Red fluorescent powder, preparation method thereof and luminescent device prepared therefrom

A technology for red phosphors and light-emitting devices, applied in the directions of light-emitting materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of slow development, difficult phosphor synthesis, harsh synthesis conditions, etc., and achieve convenient industrial production and effective excitation range. Wide, easy-to-synthesize effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

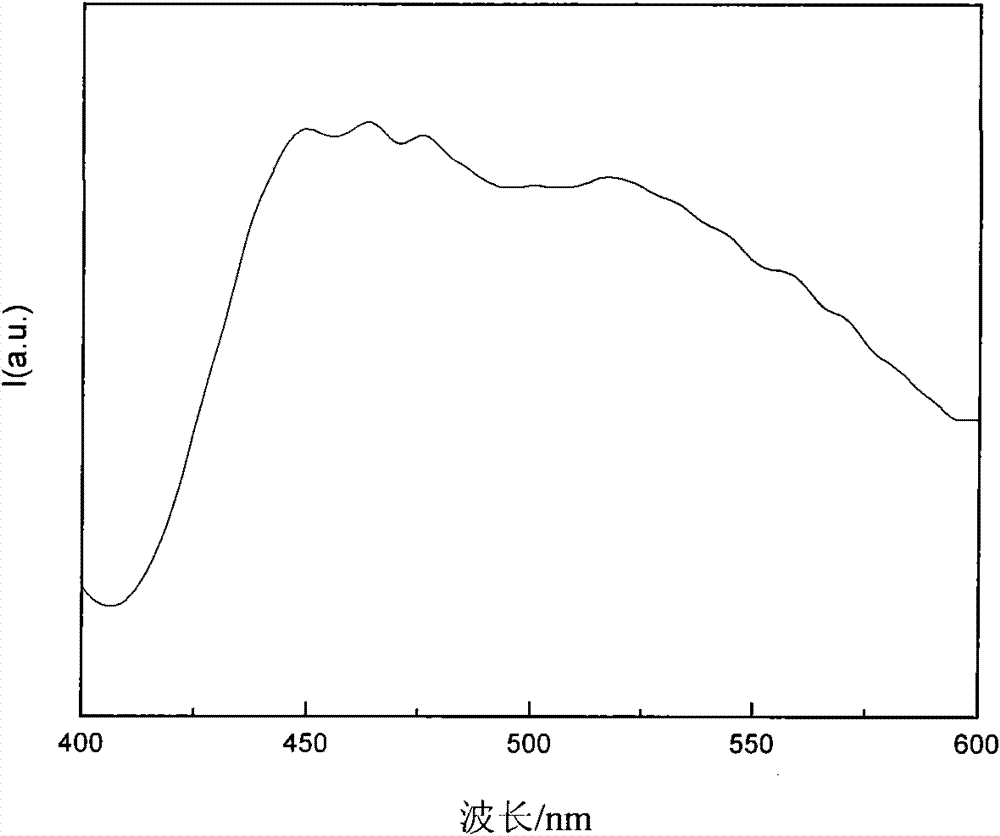

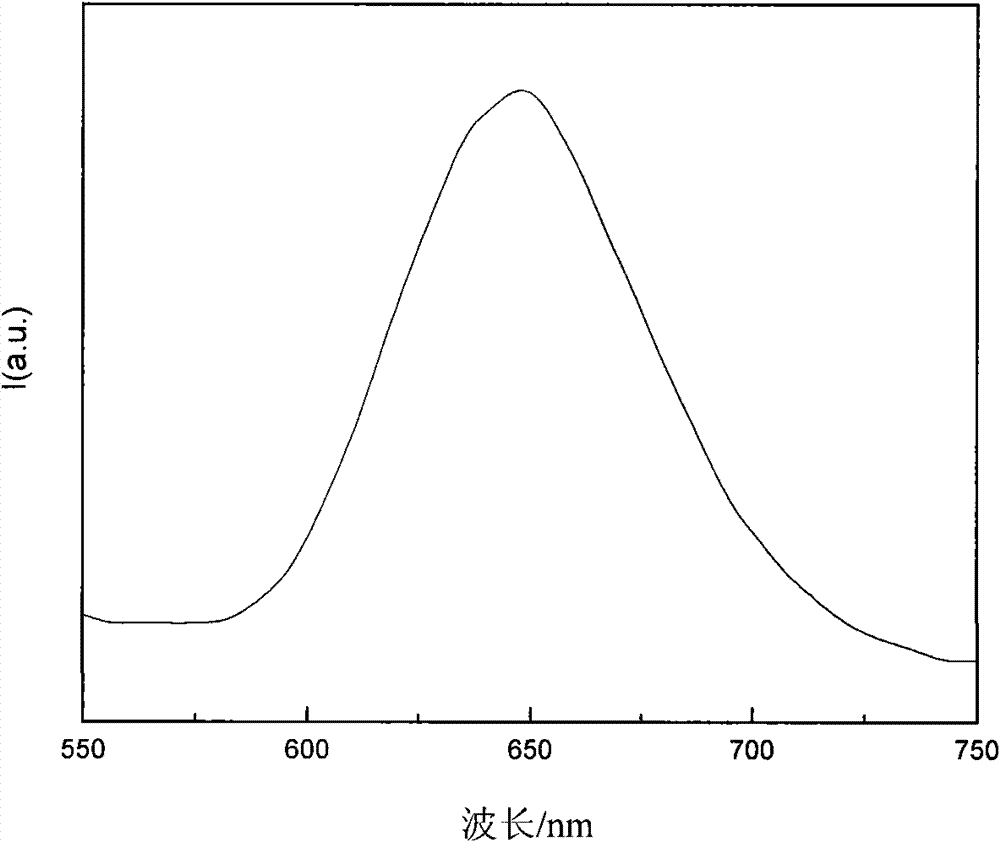

[0037] According to the chemical formula of phosphor Ca 0.9 sc 2 o 4 :Eu 0.1 Weigh 0.018mol CaCO 3 , 0.02mol Sc 2 o 3 , 0.001mol Eu 2 o 3 , and adding 1% H in phosphor weight 3 BO 3 flux. After fully mixing and grinding evenly, bake in a reducing atmosphere at 1550°C for 4 hours. After crushing, grading, washing, drying and sieving of the roasted product, the composition can be obtained as Ca 0.9 sc 2 o 4 :Eu 0.1 of red phosphor. Its excitation and emission spectra are as figure 1 , 2 shown. It can be seen that the excitation peak of the excitation spectrum is relatively broad, and the excitation effect of light with a wavelength in the range of 350-550nm is better. Its emission is a broad-spectrum emission, and the main peak is located at 640nm, showing strong red emission.

