Method for preparing hierarchical porous nano carbon materials

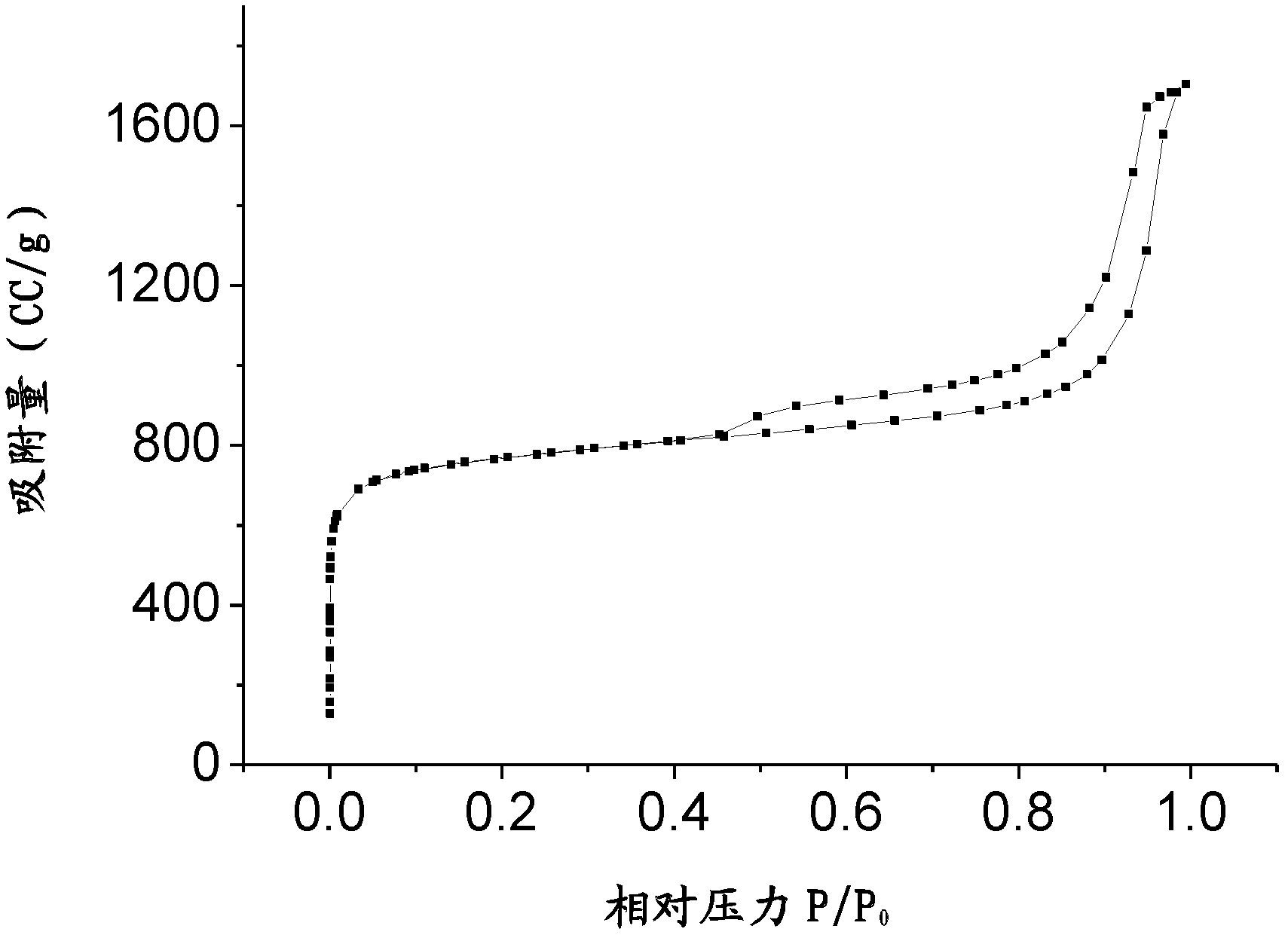

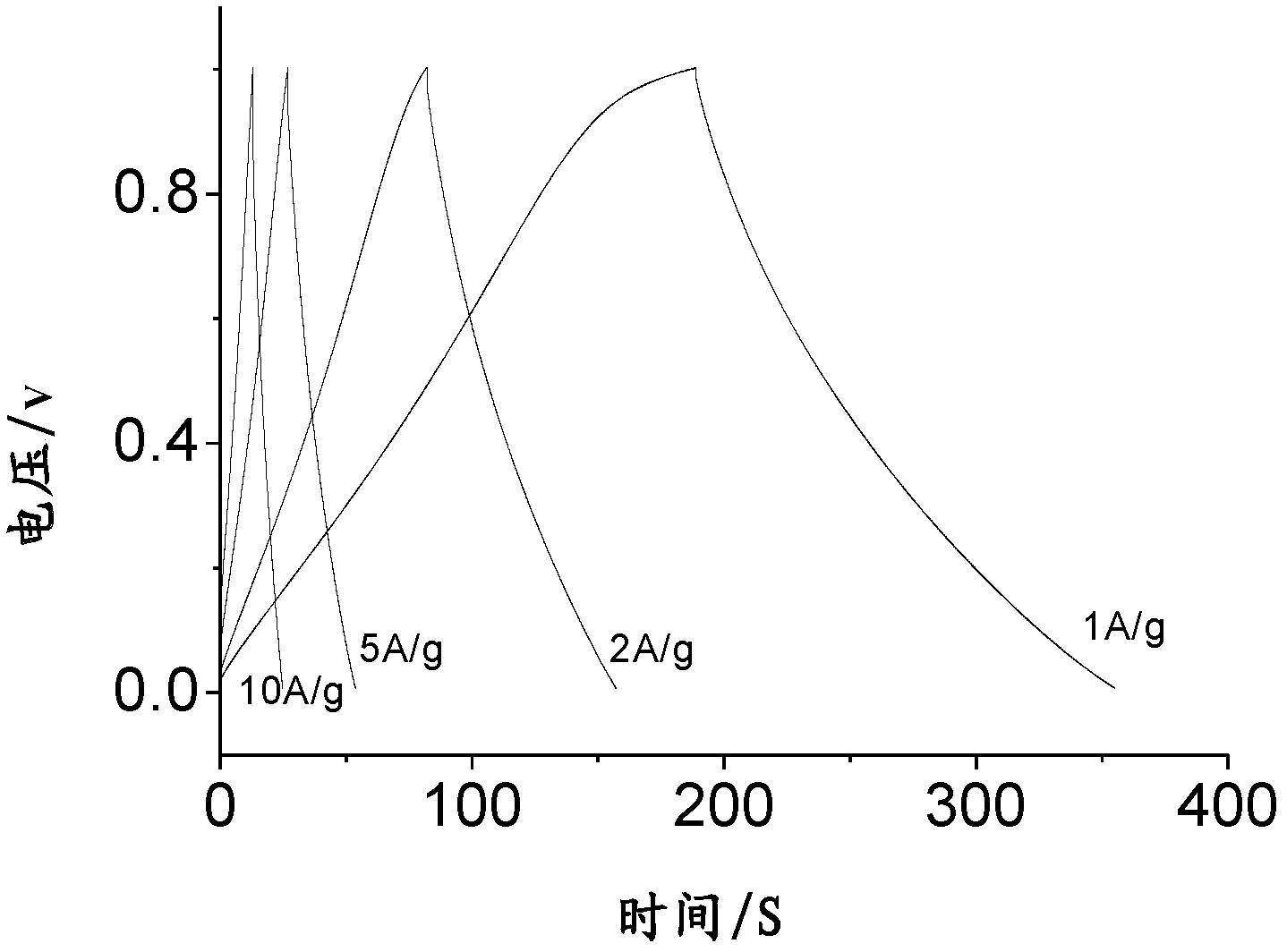

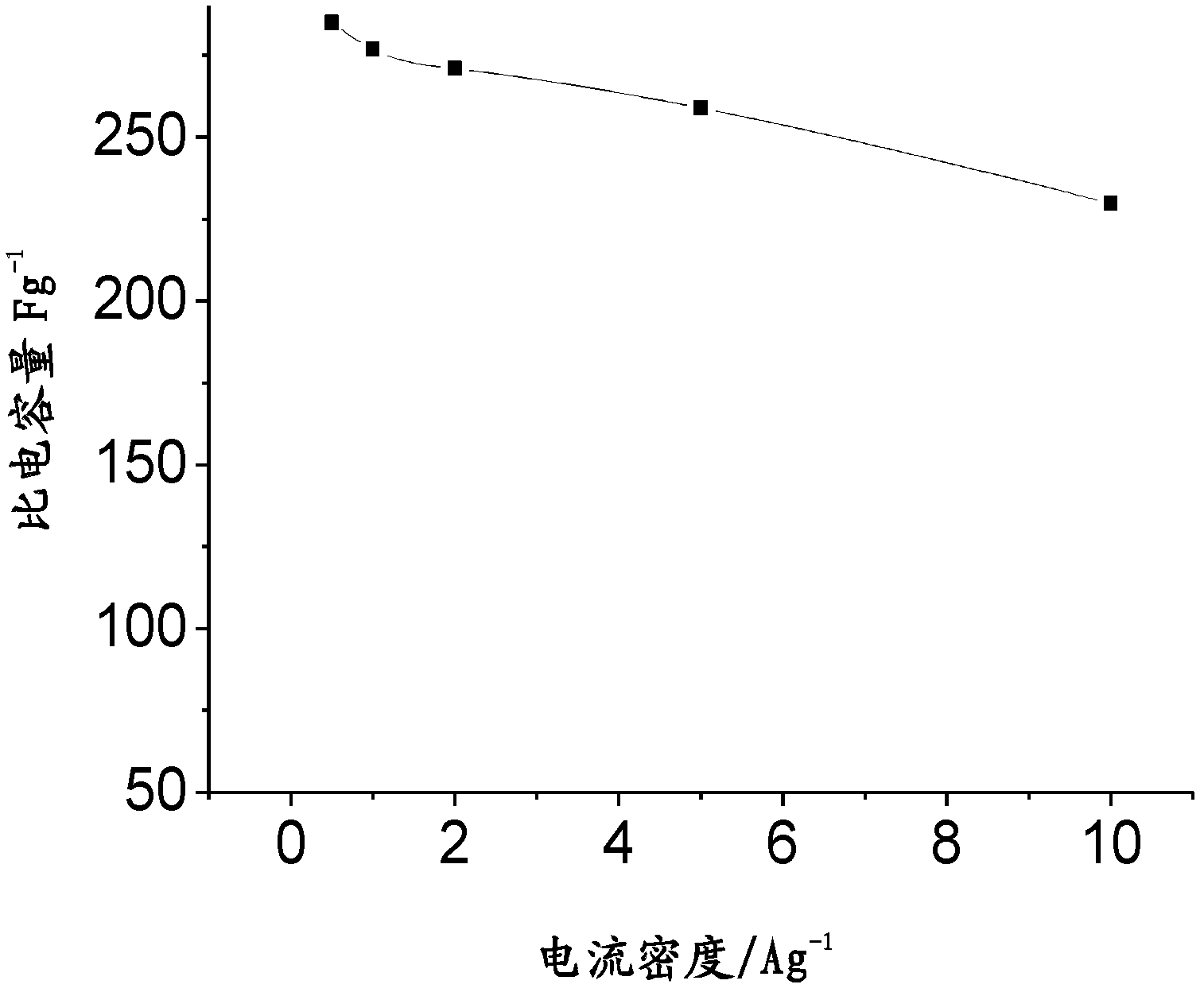

A nano-carbon material and product technology, applied in the field of materials, can solve the problems of low power density, low material utilization rate, poor conductivity, etc., and achieve the effect of reasonable pore size distribution, precise control of pore size distribution, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1), preparation of organosol: 90g resorcinol and 0.84g potassium nitrate are dissolved in the formaldehyde solution of 120ml (concentration 38%), add 11.1ml (molar concentration 0.05mol / L) Na 2 CO 3 And the deionized water of 125ml (wherein the mol ratio of resorcinol, formaldehyde and potassium nitrate is 1: 2: 0.01; The mol