Preparation method of high-temperature spherical molybdenum alloy powder

A spherical powder, molybdenum alloy technology, applied in the field of powder metallurgy, can solve the problems of excessive hollow powder, large powder particle size, difficult to form high-quality molybdenum alloy parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 585.6g of Mo powder, 8.4g of Si powder, 6.5g of B powder, 18.2g of Zr powder, and 38.2g of Ti powder in proportion. Put the mixture into the mixer for 15 hours, then put the mixture into the planetary ball mill (QM-3SP4) for 20 hours, the ratio of ball to material is 5:1, and the speed is 300r / min. A pre-alloyed powder with uniform particle size is obtained.

[0033] Put the pre-alloyed powder into Φ25×175mm 3 In the graphite mold, Φ25mm is consistent with the size required by the plasma rotary atomization equipment. In order to prevent the pre-alloyed powder from sticking to the graphite mold, graphite paper is used to isolate the powder from the mold.

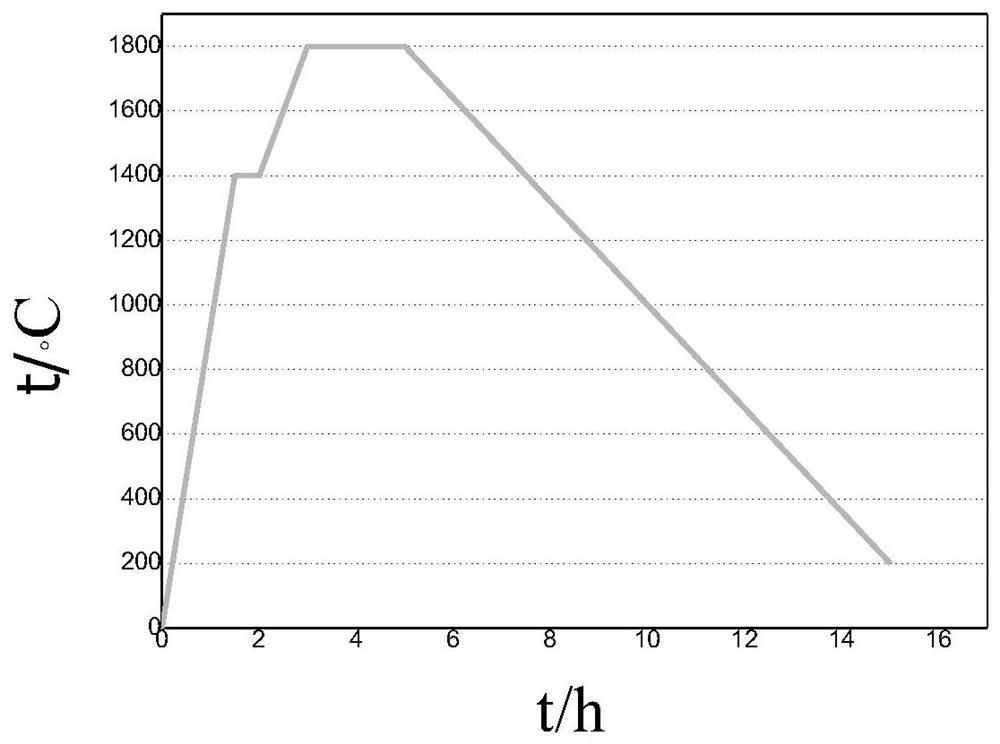

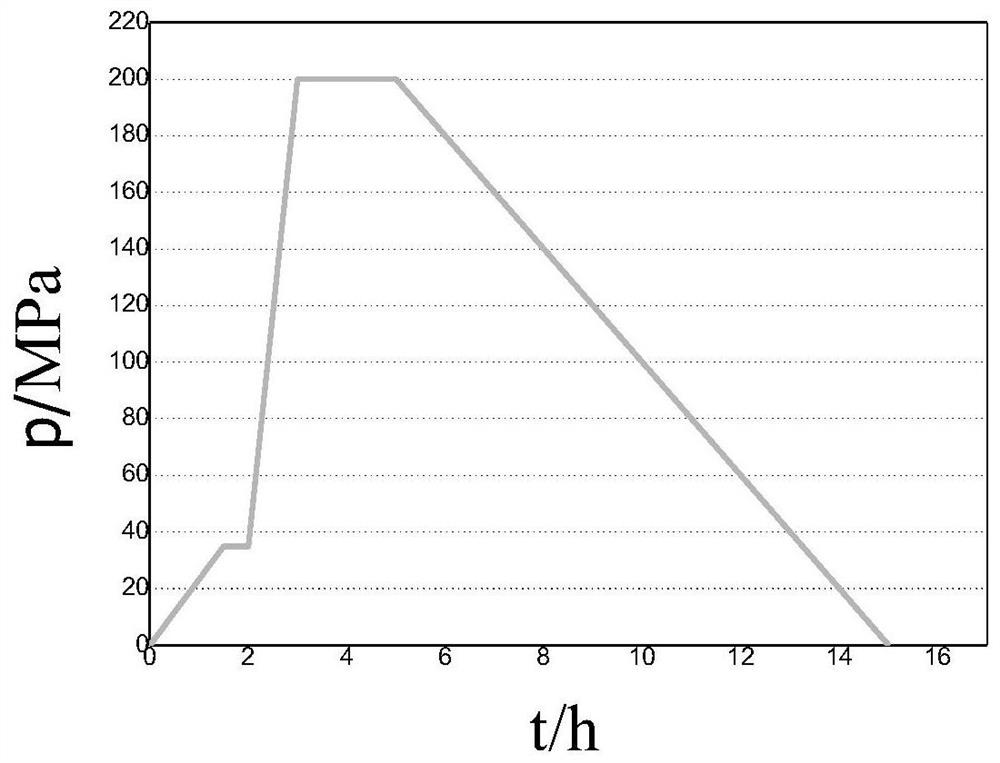

[0034] After packing, put it into 10-30H hot isostatic pressing equipment for hot isostatic pressing, and adopt the second heat preservation and second pressure holding process. First heat up to 1380°C for heat preservation. At this time, the adaptive pressure is 30Mpa for 0.5 hours, and then continue to heat ...

Embodiment 2

[0037] Weigh 591g of Mo powder, 10g of Si powder, 6.9g of B powder, 21g of Zr powder, and 42.8g of Ti powder in proportion. Put the mixture into the mixer for 15 hours, then put the mixture into the planetary ball mill (QM-3SP4) for ball milling for 20 hours, the ratio of ball to material is 5:1, and the speed is 300r / min. A pre-alloyed powder with uniform particle size is obtained.

