A kind of preparation device and preparation method of carbon nanotube resin film

A carbon nanotube and preparation device technology, applied in the field of carbon nanotube resin film preparation, can solve the problems of carbon nanotube damage, low degree of orientation, dangerous and strong oxidation of chemical reagents, etc., to improve the enhancement effect and achieve dispersion degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

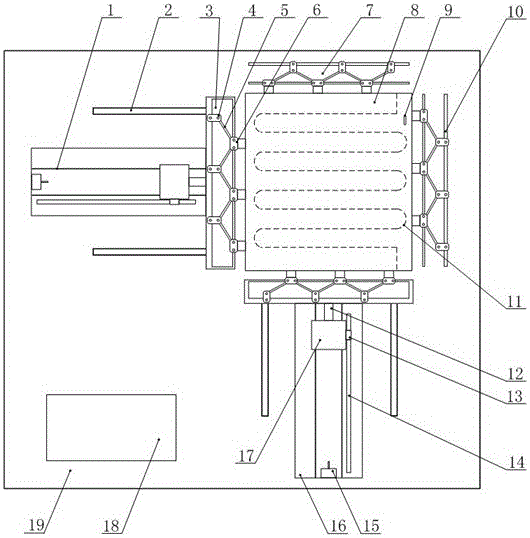

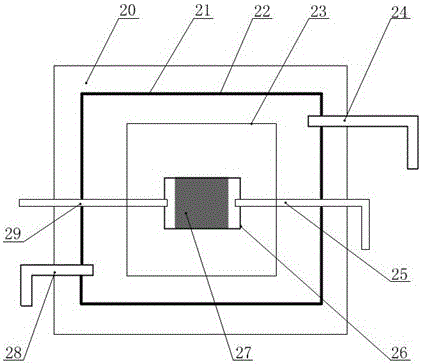

[0020] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0021] Such as figure 1 , figure 2 Shown, a kind of preparation device of carbon nanotube resin film comprises workbench 19, vacuum import mold platform 20, and square material platform 8 is set on described workbench 19, and bidirectional stretching device is arranged around material platform 8, and material A temperature measuring sensor 9 and a return-type heating tube 11 are respectively arranged on the platform 8, and a system control platform 18 is arranged on the workbench 19; a vacuum bag 21 is arranged on the vacuum introduction mold platform 20, and a vacuum bag sealing strip 22 is arranged on one side of the vacuum bag 21, The vacuum bag 21 is connected with a vacuum joint 24 and a vacuum test joint 28 respectively, and a resin introduction channel 25 , a resin guide bar 26 and a resin outflow pipe 29 are arranged between the vacuum bag 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com