Vibrating electrostatic spinning device for nano fiber

A nanofiber, electrospinning technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve problems such as easy blockage, inability to meet product application requirements, and difficulty in cleaning microporous needles 3' , to achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

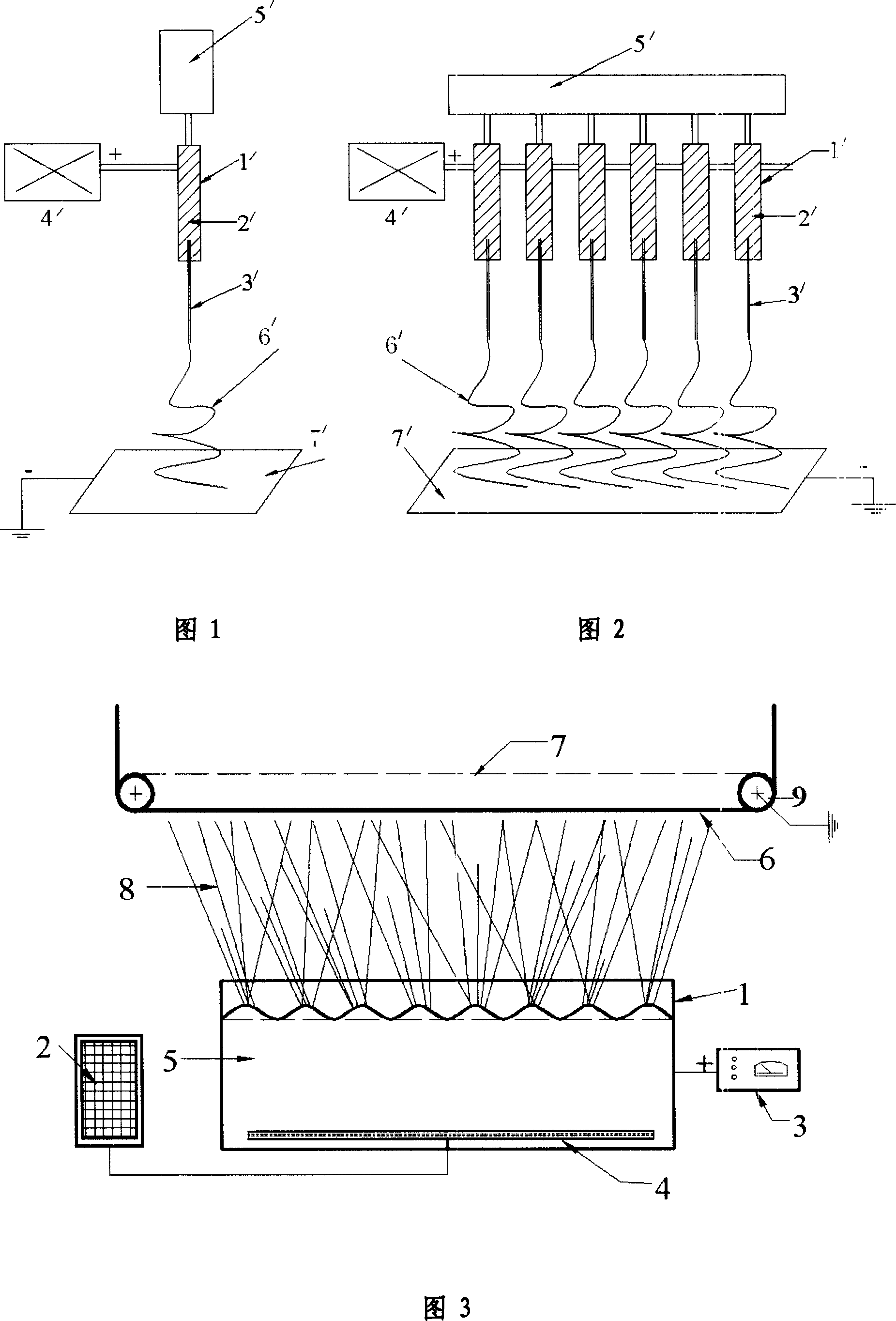

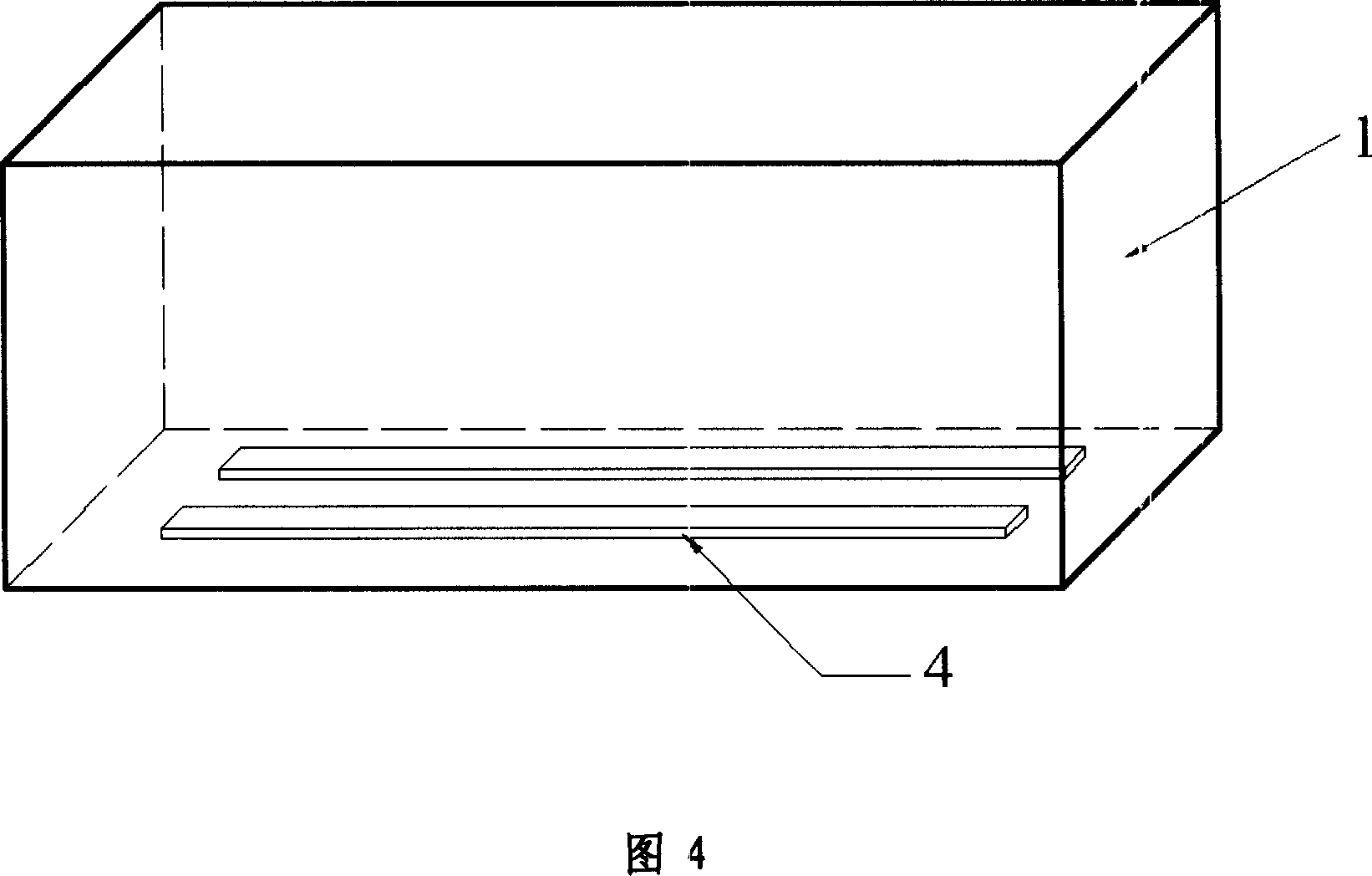

[0021] As shown in Figures 3 and 4, a vibration electrospinning device capable of producing nanofibers in large quantities mainly includes a liquid storage tank 1, a high-voltage electrostatic generator 3, an ultrasonic generator 2, and a piezoelectric sensor 4.

[0022] The liquid storage pool 1 is a cubic structure with an open top, and the pool body can be made of insulating plastic, and of course, other materials can also be used. Before production, first inject solution or melt 5 into the pool from the opening at the top of the liquid storage pool 1, the amount of liquid added should be close to the top of the liquid storage pool 1 but slightly lower than the mouth of the pool. Two parallel and symmetrical piezoelectric sensors 4 are installed near the bottom of the liquid storage tank 1. The piezoelectric sensor 4 is connected to the ultrasonic generator 2, and the solution or melt 5 generates electricity through the electrodes and the high-voltage static electricity inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com