A kind of red luminous glass material and preparation method thereof

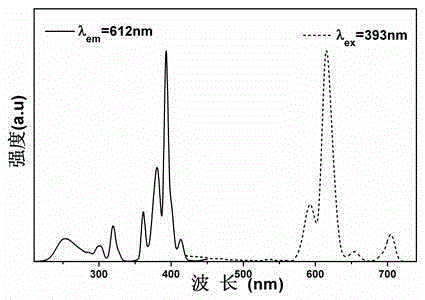

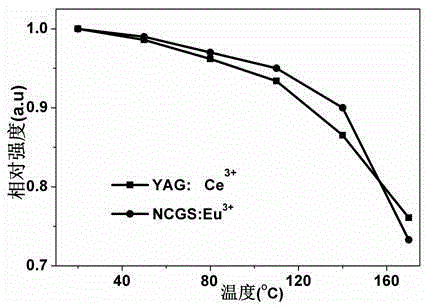

A glass material and red luminescent technology, applied in the field of rare earth luminescent materials, can solve the problems of luminous efficiency and service life decline, and achieve the effects of wide effective excitation range, simple synthesis method and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The glass material of this embodiment is 4Na 2 O-6.8CaO-57GeO 2 -22SiO2 2 -0.2Eu 2 o 3 , the specific preparation method is:

[0019] (1) Accurately weigh Na according to molar percentage 2 CO 3 (99.99%), CaCO 3 (99.99%), GeO 2 (99.99%), SiO 2 (99.99%) and Eu 2 o 3 (99.99%) mixed in an agate mortar, grind for 0.5h to make it evenly mixed, put it into an alumina crucible and put it in a silicon carbon rod electric furnace for melting, the melting temperature is 1500 °C, and the melting time is 50 Minutes to obtain glass melt, after the melt is clarified, pour it into a preheated stainless steel mold to obtain NCGS: 0.2Eu 2 o 3 Glass;

[0020] (2) Quickly put the above glass into the muffle furnace that has been heated to the material transition temperature L (550°C) and keep it warm for 1 hour, then cool down to 100°C at a rate of 8°C / h, turn off the power, and automatically cool down to room temperature. 4Na can be obtained 2 O-6.8CaO-57GeO 2 -22SiO2 2 ...

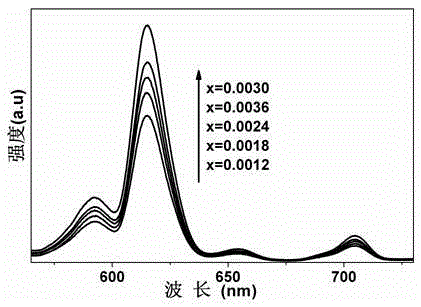

Embodiment 2

[0023] The glass material of this embodiment is 4Na 2 O-6.7988CaO-57GeO 2 -22SiO2 2 -0.2Eu 2 o 3 -0.0012Bi 2 o 3 , the specific preparation method is:

[0024] (1) Accurately weigh Na according to molar percentage 2 CO 3 (99.99%), CaCO 3 (99.99%), GeO 2 (99.99%), SiO 2 (99.99%), Eu 2 o 3 (99.99%) and Bi 2 o 3 (99.99%) mixed in an agate mortar, ground for 0.5h to make it evenly mixed; after mixing evenly, put it into an alumina crucible and place it in a silicon carbon rod electric furnace for melting, the melting temperature is 1500°C, and the melting time is 20 Minutes to obtain molten glass, after the molten liquid is clarified, pour it into a preheated stainless steel mold to obtain NCGS:0.2Eu 2 o 3 , 0.0012 Bi 2 o 3 Glass;

[0025] (2) Quickly put the above glass into the muffle furnace which has been heated to the material transition temperature L (550°C) for 1 hour, then cool down to 100°C at a rate of 7°C / hour, turn off the power, and automatically co...

Embodiment 3

[0027] The glass material of this embodiment is 4Na 2 O-6.7982CaO-57GeO 2 -22SiO2 2 -0.2Eu 2 o 3 -0.0018Bi 2 o 3 , the specific preparation method is:

[0028] (1) Accurately weigh Na according to molar percentage 2 CO 3 (99.99%), CaCO 3 (99.99%), GeO 2 (99.99%), SiO 2 (99.99%), Eu 2 o 3(99.99%) and Bi 2 o 3 (99.99%) mixed in an agate mortar, ground for 0.5h to make it evenly mixed; after mixing evenly, put it into an alumina crucible and place it in a silicon carbon rod electric furnace for melting, the melting temperature is 1500°C, and the melting time is 40 Minutes to obtain molten glass, after the molten liquid is clarified, pour it into a preheated stainless steel mold to obtain NCGS:0.2Eu 2 o 3 , 0.0018 Bi 2 o 3 Glass;

[0029] (2) Quickly put the above glass into the muffle furnace that has been heated to the material transition temperature L (550°C) and keep it warm for 1 hour, then cool down to 100°C at a rate of 6°C / hour, turn off the power, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com