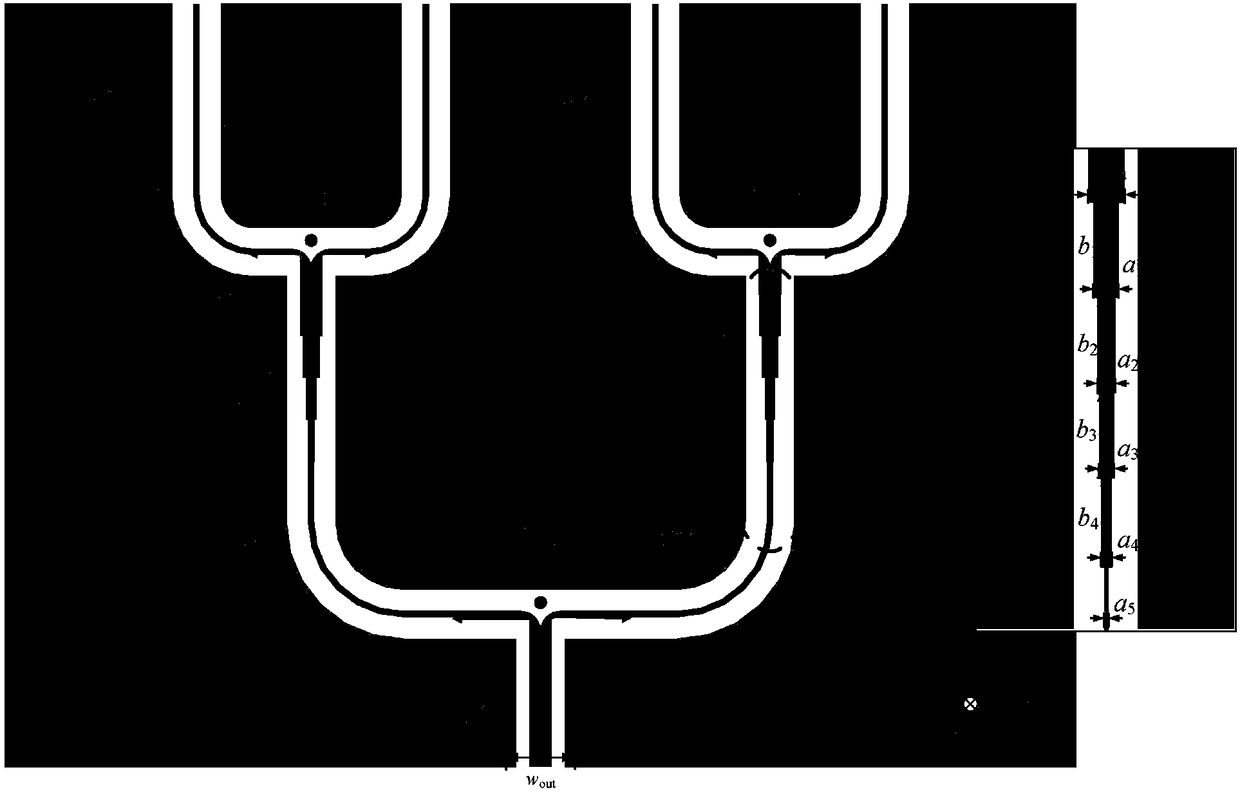

Broadband end-fire antenna array for millimeter wave communication system

ActiveCN108511924AReduce lossWide operating frequencyParticular array feeding systemsAntennas earthing switches associationPhysicsWave band

The invention discloses a broadband end-fire antenna array for a millimeter wave communication system. A power division network is designed by using a substrate-integrated coaxial line (SICL), an electromagnetic dipole antenna with a broadband working range is selected as a radiating element, and a broadband and high-gain antenna array is achieved by adopting a planar L-shaped probe excitation antenna. The broadband power division network employing the SICL disclosed by the invention has a wider working bandwidth in a millimeter wave band in comparison with the power division network employinga substrate-integrated waveguide transmission structure design, and has lower losses in the millimeter wave band in comparison with the power division network employing a microstrip line and a coplanar waveguide transmission structure design. The end-fire antenna array disclosed by the invention has the advantages of wide impedance bandwidth and radiation pattern bandwidth.

