Coating paint for high-speed inkjet printing paper and preparation method thereof

A process method and technology for printing paper, applied in paper coatings, copying/marking methods, coatings, etc., can solve problems such as poor ink adhesion, slow drying speed, and color fading, and achieve high ink adhesion, advancement, and satisfaction. The effect of market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

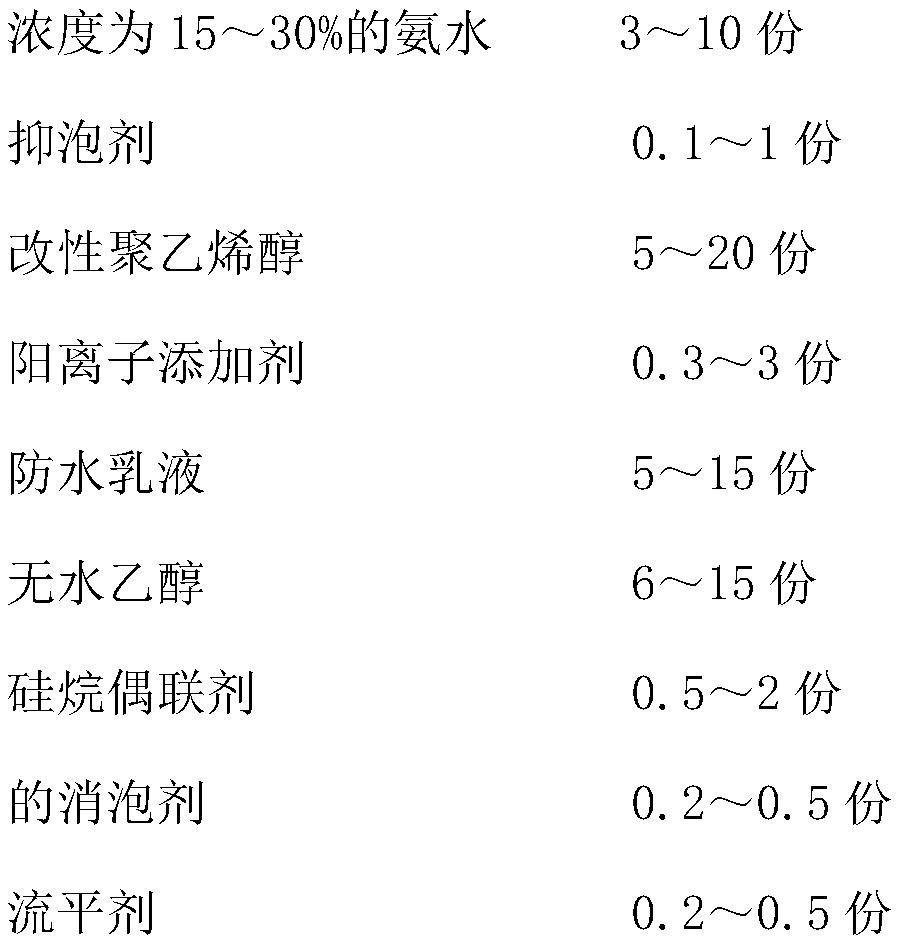

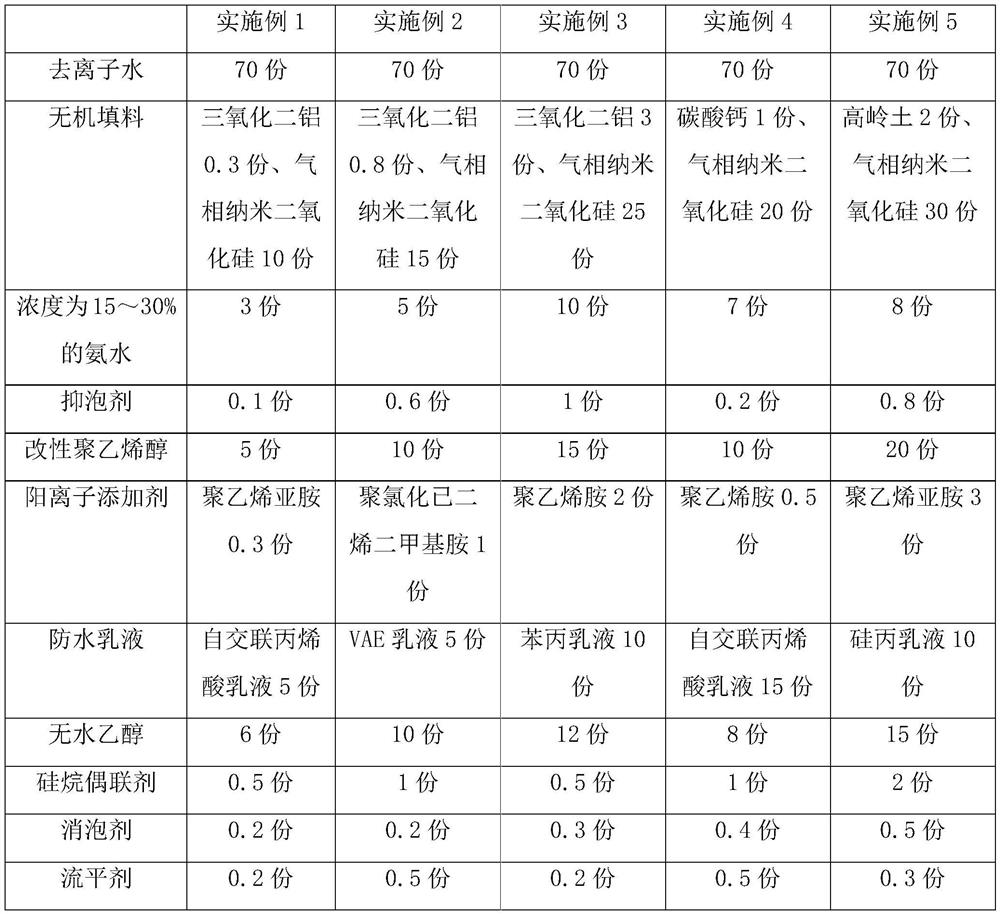

[0027] A coating coating for high-speed ink-jet printing paper, the formula used in the coating coating is as follows in parts by weight: 70 parts of deionized water, 0.3 parts of aluminum oxide, 3 parts of 15-30% ammonia water, 0.1 parts of foam inhibitor, 5 parts of modified polyvinyl alcohol, 0.3 parts of polyethyleneimine, 10 parts of fumed nano-silica, 5 parts of self-crosslinking acrylic emulsion, 6 parts of anhydrous Ethanol, 0.5 parts of silane coupling agent, 0.2 parts of defoaming agent, 0.2 parts of leveling agent, wherein, the deionized water and absolute ethanol are solvents, and the concentration of aluminum oxide is 15-30% Ammonia water, modified polyvinyl alcohol, gas-phase nano silicon dioxide and waterproof emulsion are used as base materials, and the foam suppressor, polyethyleneimine, silane coupling agent, defoamer and leveling agent are auxiliary agents.

[0028] The preparation process of a kind of high-speed inkjet printing paper coating coating provide...

Embodiment 2

