Method and device for rapid forming by combining electrostatic spinning technique

A technology of electrospinning technology and molding method, which is applied in the field of rapid prototyping to achieve the effects of fast molding speed, reduced equipment processing costs, and improved product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

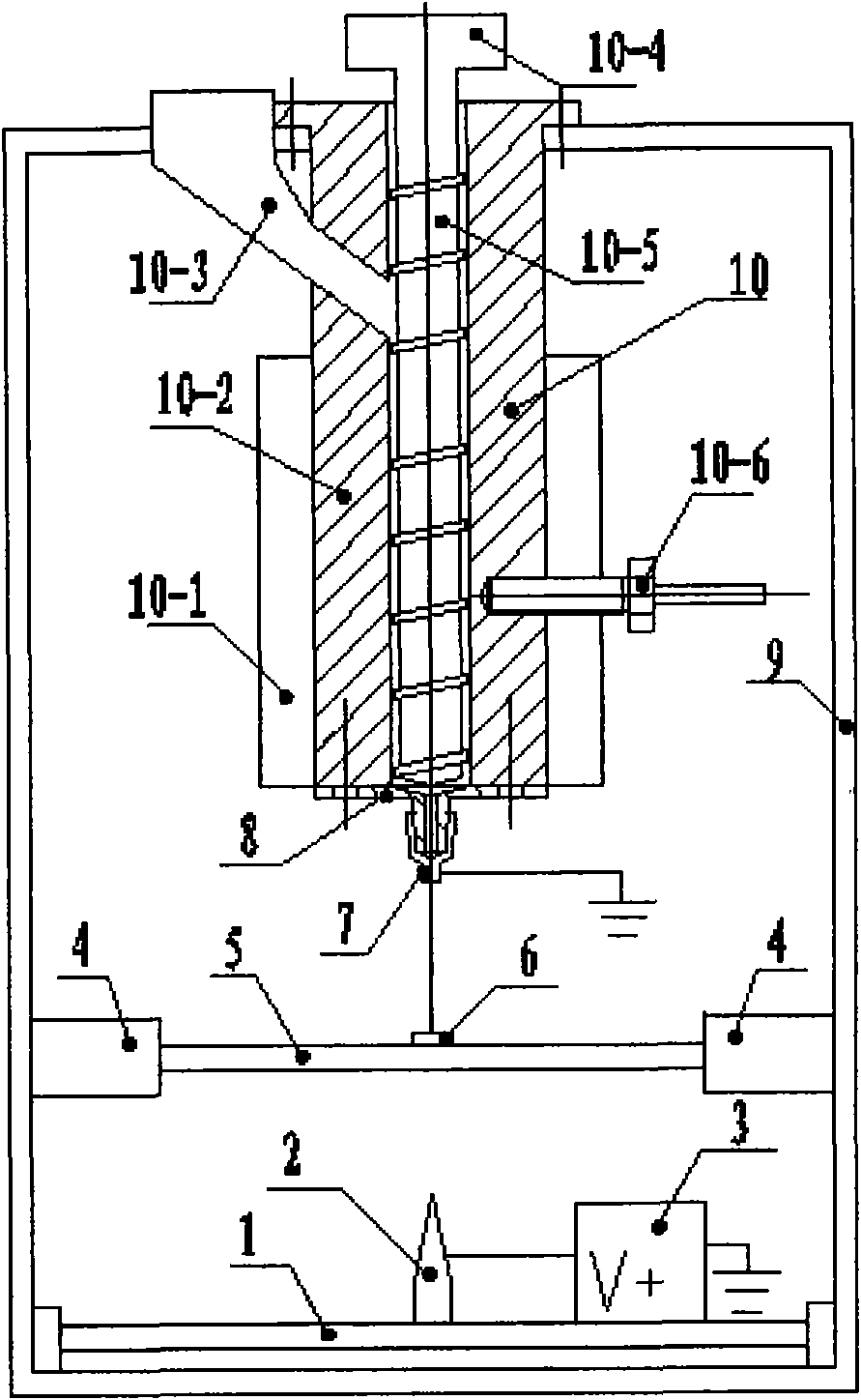

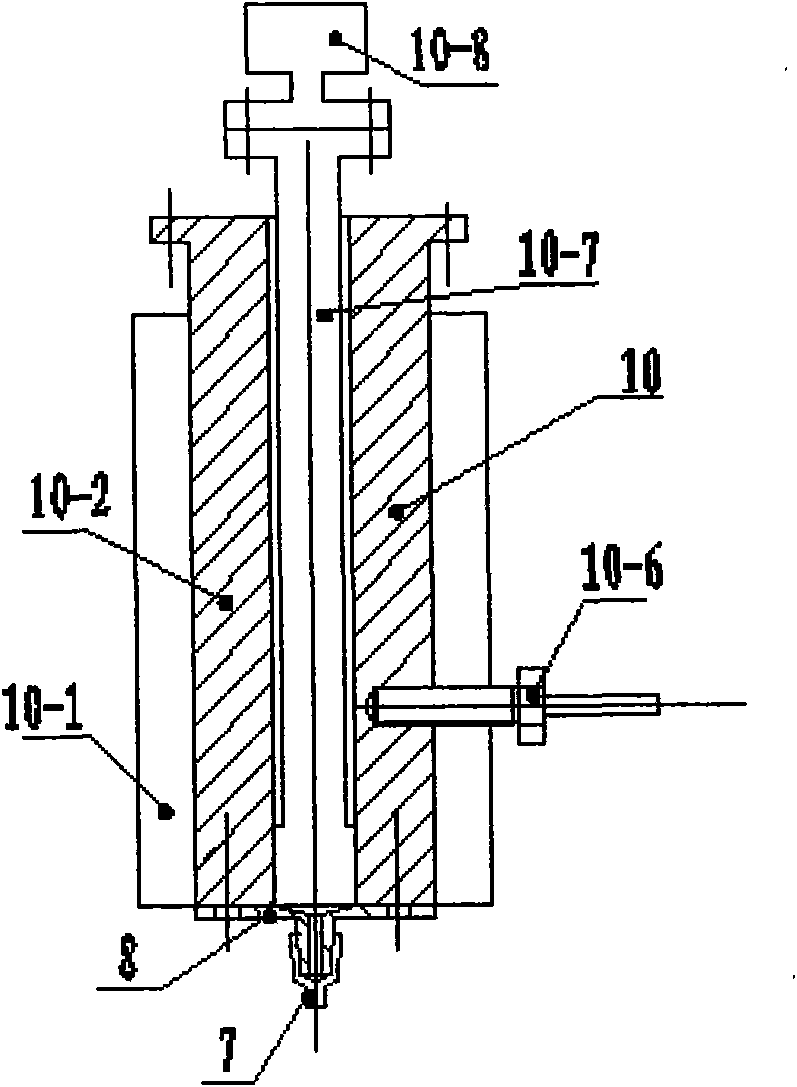

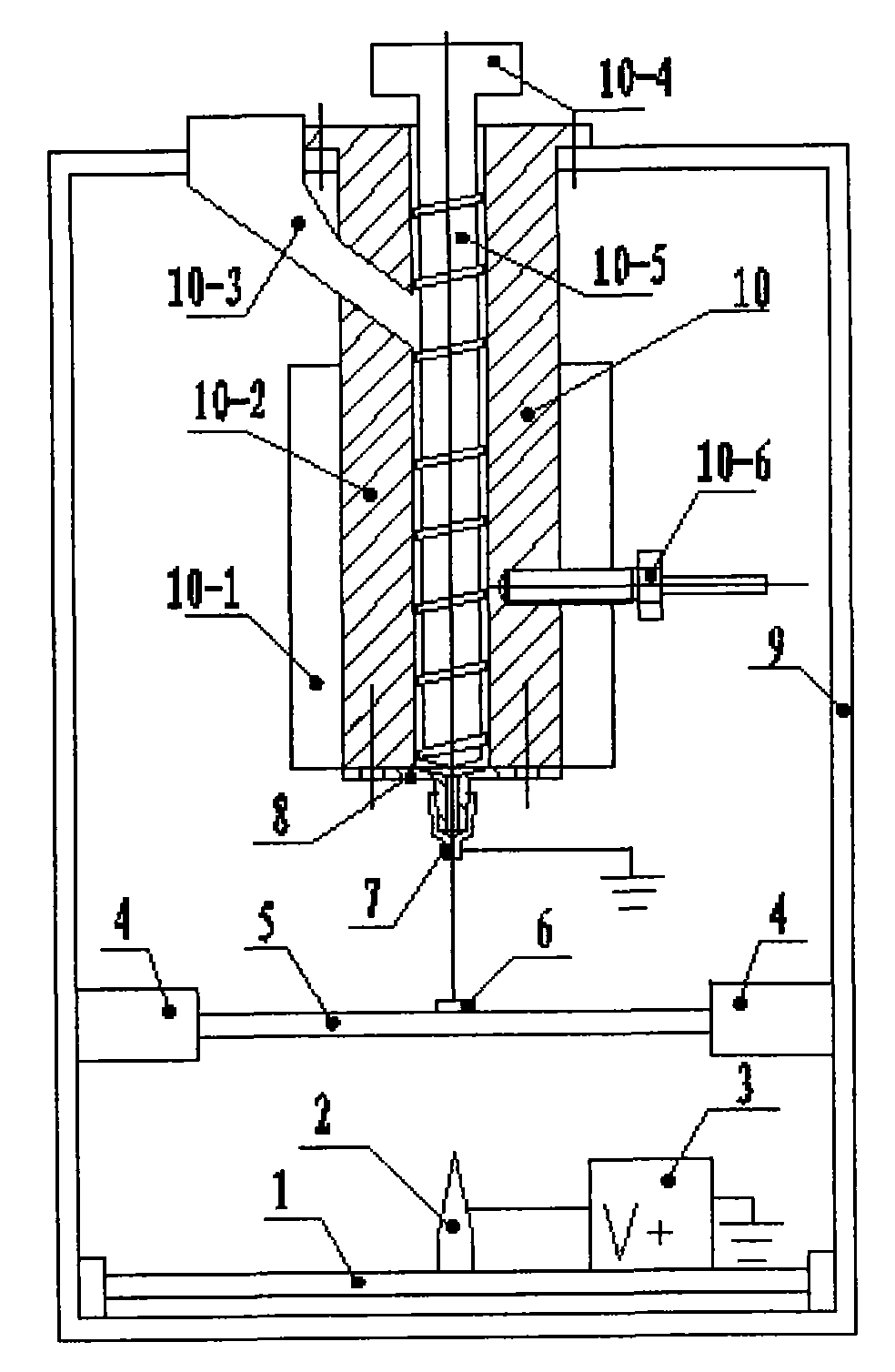

[0014] A rapid prototyping method and device combined with electrospinning technology of the present invention, the schematic diagram of the device is shown in figure 1 with figure 2 , the device includes a tip electrode 2, a tip electrode holder 1, an electrostatic generator 3, a product platform 5, a product platform motion system 4, a capillary 7, a nozzle 8, a support 9 and a spinning medium control device 10, the tip electrode 2 and the static electricity The positive electrode of the generator 3 is connected, the tip electrode 2 is installed on the tip electrode holder 1, the tip electrode holder 1 is installed on the lower end of the bracket 9, the tip electrode holder 1 can move up and down on the bracket 9, and is used to adjust the tip electrode 2 The distance between the tip of the capillary and the end of the capillary 7; the product platform motion system 4 drives the product platform 5 to move up and down on the support 9, adjusts the vertical distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com