Owner:SOUTHEAST UNIV

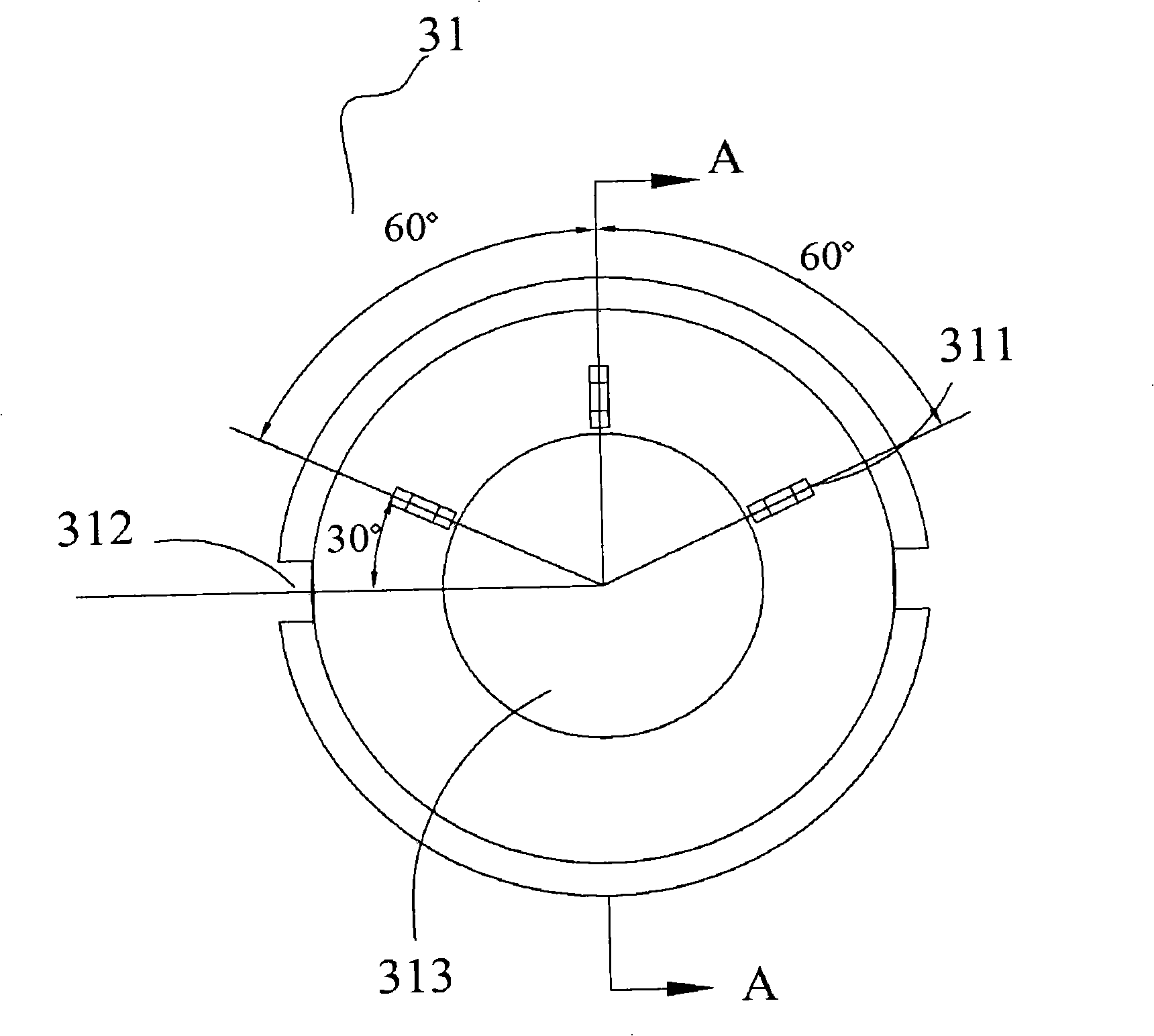

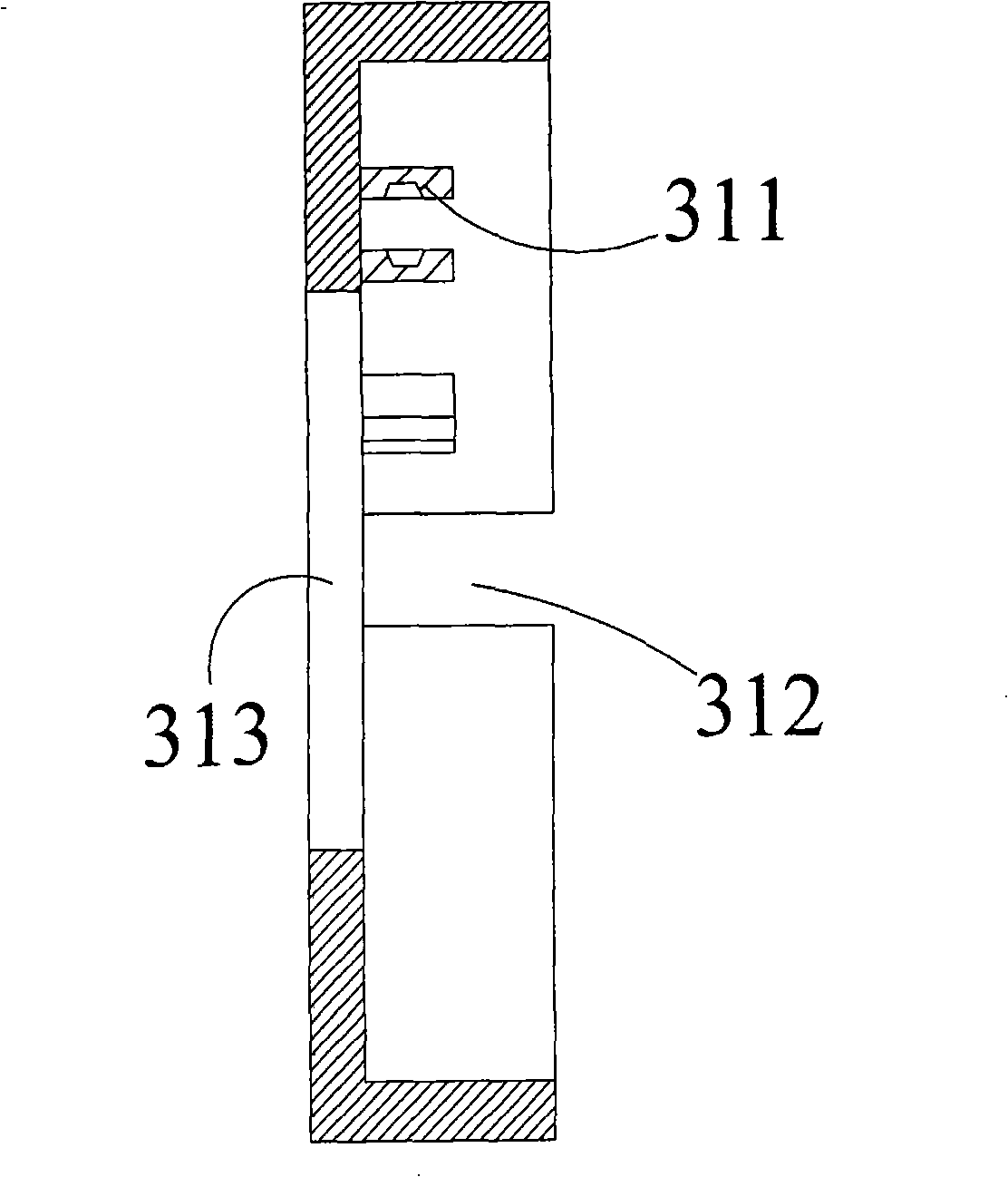

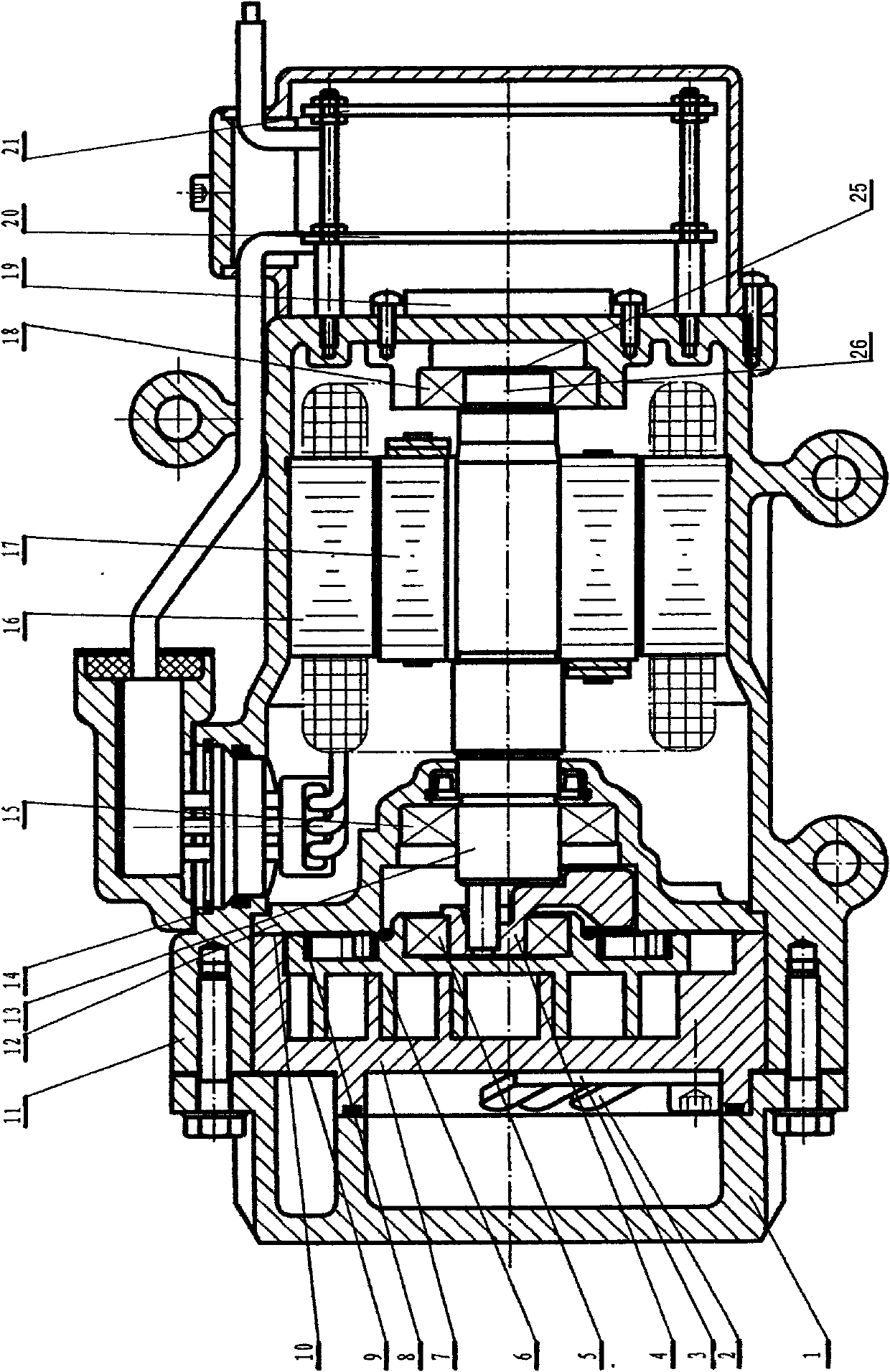

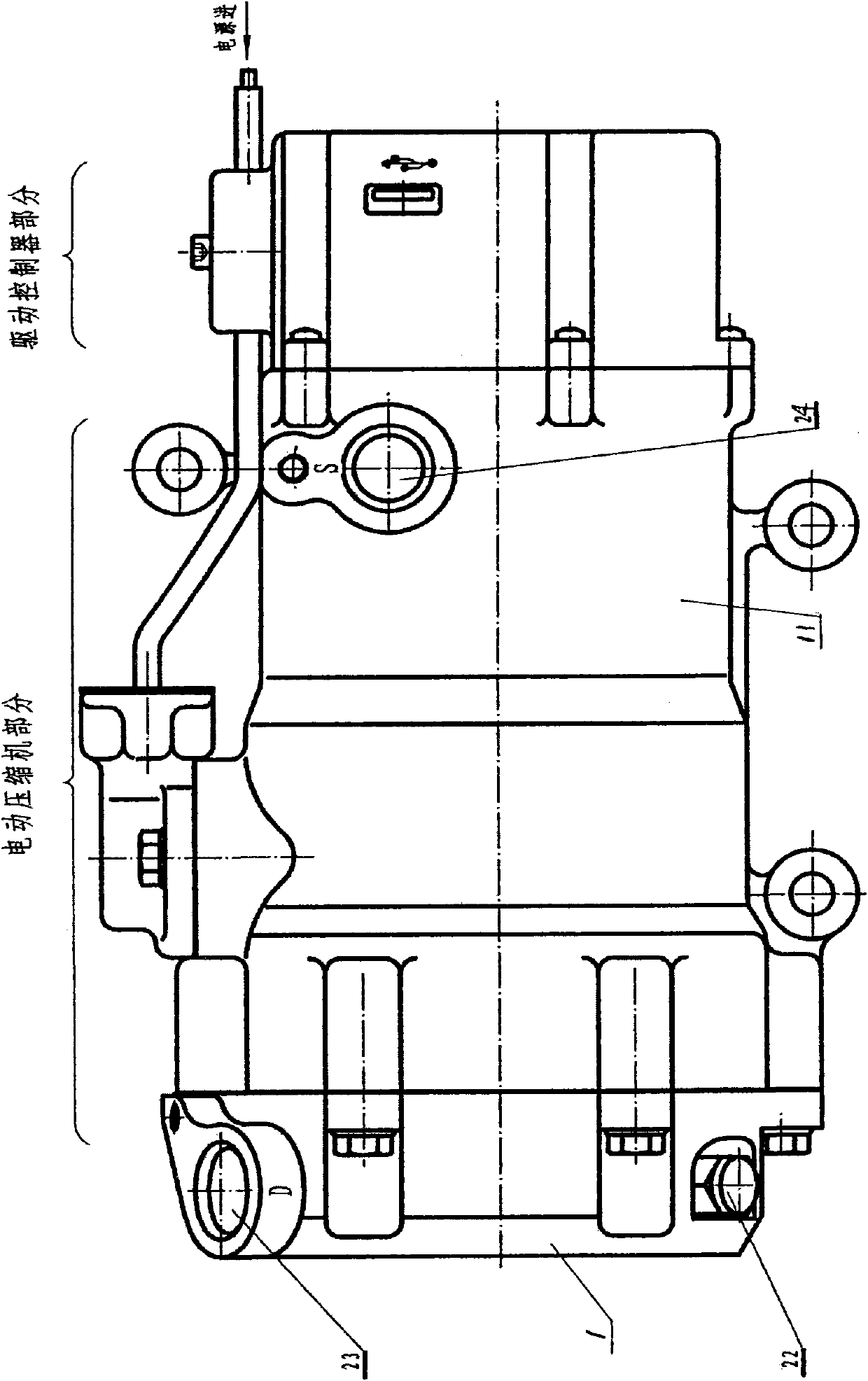

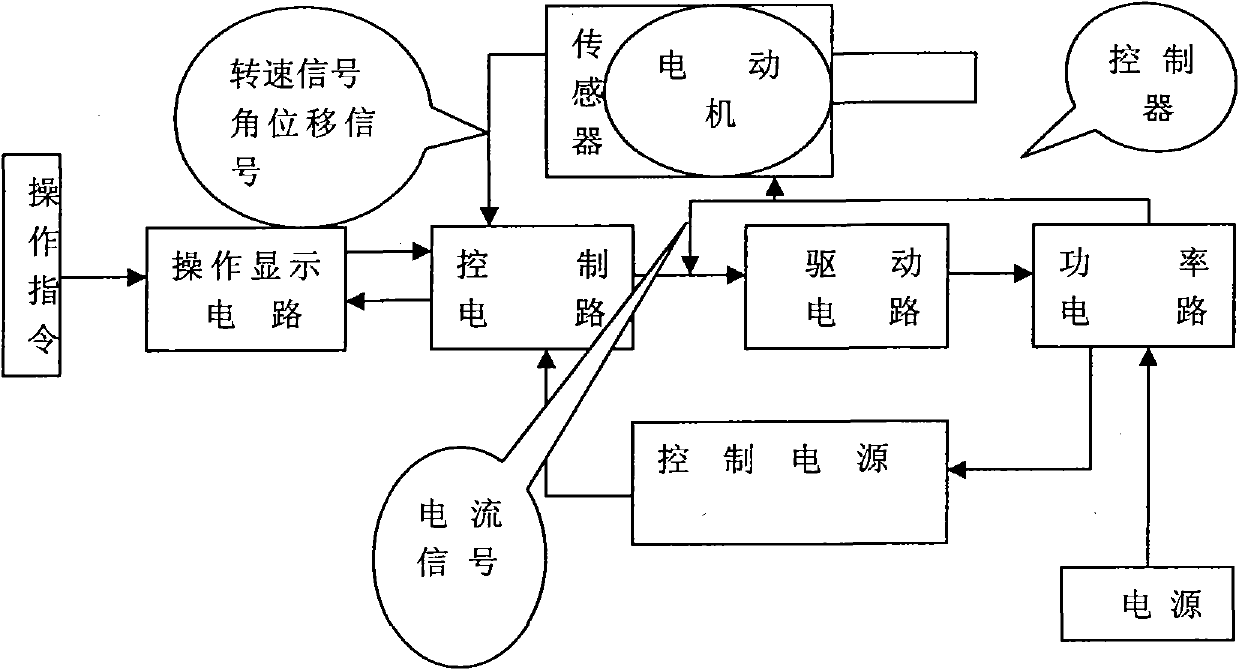

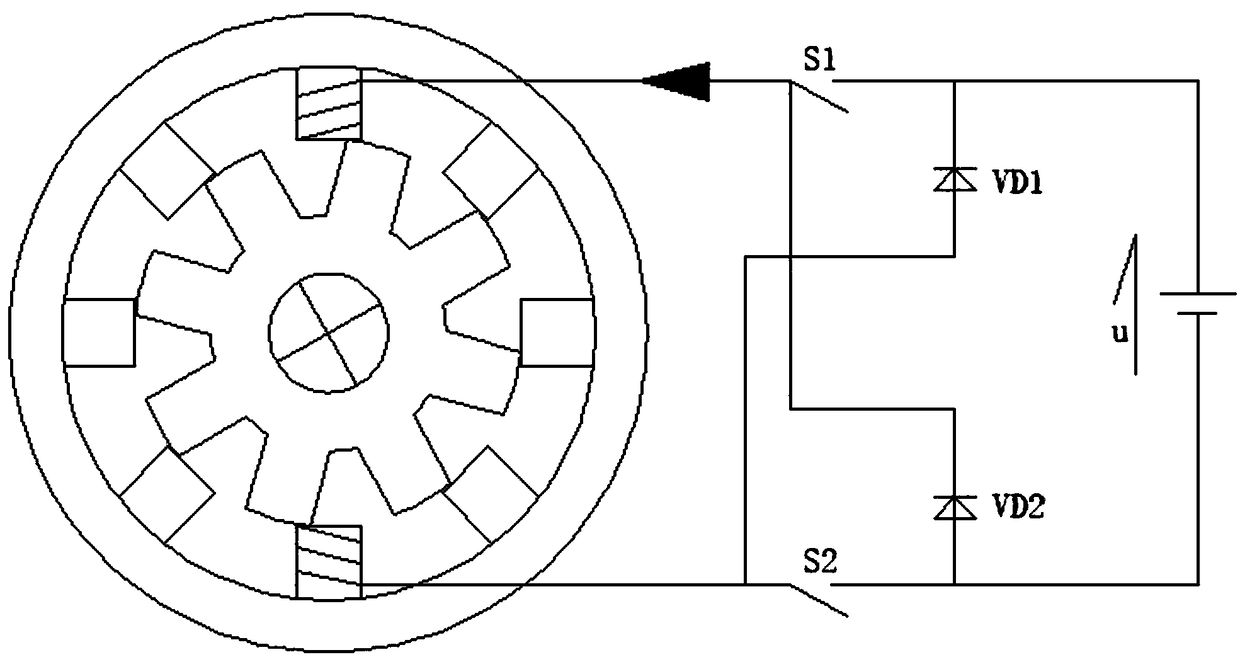

Integrated switched reluctance electric scroll compressor assembly for vehicle air conditioning

InactiveCN101769253AMany controllable parametersEfficient Optimal ControlRotary piston pumpsRotary piston liquid enginesPower controlMotor shaft

The invention discloses an integrated switched reluctance electric scroll compressor assembly for a vehicle air conditioning, and relates to a small-sized high-efficiency driving controller with or without a position sensor, a small-sized switched reluctance motor, a small-sized high-speed scroll compressor and match and combination thereof for the vehicle air conditioning. The integrated switched reluctance electric scroll compressor assembly for the vehicle air conditioning comprises a switched reluctance motor scroll compressor part and a switched reluctance motor driving controller part which are integrated into a whole, wherein the switched reluctance motor scroll compressor part consists of a switched reluctance motor and a scroll compressor; the scroll compressor comprises a rear cover, an eccentric bushing, a vortex movable disc, a vortex fixed disc, an anti-spin ring, a bearing I, an outer shell and a front cover; the switched reluctance motor comprises a motor shaft, a bearing II, a bearing III, a connecting terminal, a motor stator, a motor silicon steel sheet rotor, an angular displacement transducer and a motor controller; and the switched reluctance motor driving controller consists of an SRD driving control chip, a driving circuit board I, a protective circuit board II and a power control line connecting the driving controller with the switched reluctance motor.

Owner:NANJING YINMAO COMPRESSOR

Preparation method of fuel cell membrane electrode catalyst layer

The invention provides a preparation method of a fuel cell membrane electrode catalyst layer. The fuel cell membrane electrode catalyst layer comprises a cathode catalyst layer and an anode catalyst layer which are prepared on two sides of the substrate; both the cathode catalyst layer and the anode catalyst layer are formed by coating catalyst layer slurry on the surface of a substrate and performing drying and catalytic layer post-treatment, the catalyst layer slurry of the cathode catalyst layer comprises a catalyst containing ferromagnetic elements, a magnetic field is applied in the post-treatment process of the catalyst layer of the cathode catalyst layer, so that the catalyst containing ferromagnetic elements moves in the cathode catalyst layer, the in-situ regulation and control ofthe pore structure of the cathode catalyst layer are realized, the porosity of the catalyst layer is improved, and the mass transfer of reaction gas in the catalyst layer is promoted; moreover, the magnetic field adjusting process has many controllable parameters, the process is simple, the pollution of the catalyst layer is avoided, the magnetic field adjusting process can be realized by only additionally configuring one magnetic field adjusting device on the existing production line in commercial application, the existing process system is slightly changed, and the popularization is easy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

