A kind of nitrogen oxide green fluorescent powder and preparation method thereof

A green phosphor, nitrogen oxide technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as long afterglow time, and achieve the effects of good environment, simple and feasible preparation method, and excellent luminous performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

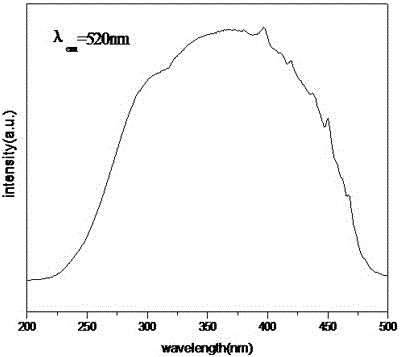

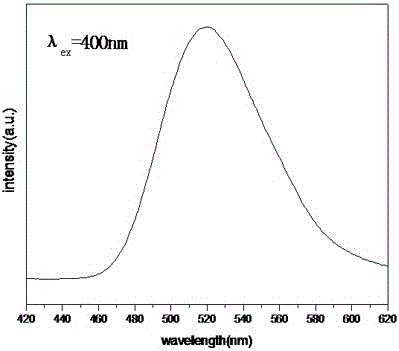

Image

Examples

Embodiment 1

[0043] Embodiment 1: Take BaCO by weighing 3 1.1584g, Eu 2 o 3 0.0212g, Al(NO 3 ) 3 9H 2 O 0.75g, SiO 2 0.03g, after mixing and grinding the above raw materials evenly, put them into a high-temperature furnace, heat uniformly from room temperature to 1000°C, keep warm for 6 hours, then cool naturally to room temperature and grind, then mix the powder with Si 3 N 4 0.07g mixed and ground evenly, NH in reducing atmosphere 3 Heating evenly from room temperature to 1400°C under the conditions, keeping the temperature for 5 hours, then cooling to room temperature naturally and then grinding to obtain the composition (Ba 0.98 Eu 0.02 ) 3 AlSiO 5 N.

Embodiment 2

[0044] Embodiment 2: take by weighing Ba(NO 3 ) 2 1.4407g, Eu(NO 3 ) 3 4H 2 O 0.1968g, Al(NO 3 ) 3 9H 2 O0.6g, SiO 2 0.036g, after mixing and grinding the above raw materials evenly, put them into a high-temperature furnace, heat uniformly from room temperature to 1100°C, keep warm for 3 hours, then cool naturally to room temperature and grind, then mix the powder with Si 3 N 4 0.084g is mixed and ground evenly, in reducing atmosphere N 2 / H 2 =10:1 under the condition of uniform heating from room temperature to 1300°C, heat preservation for 6 hours, then naturally cool to room temperature and grind to obtain the composition (Ba 0.92 Eu 0.08 ) 3 al 0.8 Si 1.2 o 4.8 N 1.2 .

Embodiment 3

[0045] Embodiment 3: take by weighing Ba(NO 3 ) 2 1.4094g, Eu 2 o 3 0.1056g, AlN 0.0492g, SiO 2 0.042g, after mixing and grinding the above raw materials evenly, put them into a high-temperature furnace, heat uniformly from room temperature to 1300°C, keep warm for 2 hours, then cool naturally to room temperature and grind, then mix the powder with Si 3 N 4 0.098g is mixed and ground evenly, in reducing atmosphere N 2 / H 2 =9.5:0.5 uniformly heated from room temperature to 1250°C, kept for 8 hours, then naturally cooled to room temperature and then ground to obtain the composition (Ba 0.9 Eu 0.1 ) 3 al 0.6 Si 1.4 o 4.6 N 1.4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com