ratio of resorcinol and carbonic sodium carbonate is 1: 0.00068; The consumption of deionized water is total 60% of the mass), stirred at a speed of 120 rpm for half an hour, and sealed;

[0038] (2), put the organosol prepared in step (1) into a 50°C incubator for one day, 70°C for one day, and 90°C for three days for aging to prepare an organic airgel;

[0039] (3) Dry the above gel in a vacuum oven for 10 hours at 80°C and 0.01 bar;

[0040] (4), under the condition that the temperature rises to 600°C at a rate of 3°C / min in a mixed atmosphere of nitrogen and carbon dioxide gas with a molar ratio of 10:1, and then is kept at a constant temper...

Embodiment 2

[0047] (1), 80g resorcinol and 0.367g potassium nitrate are dissolved in the formaldehyde solution of 105ml (concentration 38%), add 15ml (molar concentration 0.05mol / L) Na 2 CO 3 and 110ml of deionized water (wherein the mol ratio of resorcinol, formaldehyde, potassium nitrate, sodium carbonate and deionized water is 1: 2: 0.005), (wherein the mol ratio of resorcinol, formaldehyde and potassium nitrate 1: 2: 0.005; the mol ratio of resorcinol and sodium carbonate is 1: 0.001; the consumption of deionized water is 66% of the total mass), stirred at a speed of 300 rpm for half 20 minutes, and sealed;

[0048] (2), put the organosol prepared in step (1) into a thermostat at 45°C for one day, and then aging at 85°C for four days to prepare the organoaerogel;

[0049](3) Dry in a vacuum oven for 10 hours at 80°C and 0.01 bar;

[0050] (4) Under the conditions of constant temperature for 3 hours after rising to 700°C at a rate of 3°C / min under a mixed atmosphere of nitrogen and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com