Testing device for semiconductor thermoelectric refrigerating unit

A thermoelectric cooler and testing device technology, which is applied in the direction of single semiconductor device testing, etc., can solve the problems of lack of quantitative testing equipment for thermoelectric cooling devices, failure to consider the use of equipment for heat leakage and heat conduction, rough qualitative testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

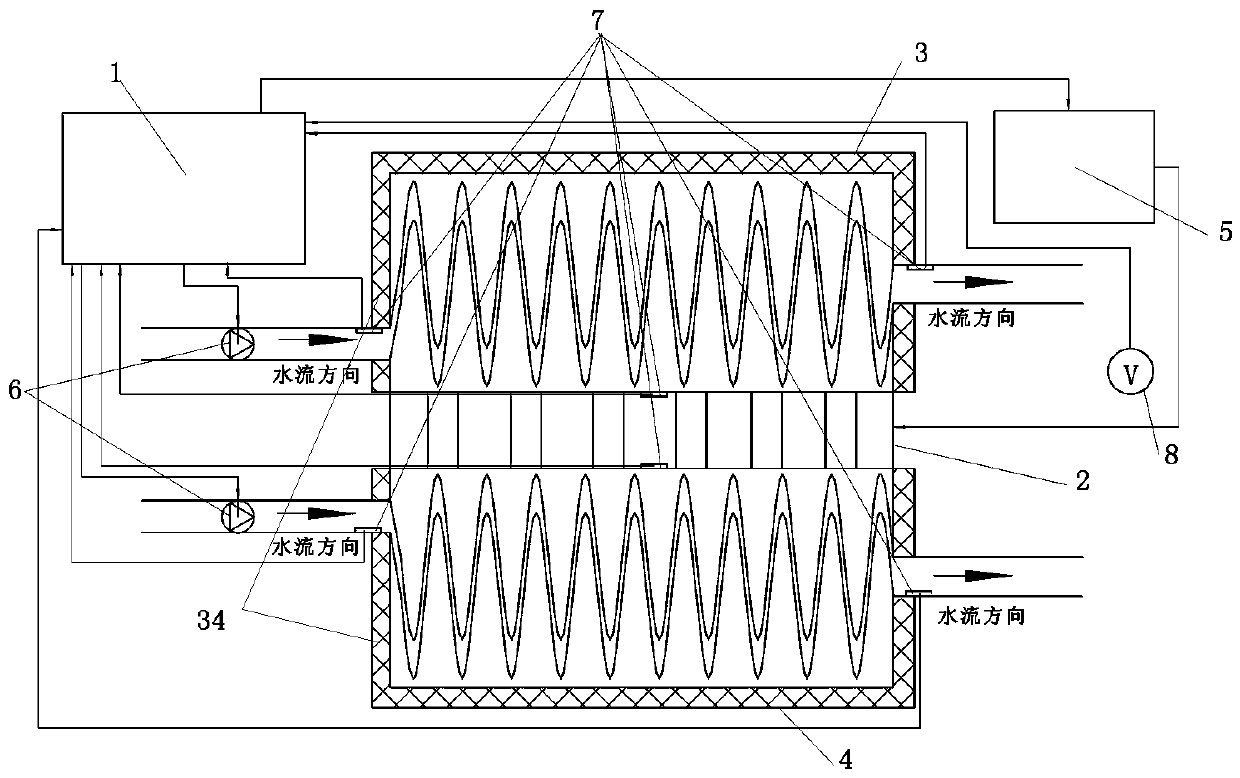

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

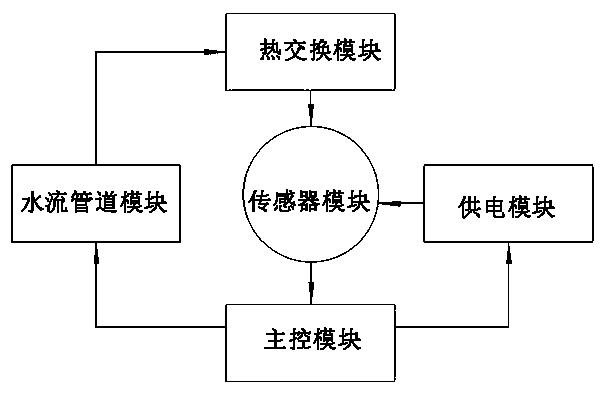

[0024] refer to Figure 1-2 , a test device for a semiconductor thermoelectric refrigerator, including a main control module, a heat exchange module, a liquid medium pipeline module, a power supply module, and a sensor module,

[0025] In this embodiment, the liquid medium is water, and the main control module is computer 1;

[0026] The heat exchange module communicates with the water flow pipeline module, and the water flow pipeline module, the power supply module, and the sensor module are respectively electrically connected to the computer 1;

[0027] The water flow pipeline module includes a hot-end water flow pipeline and a cold-end water flow pipeline, and a power pump 6 controlled by a computer 1 is arranged in the hot-end and cold-end water flow pipelines;

[0028] The heat exchange module includes a hot end exchanger 3 and a cold end exchanger 4. The hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com