Clean production technology of nano spherical high-purity aluminum oxide

A high-purity alumina and clean production technology, applied in the direction of alumina/aluminum hydroxide, nanotechnology, nanotechnology, etc., can solve problems such as technical defects, large pollution, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

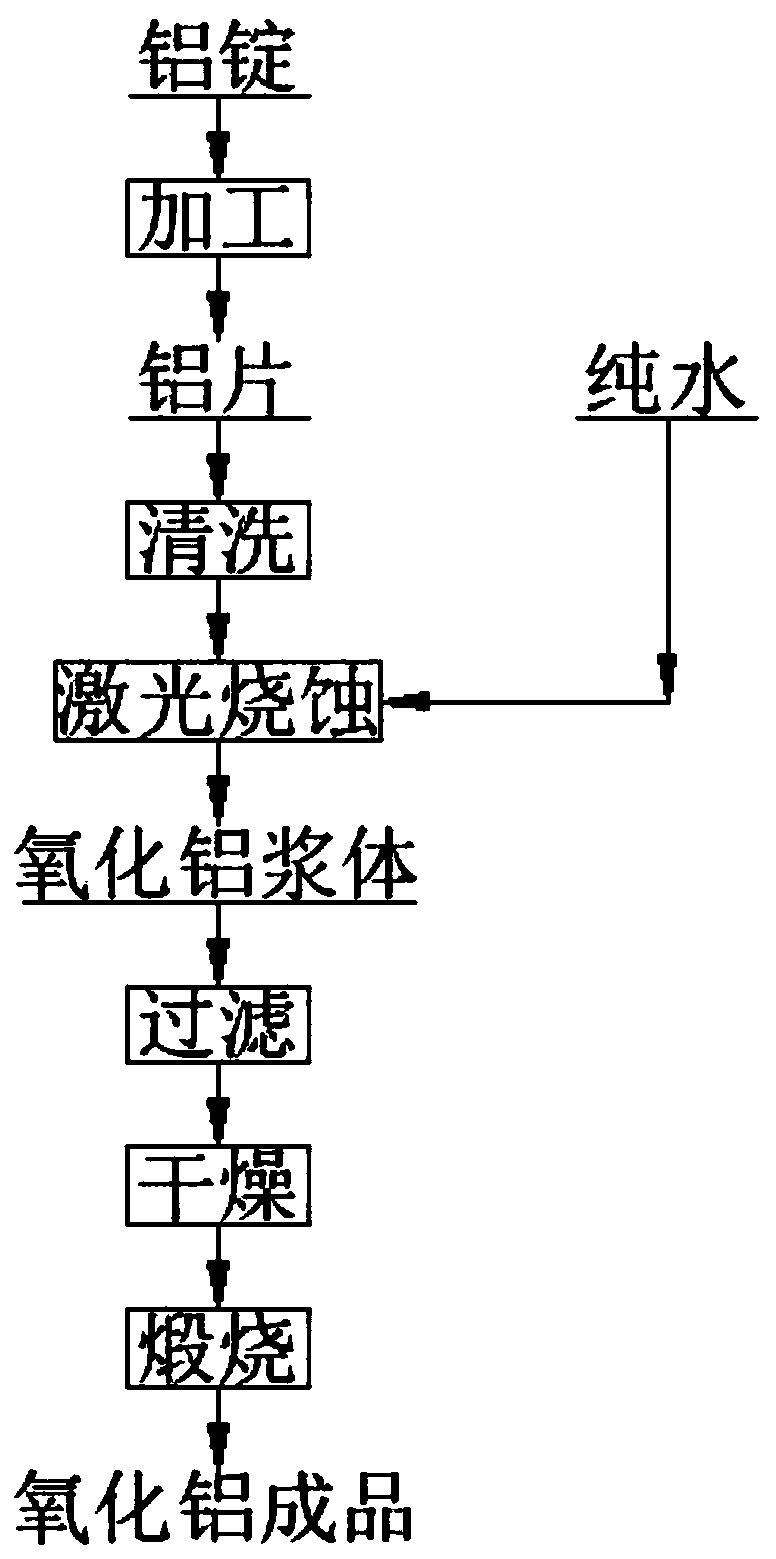

Method used

Image

Examples

Embodiment 1

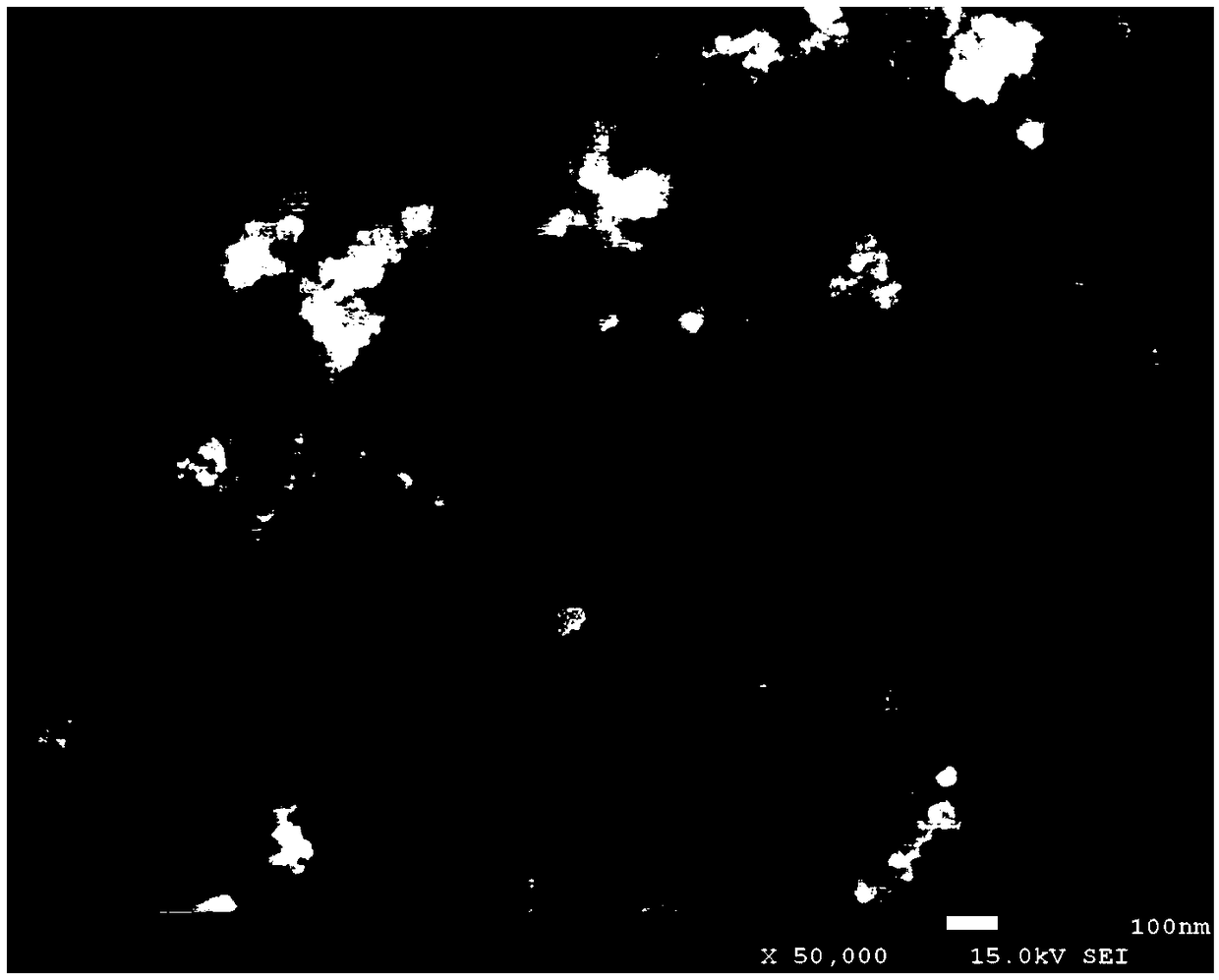

[0036] Example 1: Firstly, the 4N refined aluminum ingot for remelting is processed into a 0.3 mm high-purity aluminum sheet by casting and rolling, the surface oil stains of the high-purity aluminum sheet are thoroughly cleaned, and the high-purity aluminum sheet is placed horizontally in pure water. The water is 18MΩ·cm electronic grade pure water, and the temperature of the pure water is 30°C. The laser used in this embodiment is a nanosecond pulsed laser, and the single pulse power of the pulsed laser is adjusted to be 1mJ, the pulse width is 100ns, the laser repetition frequency is 50KHz and the focal length is adjusted so that the laser peak power density is greater than or equal to 10 7 W / cm 2 . The laser performs layer-by-layer ablation on the high-purity aluminum sheet, and after ablation, an alumina slurry is obtained until the aluminum sheet is completely exhausted. The alumina slurry is filtered by nanofiltration, the filtered filtrate is recycled, and the obtain...

Embodiment 2

[0037] Example 2: Firstly, the 4N6 remelting refined aluminum ingot is processed into a 0.5mm high-purity aluminum sheet by casting and rolling, the surface oil of the high-purity aluminum sheet is thoroughly cleaned, and the high-purity aluminum sheet is placed horizontally in pure water. The water is 18MΩ·cm electronic grade pure water, and the temperature of the pure water is 10°C. The laser used in this embodiment is a picosecond pulse laser, and the single pulse power of the pulse laser is adjusted to 50 μJ, the pulse width is 10 ps, the laser repetition frequency is 800 KHz and the focal length is adjusted to make the laser peak power density ≥ 10 9 W / cm 2 . The laser performs layer-by-layer ablation on the high-purity aluminum sheet, and after ablation, an alumina slurry is obtained until the aluminum sheet is completely exhausted. The alumina slurry is filtered by nanofiltration, and the filtered filtrate is recycled, and the obtained filter cake is dried at -30°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com