Embodiment 2

[0039] According to the chemical formula of phosphor Ca 0.65 Sr 0.1 sc 2 o 4.025 :Eu 0.2 , Dy 0.05 Weigh 0.013mol Ca(OH) 2 , 0.002mol Sr(NO 3 ) 2 , 0.02mol Sc 2 o 3 , 0.004mol Eu(NO 3 ) 3 ·6H 2 O, 0.0005mol Dy 2 o 3 , while adding 0.5% CaF by phosphor weight 2 Flux, after mixing and grinding evenly, bake in a reducing atmosphere at 1650°C for 2 hours. After crushing, grading, washing, drying and sieving of the roasted product, the composition can be obtained as Ca 0.65 Sr 0.1 sc 2 o 4.025 :Eu 0.2 , Dy 0.05 The main peak of the broad-peak emission of the phosphor is located at 642nm.

Embodiment 3

[0041] According to the chemical formula of phosphor CaMg 0.02 sc 2.2 al 0.1 o 4.475 :Eu 0.005 Weigh 0.02mol CaC 2 o 4 ·H 2 O, 0.0004mol (as Mg) Mg(OH) 2 · 3MgCO 3 0.3H 2 O, 0.044mol ScCl 3 , 0.004molAlOOH, 0.0001molEuF 3 , and adding 10% NH by phosphor weight to it 4 Cl flux. After fully mixing and grinding evenly, it is first calcined in a reducing atmosphere at 1100°C for 4 hours, and then calcined in a reducing atmosphere at 1400°C for 6 hours. The composition of the calcined product is CaMg after crushing, grading, washing, drying and sieving. 0.02 sc 2.2 al 0.1 o 4.475 :Eu 0.005 The main peak of the broad-peak emission of the phosphor is located at 630nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com