Garnet-type phosphor, preparation method, and device containing the phosphor

A phosphor and garnet technology, applied in the field of inorganic LED luminescent materials, achieves the effects of simple preparation process, wide effective excitation range and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

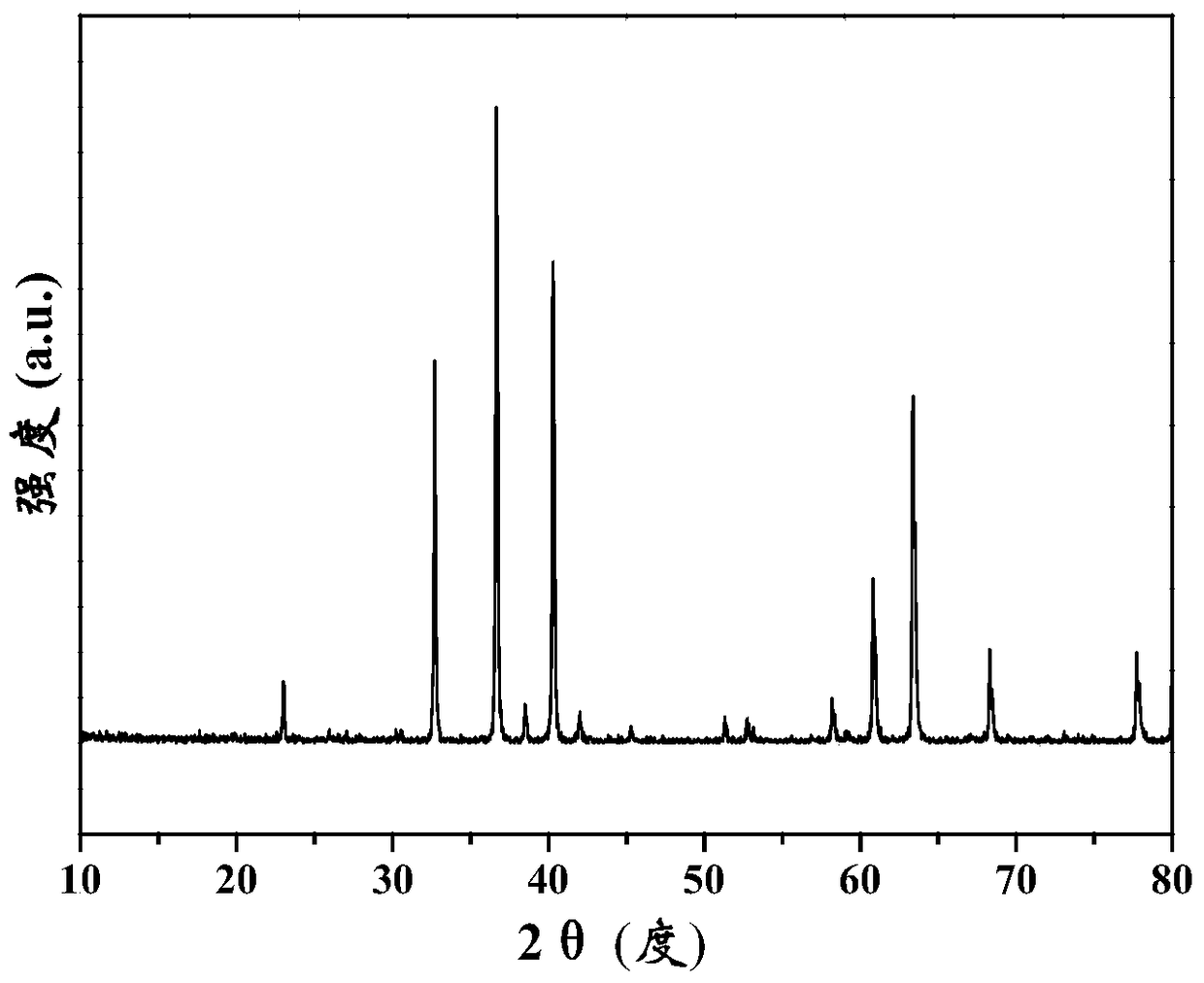

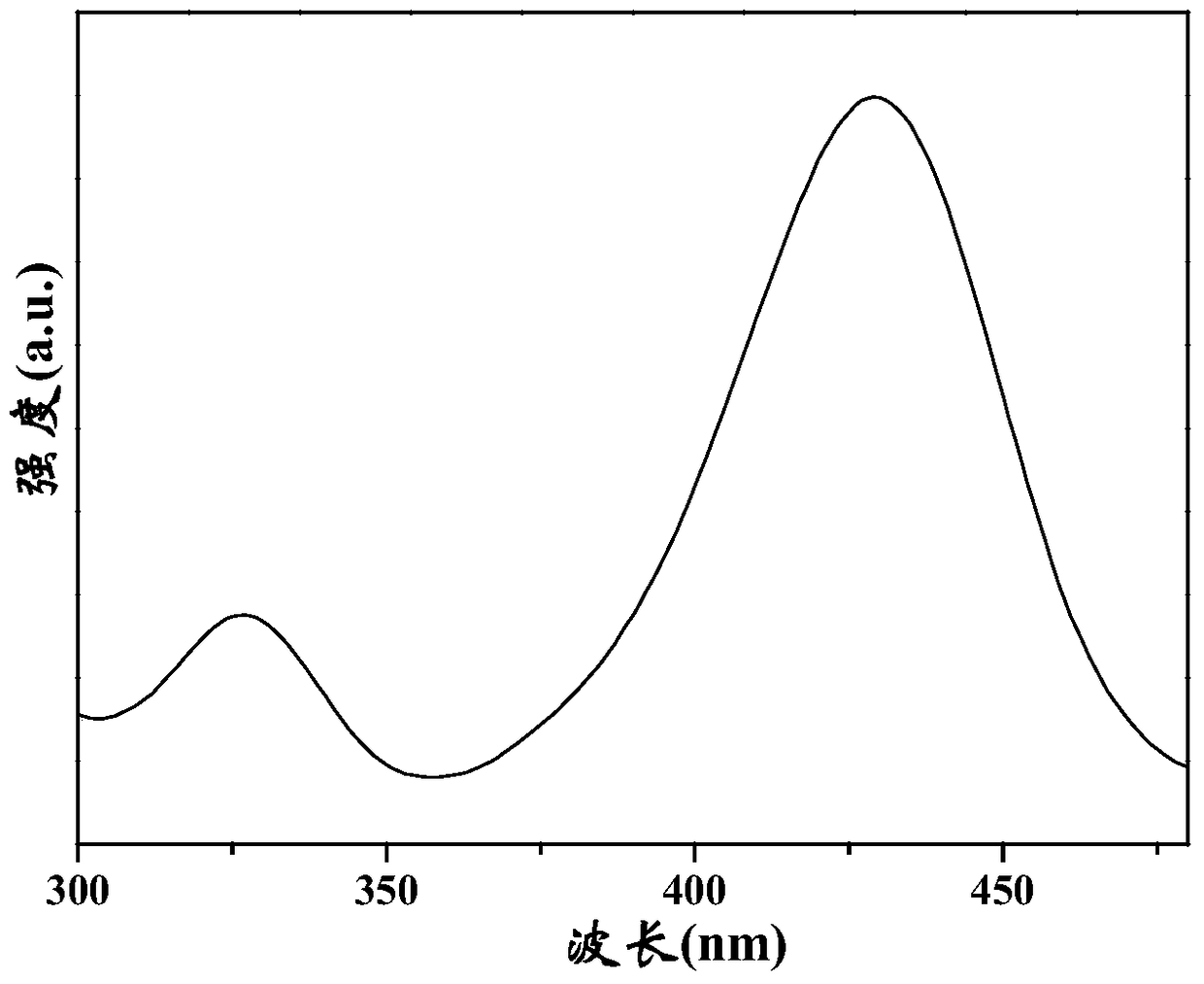

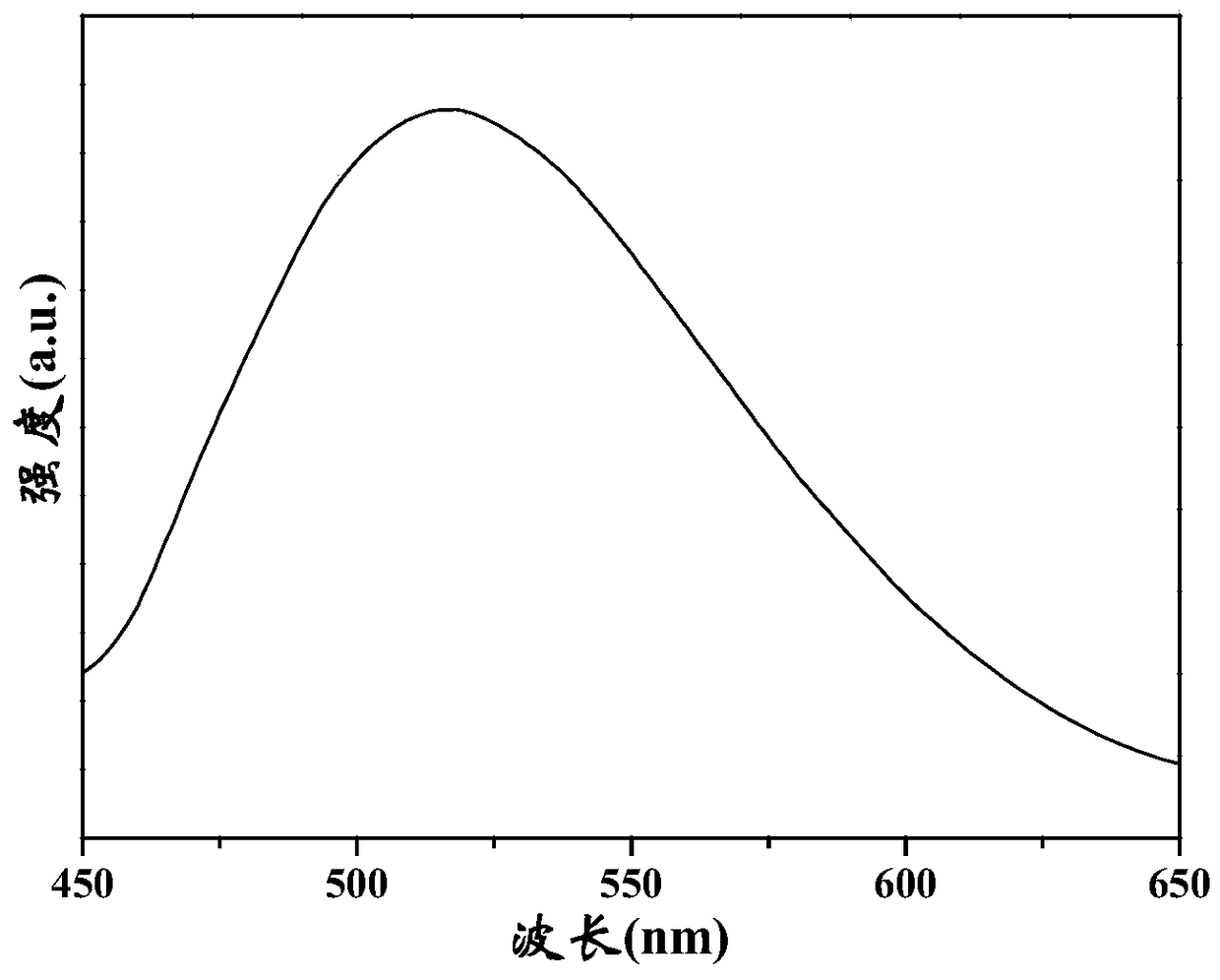

[0061] According to the chemical formula of phosphor (Ca 2 La 0.96 , Ce 0.04 )Zr 2 Ga 3 o 12 Weigh 0.2mol CaCO 3 , 0.048molLa 2 o 3 , 0.2mol ZrO 2 , 0.15mol Ga 2 o 3 , 0.004mol CeO 2 . After fully mixing and grinding, bake at 1350°C for 4 hours in a CO atmosphere. After crushing, grading, washing, drying and sieving of the roasted product, the composition can be obtained as (Ca 2 La 0.96 , Ce 0.04 )Zr 2 Ga 3 o 12 of fluorescent powder. Its X-powder diffraction pattern (Co target, λ=0.178892nm) such as figure 1 shown. Its excitation spectrum (monitored at 515nm) and emission