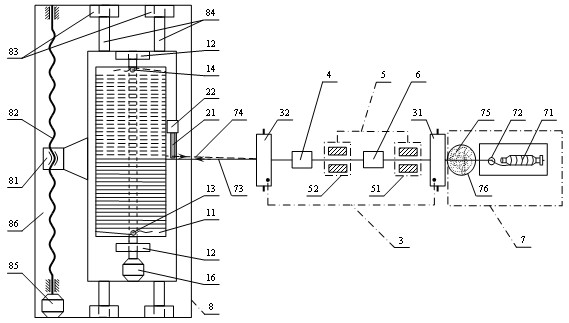

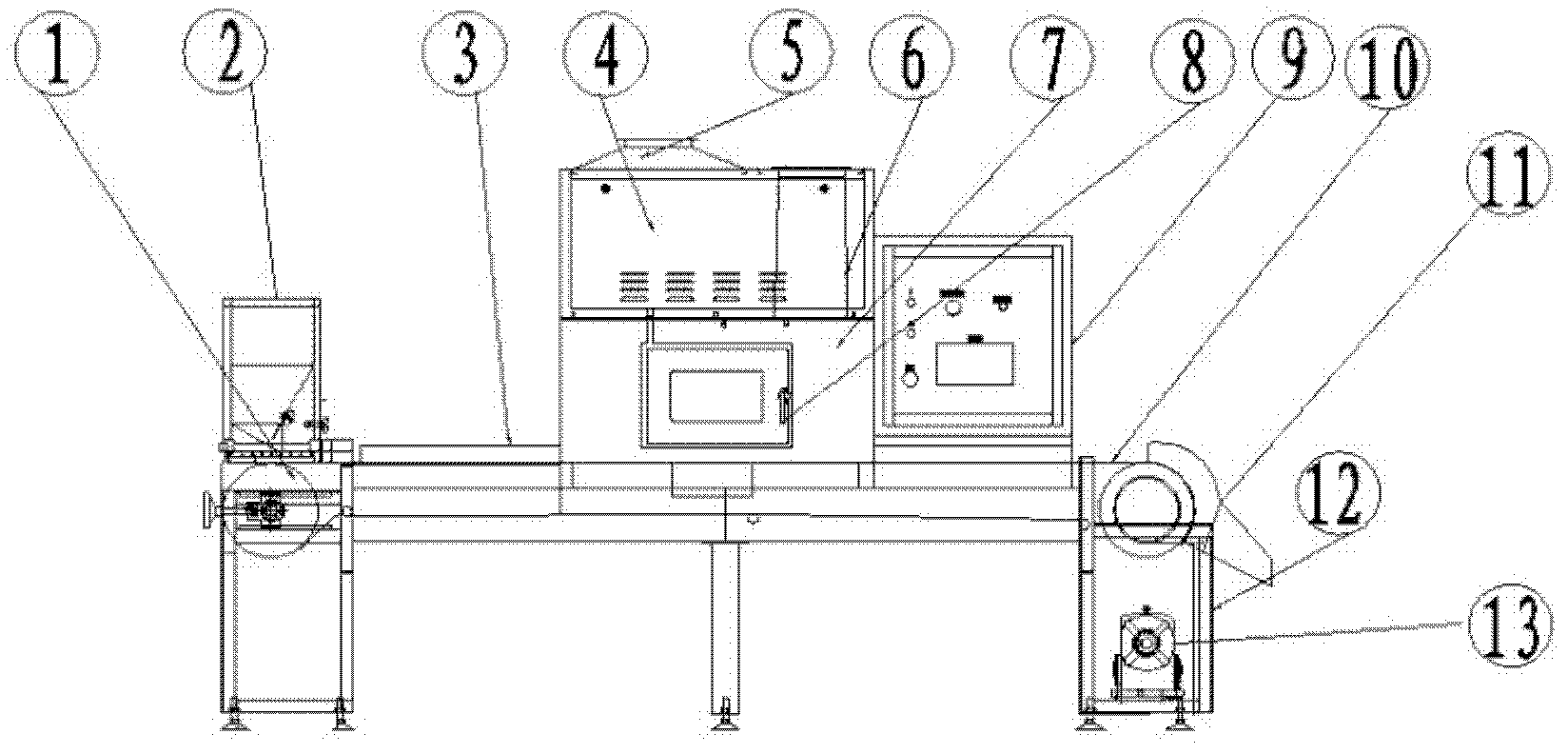

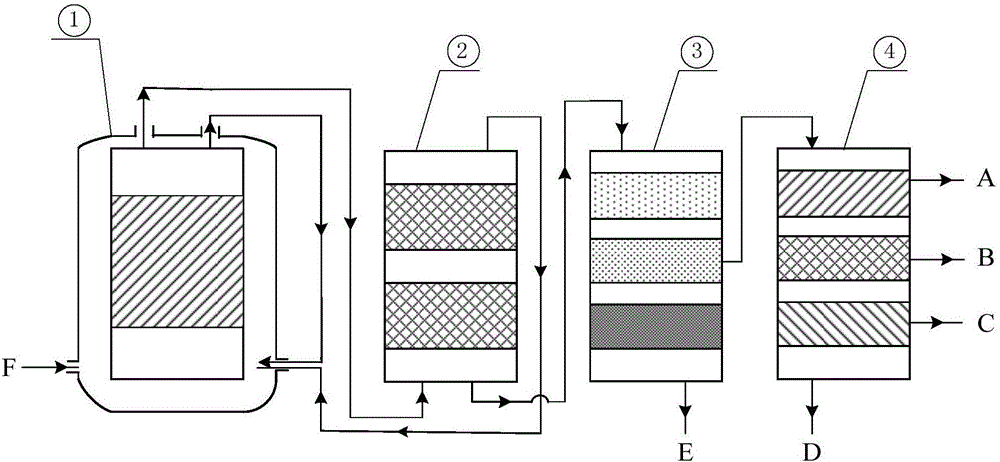

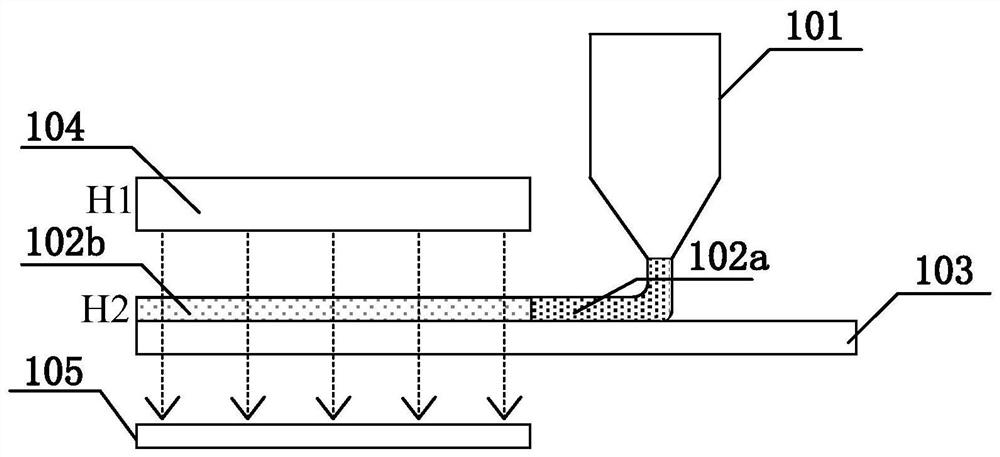

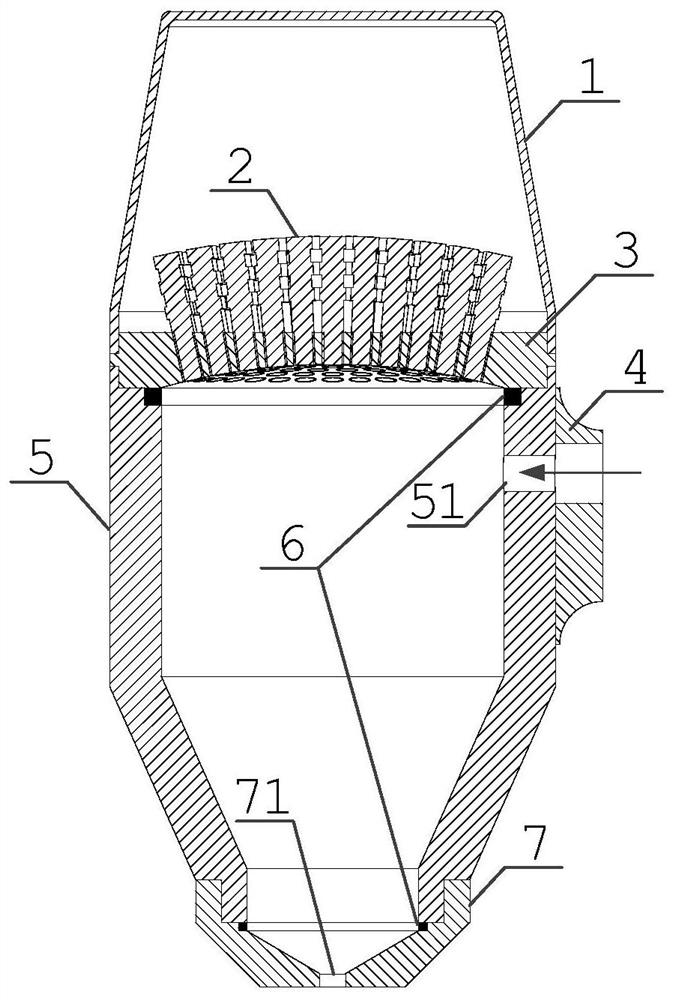

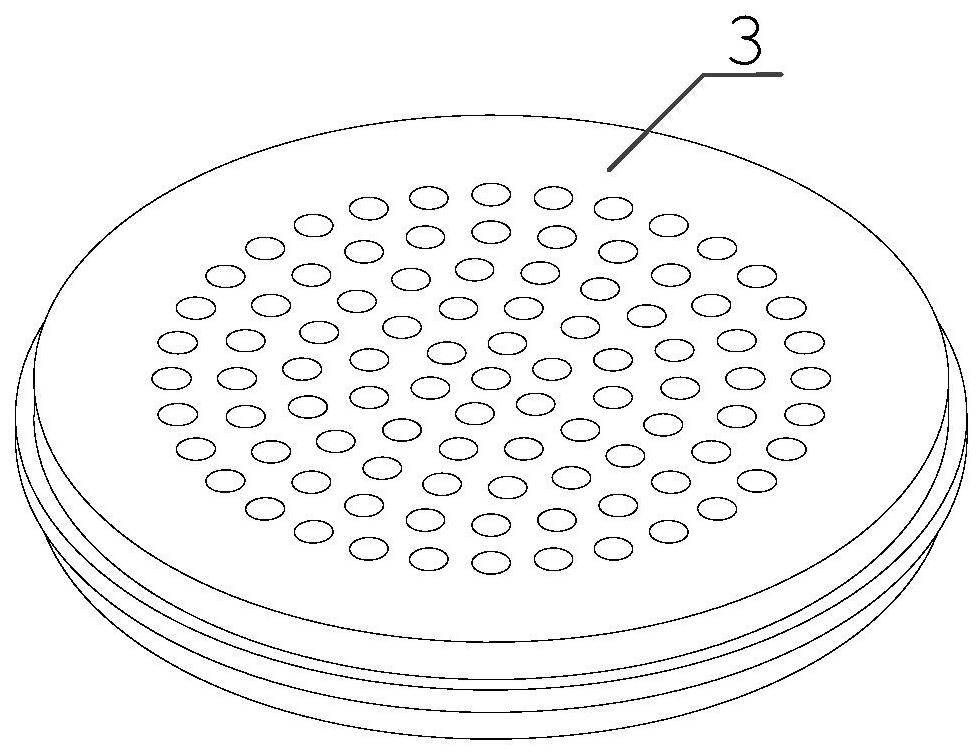

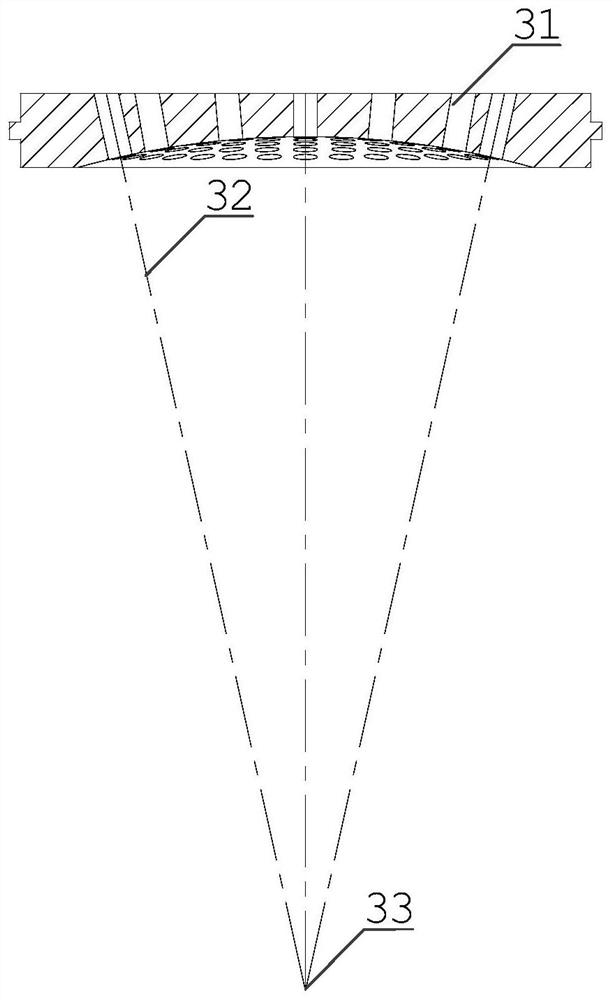

Biomass microwave continuous pretreatment reactor

InactiveCN102658077AEnables continuous preprocessingThe speed can be continuously and linearly adjustedEnergy based chemical/physical/physico-chemical processesHybrid systemHigh density

The invention discloses biomass microwave continuous pretreatment equipment, the structure of which comprises: a material continuous input system, a microwave power continuous linear-tunable reaction system, a microwave leakage prevention system, a control and detection system, a thermal discharge and dehumidification system, a material mixing system, a water supplementing system and a material output system. According to the invention, a high-density material is conveyed into a microwave reaction system through a feed device and a conveyor belt; under the control of a temperature and humidity detection system, the water supplementing system and the material mixing system, the material is adjusted within required temperature and humidity ranges, heat transfer and mass transfer of the material are uniform, and finally the material is outputted by the output system so as to realize continuous pretreatment of the material. The equipment adopts touch screen operation and dynamic display of parameters such as microwave power, temperature, humidity, time and the like, has high automatic and intelligent level, and is easy and convenient for man-machine communication. The equipment provided by the invention realizes continuous pretreatment of biomass at normal pressure, has advantages of high processing efficiency and low energy consumption, and is used to reduce pretreatment cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

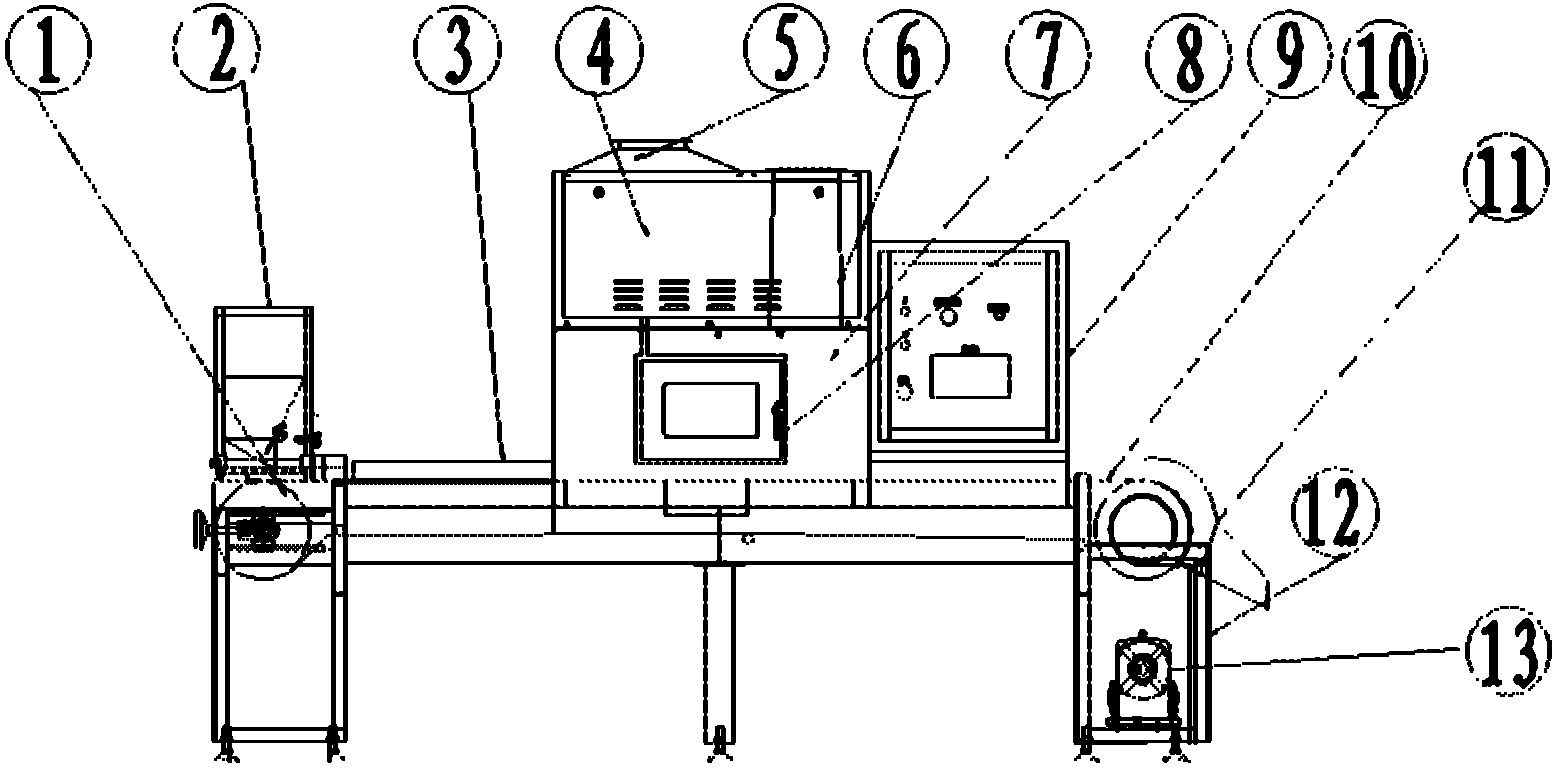

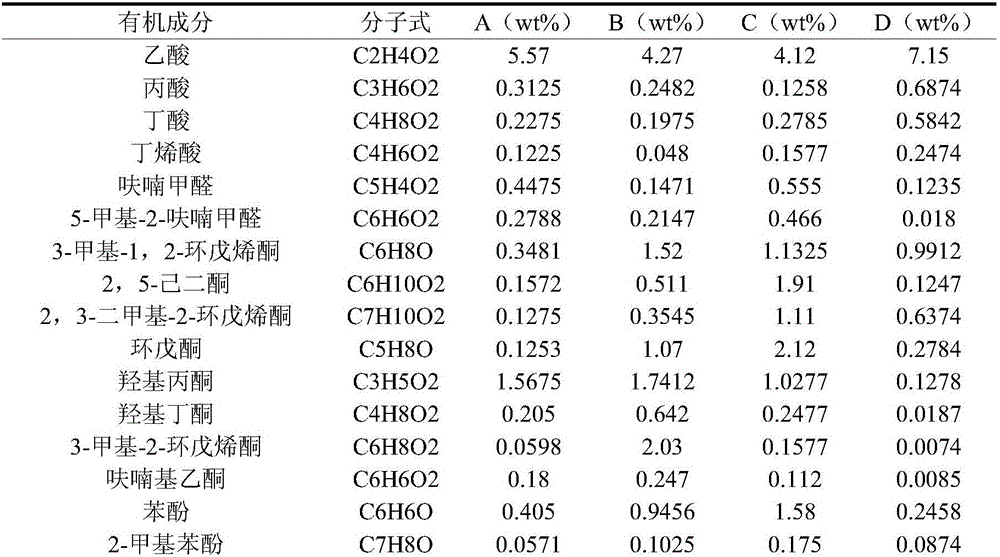

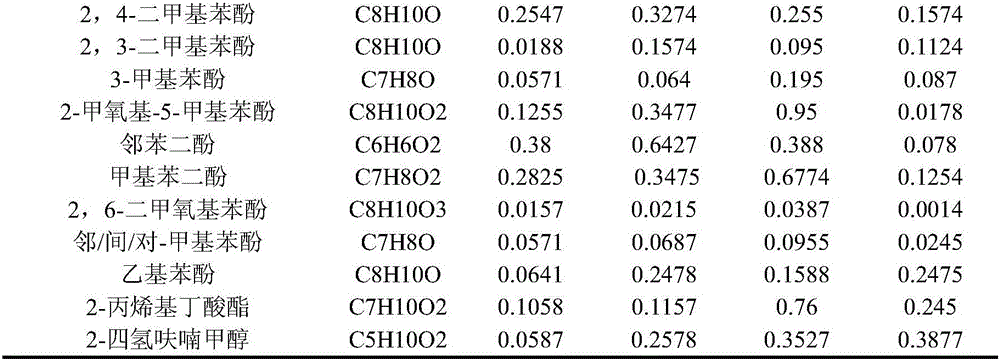

Modular equipment using solid waste catalytic pyrolysis to prepare high-value fuel gas

