Paper unwinding machine with double floating rolls

A double floating roller, paper machine technology, applied in the direction of winding strips, thin material handling, transportation and packaging, can solve the problems of easy to stretch the outer diameter, unstable tension, different, etc., to improve the accuracy, The effect of improving printing performance and reducing scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

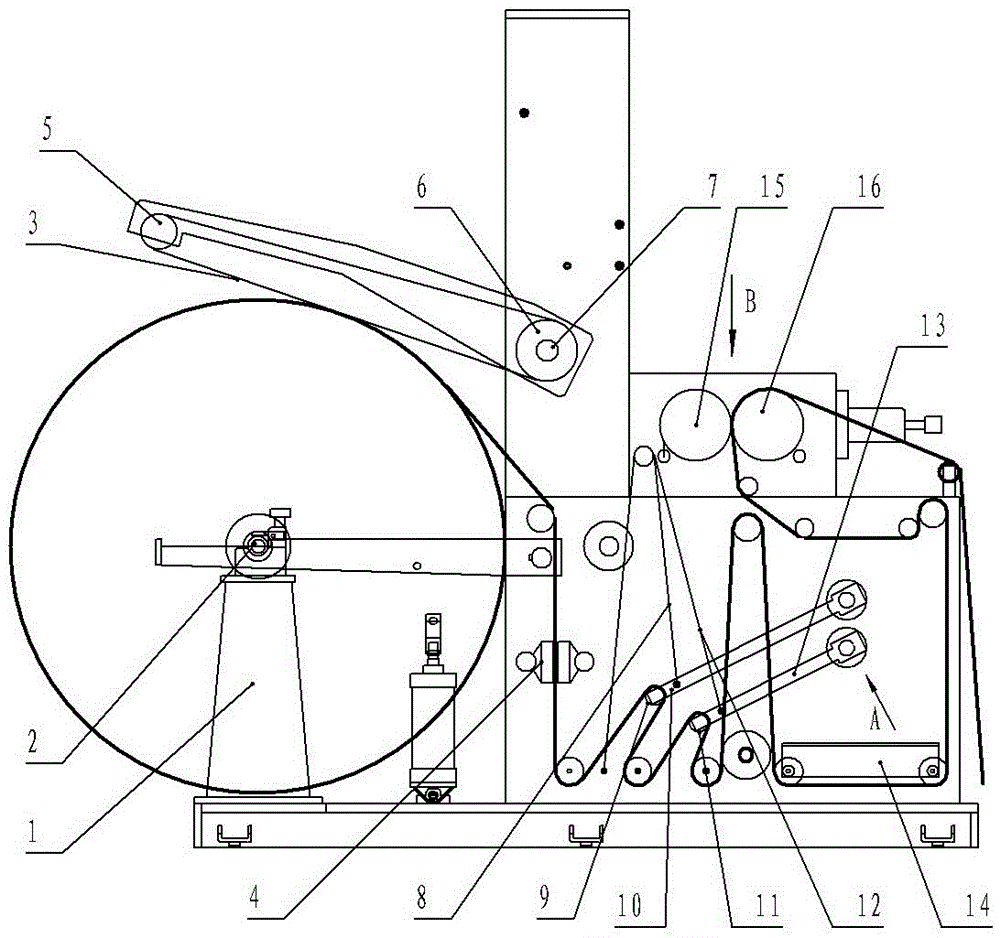

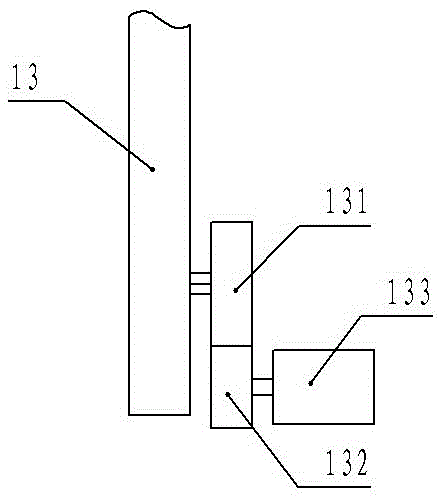

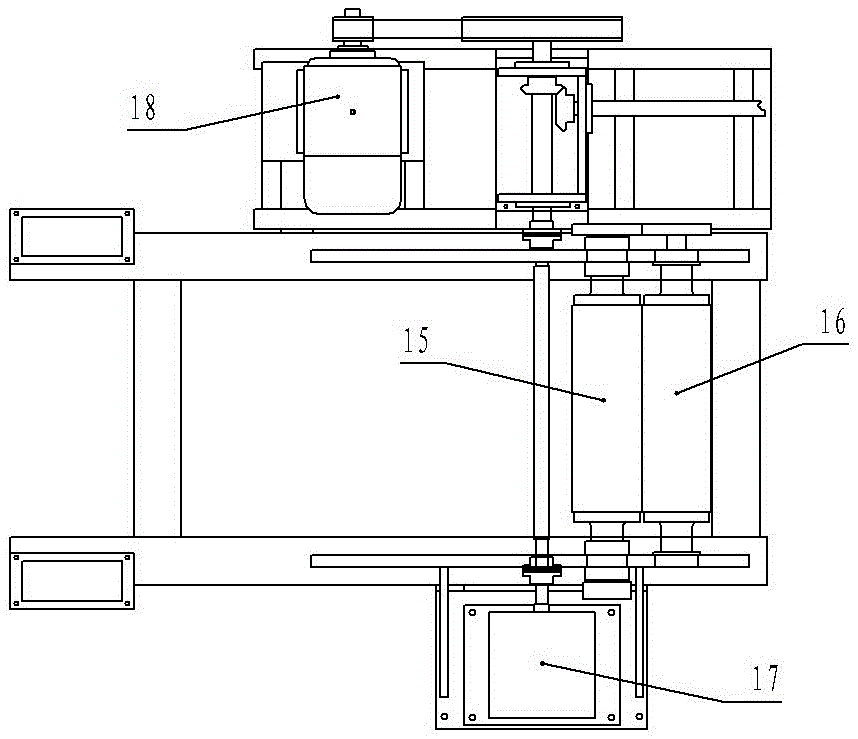

[0015] figure 1 , figure 2 , image 3 The double-floating roller unwinding machine shown includes an unwinding unit, which has an unwinding roller 2 mounted on the unwinding frame 1 and an unwinding drive device arranged on one side of the unwinding roller 2 The unwinding belt 3 driven by the set between the driving pulley 6 and the passive pulley 5, the unwinding driving device has a motor 7 controlled by a frequency converter, and the output shaft of the motor 7 is fixedly connected with the driving pulley 6. The paper output channel behind the unit is provided with a dust collector 4, and two tension disturbance absorbing devices are arranged in turn on the paper output channel after the dust collector 4, and the first tension disturbance absorbing device is formed by a first extension spring 8 connected to it. The first swing rod 10 and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com