[0038] Put the pre-alloyed powder into Φ25×175mm 3 In the graphite mold, Φ25mm is consistent with the size required by the plasma rotary atomization equipment. In order to prevent the pre-alloyed powder from sticking to the graphite mold, graphite paper is used to isolate the powder from the mold.

[0039] After packing, put it into 10-30H hot isostatic pressing equipment for hot isostatic pressing, and adopt the second heat preservation and second pressure holding process. First heat up to 1395°C for heat preservation. At this time, the adaptive pressure is 35Mpa, and the time for taking it i...

Embodiment 3

[0042] Weigh 605.6g of Mo powder, 9.9g of Si powder, 7.5g of B powder, 2.2g of Zr powder, and 4.2g of Ti powder in proportion. Put the mixture into the mixer for 15 hours, then put the mixture into the planetary ball mill (QM-3SP4) for ball milling for 20 hours, the ratio of ball to material is 5:1, and the speed is 300r / min. A pre-alloyed powder with uniform particle size is obtained.

[0043] Put the pre-alloyed powder into Φ25×175mm 3 In the graphite mold, Φ25mm is consistent with the size required by the plasma rotary atomization equipment. In order to prevent the pre-alloyed powder from sticking to the graphite mold, graphite paper is used to isolate the powder from the mold.

[0044] After packing, put it into 10-30H hot isostatic pressing equipment for hot isostatic pressing, and adopt the second heat preservation and second pressure holding process. First heat up to 1400°C for heat preservation. At this time, the adaptive pressure is 38Mpa, and the time is 1 hour. Con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D90 | aaaaa | aaaaa |

| Fluidity | aaaaa | aaaaa |

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com