Electrostatic spinning machine

An electrospinning and silk instrument technology, which is applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of cumbersome process, no adjustable and controllable complete set of instruments, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention, it will be further described in conjunction with the accompanying drawings.

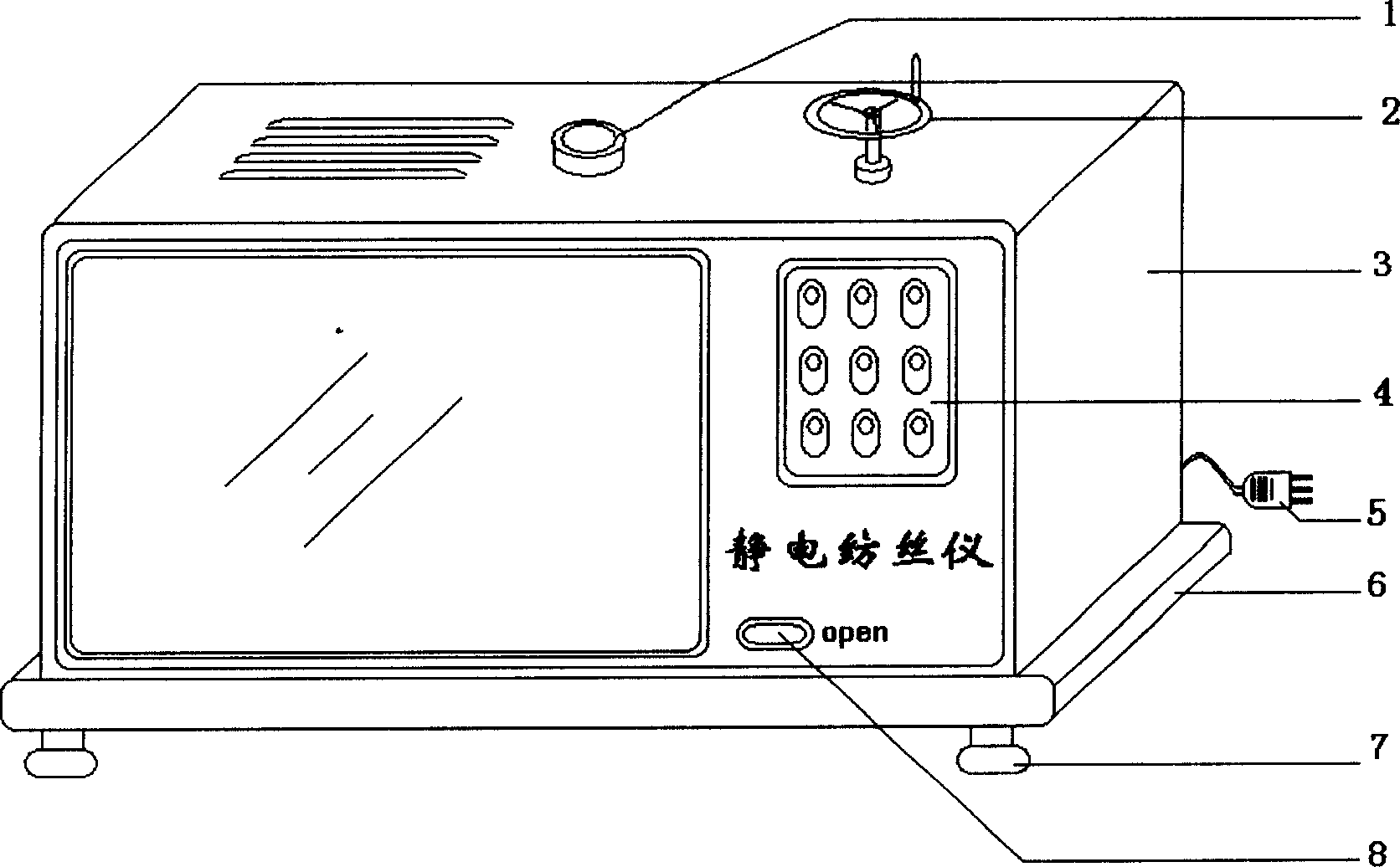

[0025] figure 1 Among them, 1 is the cup holder of the liquid storage cup, which is made of insulating material; 2 is the rotating turntable connected with the worm; 3 is the outer wall of the electrospinning instrument box; 4 is the control panel button; 5 is the power cord; 6 is the box body Base; 7 is a box body leg; 8 is a visual door switch with glass.