InactiveCN105567264AEasy to integrateHigh degree of functionalityCombustible gas catalytic treatmentSpecial form destructive distillationCatalytic pyrolysisLiquid product

The invention discloses modular equipment using solid waste catalytic pyrolysis to prepare high-value fuel gas. The equipment comprises a control module, a preprocessing module, a pyrolysis module, a secondary catalyzing module, a condensation module, a purification and absorption module, a liquid collecting module and a gas collecting module. The equipment has the advantages that corresponding modules are started and selected to work according the properties of to-be-processed materials and processing requirements, the control module is used to control the whole system, reaction device temperature, gas pressure and flow speed, multistage cooling system temperature, absorption liquid flow speed and reflux ratio, and the like are regulated to the required temperature, pressure and flow speed range, uniform heat transfer and mass transfer are achieved, gas and liquid products are stored in corresponding storage modules, and the high-value fuel gas is prepared through solid waste catalytic pyrolysis; the equipment using touch-screen operation is capable of dynamically displaying parameters such as temperature, pressure, flow speed and time, high in automation and intelligent level, simple and convenient in man-machine communication, capable of modularly designing and combining production processes according to the properties and processing degree of raw materials and product quality requirements, and efficiency and economy of a solid waste treatment process are increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

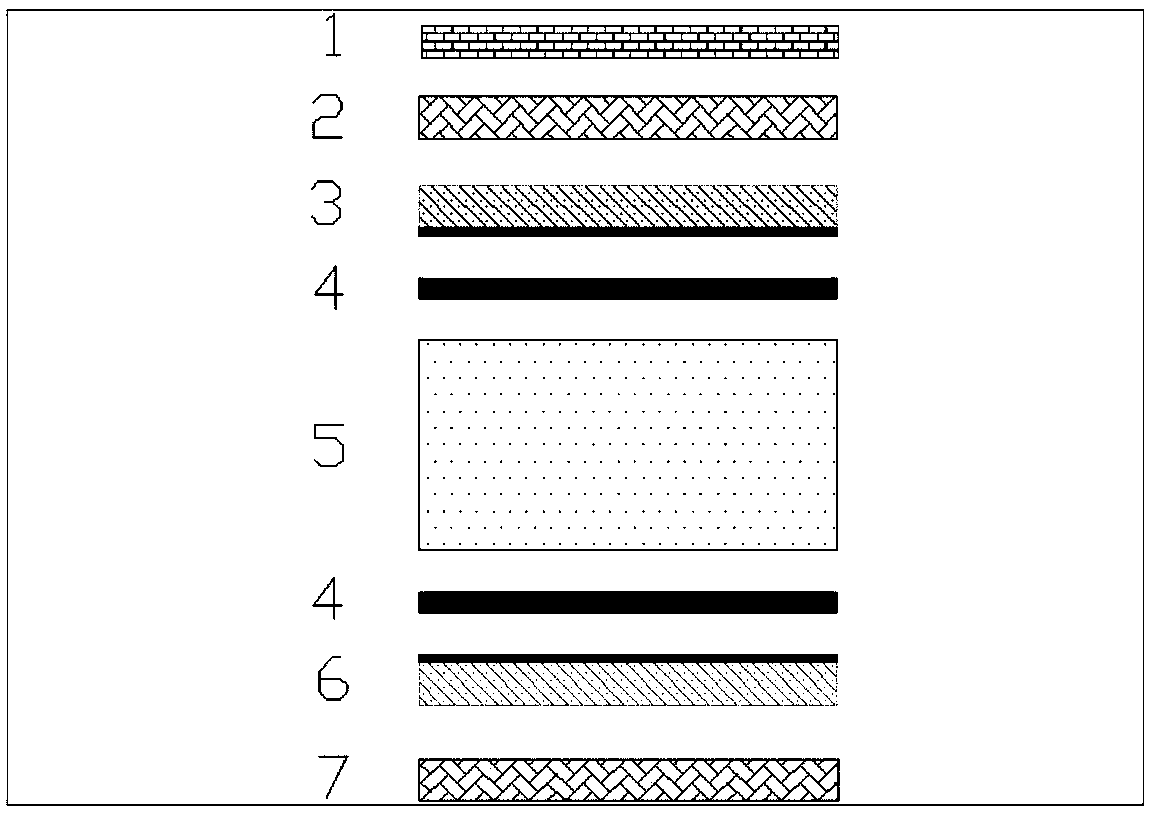

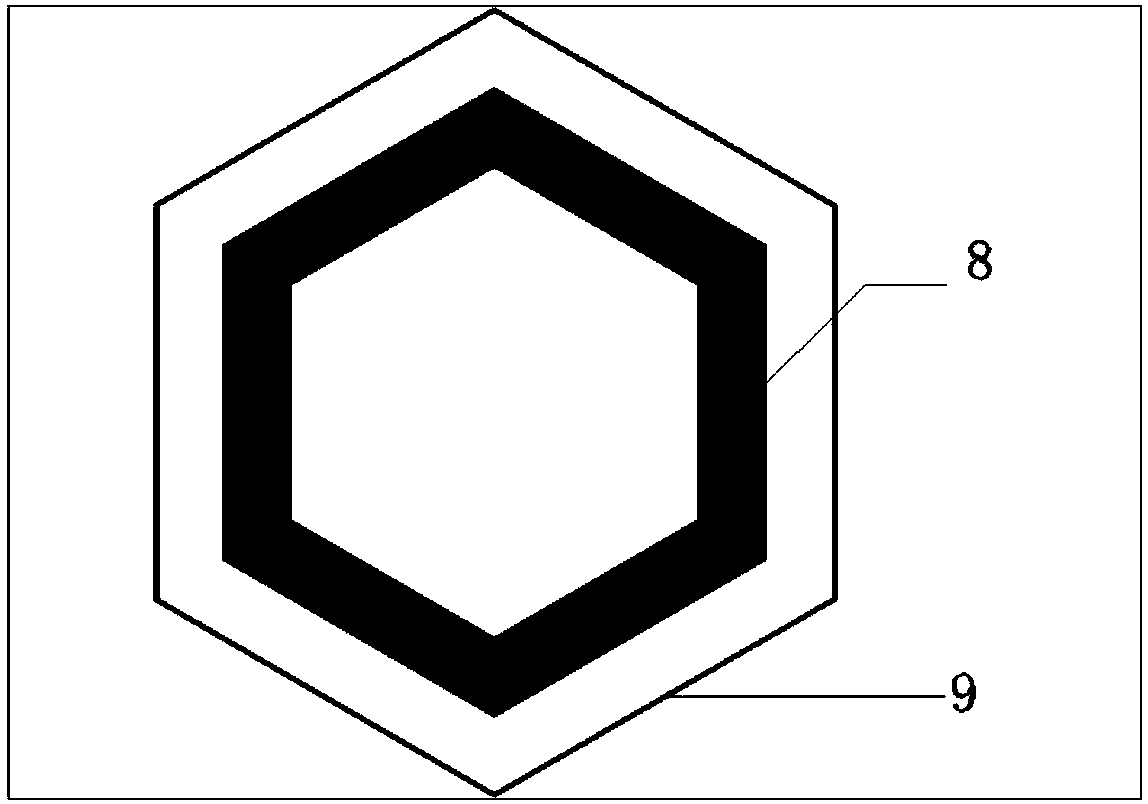

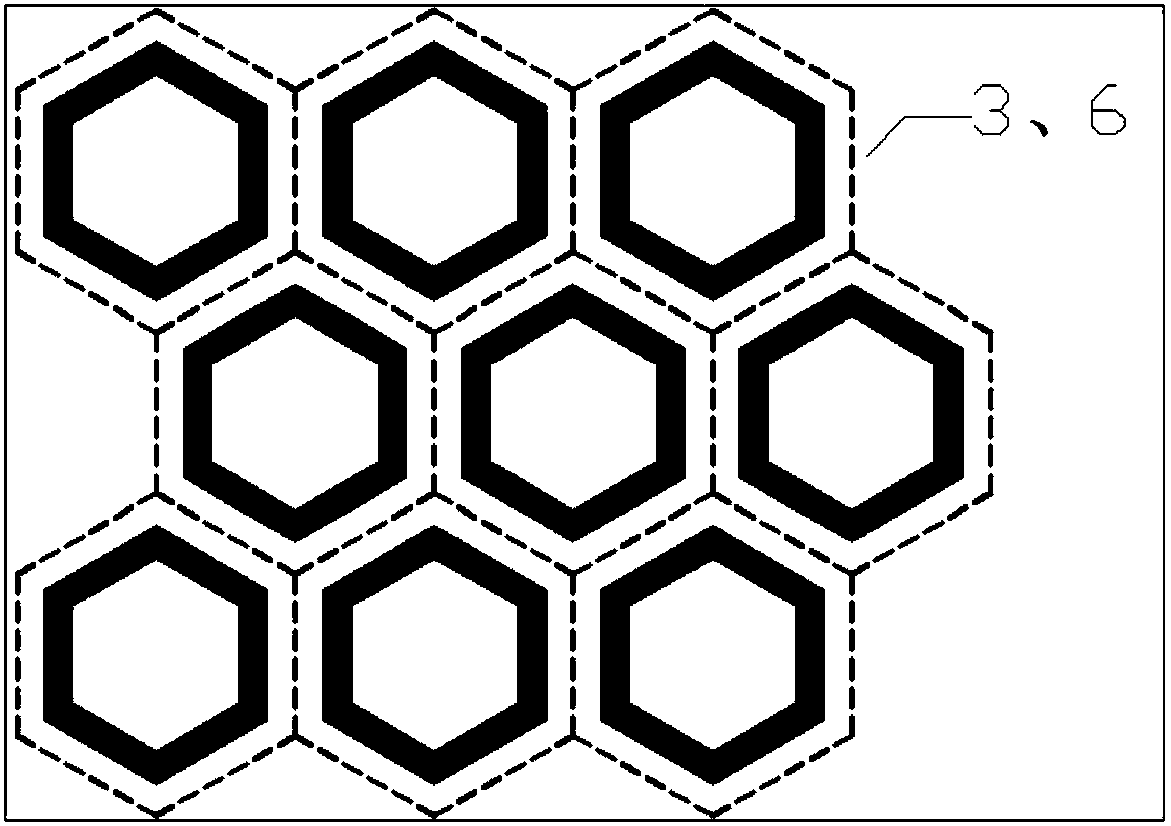

Frequency selecting radome for wideband wide-angle operation

InactiveCN108110418ALow costComposite process is matureRadiating element housingsEngineeringRadar cross-section

The invention relates to a frequency selecting metalized radome which can be widely used for various fields such as radar, communication and electronic countermeasures for realizing specific electromagnetic compatibility, reducing a radar scattering section area of the equipment, reducing interception probability and improving stealth performance. The radome is substantially a spatial domain filter which has advantages of low in-band insertion loss, high out-band suppression degree, wide passband, wide stopband and large incidence angle operation. The radome is composed of two frequency selecting surface layers and a plurality of dielectric layers. The cross section of the cover wall is provided with a fluorine carbon paint layer, an outer sheath, a periodical metal paster layer and a medium substrate thereof, a rubber film, a core layer, a periodical metal paster layer and a substrate thereof, and an inner sheath layer. The radome has advantages of excellent telecommunication performance, excellent structure and environment adaptability, and relatively high engineering practicability.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

