Silicon dioxide, and preparation and use thereof

A silicon dioxide, sodium silicate solution technology, applied in the direction of silicon dioxide, silicon oxide, copying/marking methods, etc., can solve the problems of high viscosity, unfavorable, unfavorable technology promotion, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 1000ml of sodium silicate solution with a concentration of 1.5M into the reaction kettle with stirring device, control the temperature at 20°C, add 20wt% dilute sulfuric acid to pH 10 under constant stirring, continue to add acid to pH 4, heat to 65°C, add ammonia water, adjust the pH value to 10, heat up to 100°C and age for 2 hours, add acid to pH 3 after aging, age for 1 hour, add 1.5M sodium silicate solution to pH after aging The value was 7.5, and stirred at 80°C for 30 minutes, filtered and washed three times with deionized water, dried and pulverized to obtain the finished product.

Embodiment 2

[0048] Add 1000ml of sodium silicate solution with a concentration of 2.0M into the reaction kettle with a stirring device. At this time, the temperature is 30°C. With constant stirring, add 20wt% dilute sulfuric acid until the pH is 10. After stirring for 20 minutes, continue to add acid to pH 3, heat to 50°C, add ammonia water, adjust the pH to 9, heat up to 100°C and age for 1 hour, add acid to pH 3 after aging, age for 3 hours, add 2.0M water glass again after aging to pH 6.5 , and stirred at 90°C for 30 minutes, filtered and washed three times with deionized water, dried and pulverized to obtain the finished product.

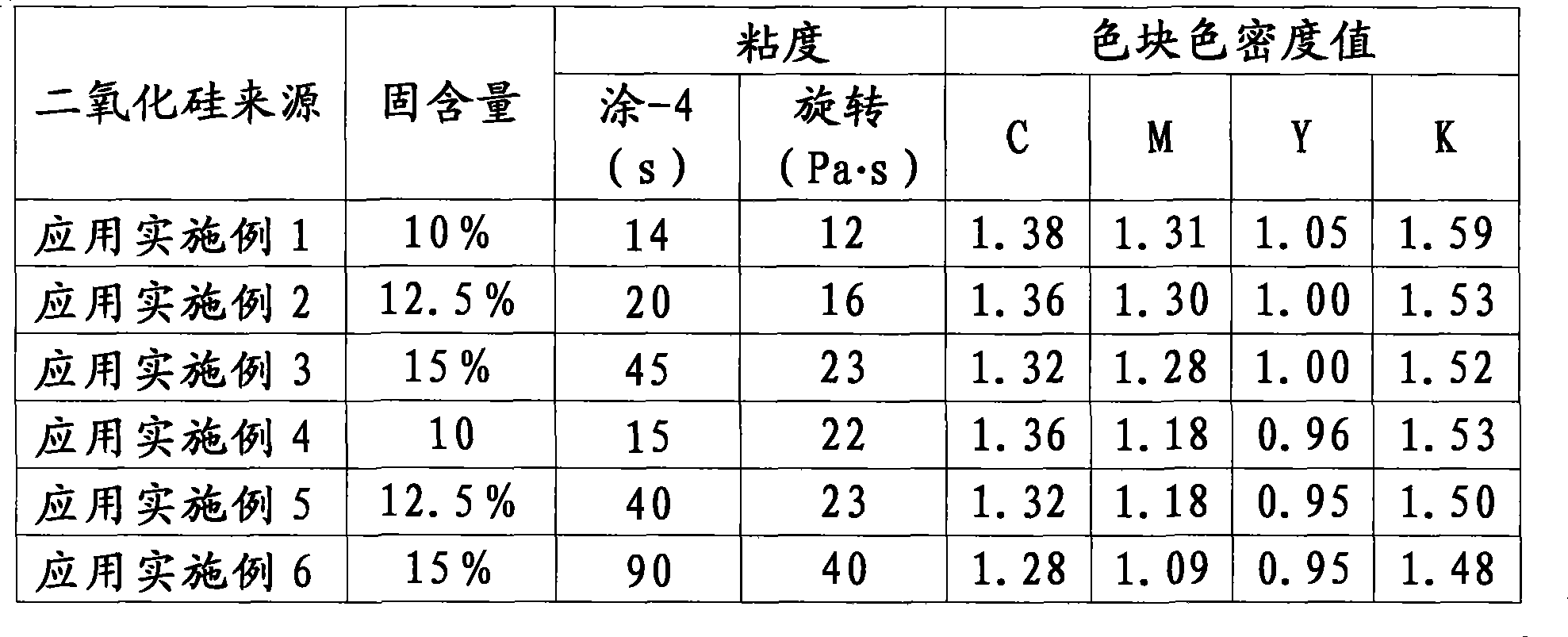

[0049] The product parameters of the above examples and commercially available silica (P508, produced by Grace) are shown in the table below. The test method of silica is: the pore volume is measured according to the DIN66134 method; the specific surface area is measured according to the DIN66131 method; the DBP absorption value is measured according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com