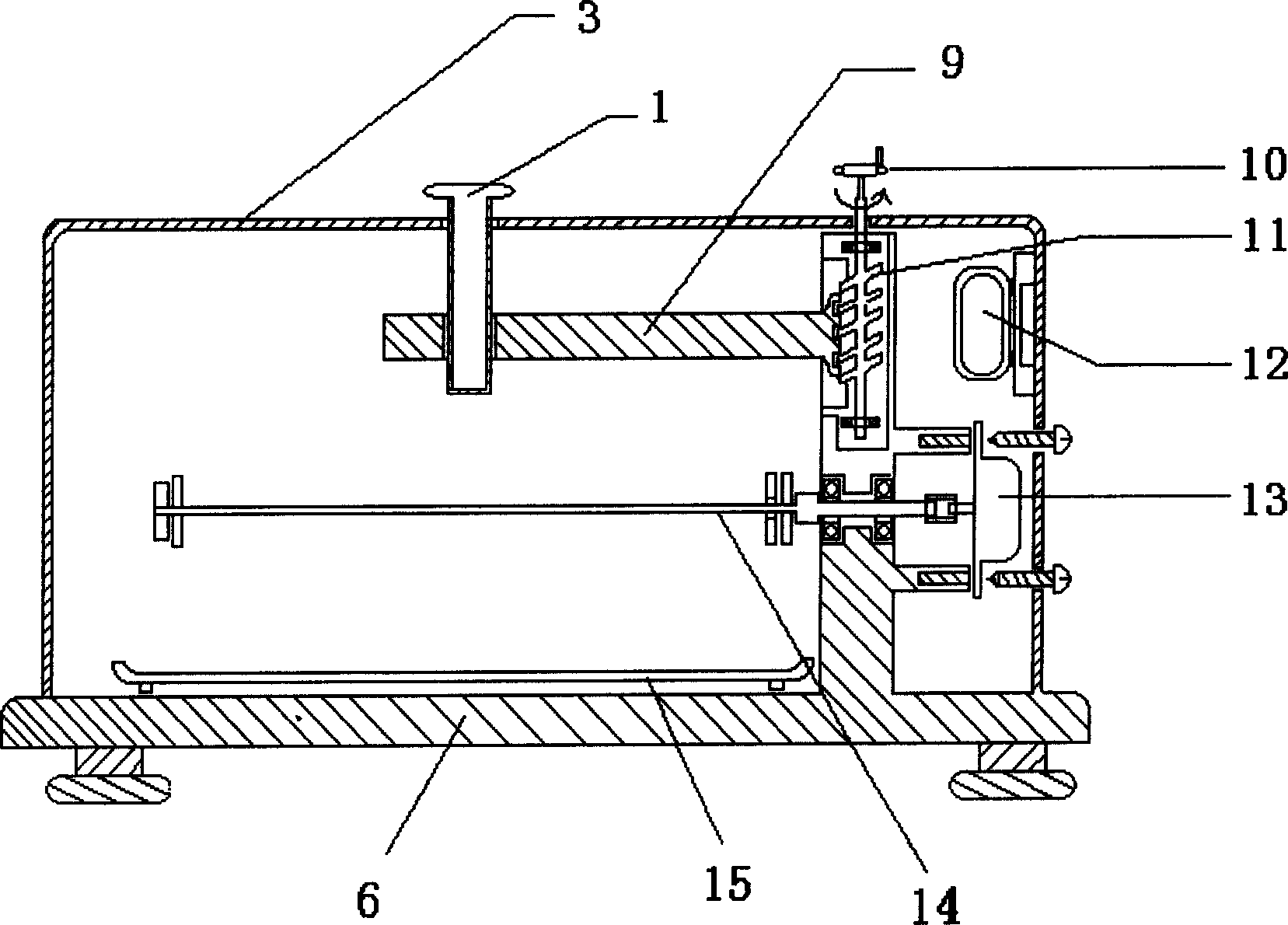

[0026] figure 2 Among them, 9 is the lifting rod of the liquid storage cup in the spray height adjustment system; 10 is the handle on the lifting turntable; 11 is the worm, installed in the worm groove; 12 is a high-voltage electrostatic generator, which can produce 30-100kV high-voltage static electricity; 13 It is a small stepping motor, its pulse frequency can be adjusted through the adjustment button on the panel, so as to achieve the purpose of controlling the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com