spectrum (excited at 420nm) are as figure 2 with image 3 As shown, it can be seen from the figure that the excitation wavelength range covers 280-480nm, and the emission spectrum peak wavelength is 515nm under excitation at 420nm, and the relative luminous intensity is shown in Table 3.

Embodiment 2

[0063]According to the chemical formula of phosphor (Ca 2.91 , Ce 0.06 )Zr 2 (Ga 2 Ge)O 12 Weigh 0.291mol CaCO 3 , 0.2molZrO 2 , 0.1mol GeO 2 , 0.1mol Ga 2 o 3 , 0.006mol CeO 2 . After fully mixing and grinding, bake at 1320°C for 8 hours in a CO atmosphere. After crushing, grading, washing, drying and sieving of the roasted product, the composition can be obtained as (Ca 2.91 , Ce 0.06 )Zr 2 (Ga 2 Ge)O 12 of fluorescent powder. Its X-powder diffraction pattern (Co target, λ=0.178892nm) such as Figure 4 shown. Its excitation spectrum (monitored at 475nm) and emission spectrum (excited at 420nm) are as Figure 5 with Image 6 As shown, it can be seen from the figure that the excitation spectrum wavelength range covers 280-440nm, and the emission spectrum peak wavelength is 475nm under excitation at 420nm, and the relative luminous intensity is shown in Table 3.

Embodiment 3

[0065] According to the chemical formula of phosphor (Ca 2 Y 0.94 , Ce 0.06 )Zr 2 Ga 3 o 12 Weigh 0.2mol CaCO 3 , 0.2mol ZrO 2 , 0.047mol Y 2 o 3 , 0.15mol Ga 2 o 3 , 0.006mol Ce(NO 3 ) 3 . After fully mixing and grinding, in H 2 / N 2 In a mixed atmosphere, bake at 1360°C for 6 hours. After crushing, grading, washing, drying and sieving of the roasted product, the composition can be obtained as (Ca 2 Y 0.94 , Ce 0.06 )Zr 2 Ga 3 o 12 of fluorescent powder. The fitting parameters of its X-powder ray diffraction refinement are shown in Table 1 and Table 2, and the fitting of the spectrum is shown in Figure 7 The wavelength range of its excitation spectrum covers 280-480nm, under the excitation of 420nm, the peak wavelength of emission spectrum is 512nm, and the relative luminous intensity is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com