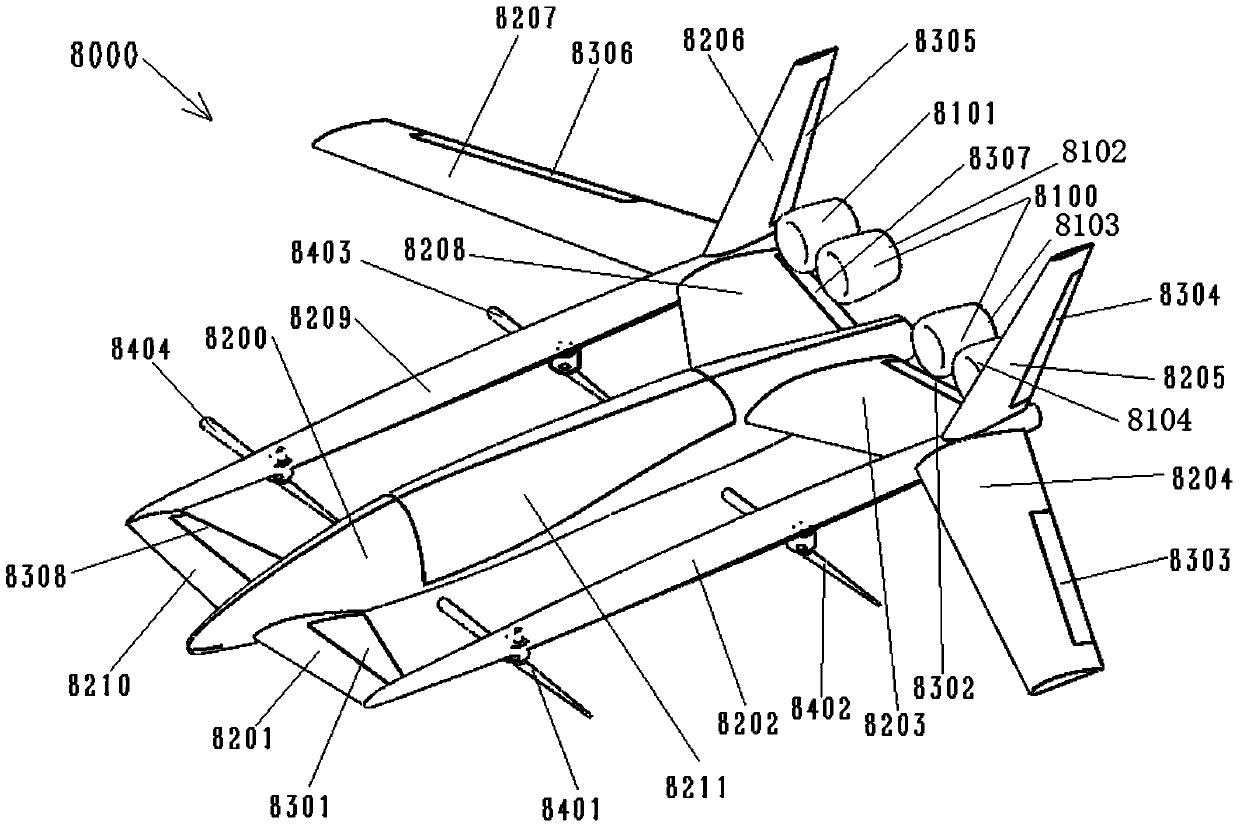

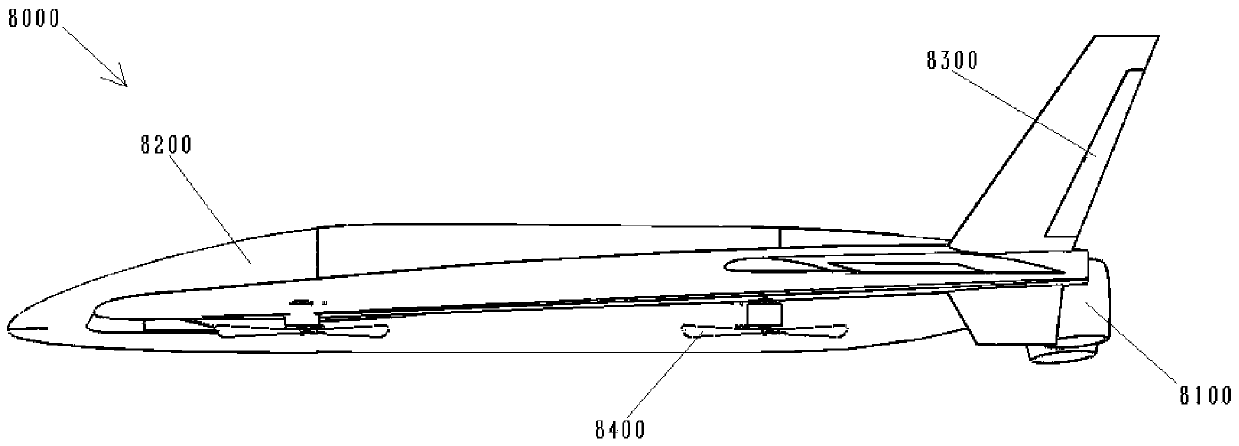

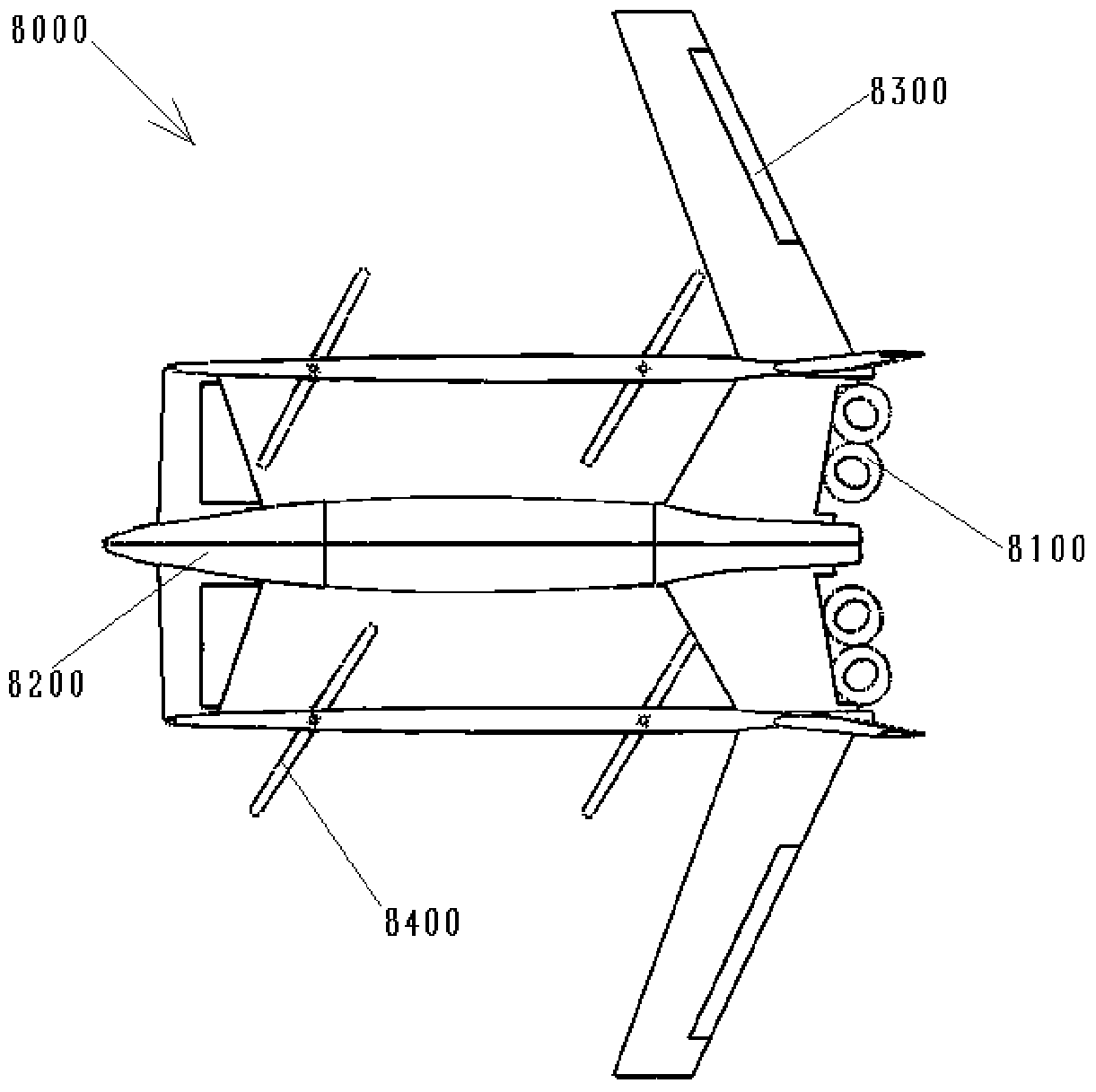

Combined type aircraft adopting rotors and vector propulsion system

The invention discloses a combined type aircraft adopting rotors and a vector propulsion system. The combined type aircraft includes a lift body, the rotors and the propulsion system, the angle of thrust generated by the propulsion system is variable, vertical upward lift can be generated during take-off, and the thrust is generated during flat flight; during the vertical take-off stage of the aircraft, the lift is provided by the rotors and the vector propulsion system; during acceleration of the aircraft, the lift generated by the lift body of the aircraft gradually increases, and the lift generated by the rotors gradually decreases; and in the cruising state, the lift of the aircraft is mainly generated by the lift body, the thrust is generated by a propulsion unit, in this way, the cruising flight efficiency is high, and good flight stability and maneuverability are achieved. According to the combined type aircraft, the rotors and the propulsion unit are enabled to work cooperatively, by changing the thrust direction of the propulsion unit, the propulsion unit can work effectively during take-off, flat flight and landing, and thus the performance of the aircraft is optimized.

