Modular equipment using solid waste catalytic pyrolysis to prepare high-value fuel gas

A solid waste, catalytic pyrolysis technology, applied in the direction of catalytic treatment of combustible gas, removal of gas pollutants, combustible gas purification, etc. Simple structure and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

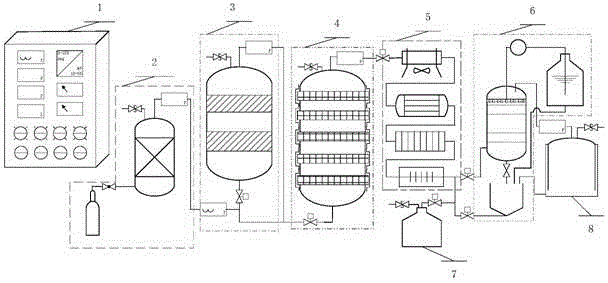

[0029] Modular solid waste catalytic pyrolysis equipment for processing 1kg of corn stalks.

[0030] as attached figure 1 , the solid-liquid ratio is 40% (m / v) The material is first placed in the pretreatment module 2, and the microwave pretreatment method is selected, the microwave power is 4KW, the reaction time is 10min, and then dehydrated and dried to control the water content to 95%, and then placed In the pyrolysis module 3, turn on the dual temperature control mode, the catalyst placed last time is 50g, the active component is nickel nitrate, the loading capacity is 5%, the carrier is alumina, the temperature is 700°C; the pyrolysis temperature of the lower layer is 500°C , the valve reflux ratio is 2:8, after the pyrolysis gas passes through the condensation module 5, it enters the purification module 6, and the purification is sprayed with 1% NaOH solution, the spray flow rate is 10ml / min, and the absorption liquid reflux ratio is 4:6 , the gas after the three-stage...

Embodiment 2

[0033] Modular solid waste catalytic pyrolysis equipment for processing 0.8kg of kitchen waste.

[0034] as attached figure 1, adjust the solid-liquid ratio to 20% (m / v) The material is first placed in the pretreatment module 2, adopts the hydrothermal pretreatment method, treats at 200°C for 100 minutes, and then dehydrates and dries to control the water content to 90%, and then places it in the hot water Decomposition module 3, open the single temperature control mode, the pyrolysis temperature is 600 ℃, the crude decomposition gas enters the secondary catalytic module 4 through the reflux ratio of 4:6, this module is divided into 3 levels, from bottom to top in order of porcelain stone primary Absorption, zeolite absorption, monolithic catalyst, the active component of the catalyst is spinel iron oxide, and the catalytic temperature is 700°C. After catalysis, the gas enters the purification module 6 through the condensation module 5, and the purification is sprayed with 1% ...

Embodiment 3

[0037] Modular solid waste catalytic pyrolysis equipment for processing 2kg of municipal sludge.

[0038] as attached figure 1 , adjust the solid-liquid ratio to 30% (m / v) The material is first placed in the pretreatment module 2, adopts the hydrothermal pretreatment method, treats at 220°C for 60 minutes, and then dehydrates and dries to control the water content to 90%, and then places it in the hot water Solution module 3, open the dual temperature control mode, the catalyst placed last time is 80g, the active component is nickel phosphotungstate, the loading capacity is 10%, the carrier is molecular sieve, the temperature is 800°C; the pyrolysis temperature of the lower layer is 600°C, the valve The reflux ratio is 3:7, and it enters the secondary catalytic module 4. This module is divided into 3 levels, from bottom to top, it is porcelain stone primary absorption, zeolite absorption, and monolithic catalyst. The active component of the catalyst is spinel iron oxide , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com