Alumina ceramic slip suitable for 3D printing, preparation method and application thereof

A kind of alumina ceramics, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of large amount of plasticizer, low strength of ceramic parts, high sintering temperature, etc., and achieve the effect of improving plasticity and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

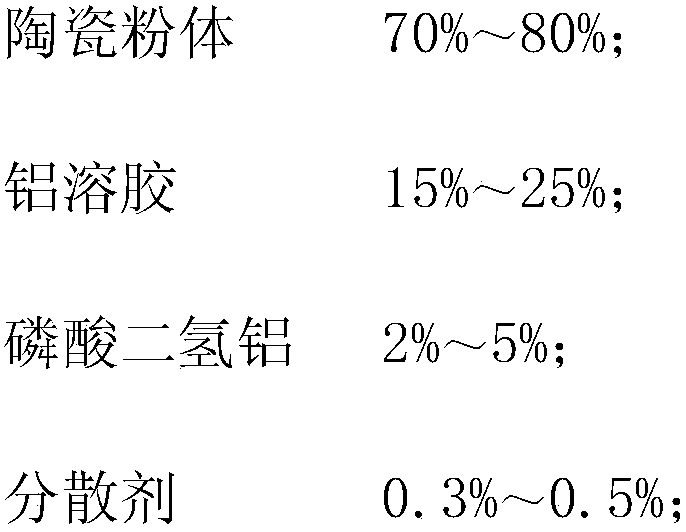

Method used

Image

Examples

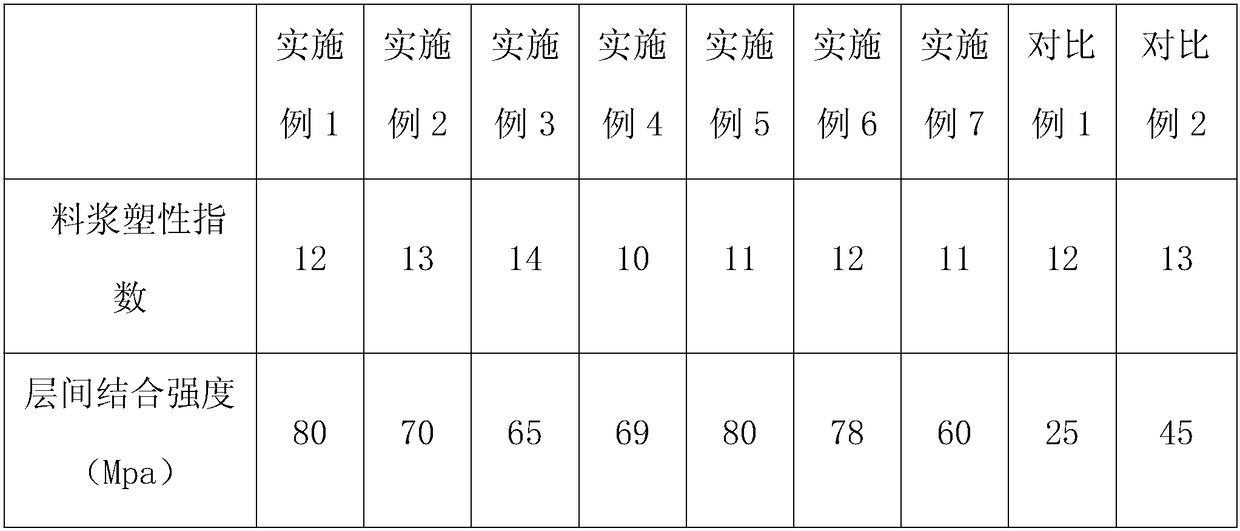

Embodiment 1

[0024] First, according to the mass ratio of 0.3% glycerin, 0.1% polyvinyl alcohol 2000, and 76.8% ceramic powder, they were added to the acidic aluminum sol with a mass fraction of 20%, a pH of 3, and a concentration of 20%. The ceramic powder The body contains 5% of 20-80nm silicon dioxide and 95% of 0.5-2μm alumina; then add aluminum dihydrogen phosphate with a mass fraction of 2.8%, a pH of 2.5, and a concentration of 12% for 20 minutes to induce localized The sol was polymerized to improve the uniformity of the slurry; finally, it was aged for 48 hours, and the properties of the alumina slurry and its products obtained in this example are shown in Table 1.

Embodiment 2

[0026] First, according to the mass ratio of 0.2% glycerin, 0.3% polyethylene glycol 400, and 75% ceramic powder, they are added to the acidic aluminum sol with a mass fraction of 21%, a pH of 2.8, and a concentration of 25%. The powder contains 10% of 20-80nm silica and 90% of 0.5-2μm alumina; then add aluminum dihydrogen phosphate with a mass fraction of 3.5%, a pH of 2, and a concentration of 15% for 30 minutes to initiate local sol Polymerize and improve the uniformity of the slurry; finally, stale for 36 hours, the properties of the alumina slurry and its products obtained in this example are shown in Table 1.

Embodiment 3

[0028] First, according to the mass ratio of 0.2% glycerin, 0.2% carboxymethyl cellulose 1750, and 75.9% ceramic powder, they were added to the acidic aluminum sol with a mass fraction of 20%, a pH of 4, and a concentration of 15%. The ceramic powder contains 25% of 20-80nm silica and 75% of 0.5-1μm alumina; then add aluminum dihydrogen phosphate with a mass fraction of 3.7%, a pH of 2.2 and a concentration of 15% for 10 minutes to initiate local sol Polymerize and improve the uniformity of the slurry; finally, stale for 48 hours, the properties of the alumina slurry and its products obtained in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com