Owner:PEKING UNIV

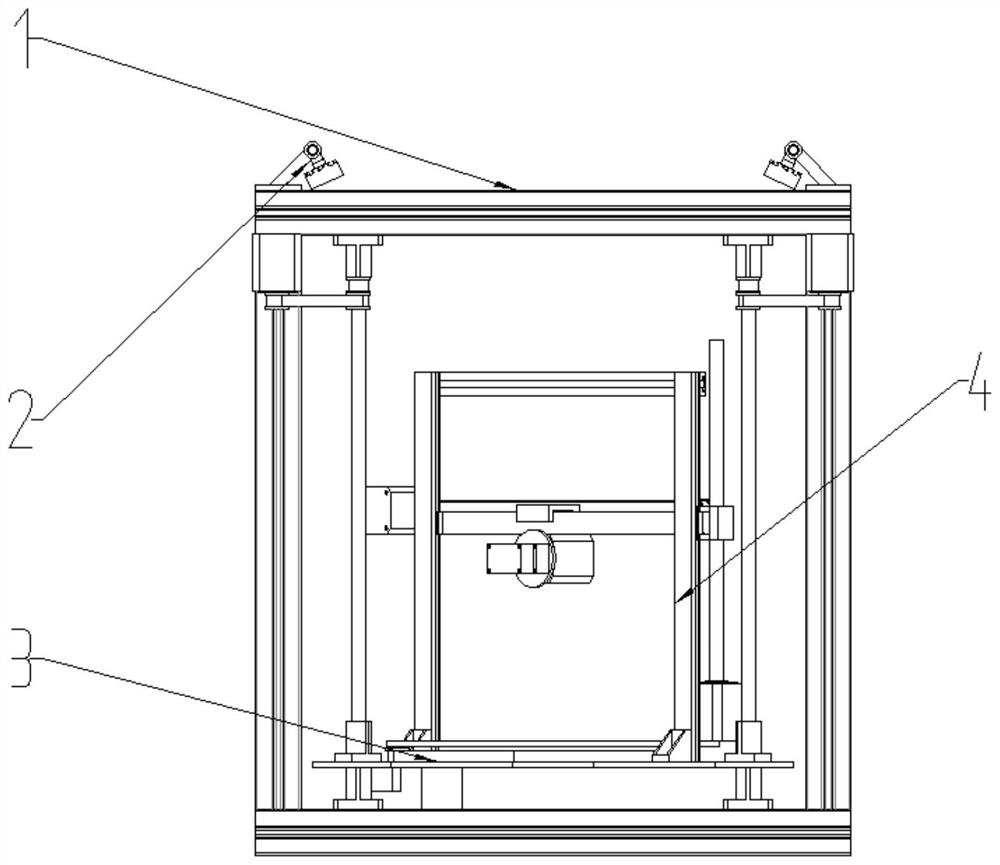

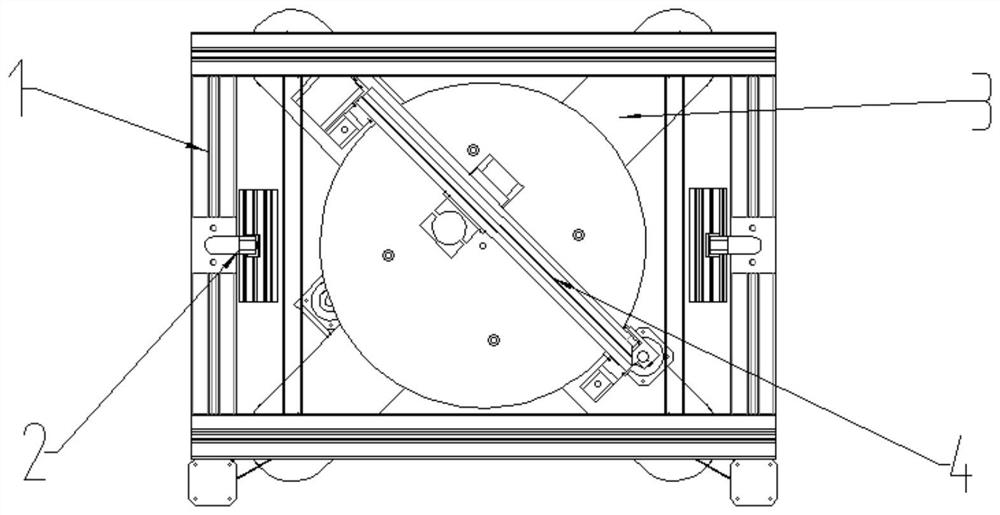

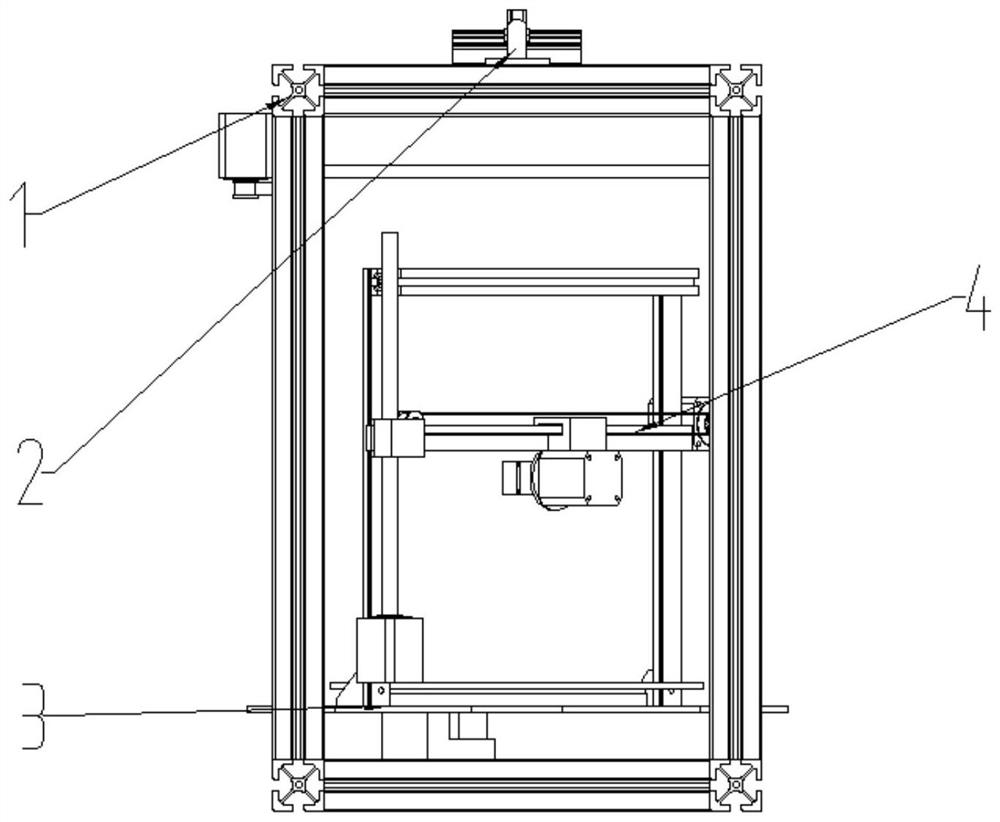

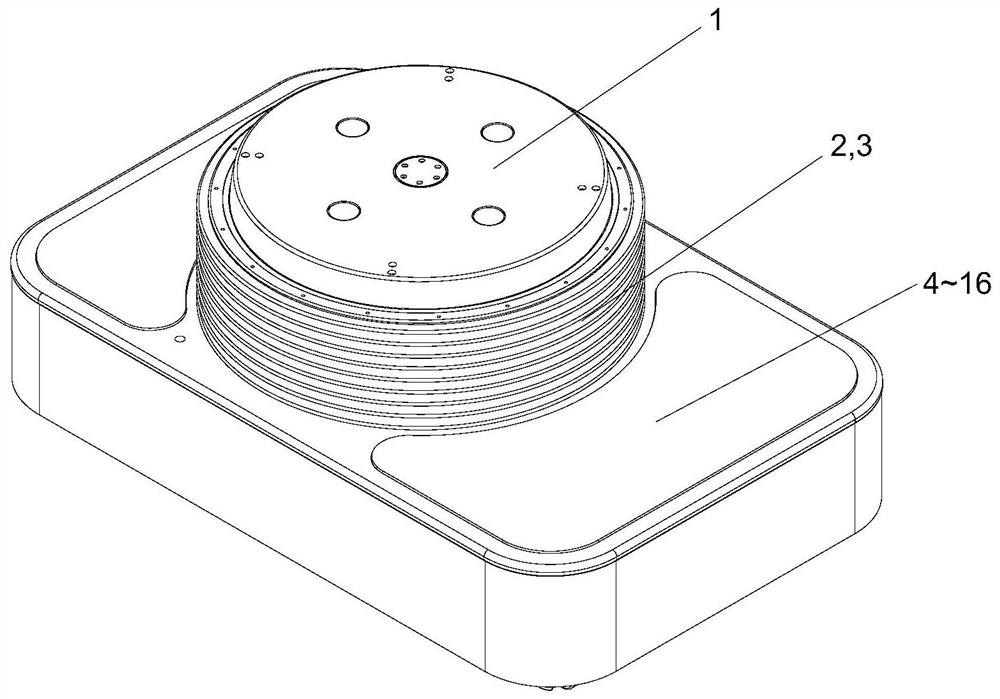

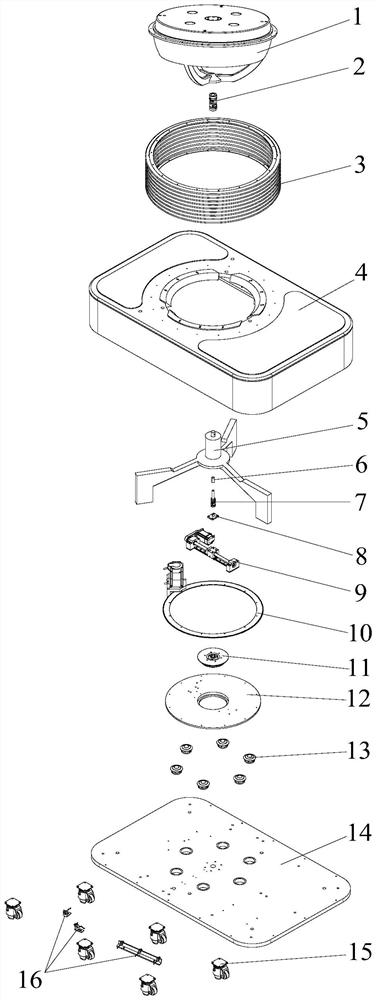

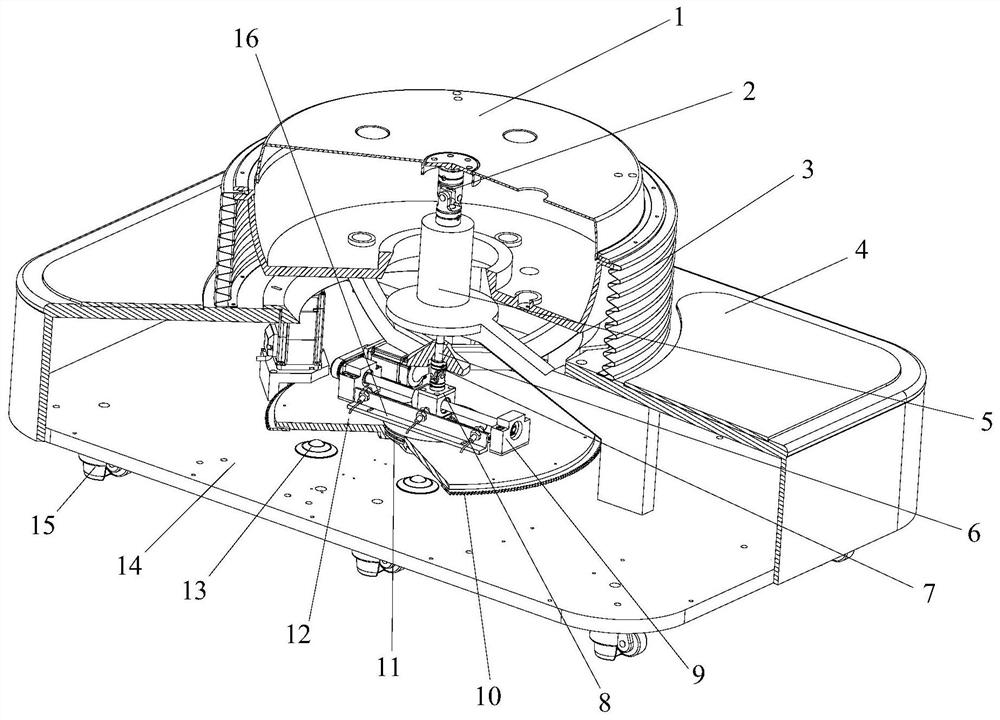

Part identification data set acquisition device

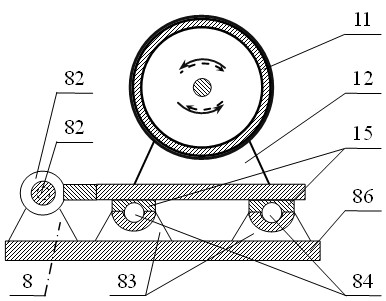

ActiveCN112488093AFast convergenceEasy to identifyThree-dimensional object recognitionCamera controlData set

The invention discloses a part identification data set acquisition device which comprises a lifting type frame structure, a light source control mechanism, a part tray and a camera control assembly. The lifting type frame structure is a cuboid frame. The light source control mechanism is installed at the top of the lifting type frame structure and provides illumination for parts. The part tray isinstalled on the lower portion in the lifting type frame structure and used for containing parts. The camera control assembly is installed above the part tray and used for fixing the camera and changing the relative position of the camera and the part. The acquisition device can simultaneously control one or more of five parameters including illumination intensity, illumination angle, illuminationdistance, camera angle and camera distance. Variable control is strict, angle, strength and distance change gradients are uniform and reasonable, the data set quality is high, the convergence rate ofthe part recognition algorithm training process can be increased, and the algorithm recognition capacity is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

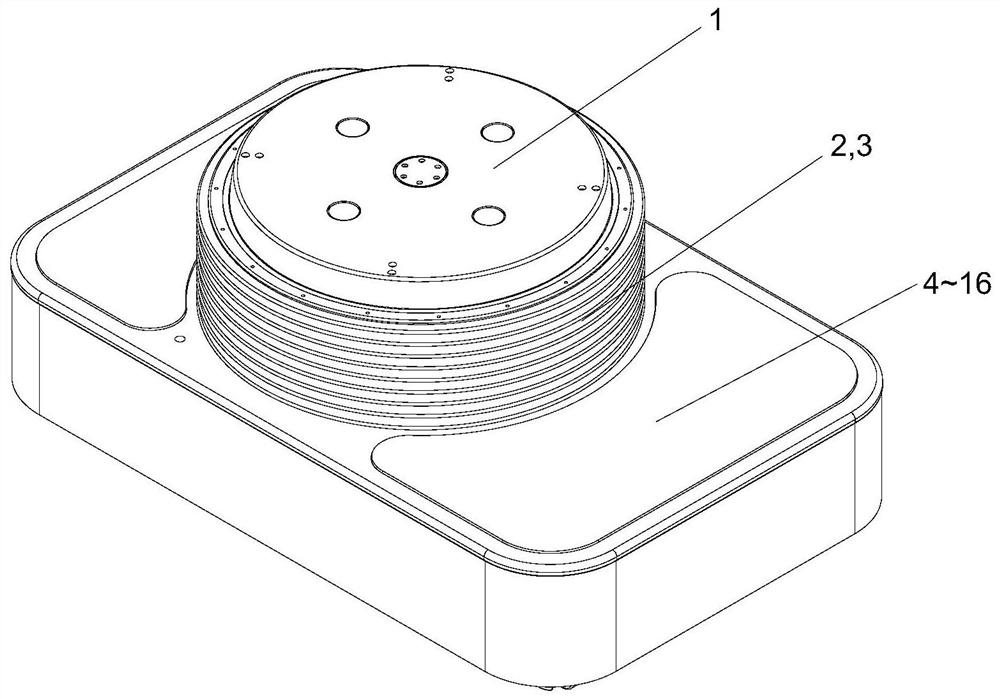

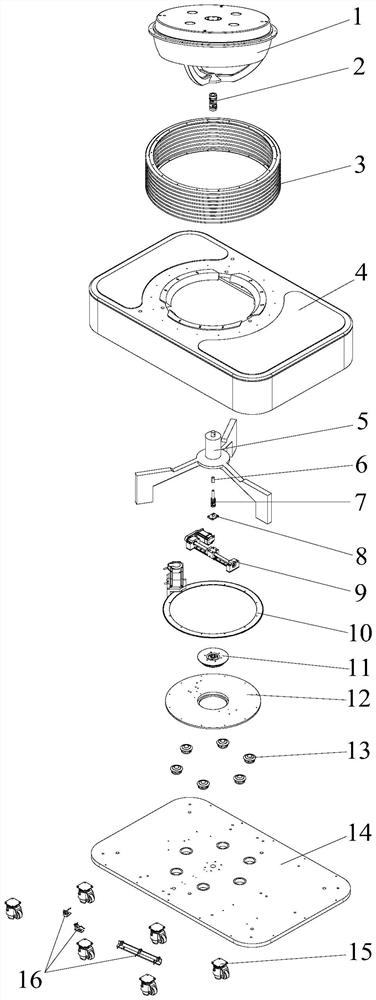

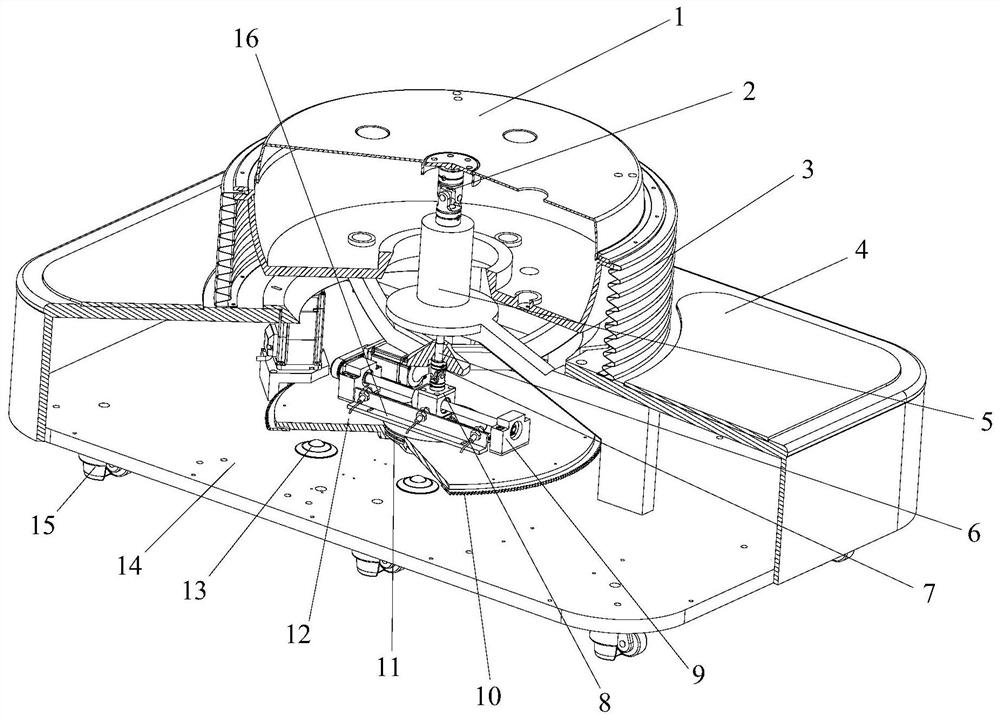

Driving device for passive dynamic balance training of human body

The invention relates to a driving device for passive dynamic balance training of a human body, which comprises a base plate (14), a pedal box (4) arranged on the base plate (14), a circumferential driving mechanism (10), a radial driving mechanism (9) and a movable platform (1) connected with the pedal box (4), the movable platform (1) is provided with a pedal plate (101), and the circumferential driving mechanism (10) and the radial driving mechanism (9) are connected with the movable platform (1) in series. The radial driving mechanism (9) controls the inclination angle change of a pedal plate (101) on the movable platform (1), and the circumferential driving mechanism (10) controls the orientation of the upper surface of the pedal plate (101). Compared with the prior art, the driving device has the advantages of avoiding bloating and vibration of the pedal of the movable platform, being long in driving force arm, being capable of realizing multiple motion modes, being simple in inclination angle adjustment, being convenient to control and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

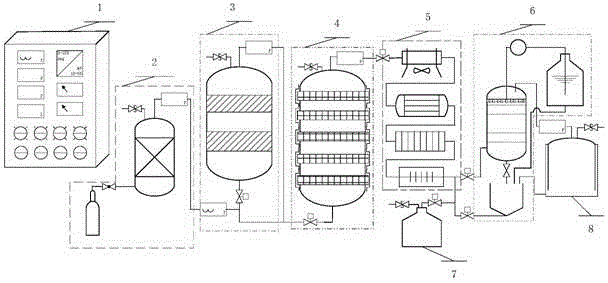

Internal circulation type wood vinegar production and purification device

InactiveCN106520167AHigh degree of functionalityReduce intakeBiofuelsPyroligneous acid productionData recordingHeating power

The invention discloses an internal circulation type wood vinegar production and purification device. The device is composed of a biomass solid waste pyrolysis furnace, a display control touch screen, a two-section type purification tower, a coarse purification tower and a wood vinegar purification tower, wherein a heat source of the biomass solid waste pyrolysis furnace is provided by pyrolysis gas; the two-section type purification tower is composed of two charcoal filling plates and a temperature and pressure sensing system; and the wood vinegar purification tower is formed by coupling a film separation device and a rectification purification device body. The device adopts touch screen operation, the parameters such as the burning gas / burning oil flow rate, the pyrolysis gas reflux ratio, and the heating power, temperature, pressure and time of the two-section type purification tower are dynamically displayed, and data recording is conducted through a paperless recorder. The device is suitable for preparing wood vinegar through biomass raw materials in a pyrolysis mode and has the refining function and the advantages of high integration and automation degree and the like. The biomass solid waste pyrolysis process and the wood vinegar refining process are coupled, and the corresponding pyrolysis and separation conditions can be adopted according to characters of to-be-processed materials and the quality of obtained products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

