Preparation method of nano-silver paste for electric field driven jet micro-nano 3D printing

A nano-silver paste, 3D printing technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of difficult to achieve ultra-fine, large aspect ratio high-performance conductive pattern manufacturing, nano-silver It is difficult to meet the technical requirements of the slurry, the agglomeration of nano-silver materials and other problems, and achieve the effects of good dispersion performance and electrical conductivity, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

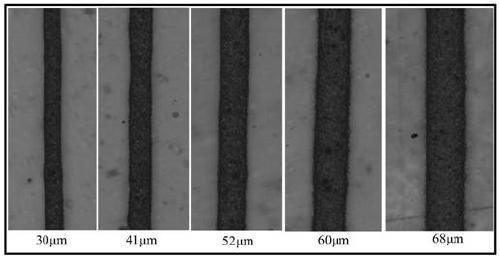

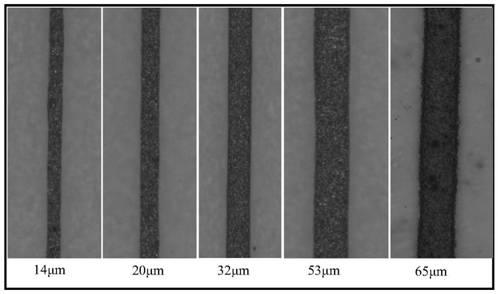

Embodiment 1

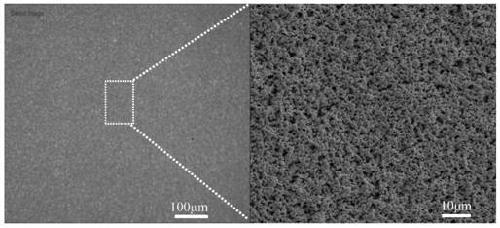

[0038] A nano-silver paste for electric field-driven spraying micro-nano 3D printing technology, its composition includes: modified nano-silver powder 55wt%, organic vehicle 39wt%, polyurethane resin 3wt%, epoxy resin 3wt%, silver powder A spherical silver powder with a diameter of 300nm.

[0039] Concrete preparation process is as follows:

[0040](1) Preparation of modified nano-silver powder: take a certain proportion of succinic acid and PVP and be dissolved in ethanol solution respectively, obtain succinic acid-ethanol solution as solution I, and PVP-ethanol solution as solution II; The mass ratio of diacid and silver powder is 1:1 and takes by weighing corresponding silver powder, slowly adds the silver powder that takes by weighing in the solution I, is placed on the magnetic stirrer and stirs 30min, pours off supernatant after standing layering, and then Add the prepared solution II, ultrasonically treat for 60 minutes, and stir simultaneously during the ultrasonic st...

Embodiment 2

[0045] Provide a nano-silver paste for electric field-driven spraying micro-nano 3D printing technology, its composition includes: nano-modified silver powder 65wt%, organic vehicle 27wt%, alkyd resin 4wt%, epoxy resin 4wt%, The silver powder is a spherical silver powder with a particle size of 300nm.

[0046] Concrete preparation process is as follows:

[0047] Process one: the preparation of nano-modified silver powder: take a certain proportion of succinic acid and PVP and dissolve them in ethanol solution respectively, and obtain succinic acid-ethanol solution as solution I, and PVP-ethanol solution as solution II; The mass ratio of diacid and silver powder is 1:1 and takes by weighing corresponding silver powder, slowly adds the silver powder that takes by weighing in the solution I, is placed on the magnetic stirrer and stirs 30min, pours off supernatant after standing layering, and then Add the prepared solution II, ultrasonically treat for 60 minutes, and stir simulta...

Embodiment 3

[0052] Provides a nano-silver paste for electric field-driven spraying micro-nano 3D printing technology, its composition by weight includes: silver powder 75wt%, organic vehicle 19wt%, alkyd resin 3wt%, epoxy resin 3wt%, silver powder particle size Spherical silver powder with a size of 300nm.

[0053] Concrete preparation process is as follows:

[0054] Process one: the preparation of modified nano-silver powder: take a certain proportion of succinic acid and PVP and dissolve them in ethanol solution respectively, and obtain succinic acid-ethanol solution as solution I, and PVP-ethanol solution as solution II; The mass ratio of diacid and silver powder is 1:1 to take by weighing corresponding silver powder, slowly add the silver powder that weighs in the solution I, be placed on the magnetic stirrer and stir 30min, pour off the supernatant after standing stratification, put The prepared solution II is poured into the beaker of solution I containing silver powder, ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com