A kind of vanadate red phosphor material and preparation method thereof

A technology of red fluorescent powder and vanadate, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of good environment, excellent luminescent performance, and simple and feasible preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

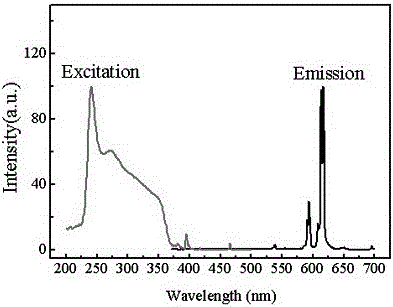

[0024] Embodiment 1: take by weighing Sc 2 o 3 1.0250g, NH 4 VO 3 1.9496g, Eu 2 o 3 0.0293g, Y 2 o 3 0.1882g, after mixing and grinding the above raw materials evenly, put them into a high-temperature furnace, uniformly heat from room temperature to 1000°C, keep warm for 5 hours, then naturally cool to room temperature and grind, wash the product once with NaOH dilute solution, and then use Washed twice with ionized water, filtered, and dried at 120°C to obtain the composition Sc 0.89 Y 0.1 VO 4 :Eu 3+ 0.01 , its color coordinates are (0.6530, 0.3252), and its relative brightness is 1.0000 (using itself as a standard sample, see the attached figure 1 , the following examples are all taken as the standard sample).

Embodiment 2

[0025] Embodiment 2: take by weighing Sc 2 (SO 4 ) 3 1.3858g, NH 4 VO 3 1.6711g, Eu 2 (SO 4 ) 3 0.0241g, Y 2 (SO 4 ) 3 0.1964g, Gd 2 (SO 4 ) 3 0.1226g, after mixing and grinding the above raw materials evenly, put them into a high-temperature furnace, uniformly heat from room temperature to 1000°C, keep warm for 5 hours, then cool naturally to room temperature and grind, wash the product with NaOH dilute solution for 3 times, and then use Wash 5 times with ionized water, filter, and dry at 120°C to obtain the composition Sc 0.84 Y 0.1 Gd 0.05 VO 4 :Eu 3+ 0.01 , its color coordinates are (0.6518, 0.3280), and its relative brightness is 1.0832.

Embodiment 3

[0026] Embodiment 3: take by weighing Sc (NO 3 ) 3 1.6378g, Y(NO 3 ) 3 0.1250g, Gd(NO 3 ) 3 0.3121g, La(NO 3 ) 3 0.1477g, V 2 o 5 0.8267g, Eu(NO 3 ) 3 0.0307g, Sm(NO 3 ) 3 0.0306g, after mixing and grinding the above raw materials, put them into a high-temperature furnace, uniformly heat from room temperature to 1100°C, keep warm for 4 hours, then naturally cool to room temperature and grind, wash the product with NaOH dilute solution for 3 times, and then use Wash 4 times with ionic water, filter, and dry at 120°C to obtain the composition Sc 0.78 Y 0.05 Gd 0.1 La 0.05 VO 4 :Eu 3+ 0.01 ,Sm 3+ 0.01 , its color coordinates are (0.6590, 0.3262), and its relative brightness is 1.1202.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com