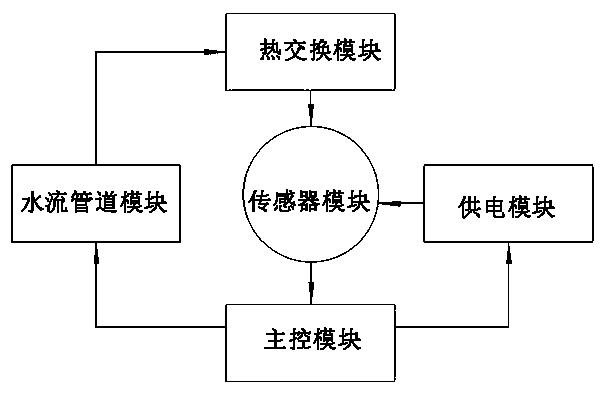

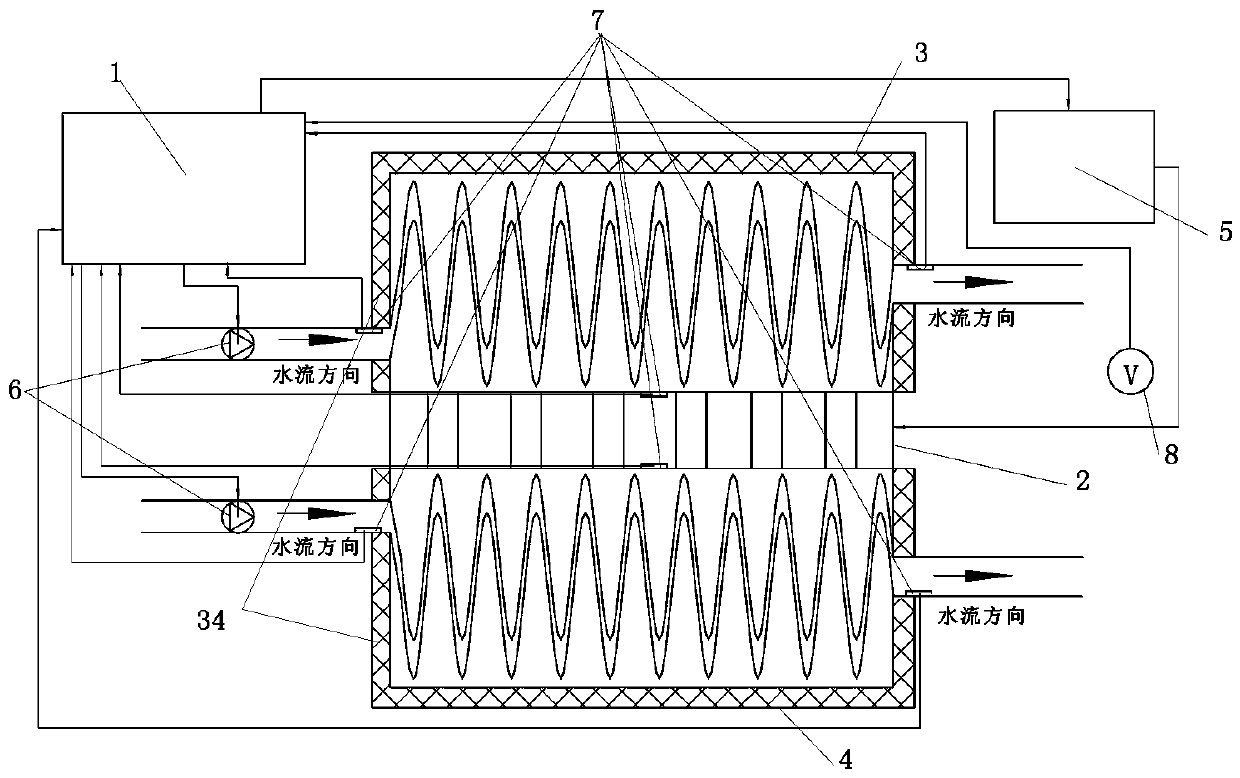

Testing device for semiconductor thermoelectric refrigerating unit

InactiveCN109884491AMany controllable parametersSimple structureIndividual semiconductor device testingElectricityLiquid medium

The invention belongs to the technical field of semiconductor thermoelectricity, and particularly relates to a testing device for a semiconductor thermoelectric refrigerating unit. The testing devicecomprises a main control module, a heat exchange module, a liquid medium pipeline module, an electricity supply module and a sensor module; the heat exchange module comprises a hot end exchanger and acold end exchanger, the hot end exchanger and the cold end exchanger are each provided with a liquid medium outlet and a liquid medium inlet, the liquid medium outlets and the liquid medium inlets are provided with temperature sensors correspondingly, the hot end exchanger and the cold end exchanger are provided with heat exchanging faces making contact with the cold end and the hot end of the semiconductor thermoelectric refrigerating unit, and heat-insulation layers are arranged on the outer surfaces, except for the outer surfaces of the heat exchanging faces and the liquid medium outlet and the liquid medium inlet, of the hot end exchanger and the cold end exchanger correspondingly; the liquid medium pipeline module is provided with a power pump controlled by the main control module; the electricity supply module comprises a direct-current electricity source controlled by the main control module; and the main control module is a computer. The testing device works through a water flow heat metering method, the heat exchange module in heat insulation with the exterior is adopted, thus heat emission in testing can be effectively prevented, and the measurement error can be effectively reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

H-1type electrically-controlled magnetic motor

ActiveCN103414387AImprove reliabilityIncrease starting torqueGenerators/motorsStator coilConductive materials

The invention relates to an H-1type electrically-controlled magnetic motor belonging to the field of permanent magnet energy development. The H-1type electrically-controlled magnetic motor mainly consists of a non-magnetic conductive material case, a front end cover, a rear end cover, a main shaft, a position detection circuit board, a shielding plate, an H-1type stator, a salient pole type rotor, a bearing, an inner bearing pressure cover and an outer bearing pressure cover, wherein the H-1type stator consists of a magnetic conductive material, an electromagnetic coil and a permanent magnet; a stator core and an inner circle wall of the case are connected by bolts; the salient pole type rotor is in key joint with the main shaft; and a trough-type optocoupler of the sensor is mounted on the position detection circuit board on the outer side of the rear end cover of the main shaft. According to the H-1type electrically-controlled magnetic motor, the stator coil is controlled by a three-phase winding through a controller and acts on a magnetic conductive salient pole of the rotor, so as to drive the rotor to rotate, thus the permanent magnet energy can be effectively converted with low power consumption.

Owner:赵明珍

Polarization maintaining optical fiber with microstructure

InactiveCN100592114CRefractive index adjustmentMany controllable parametersOptical fibre with polarisationOptical waveguide light guideRefractive indexPolarization-maintaining optical fiber

A polarization preserving fiber of microstructure mode is prepared for forming fiber core by media material 1 and hole 2 being cyclically arranged, obtaining refractivity relation of n1 >n3 >n2 for media material 3 when cladded layer is only prepared by media material 3 and obtaining refractivity relation of n3 >n4 and n1>n3 >n2 for media material 3 and hole 4 being cyclically arranged when cladded layer is prepared by media material 3 and hole 4 being cyclically arranged.

Owner:JIANGSU UNIV

A kind of preparation method of fuel cell membrane electrode catalytic layer

The invention provides a method for preparing a fuel cell membrane electrode catalyst layer. The fuel cell membrane electrode catalyst layer includes a cathode catalyst layer and an anode catalyst layer prepared on both sides of a substrate, and both the cathode catalyst layer and the anode catalyst layer are the catalyst layer slurry Coated on the surface of the substrate, dried and post-treated on the catalytic layer, the catalytic layer slurry of the cathode catalytic layer includes a catalyst containing ferromagnetic elements, and a magnetic field is applied during the post-treatment of the catalytic layer of the cathode catalytic layer, so that the slurry containing ferromagnetic The catalyst of the element moves in the cathode catalytic layer to realize the in-situ regulation of the pore structure of the cathode catalytic layer, increase the porosity of the catalytic layer, and promote the mass transfer of the reaction gas in the catalytic layer; in addition, there are many controllable parameters in the magnetic field adjustment process, and the process is simple , will not cause pollution to the catalytic layer, and in commercial application, it only needs to be equipped with an additional magnetic field adjustment device on the existing production line, and the modification to the existing process system is small, and it is easy to promote.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

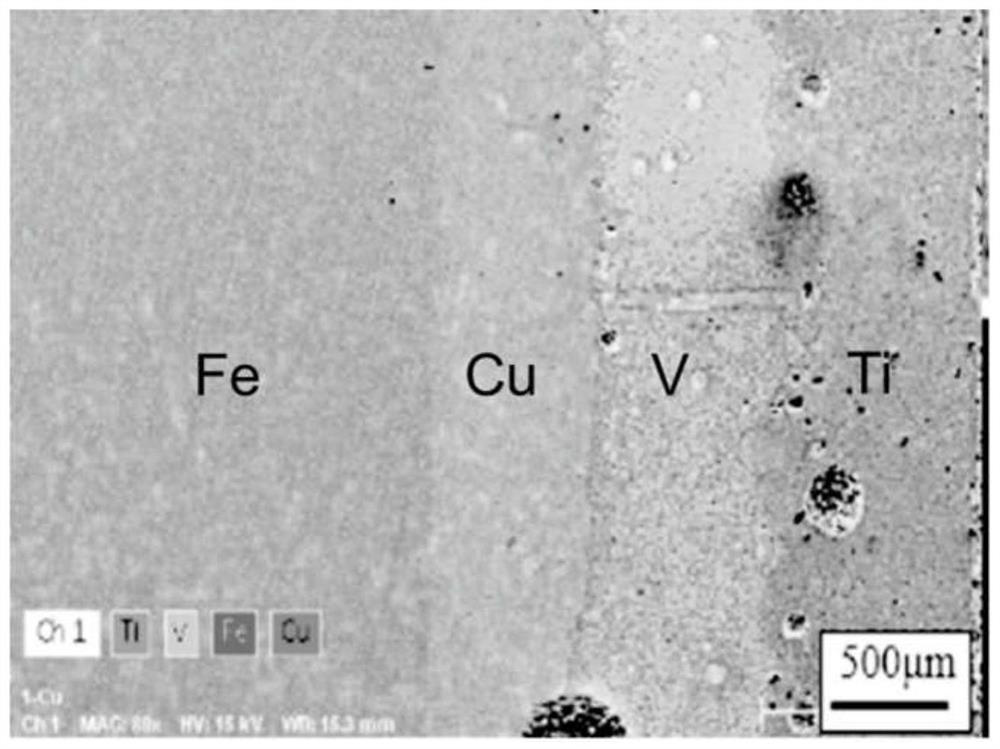

Method for preparing metal transition layer by plasma cladding

InactiveCN111607754AOvercoming disadvantagesSave cladding materialMolten spray coatingPhysical chemistryTitanium

The invention belongs to the technical field of metal surface processing, and particularly relates to a method for preparing a metal transition layer by plasma cladding. The method comprises the stepsof preparing the transition layer on a matrix material in a plasma cladding mode by adopting metal powder as a raw material; and performing the plasma cladding in cooperation with synchronous powderfeeding. On this basis, the method can also comprises the step of further preparing at least one layer of transition layer on the transition layer in the plasma cladding mode by taking the metal powder as the raw material. According to the method, through the mode that the plasma cladding is in cooperation with the synchronous powder feeding, the difficulty in iron-titanium linking is overcome; when the whole scheme is implemented, the cladding can be carried out in selected areas, and the process flexibility is improved while the cladding materials are saved; and when a titanium and titaniumalloy coating is subsequently prepared after the transition layer is prepared, defects such as air holes and cracks can be remarkably reduced, the bonding stability of the titanium and titanium alloycoating is enhanced, and the titanium and titanium alloy coating with excellent performance is obtained.

Owner:SUN YAT SEN UNIV

A driving device for human passive dynamic balance training

ActiveCN113648621BLow costIncrease profitChiropractic devicesStiltsPhysical medicine and rehabilitationDynamic balance

The invention relates to a driving device for human passive dynamic balance training, comprising a base plate (14), a pedal box (4) arranged on the base plate (14), a circumferential drive mechanism (10) and a radial drive mechanism (9). ), and a moving platform (1) connected with the pedal box (4), the moving platform (1) is provided with a foot pedal (101), the circumferential drive mechanism (10) and the radial drive mechanism ( 9) Connected in series with the moving platform (1), the radial drive mechanism (9) controls the change of the inclination of the foot pedal (101) on the moving platform (1), and the circumferential drive mechanism (10) controls the foot pedal The orientation of the upper surface of (101). Compared with the prior art, the present invention has the advantages of avoiding the bloat and vibration of the foot pedal of the moving platform, having a long driving force arm, realizing various motion modes, simple adjustment of the inclination angle, and convenient control.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A polishing device and method based on confocal megasonic micro-jet

The invention discloses a polishing device and method based on confocal megasonic micro-jet, belonging to the field of ultra-precision optical surface processing. The polishing device includes a top cover, a megasonic transducer, a transducer cluster seat, a connecting seat, a liquid storage chamber, a sealing ring, and a nozzle, and the nozzle is provided with a small hole for ejecting the polishing liquid. In addition to the advantages of traditional jet polishing, the confocal megasonic wave micro-jet polishing device and method can suppress the agglomeration effect of polishing powder particles and improve Suspension and dispersion of the polishing liquid; in addition, compared with traditional jet polishing, the device and method have more controllable parameters, and different polishing spots can be realized by adjusting the power and frequency parameters of the megasonic transducer array , polishing efficiency, polishing quality, and has good time response characteristics.

