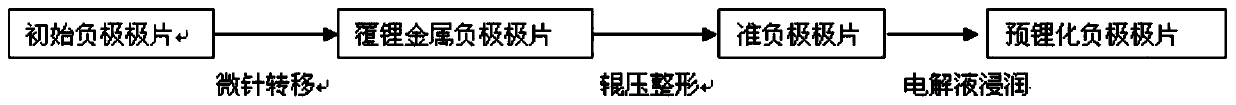

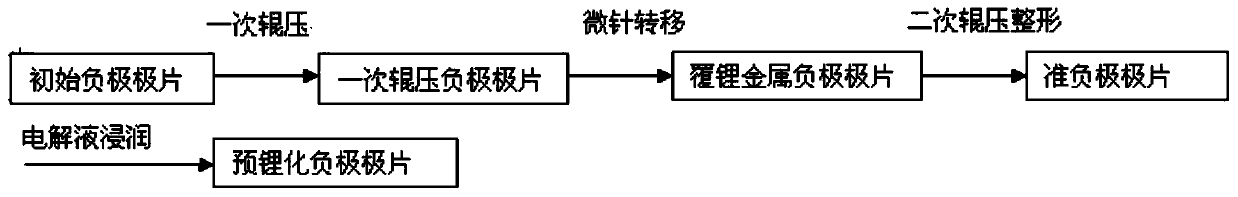

Pre-lithiation process of negative pole piece

A negative pole piece and pre-lithiation technology, applied in the field of pre-lithiation process of negative pole piece, can solve the problems of increased production cost of reaction buffer layer, complicated manufacturing method, loss of capacity density and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Negative electrode slurry is mixed according to silicon carbon negative electrode (93%), conductive agent carbon black (1.75%), thickener CMC (1.45%), binder PAA (3.8%), and the slurry is coated to an area density 12mg / cm 2 the negative pole piece. The selected needle density is 30 needles / cm 2 1. With a tapered roller mold with a needle length of 80 μm, cover the 50 μm thick lithium metal foil covered with PET film on the surface of the 47*57mm negative electrode sheet, and roll it over 3 times with a pressure of 20kg. The weight gain (pre-lithium amount) of the pole piece after rolling is 2 mg. Roll the lithium-coated metal negative electrode sheet at a linear speed of 7.5m / min, and roll until the compacted density is 1.45g / cm 3 . The obtained quasi-negative electrode sheet was soaked in the electrolyte solution and allowed to stand for 3 hours to obtain a pre-lithiated negative electrode sheet. The electrolyte is LiPF with a lithium salt of 1mol / L 6 , the solve...

Embodiment 2

[0067] Negative electrode slurry is mixed according to silicon carbon negative electrode (93%), conductive agent carbon black (1.75%), thickener CMC (1.45%), binder PAA (3.8%), and the slurry is coated to an area density 12mg / cm 2 the negative pole piece. The selected needle density is 80 needles / cm 2 1. With a tapered roller mold with a needle length of 80 μm, cover the 10 μm lithium metal foil covered with PET film on the surface of the 47*57mm negative electrode sheet, and roll it over 10 times with a pressure of 20kg, and the linear speed is 7.5m / min. The weight gain (pre-lithium amount) of the pole piece after rolling was 4.5mg. Roll the lithium-coated metal negative electrode sheet to a compacted density of 1.45g / cm 3 . The obtained quasi-negative electrode sheet was soaked in the electrolyte solution and allowed to stand for 3 hours to obtain a pre-lithiated negative electrode sheet. The electrolyte is LiPF with a lithium salt of 1mol / L 6 , the solvent is a mixed ...

Embodiment 3

[0070]The negative electrode slurry is mixed according to silicon carbon negative electrode (93%), conductive agent carbon black (1.75%), thickener CMC (1.45%), and binder SBR (3.8%), and the slurry is coated to an area density 12mg / cm 2 the negative pole piece. The selected needle density is 100 needles / cm 2 1. With a tapered roller mold with a needle length of 80 μm, cover the 10 μm lithium metal foil covered with PET film on the surface of the 47*57mm negative electrode sheet, and roll it over 30 times with a pressure of 40kg and a linear speed of 8.3m / min. The weight gain (pre-lithium amount) of the pole piece after rolling was 11.2 mg. Roll the lithium-coated metal negative electrode sheet to a compacted density of 1.45g / cm 3 . The obtained quasi-negative electrode sheet was soaked in the electrolyte solution and allowed to stand for 3 hours to obtain a pre-lithiated negative electrode sheet. The electrolyte is LiPF with a lithium salt of 1mol / L 6 , the solvent is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com