A preparation method of silver micropowder capable of precisely controlling specific surface area

A specific surface area, precise control technology, applied in the field of preparation of silver micropowder, can solve the problems of large sintering shrinkage, poor sintering activity, non-mass production, etc., and achieve the effect of low production cost, good consistency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of silver micropowder capable of precisely controlling the specific surface area, comprising the following steps:

[0026] (1) silver nitrate solution is prepared with deionized water, and the concentration of silver nitrate in the solution is 0.5mol / L;

[0027] (2) in the silver nitrate solution prepared in step (1), dropwise concentration is the sodium carbonate solution of 1.2mol / L, adjusts pH to 12, stirs with the rotating speed of 80r / min;

[0028] (3) Put the mixed powder of polyvinyl alcohol and gelatin with a mass ratio of 1:5 into deionized water at a temperature of 80°C, and stir for 1-2 hours to obtain a mixed solution of polyvinyl alcohol and gelatin with a mass fraction of 0.1%;

[0029] (4) Add the mixed solution of step (3) into the silver nitrate solution of step (2), stir and mix evenly at a speed of 60r / min, wherein the polyvinyl alcohol quality is 0.2% of the silver nitrate solid mass;

[0030] (5) triethanolamine solution is dri...

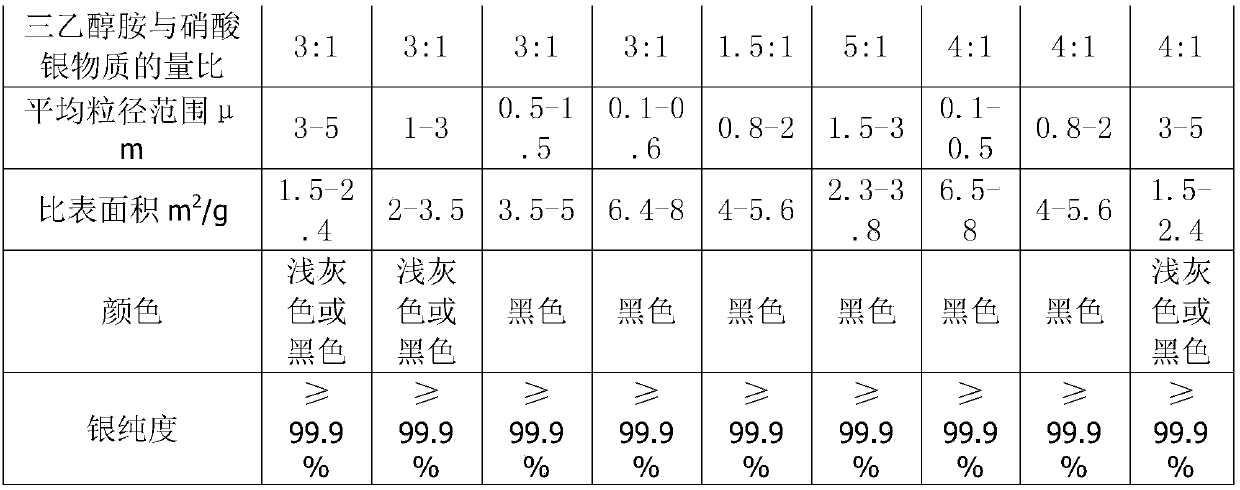

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com