Owner:成都精密光学工程研究中心

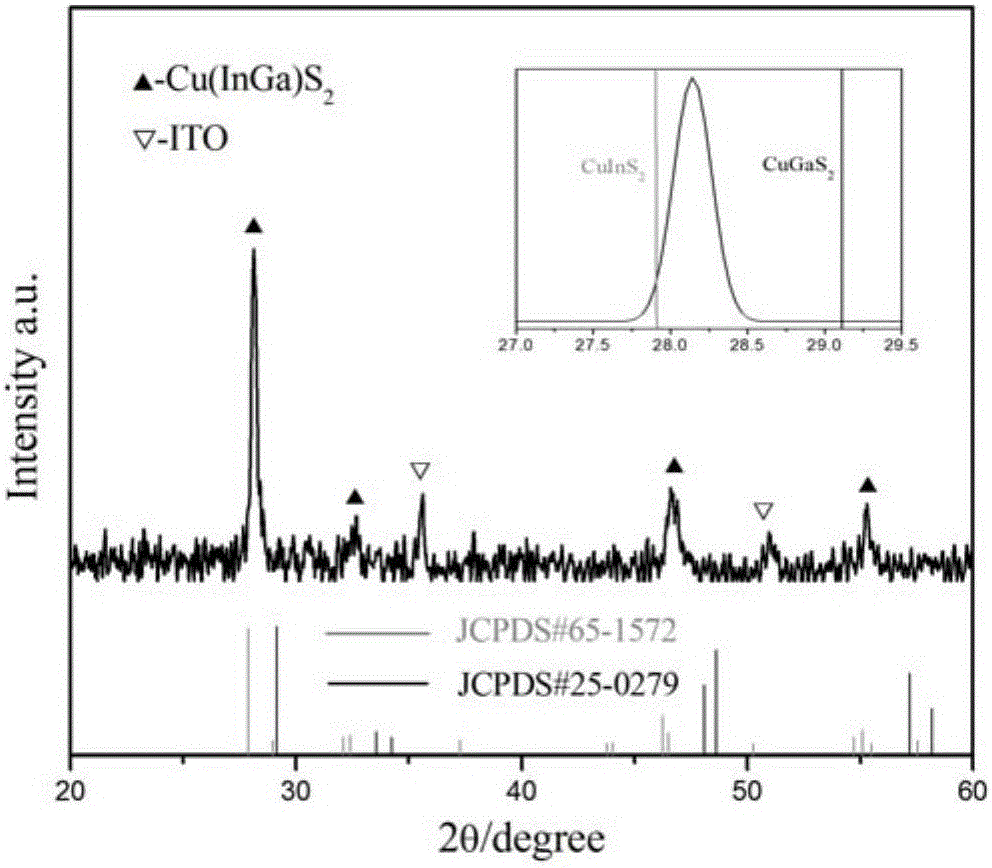

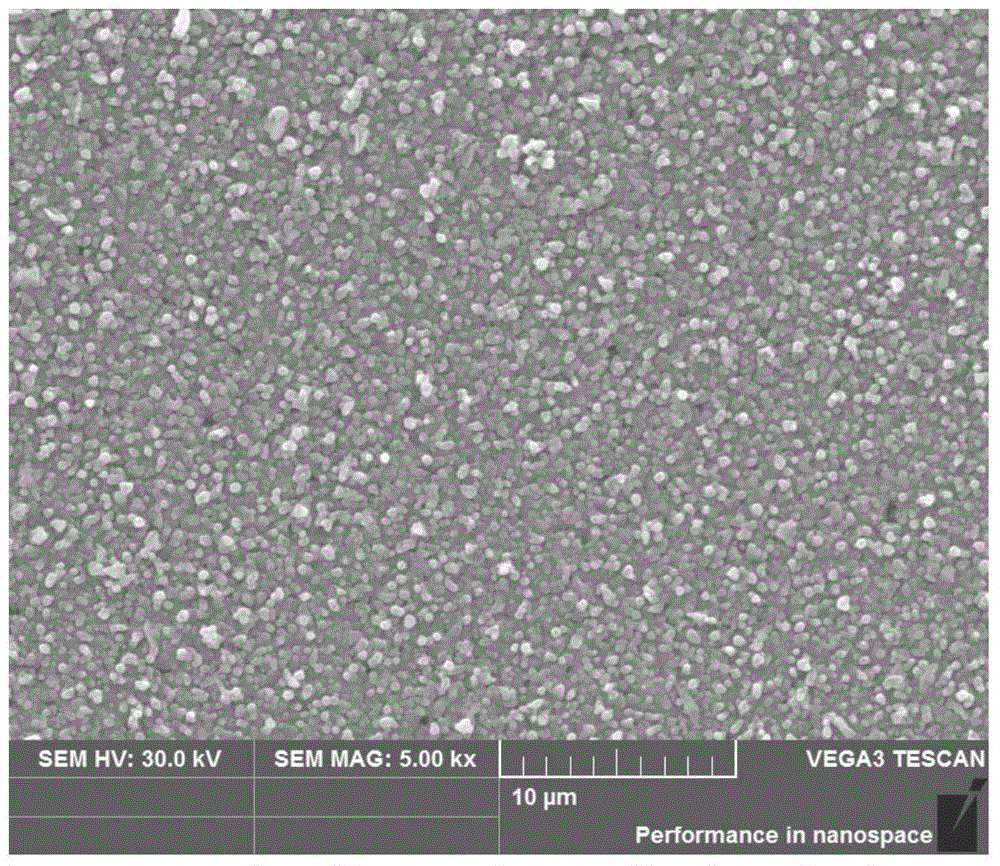

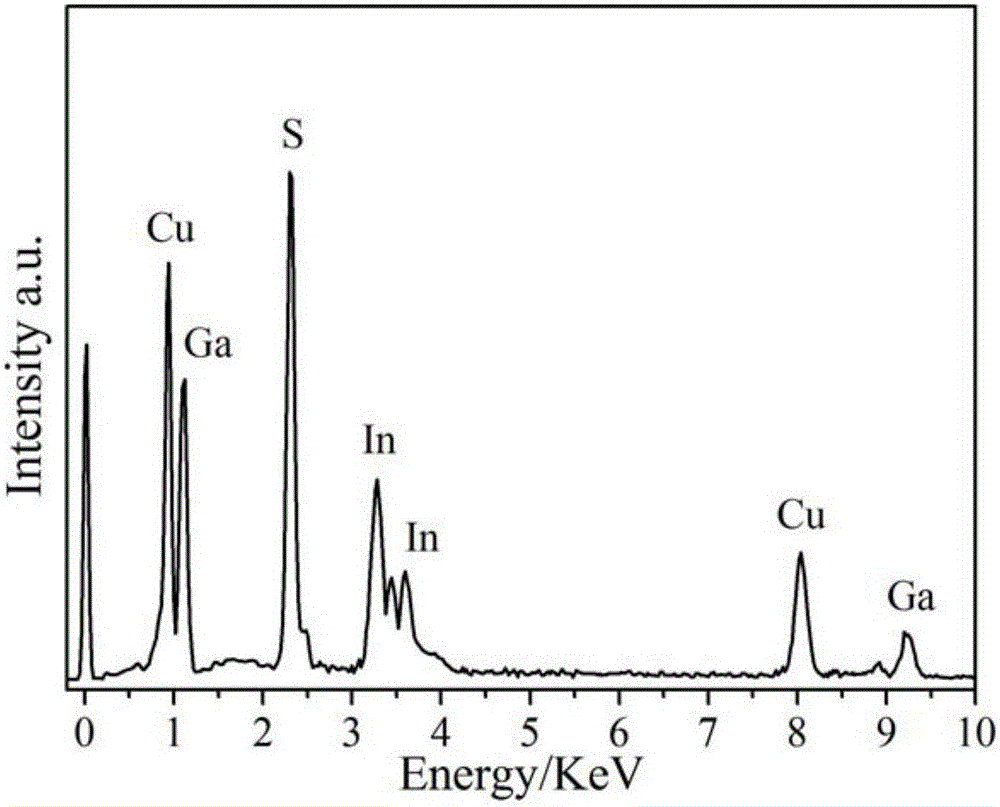

A method for preparing copper-indium-gallium-sulfur solar cell thin film material after electrodeposition by bipotential step method

ActiveCN105226117BGood lookingShape is easy to controlPhotovoltaic energy generationSemiconductor devicesThin film morphologyIndium

The invention discloses a sulfide annealing copper indium gallium sulfur solar cell thin film material preparation method after double-potential step method electrodeposition. The method comprises the steps that copper and gallium metal salt is used as a main raw material; the main raw material is dissolved in an ionic liquid at a certain concentration; a copper gallium precursor thin film is prepared on ITO conductive glass through double-potential cycle step method electrodeposition; sulfide annealing is carried out on the precursor thin film; in the annealing process, indium in the ITO conductive layer diffuses into the thin film; and finally a copper indium gallium sulfur thin film is generated. Compared with a traditional constant potential deposition technology, the method provided by the invention has the advantages that by controlling double potential pulse potential, controllable preparation of the crystalline phase, the composition, the morphology and the like of the thin film can be realized; pore structures are reduced; the thin film morphology is improved; the plating rate is improved; and hydrogen evolution reaction does not produce any adverse effect on the thin film in the deposition process. Compared with a high-vacuum vapor phase method, the method provided by the invention has the advantages of good film quality, low cost, high controllability and the like.

Owner:XIANGTAN UNIV

Water temperature control method, device, thermal management system and storage medium

ActiveCN111005799BReduce lossImprove water temperature control accuracyCoolant flow controlMachines/enginesHeat managementThermal management system

The invention discloses a water temperature control method and device, a whole vehicle heat management system and a storage medium. The water temperature control method comprises the steps that the water temperature of a diesel engine is monitored, and whether the water temperature is higher than a set temperature threshold value or not is judged; if yes, a target temperature and a pre-establishedstate space equation of the water temperature of the diesel engine are obtained; according to the target temperature and the state space equation, control variables of the water temperature are determined, wherein the control variables comprise the fan rotating speed, the electric control water pump rotating speed and the thermostat opening degree; and the water temperature of the diesel engine is controlled according to the control variables. According to the technical scheme, the water temperature is monitored in real time, the state space equation of the water temperature is established, the corresponding relation between the water temperature and the control variables is determined, the values of the control variables reaching the target temperature are determined according to the corresponding relation, the values of the control variables are optimized online, the water temperature control precision is improved, and the energy consumption of the system is reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

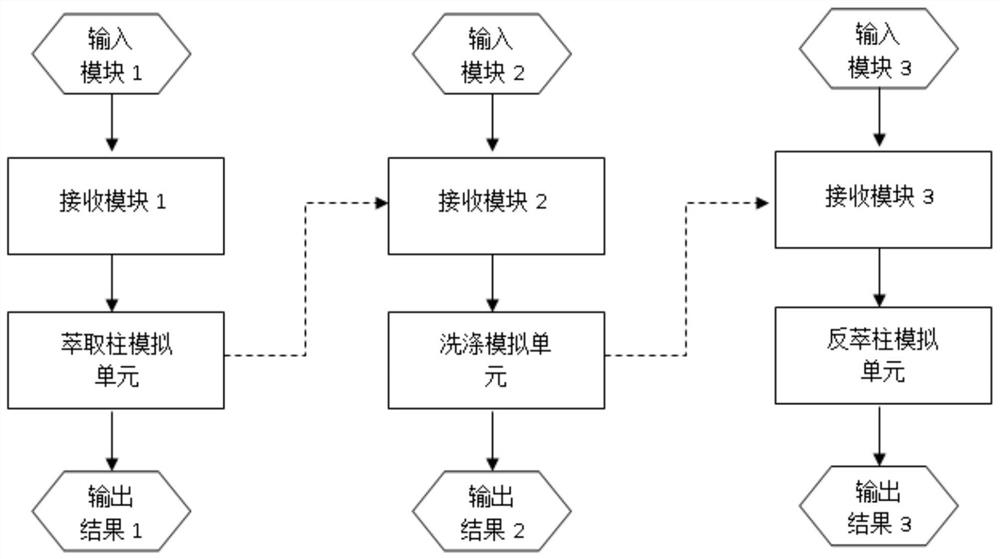

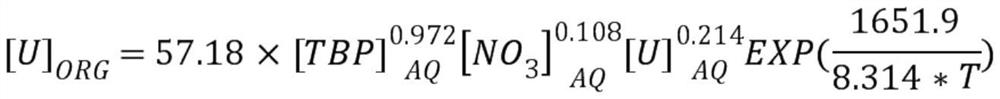

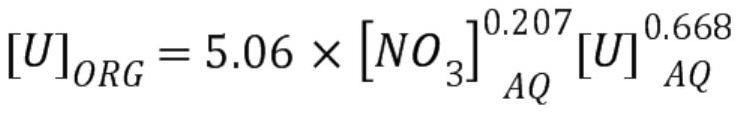

Simulation modeling method of natural uranium extraction and purification system

PendingCN114647916AHigh precisionImprove reliabilityDesign optimisation/simulationSpecial data processing applicationsPhysicsProcess engineering

The invention belongs to the technical field of extraction and purification of natural uranium in nuclear fuel circulation, and particularly relates to a simulation modeling method of a natural uranium extraction and purification system. Determining parameter types of the extraction and purification system, and dividing the parameter types into process operation parameters and pulse column structure parameters; technological operation parameters are used as input operation variables, and pulse column structure parameters are used as fixed quantities; respectively establishing mass transfer models of an extraction column, a washing column and a reverse extraction column in the extraction and purification system by a unit differential method; carrying out nondimensionalization on the mass transfer model; solving the dimensionless mass transfer model, establishing a thermodynamic model and a hydraulic model of a pulse column in the uranyl nitrate extraction and purification process, and combining the thermodynamic model and the hydraulic model, namely combining the extraction reaction process and the pulse column structure characteristics used in the extraction reaction process. The operation result of the natural uranium extraction and purification process can be truly simulated, and the operation results under different two-phase flow ratios, concentrations, acidity and temperatures can be simulated and calculated.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

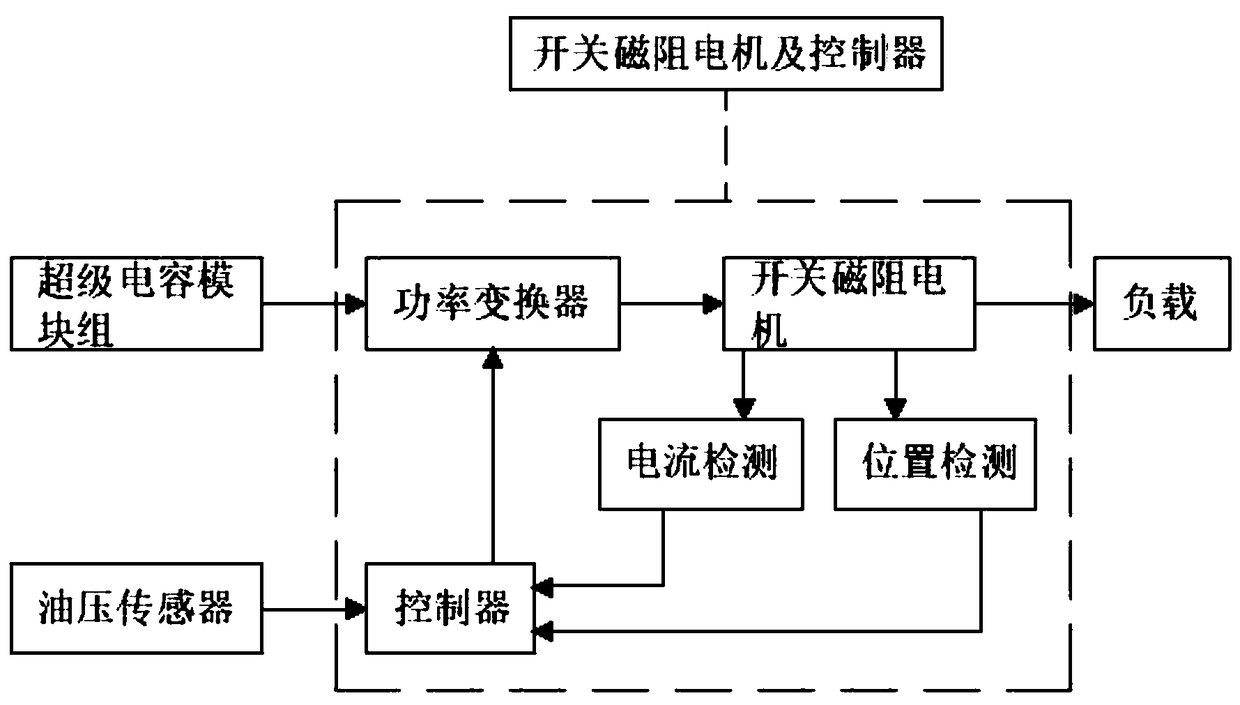

Switched reluctance motor and controller for trailer braking and acceleration system

The invention relates to the technical field of electric vehicle control, in particular to a switched reluctance motor and controller for a trailer braking and acceleration system, which comprises a switched reluctance motor and a controller, wherein the switched reluctance motor communicates with the controller through a current detection module and a position detection module; the controller receives signals given by an external oil pressure sensor and further sends a working instruction to the switched reluctance motor through a power converter; the power converter communicates with an external supercapacitor module group; and the switched reluctance motor is in drive connection with an external load module. The switched reluctance motor and controller for the trailer braking and acceleration system has the beneficial effects that the structure is simpler than that of a squirrel-cage induction motor, the cost is low, the circuit is simple and reliable, the system reliability is high, the starting torque is large, the starting current is low, multiple controllable parameters exist, the speed regulation performance is good, the efficiency is high, and the loss is small.

Owner:毛琦

High-efficiency energy-saving double-salient-pole synchronous reluctance motor

ActiveCN101409471BSimple structureLow costMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous reluctance motorMotor control

The invention provides an efficient energy-saving dual salient pole synchronous reluctance motor, comprising a motor mechanical body and a motor control part; wherein, the motor mechanical body comprises a motor shell, a stator which is arranged on the internal wall of the motor shell and a rotor which is arranged at the center in the motor shell; the rotor is arranged on a motor shaft; the motormechanical body also comprises a motor end cover which is arranged at the two ends of the motor shell; the motor shaft is connected with the motor end cover by a bearing; a shaft sleeve and an oil seal are arranged between the internal end surface of the bearing and the rotor; wherein, the rotor is provided with 8 salient poles; the stator is provided with 12 salient poles and 12 winding coils which are corresponding to the 12 salient poles.

Owner:黑龙江三众科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com