Calcium samarium tin aluminum garnet-based orange-yellow fluorescent powder and preparation method thereof

A garnet-based, calcium-samarium-tin-aluminum technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems that phosphors affect the luminous efficiency of devices, the content of luminescent centers is not high enough, and the position of the main peak of red light is not ideal, etc. The effect of wide emission coverage, wide excitation range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

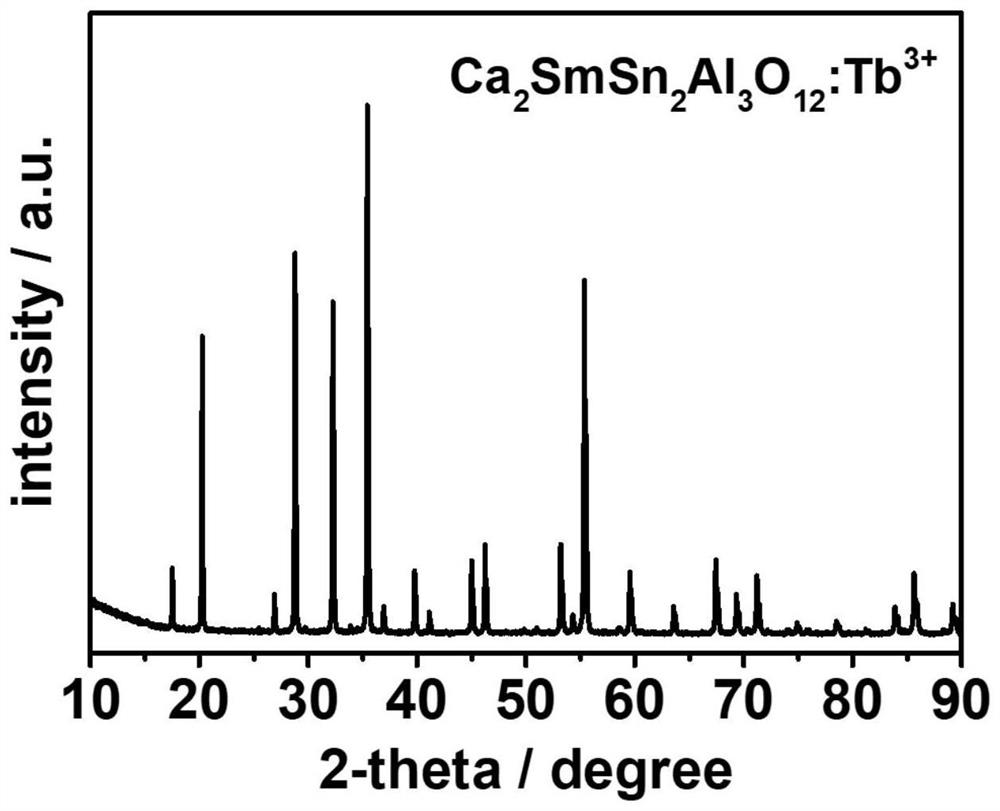

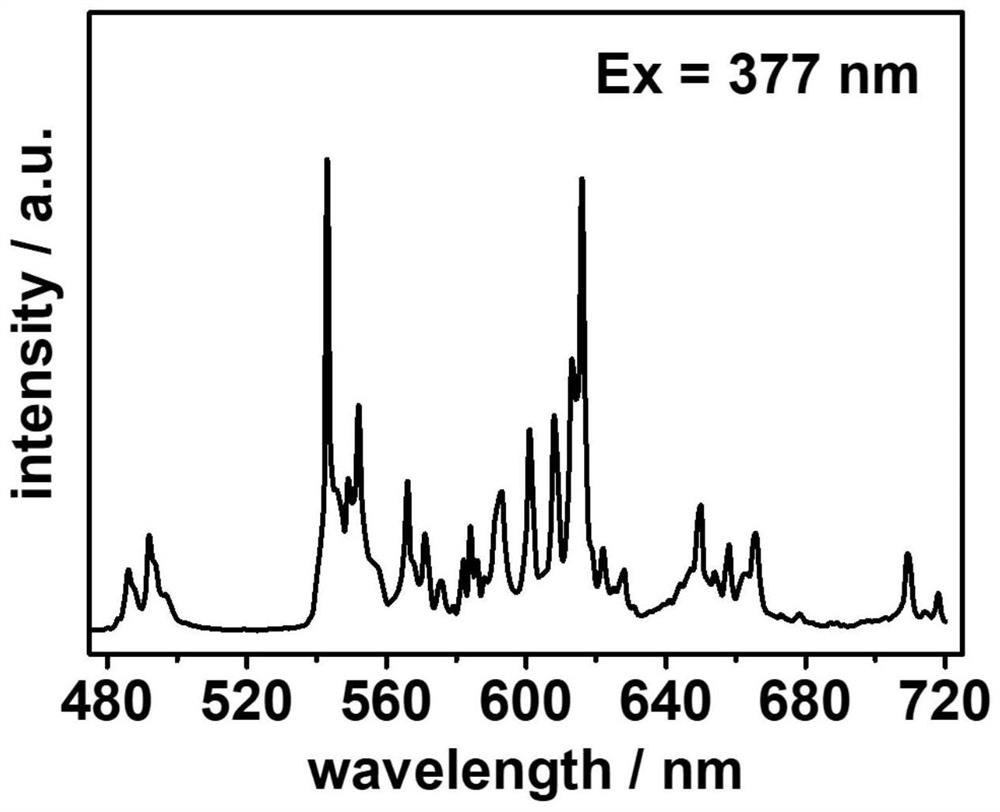

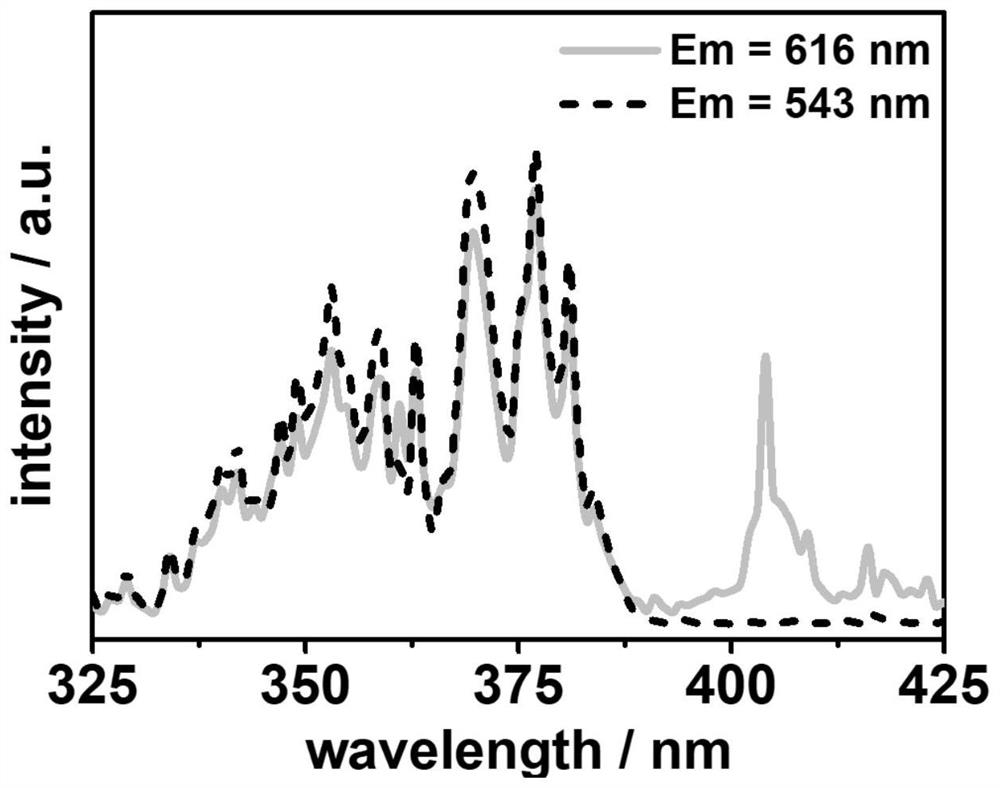

[0027] Weigh calcium carbonate (CaCO 3 ) 0.2002g, aluminum hydroxide ((Al(OH) 3 ) 0.2340g, tin oxide (SnO 2 ) 0.3014g, samarium oxide (Sm 2 o 3 ) 0.0052g, terbium oxide (Tb 4 o 7 ) 0.1813g, boric acid (H 3 BO 3) 0.0031g Grind the above raw materials in an agate mortar, put them into a corundum crucible after grinding evenly, and carry out the first step of sintering in an air atmosphere at 1450°C under normal pressure. The constant temperature time is 6h. Carry out the second step of sintering in a compressed air atmosphere, the constant temperature time is 6h, after the second step is completed, let it cool naturally, grind evenly and obtain Tb 3+ Ca-doped 2 wxya 2 Al 3 o 12 Yellow-orange phosphor.

[0028] To get Tb 3+ Ca-doped 2 wxya 2 Al 3 o 12 Yellow-orange phosphors were tested as Figure 1-4 shown.

Embodiment 2

[0030] Weigh calcium carbonate (CaCO 3 ) 0.2002g, aluminum hydroxide ((Al(OH) 3 ) 0.2340g, tin oxide (SnO 2 ) 0.3014g, samarium oxide (Sm 2 o 3 )0.0105g, terbium oxide (Tb 4 o 7 ) 0.1757g, boric acid (H 3 BO 3 ) 0.0031g Grind the above raw materials in an agate mortar, put them into a corundum crucible after grinding evenly, and carry out the first step of sintering in an air atmosphere at 1450°C under normal pressure. The constant temperature time is 6h. The second step of sintering is carried out in compressed air atmosphere, and the constant temperature time is 6h. After the second step is finished, wait for it to cool naturally, grind evenly and obtain Tb 3+ Ca-doped 2 wxya 2 Al 3 o 12 Yellow-orange phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com