[0036] A kind of coating paint for high-speed inkjet printing paper, by weight, the formula that described coating paint adopts is as follows: 70 parts of deionized water, 0.8 parts of aluminum oxide, 5 parts of concentration of 15-30% ammonia water, 0.6 parts of foam suppressor, 10 parts of modified polyvinyl alcohol, 1 part of polychlorinated dimethylamine, 15 parts of fumed nano-silica, 5 parts of VEA emulsion, 10 parts of absolute ethanol, 1 part of silane coupling agent, 0.2 part of defoamer, and 0.5 part of leveling agent, wherein the deionized water and absolute ethanol are solvents, and the concentration of aluminum oxide is 15-30% of ammonia water, modified polyvinyl alcohol, gas-phase nano silicon dioxide and VEA emulsion are used as the base material, and the foam suppressor, polychlorinated hexadiene dimethylamine, silane coupling agent, and defoamer And leveling agent as auxiliary.

[0037] The preparation method of a kind of high-speed inkjet printing paper coat...

Embodiment 3

[0045] A coating coating for high-speed ink-jet printing paper, in parts by weight, the formulation of the coating coating is as follows: 70 parts of deionized water, 3 parts of aluminum oxide, 10 parts of 15-30% Ammonia, 1 part of antifoaming agent, 15 parts of modified polyvinyl alcohol, 2 parts of polyvinylamine, 25 parts of fumed nano-silica, 10 parts of styrene-acrylic emulsion, 12 parts of absolute ethanol, 0.5 Part of silane coupling agent, 0.3 part of defoamer, 0.2 part of leveling agent, wherein, the deionized water and absolute ethanol are solvents, the inorganic filler, the concentration of ammonia water of 15 to 30%, modified The antifoaming agent, polyvinylamine, silane coupling agent, defoaming agent and leveling agent are auxiliary agents.

[0046] The preparation method of a kind of high-speed inkjet printing paper coating coating provided by the present embodiment is as follows:

[0047] Step 1: In parts by weight, weigh 70 parts of deionized water, stir at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com